Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

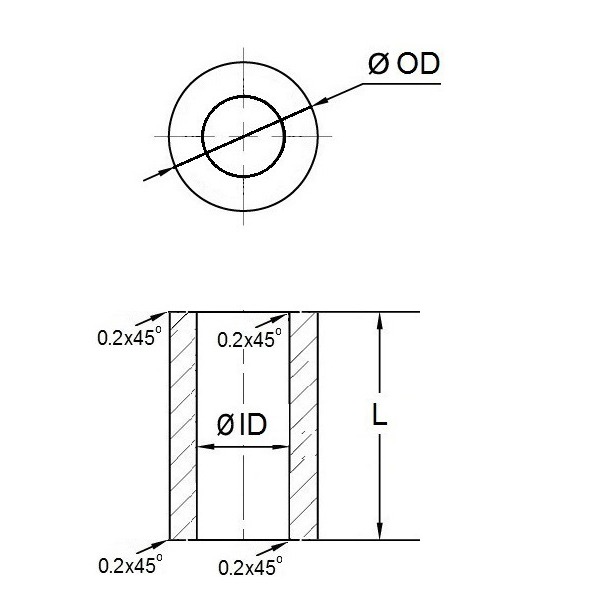

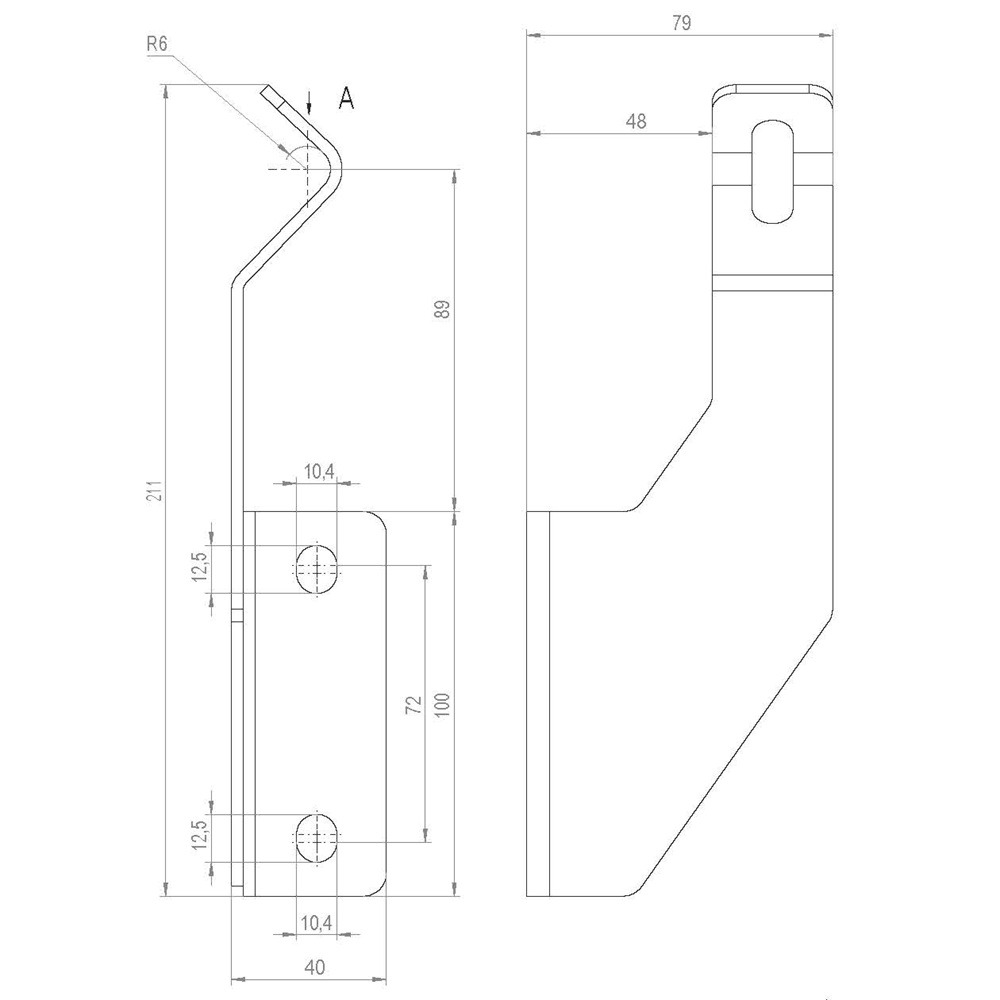

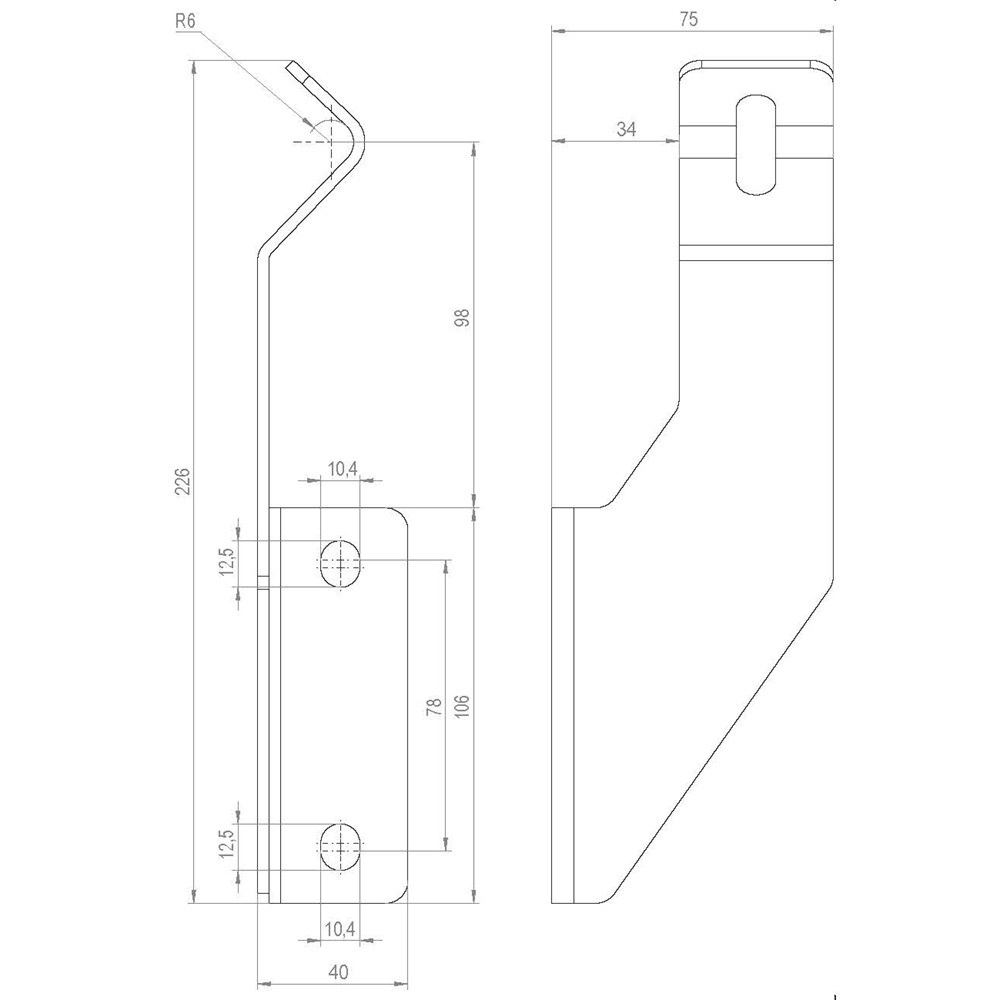

