Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

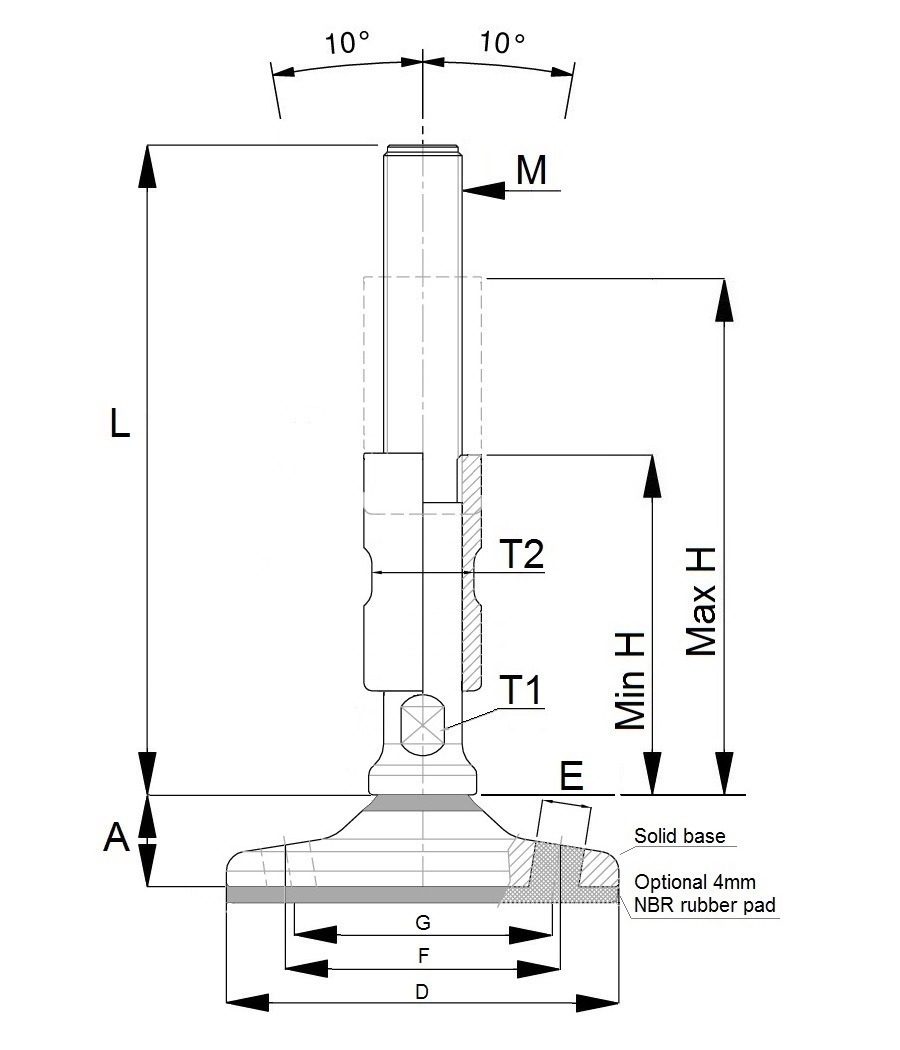

Stainless steel feet in hygienic design with floor lock holes and protected spindle

Ensuring Cleanliness and Stability

Designed for heavy load in harsh environments under tough conditions

Hygienic stainless steel feet can be applied with rubber pad for vibration reduction and anti-slip properties

Our hygienic stainless steel feet are provided with FDA certificate (FDA CFR 21 177 2600) with unique batch ID number for food safety traceability

