Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

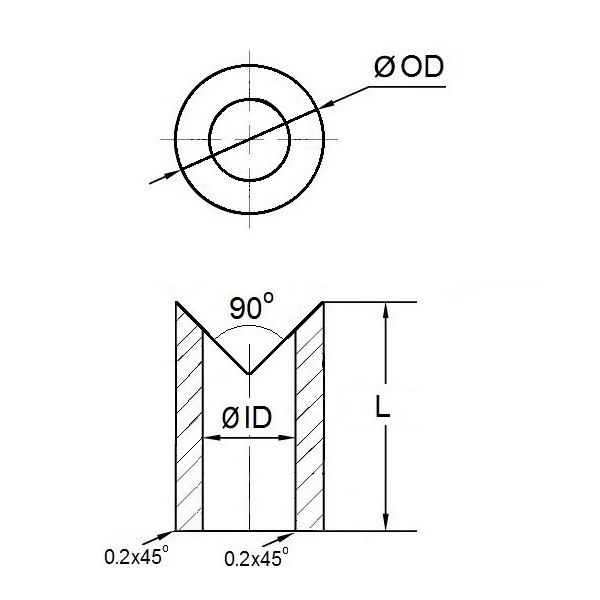

Corner nut in stainless steel for welding

Corner nut

Our corner nut and spacer series are designed for the industries where continuously heavier demands on the material resistance and a design for easy-to-clean. Industries like: medical equipment, food & pharmaceutical processing equipment, packaging machinery, 3A design-meat & poultry processing equipment, dairy processing machines.

Threaded stainless steel corner nut (Aisi 1.4301)

Corner nut in stainless steel (Aisi 1.4301)

Corner nut M8-16-15 – ID=8.2 – OD=16.0 – L=15 – L1=6

Corner nut M8-16-20 – ID=8.2 – OD=16.0 – L=20 – L1=6

Corner nut M8-16-25 – ID=8.2 – OD=16.0 – L=25 – L1=10

Corner nut M10-18-15 – ID=10.2 – OD=18.0 – L=15 – L1=6

Corner nut M10-18-25 – ID=10.2 – OD=18.0 – L=25 – L1=10

Corner nut M12-22-15 – ID=12.2 – OD=22.0 – L=15 – L1=6

Corner nut M12-22-25 – ID=12.2 – OD=22.0 – L=25 – L1=10

Corner nut M16-26-15 – ID=16.2 – OD=26.0 – L=15 – L1=6

Corner nut M16-26-25 – ID=16.2 – OD=26.0 – L=25 – L1=10

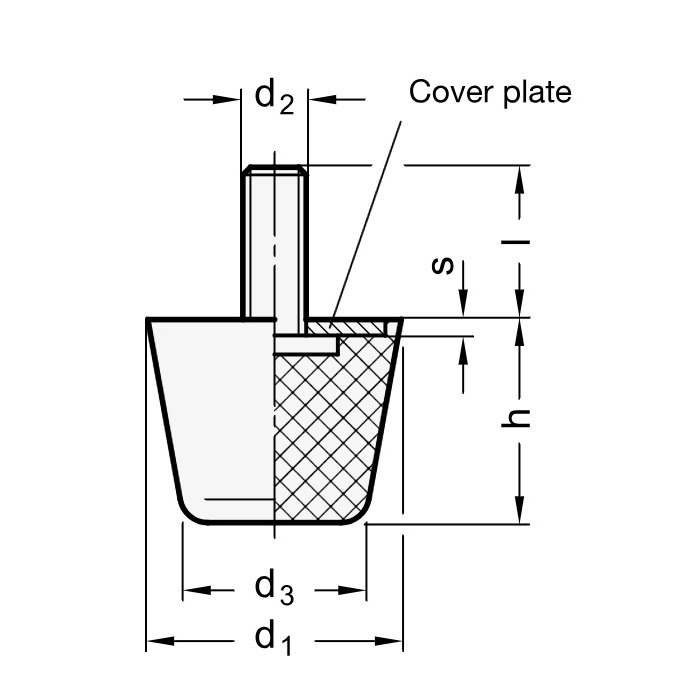

Corner spacer in stainless steel (Aisi 1.4301)