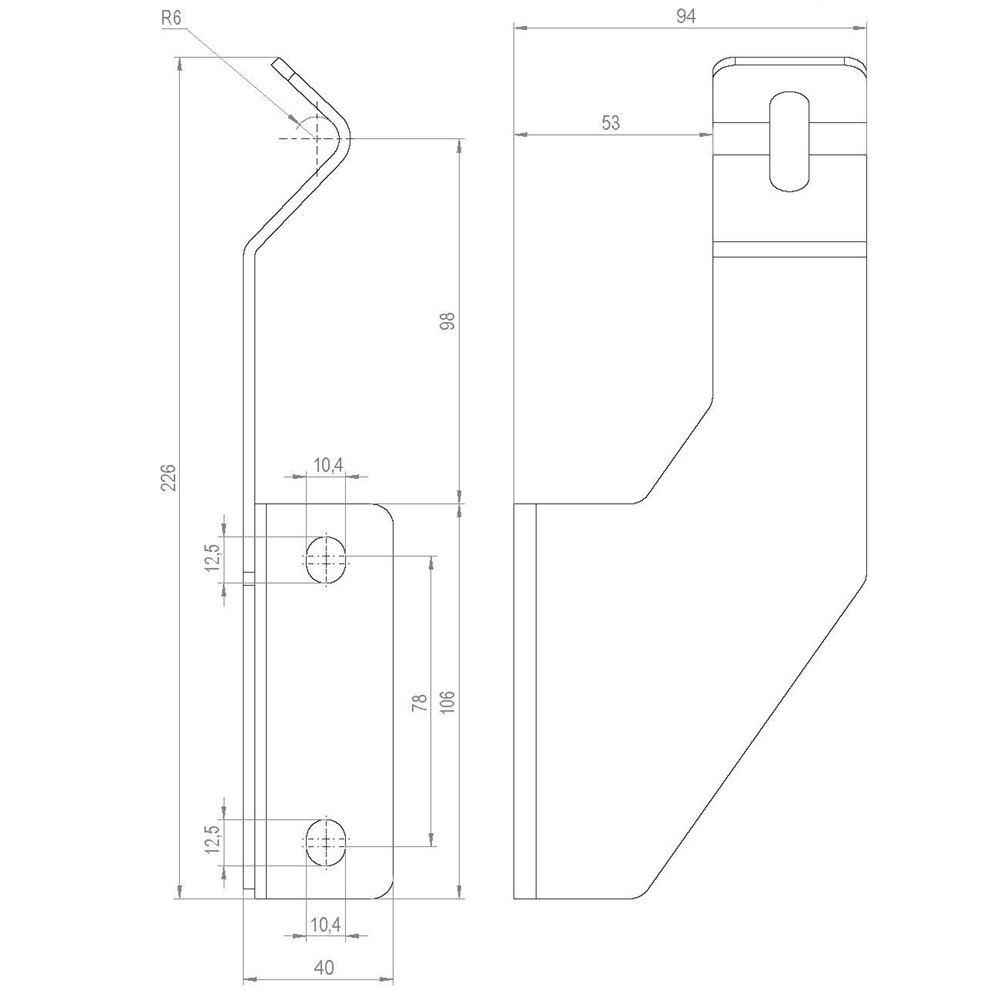

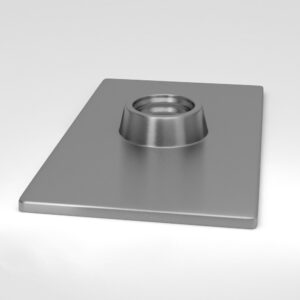

Spacer in stainless steel for welding