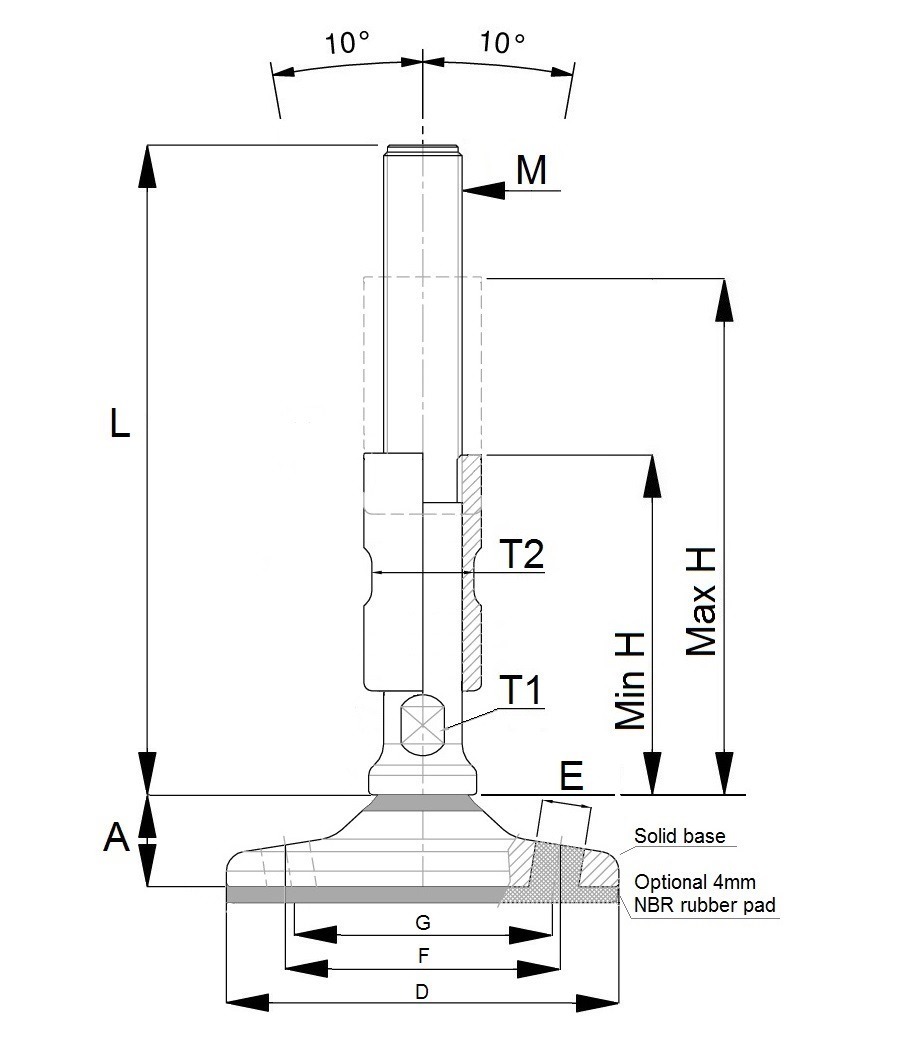

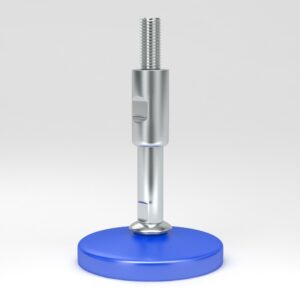