Inner diameter is ready for making threads after welded

Corner spacer 6.8-16-15 – ID=6.8 – OD=16.0 – L=15

Corner spacer 6.8-16-25 – ID=6.8 – OD=16.0 – L=25

Corner spacer 8.5-18-15 – ID=8.5 – OD=18.0 – L=15

Corner spacer 8.5-18-25 – ID=8.5 – OD=18.0 – L=25

Corner spacer 10.2-22-15 – ID=10.2 – OD=22.0 – L=15

Corner spacer 10.2-22-25 – ID=10.2 – OD=22.0 – L=25

Corner spacer 14.0-26-15 – ID=14.0 – OD=26.0 – L=15

Corner spacer 14.0-26-25 – ID=14.0 – OD=26.0 – L=25

Conveyor components in hygienic design

For other size, please contact us.

Stainless Steel Corner Nut for Welding Mounting

A Versatile Solution for Industrial Applications

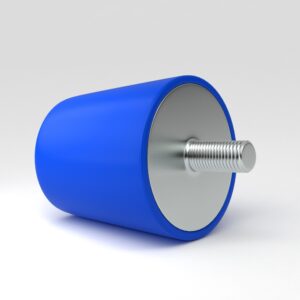

In the world of industrial hardware, the corner nut in stainless steel for welding mounting stands out as a robust, versatile, and indispensable component. Designed to offer both durability and precision, these corner nuts are ideal for applications in environments where hygiene, strength, and corrosion resistance are paramount.

What Is a Stainless Steel Corner Nut?

A stainless steel corner nut is a specialized fastening solution designed for welding onto surfaces. These components are crafted from high-grade stainless steel, offering excellent durability and resistance to environmental factors. Their primary purpose is to provide a reliable mounting point for machinery, equipment, or structural elements, especially in industries requiring high cleanliness standards.

Key Benefits of Stainless Steel Corner Nuts

1. Superior Corrosion Resistance

One of the standout features of stainless steel corner nuts is their exceptional resistance to rust and corrosion. Whether used in food processing plants, pharmaceutical facilities, or chemical industries, these nuts maintain their integrity even in harsh environments.

2. Enhanced Durability

Stainless steel’s inherent strength ensures that corner nuts can withstand significant mechanical stress. This durability makes them a cost-effective choice for heavy-duty applications, reducing the need for frequent replacements.

3. Hygienic Design

Industries like food and pharmaceuticals demand components that are easy to clean and comply with strict hygiene standards. Stainless steel corner nuts are designed with smooth surfaces that prevent the accumulation of contaminants, meeting EHEDG and 3A certifications.

4. Versatile Welding Mounting

These corner nuts are specifically engineered for seamless welding onto various surfaces, providing a sturdy and permanent attachment point. Their versatility allows them to adapt to different configurations and setups.

Applications of Stainless Steel Corner Nuts

1. Food and Beverage Industry

In food processing facilities, stainless steel corner nuts are used to mount equipment like conveyor systems, mixers, and packaging machines. Their hygienic properties ensure compliance with industry standards while resisting frequent exposure to cleaning agents and high moisture levels.

2. Pharmaceutical and Biotechnology

The pharmaceutical industry requires components that maintain sterility and withstand exposure to chemicals. Corner nuts in stainless steel are ideal for securely mounting laboratory and manufacturing equipment.

3. Packaging and Logistics

For machinery in packaging lines, stainless steel corner nuts provide reliable mounting solutions. Their ability to handle dynamic loads makes them indispensable for maintaining operational efficiency.

4. Chemical Processing

The chemical industry often operates in environments with aggressive chemicals and high temperatures. Stainless steel corner nuts deliver unmatched performance in such conditions, ensuring long-lasting reliability.

How to Choose the Right Corner Nut for Your Needs

Selecting the appropriate corner nut depends on the specific requirements of your application. Key factors to consider include:

- Grade of Stainless Steel: Choose between 304 or 316 stainless steel based on your environment’s exposure to corrosive substances.

- Size and Dimensions: Ensure compatibility with your machinery or structural components.