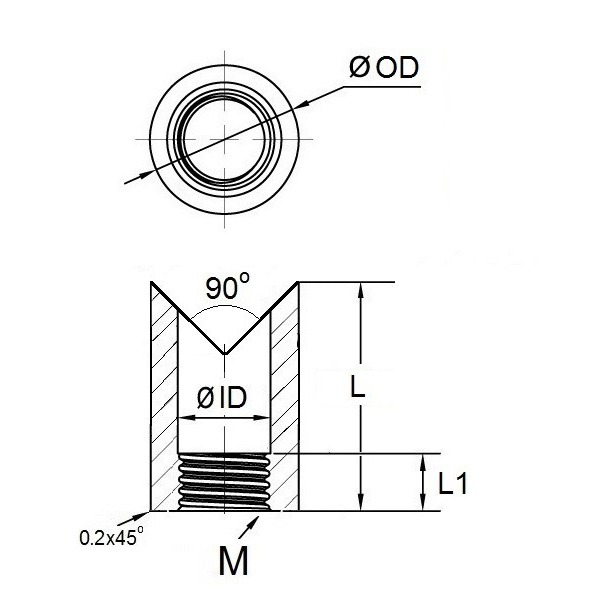

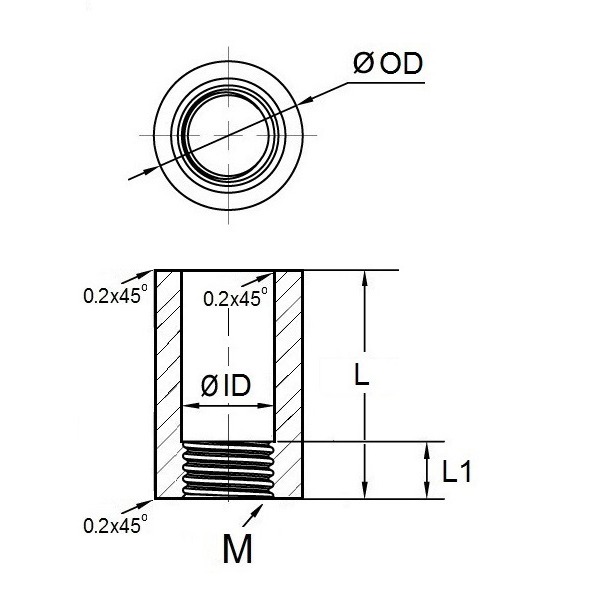

Spacer nut in stainless steel (Aisi 1.4301)

Threaded stainless steel spacer nut (Aisi 1.4301)