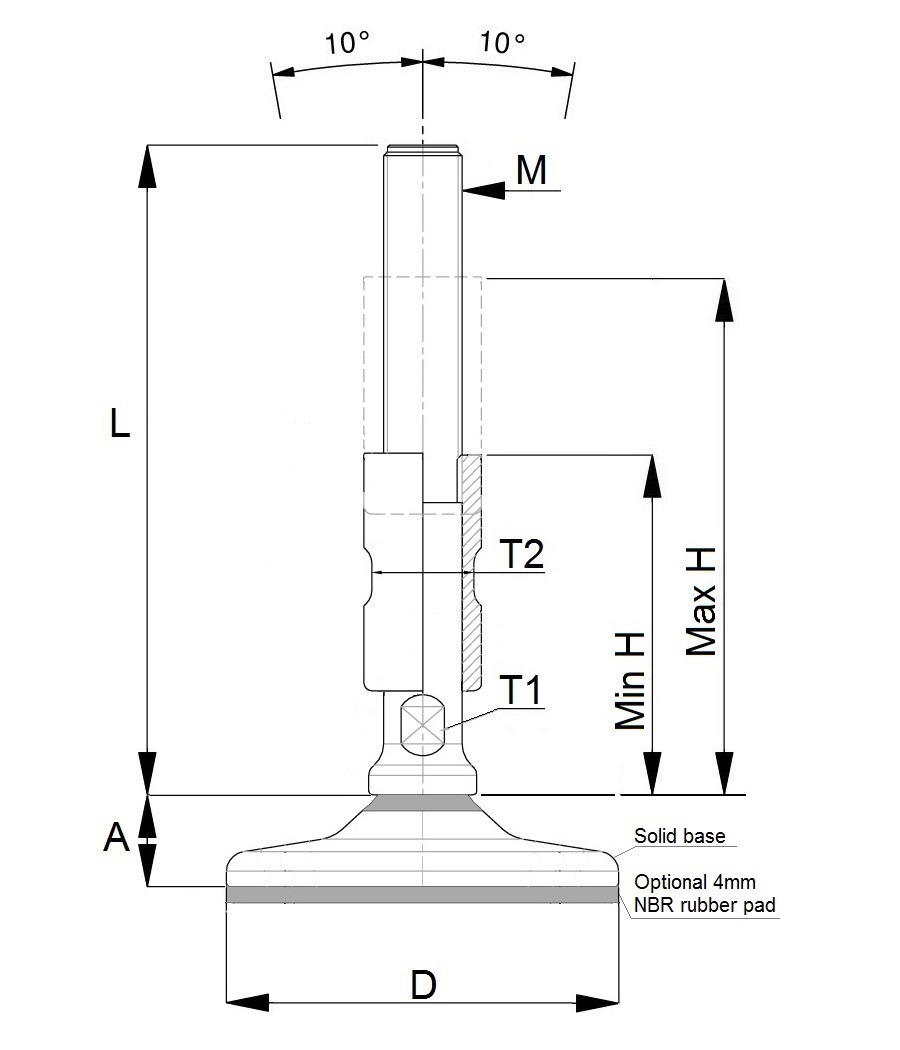

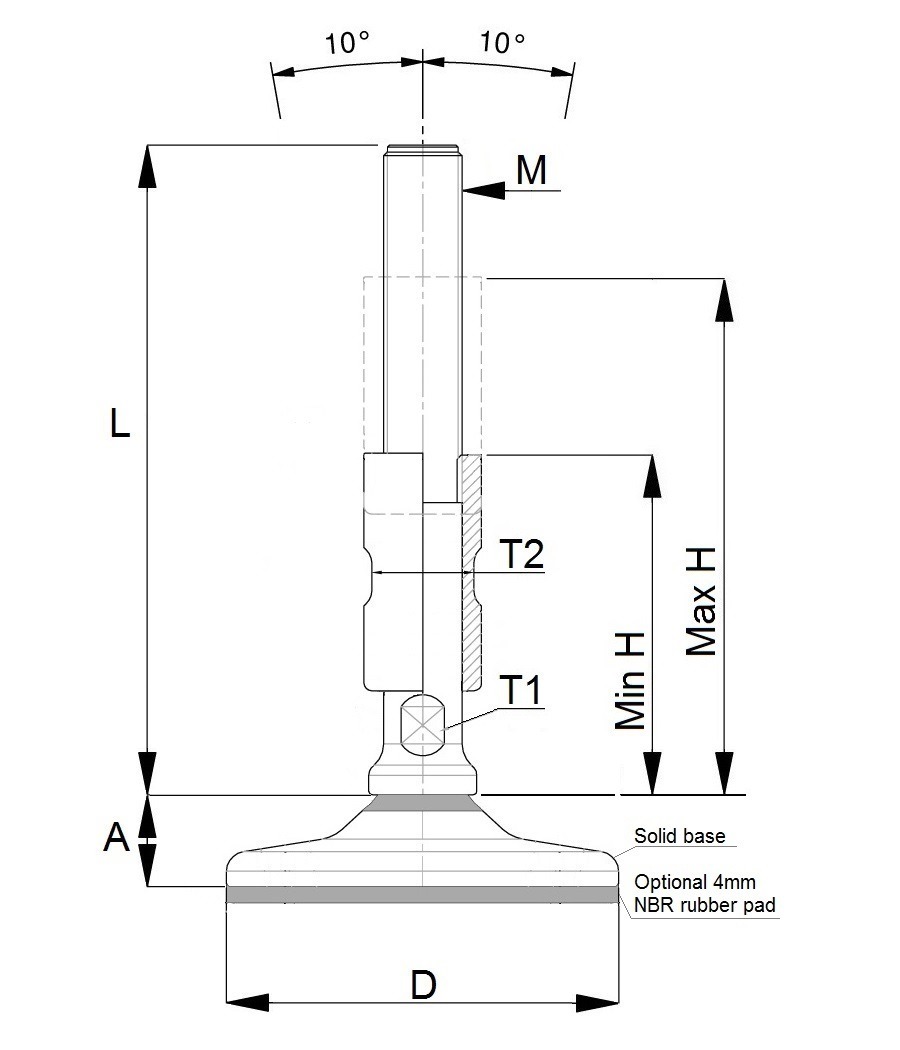

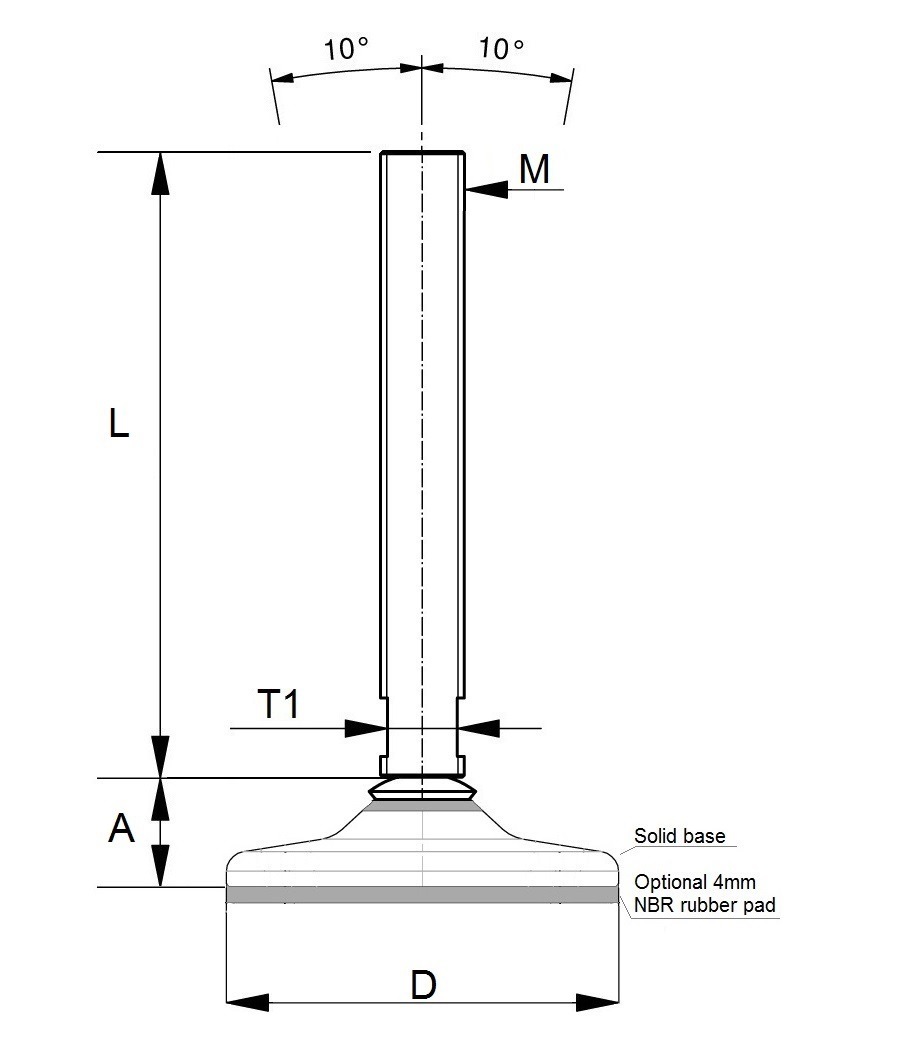

Sanitary solid base with floor lock holes stainless steel feet with protected spindle