- Certifications: Verify that the corner nuts meet industry-specific standards like EHEDG, 3A, or FDA compliance.

Maintaining Stainless Steel Corner Nuts

To maximize the longevity and performance of stainless steel corner nuts, regular maintenance is essential. Periodic cleaning with approved solutions helps prevent residue buildup and ensures hygiene in sensitive applications.

Stainless Steel Corner Nut for Welding Mounting

The Industrial Essential

Stainless steel corner nuts for welding mounting are an invaluable component in industrial settings. Combining strength, hygiene, and versatility, they cater to the demanding requirements of industries like food processing, pharmaceuticals, and chemical manufacturing. Investing in these durable components ensures operational efficiency and long-term reliability.

When selecting corner nuts, trust high-quality products that meet stringent industry standards for maximum performance and safety.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Corner nut

Our corner nut and spacer series are designed for the industries where continuously heavier demands on the material resistance and a design for easy-to-clean. Industries like: medical equipment, food & pharmaceutical processing equipment, packaging machinery, 3A design-meat & poultry processing equipment, dairy processing machines.

Threaded stainless steel corner nut (Aisi 1.4301)

Corner nut in stainless steel (Aisi 1.4301)

Corner nut M8-16-15 – ID=8.2 – OD=16.0 – L=15 – L1=6

Corner nut M8-16-20 – ID=8.2 – OD=16.0 – L=20 – L1=6

Corner nut M8-16-25 – ID=8.2 – OD=16.0 – L=25 – L1=10

Corner nut M10-18-15 – ID=10.2 – OD=18.0 – L=15 – L1=6

Corner nut M10-18-25 – ID=10.2 – OD=18.0 – L=25 – L1=10

Corner nut M12-22-15 – ID=12.2 – OD=22.0 – L=15 – L1=6

Corner nut M12-22-25 – ID=12.2 – OD=22.0 – L=25 – L1=10

Corner nut M16-26-15 – ID=16.2 – OD=26.0 – L=15 – L1=6

Corner nut M16-26-25 – ID=16.2 – OD=26.0 – L=25 – L1=10

Corner spacer in stainless steel (Aisi 1.4301)