Spacer nut M8-16-9 – ID=8.2 – OD=16.0 – L=9 – L1=6

Spacer nut M8-16-18 – ID=8.2 – OD=16.0 – L=18 – L1=12

Spacer nut M10-18-9 – ID=10.2 – OD=18.0 – L=9 – L1=6

Spacer nut M10-18-18 – ID=10.2 – OD=18.0 – L=18 – L1=12

Spacer nut M12-22-9 – ID=12.2 – OD=22.0 – L=9 – L1=6

Spacer nut M12-22-18 – ID=12.2 – OD=22.0 – L=18 – L1=12

Spacer nut M16-26-9 – ID=16.2 – OD=26.0 – L=9 – L1=6

Spacer nut M16-26-18 – ID=16.2 – OD=26.0 – L=18 – L1=12

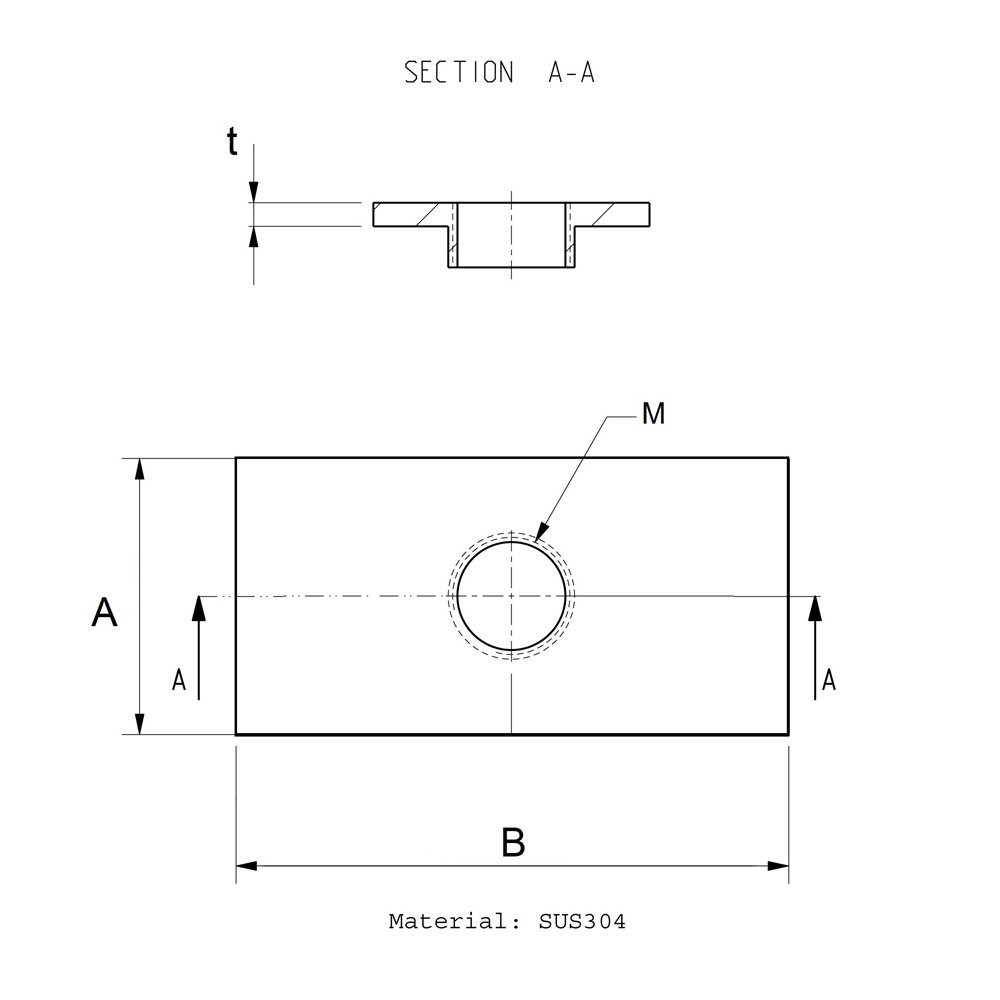

Spacer in stainless steel (Aisi 1.4301)

Spacer 8-16-9 – ID=8.2 – OD=16.0 – L=9

Spacer 8-16-18 – ID=8.2 – OD=16.0 – L=18

Spacer 10-18-9 – ID=10.2 – OD=18.0 – L=9

Spacer 10-18-18 – ID=10.2 – OD=18.0 – L=18

Spacer 12-22-9 – ID=12.2 – OD=22.0 – L=9

Spacer 12-22-18 – ID=12.2 – OD=22.0 – L=18

Spacer 16-26-9 – ID=16.2 – OD=26.0 – L=9

Spacer 16-26-18 – ID=16.2 – OD=26.0 – L=18

Stainless steel spacer for threading (Aisi 1.4301)

Inner diameter is ready for making threads after welded

Spacer for threads 6.8-16-15 – ID=6.8 – OD=16.0 – L=9

Spacer for threads 6.8-16-25 – ID=6.8 – OD=16.0 – L=18