Inner diameter is ready for making threads after welded

Corner spacer 6.8-16-15 – ID=6.8 – OD=16.0 – L=15

Corner spacer 6.8-16-25 – ID=6.8 – OD=16.0 – L=25

Corner spacer 8.5-18-15 – ID=8.5 – OD=18.0 – L=15

Corner spacer 8.5-18-25 – ID=8.5 – OD=18.0 – L=25

Corner spacer 10.2-22-15 – ID=10.2 – OD=22.0 – L=15

Corner spacer 10.2-22-25 – ID=10.2 – OD=22.0 – L=25

Corner spacer 14.0-26-15 – ID=14.0 – OD=26.0 – L=15

Corner spacer 14.0-26-25 – ID=14.0 – OD=26.0 – L=25

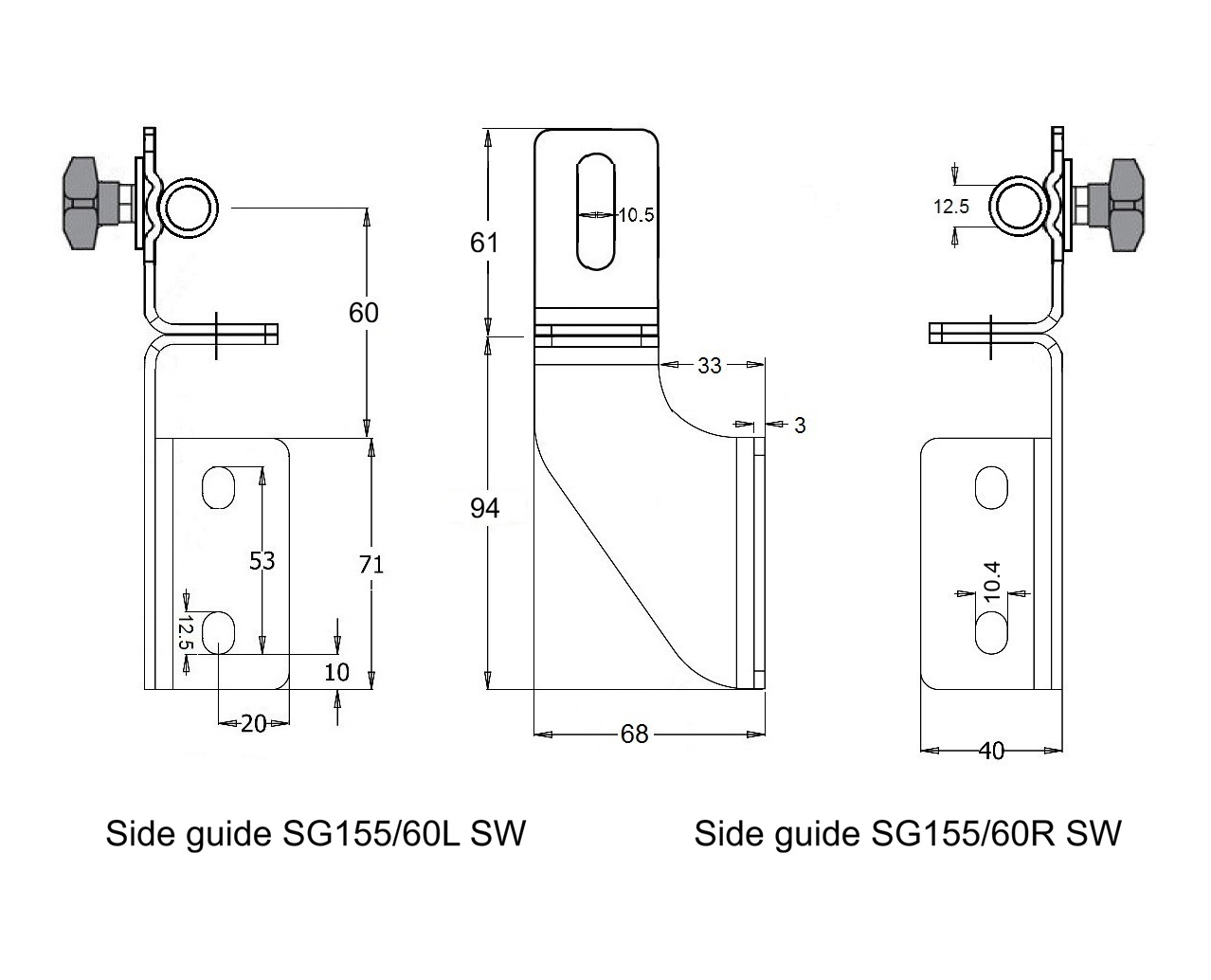

Conveyor components in hygienic design

For other size, please contact us.

Stainless Steel Corner Nut for Welding Mounting

A Versatile Solution for Industrial Applications

In the world of industrial hardware, the corner nut in stainless steel for welding mounting stands out as a robust, versatile, and indispensable component. Designed to offer both durability and precision, these corner nuts are ideal for applications in environments where hygiene, strength, and corrosion resistance are paramount.

What Is a Stainless Steel Corner Nut?

A stainless steel corner nut is a specialized fastening solution designed for welding onto surfaces. These components are crafted from high-grade stainless steel, offering excellent durability and resistance to environmental factors. Their primary purpose is to provide a reliable mounting point for machinery, equipment, or structural elements, especially in industries requiring high cleanliness standards.

Key Benefits of Stainless Steel Corner Nuts

1. Superior Corrosion Resistance

One of the standout features of stainless steel corner nuts is their exceptional resistance to rust and corrosion. Whether used in food processing plants, pharmaceutical facilities, or chemical industries, these nuts maintain their integrity even in harsh environments.

2. Enhanced Durability

Stainless steel’s inherent strength ensures that corner nuts can withstand significant mechanical stress. This durability makes them a cost-effective choice for heavy-duty applications, reducing the need for frequent replacements.

3. Hygienic Design

Industries like food and pharmaceuticals demand components that are easy to clean and comply with strict hygiene standards. Stainless steel corner nuts are designed with smooth surfaces that prevent the accumulation of contaminants, meeting EHEDG and 3A certifications.

4. Versatile Welding Mounting

These corner nuts are specifically engineered for seamless welding onto various surfaces, providing a sturdy and permanent attachment point. Their versatility allows them to adapt to different configurations and setups.

Applications of Stainless Steel Corner Nuts

1. Food and Beverage Industry

In food processing facilities, stainless steel corner nuts are used to mount equipment like conveyor systems, mixers, and packaging machines. Their hygienic properties ensure compliance with industry standards while resisting frequent exposure to cleaning agents and high moisture levels.

2. Pharmaceutical and Biotechnology

The pharmaceutical industry requires components that maintain sterility and withstand exposure to chemicals. Corner nuts in stainless steel are ideal for securely mounting laboratory and manufacturing equipment.

3. Packaging and Logistics

For machinery in packaging lines, stainless steel corner nuts provide reliable mounting solutions. Their ability to handle dynamic loads makes them indispensable for maintaining operational efficiency.

4. Chemical Processing

The chemical industry often operates in environments with aggressive chemicals and high temperatures. Stainless steel corner nuts deliver unmatched performance in such conditions, ensuring long-lasting reliability.

How to Choose the Right Corner Nut for Your Needs

Selecting the appropriate corner nut depends on the specific requirements of your application. Key factors to consider include:

- Grade of Stainless Steel: Choose between 304 or 316 stainless steel based on your environment’s exposure to corrosive substances.

- Size and Dimensions: Ensure compatibility with your machinery or structural components.

- Certifications: Verify that the corner nuts meet industry-specific standards like EHEDG, 3A, or FDA compliance.

Maintaining Stainless Steel Corner Nuts

To maximize the longevity and performance of stainless steel corner nuts, regular maintenance is essential. Periodic cleaning with approved solutions helps prevent residue buildup and ensures hygiene in sensitive applications.

Stainless Steel Corner Nut for Welding Mounting

The Industrial Essential

Stainless steel corner nuts for welding mounting are an invaluable component in industrial settings. Combining strength, hygiene, and versatility, they cater to the demanding requirements of industries like food processing, pharmaceuticals, and chemical manufacturing. Investing in these durable components ensures operational efficiency and long-term reliability.

When selecting corner nuts, trust high-quality products that meet stringent industry standards for maximum performance and safety.

Corner nut

Our corner nut and spacer series are designed for the industries where continuously heavier demands on the material resistance and a design for easy-to-clean. Industries like: medical equipment, food & pharmaceutical processing equipment, packaging machinery, 3A design-meat & poultry processing equipment, dairy processing machines.

Threaded stainless steel corner nut (Aisi 1.4301)

Corner nut in stainless steel (Aisi 1.4301)

Corner nut M8-16-15 – ID=8.2 – OD=16.0 – L=15 – L1=6

Corner nut M8-16-20 – ID=8.2 – OD=16.0 – L=20 – L1=6

Corner nut M8-16-25 – ID=8.2 – OD=16.0 – L=25 – L1=10

Corner nut M10-18-15 – ID=10.2 – OD=18.0 – L=15 – L1=6

Corner nut M10-18-25 – ID=10.2 – OD=18.0 – L=25 – L1=10

Corner nut M12-22-15 – ID=12.2 – OD=22.0 – L=15 – L1=6

Corner nut M12-22-25 – ID=12.2 – OD=22.0 – L=25 – L1=10

Corner nut M16-26-15 – ID=16.2 – OD=26.0 – L=15 – L1=6

Corner nut M16-26-25 – ID=16.2 – OD=26.0 – L=25 – L1=10

Corner spacer in stainless steel (Aisi 1.4301)

Inner diameter is ready for making threads after welded

Corner spacer 6.8-16-15 – ID=6.8 – OD=16.0 – L=15

Corner spacer 6.8-16-25 – ID=6.8 – OD=16.0 – L=25

Corner spacer 8.5-18-15 – ID=8.5 – OD=18.0 – L=15

Corner spacer 8.5-18-25 – ID=8.5 – OD=18.0 – L=25

Corner spacer 10.2-22-15 – ID=10.2 – OD=22.0 – L=15

Corner spacer 10.2-22-25 – ID=10.2 – OD=22.0 – L=25

Corner spacer 14.0-26-15 – ID=14.0 – OD=26.0 – L=15

Corner spacer 14.0-26-25 – ID=14.0 – OD=26.0 – L=25

Conveyor components in hygienic design

For other size, please contact us.