Spacer for threads 8.5-18-15 – ID=8.5 – OD=18.0 – L=9

Spacer for threads 8.5-18-25 – ID=8.5 – OD=18.0 – L=18

Spacer for threads 10.2-22-15 – ID=10.2 – OD=22.0 – L=9

Spacer for threads 10.2-22-25 – ID=10.2 – OD=22.0 – L=18

Spacer for threads 14.0-26-15 – ID=14.0 – OD=26.0 – L=9

Spacer for threads 14.0-26-25 – ID=14.0 – OD=26.0 – L=18

Machinery components in hygienic design

For other size, please contact us.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Spacer nut in stainless steel (Aisi 1.4301)

Threaded stainless steel spacer nut (Aisi 1.4301)

Spacer nut M8-16-9 – ID=8.2 – OD=16.0 – L=9 – L1=6

Spacer nut M8-16-18 – ID=8.2 – OD=16.0 – L=18 – L1=12

Spacer nut M10-18-9 – ID=10.2 – OD=18.0 – L=9 – L1=6

Spacer nut M10-18-18 – ID=10.2 – OD=18.0 – L=18 – L1=12

Spacer nut M12-22-9 – ID=12.2 – OD=22.0 – L=9 – L1=6

Spacer nut M12-22-18 – ID=12.2 – OD=22.0 – L=18 – L1=12

Spacer nut M16-26-9 – ID=16.2 – OD=26.0 – L=9 – L1=6

Spacer nut M16-26-18 – ID=16.2 – OD=26.0 – L=18 – L1=12

Spacer in stainless steel (Aisi 1.4301)