Stainless Steel Corner Nut for Welding Mounting

A Versatile Solution for Industrial Applications

In the world of industrial hardware, the corner nut in stainless steel for welding mounting stands out as a robust, versatile, and indispensable component. Designed to offer both durability and precision, these corner nuts are ideal for applications in environments where hygiene, strength, and corrosion resistance are paramount.

What Is a Stainless Steel Corner Nut?

A stainless steel corner nut is a specialized fastening solution designed for welding onto surfaces. These components are crafted from high-grade stainless steel, offering excellent durability and resistance to environmental factors. Their primary purpose is to provide a reliable mounting point for machinery, equipment, or structural elements, especially in industries requiring high cleanliness standards.

Key Benefits of Stainless Steel Corner Nuts

1. Superior Corrosion Resistance

One of the standout features of stainless steel corner nuts is their exceptional resistance to rust and corrosion. Whether used in food processing plants, pharmaceutical facilities, or chemical industries, these nuts maintain their integrity even in harsh environments.

2. Enhanced Durability

Stainless steel’s inherent strength ensures that corner nuts can withstand significant mechanical stress. This durability makes them a cost-effective choice for heavy-duty applications, reducing the need for frequent replacements.

3. Hygienic Design

Industries like food and pharmaceuticals demand components that are easy to clean and comply with strict hygiene standards. Stainless steel corner nuts are designed with smooth surfaces that prevent the accumulation of contaminants, meeting EHEDG and 3A certifications.

4. Versatile Welding Mounting

These corner nuts are specifically engineered for seamless welding onto various surfaces, providing a sturdy and permanent attachment point. Their versatility allows them to adapt to different configurations and setups.

Applications of Stainless Steel Corner Nuts

1. Food and Beverage Industry

In food processing facilities, stainless steel corner nuts are used to mount equipment like conveyor systems, mixers, and packaging machines. Their hygienic properties ensure compliance with industry standards while resisting frequent exposure to cleaning agents and high moisture levels.

2. Pharmaceutical and Biotechnology

The pharmaceutical industry requires components that maintain sterility and withstand exposure to chemicals. Corner nuts in stainless steel are ideal for securely mounting laboratory and manufacturing equipment.

3. Packaging and Logistics

For machinery in packaging lines, stainless steel corner nuts provide reliable mounting solutions. Their ability to handle dynamic loads makes them indispensable for maintaining operational efficiency.

4. Chemical Processing

The chemical industry often operates in environments with aggressive chemicals and high temperatures. Stainless steel corner nuts deliver unmatched performance in such conditions, ensuring long-lasting reliability.

How to Choose the Right Corner Nut for Your Needs

Selecting the appropriate corner nut depends on the specific requirements of your application. Key factors to consider include:

- Grade of Stainless Steel: Choose between 304 or 316 stainless steel based on your environment’s exposure to corrosive substances.

- Size and Dimensions: Ensure compatibility with your machinery or structural components.

- Certifications: Verify that the corner nuts meet industry-specific standards like EHEDG, 3A, or FDA compliance.

Maintaining Stainless Steel Corner Nuts

To maximize the longevity and performance of stainless steel corner nuts, regular maintenance is essential. Periodic cleaning with approved solutions helps prevent residue buildup and ensures hygiene in sensitive applications.

Stainless Steel Corner Nut for Welding Mounting

The Industrial Essential

Stainless steel corner nuts for welding mounting are an invaluable component in industrial settings. Combining strength, hygiene, and versatility, they cater to the demanding requirements of industries like food processing, pharmaceuticals, and chemical manufacturing. Investing in these durable components ensures operational efficiency and long-term reliability.

When selecting corner nuts, trust high-quality products that meet stringent industry standards for maximum performance and safety.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.