Spacer 8-16-9 – ID=8.2 – OD=16.0 – L=9

Spacer 8-16-18 – ID=8.2 – OD=16.0 – L=18

Spacer 10-18-9 – ID=10.2 – OD=18.0 – L=9

Spacer 10-18-18 – ID=10.2 – OD=18.0 – L=18

Spacer 12-22-9 – ID=12.2 – OD=22.0 – L=9

Spacer 12-22-18 – ID=12.2 – OD=22.0 – L=18

Spacer 16-26-9 – ID=16.2 – OD=26.0 – L=9

Spacer 16-26-18 – ID=16.2 – OD=26.0 – L=18

Stainless steel spacer for threading (Aisi 1.4301)

Inner diameter is ready for making threads after welded

Spacer for threads 6.8-16-15 – ID=6.8 – OD=16.0 – L=9

Spacer for threads 6.8-16-25 – ID=6.8 – OD=16.0 – L=18

Spacer for threads 8.5-18-15 – ID=8.5 – OD=18.0 – L=9

Spacer for threads 8.5-18-25 – ID=8.5 – OD=18.0 – L=18

Spacer for threads 10.2-22-15 – ID=10.2 – OD=22.0 – L=9

Spacer for threads 10.2-22-25 – ID=10.2 – OD=22.0 – L=18

Spacer for threads 14.0-26-15 – ID=14.0 – OD=26.0 – L=9

Spacer for threads 14.0-26-25 – ID=14.0 – OD=26.0 – L=18

Machinery components in hygienic design

For other size, please contact us.

Spacer nut in stainless steel (Aisi 1.4301)

Threaded stainless steel spacer nut (Aisi 1.4301)

Spacer nut M8-16-9 – ID=8.2 – OD=16.0 – L=9 – L1=6

Spacer nut M8-16-18 – ID=8.2 – OD=16.0 – L=18 – L1=12

Spacer nut M10-18-9 – ID=10.2 – OD=18.0 – L=9 – L1=6

Spacer nut M10-18-18 – ID=10.2 – OD=18.0 – L=18 – L1=12

Spacer nut M12-22-9 – ID=12.2 – OD=22.0 – L=9 – L1=6

Spacer nut M12-22-18 – ID=12.2 – OD=22.0 – L=18 – L1=12

Spacer nut M16-26-9 – ID=16.2 – OD=26.0 – L=9 – L1=6

Spacer nut M16-26-18 – ID=16.2 – OD=26.0 – L=18 – L1=12

Spacer in stainless steel (Aisi 1.4301)

Spacer 8-16-9 – ID=8.2 – OD=16.0 – L=9

Spacer 8-16-18 – ID=8.2 – OD=16.0 – L=18

Spacer 10-18-9 – ID=10.2 – OD=18.0 – L=9

Spacer 10-18-18 – ID=10.2 – OD=18.0 – L=18

Spacer 12-22-9 – ID=12.2 – OD=22.0 – L=9

Spacer 12-22-18 – ID=12.2 – OD=22.0 – L=18

Spacer 16-26-9 – ID=16.2 – OD=26.0 – L=9

Spacer 16-26-18 – ID=16.2 – OD=26.0 – L=18

Stainless steel spacer for threading (Aisi 1.4301)

Inner diameter is ready for making threads after welded

Spacer for threads 6.8-16-15 – ID=6.8 – OD=16.0 – L=9

Spacer for threads 6.8-16-25 – ID=6.8 – OD=16.0 – L=18

Spacer for threads 8.5-18-15 – ID=8.5 – OD=18.0 – L=9

Spacer for threads 8.5-18-25 – ID=8.5 – OD=18.0 – L=18

Spacer for threads 10.2-22-15 – ID=10.2 – OD=22.0 – L=9

Spacer for threads 10.2-22-25 – ID=10.2 – OD=22.0 – L=18

Spacer for threads 14.0-26-15 – ID=14.0 – OD=26.0 – L=9

Spacer for threads 14.0-26-25 – ID=14.0 – OD=26.0 – L=18

Machinery components in hygienic design

For other size, please contact us.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.