The spindles are smooth at the end towards the base and the threads are protected by a sleeve to ensure easy cleaning.

The sleeve also functions as a nut.

Hygienic stainless steel feet have a rounded, hygienic design which makes it easy to clean and is for suitable for demanding sanitary applications.

Hygienic stainless steel feet can cope with up to 10 degree slopes on floors and equipment.

Materials

Hygienic stainless steel feet rubber pad with FDA Certificate according to FDA CFR 21 177 2600.

Base plate material description:

Stainless steel Aisi 304 or Aisi 316

Spindle material description:

Stainless steel A2-70 or A4-70

Rubber base material description:

NBR Rubber (Nitrile rubber CAS no. 9005-98-5)

FDA Certificate according to FDA CFR 21 177 2600

All materials are highly resistant to chemicals and commonly applied cleaning agents and to resistant oils and fats.

Stainless steel solid base feet Sizes

Hygienic stainless steel feet base are available in a wide range, giving the optimal flexibility and choice.

| Base Size | Base Diameter D |

|---|---|

| HSF 79 | 78 mm |

| HSF 99 | 98 mm |

| HSF 119 | 118 mm |

| HSF 139 | 138 mm |

| HSF 159 | 158 mm |

| HSF 179 | 178 mm |

| HSF 199 | 198 mm |

| HSF 249 | 248 mm |

| HSF 299 | 298 mm |

For other Base Diameter D, please contact us

Nominal load depend on the spindle threads

For rubber pad, suffix “R” is added to numbers. ex.: HSF79-LC-M16-L140-R

Hygienic stainless steel feet spindles and sleeves are available in a wide range, giving the optimal flexibility and choice.

Stainless steel solid base feet spindle

| EHSF Spindle and sleeve diameter | ||||||

| M16 | M20 | M24 | M30 | M36 | M42 | M48 |

| EHSF Spindle length (L) and Sleeve length (H) | Adjustment height | |||||

| L=135 mm H=55 mm | Min 80 mm to Max 120 mm | |||||

| L=175 mm H=75 mm | Min 100 mm to Max 160 mm | |||||

| L=215 mm H=95 mm | Min 120 mm to Max 200 mm | |||||

| L=255 mm H=115 mm | Min 140 mm to Max 240 mm | |||||

| L=295 mm H=125 mm | Min 180 mm to Max 280 mm | |||||

For other threaded spindle length (L), please contact us

Threads in inch is available upon request

The thread can also be customized according to specific request, ex trapezoid thread etc.

Delivery option

For large orders we offer to supply the base and spindles separate

The advantage is flexibility for the costumer which are using many different sizes of spindles

Stainless steel feet in hygienic design with floor lock holes and protected spindle

In industries where hygiene is paramount, such as food processing and pharmaceuticals, equipment design plays a crucial role in maintaining cleanliness. Stainless steel feet with hygienic designs, featuring floor lock holes and protected spindles, are essential components that enhance both sanitation and stability.

Hygienic Design Features

Stainless steel leveling feet are engineered to meet stringent hygiene standards. These feet are constructed from high-quality stainless steel, offering excellent corrosion resistance and durability. The design includes self-draining surfaces, preventing the accumulation of liquids and reducing the risk of bacterial growth. Additionally, the fully threaded spindles are protected, minimizing exposed threads where contaminants could reside. This design ensures easy cleaning and maintenance, aligning with guidelines from organizations such as USDA, EHEDG, and 3-A.

Floor Lock Holes for Enhanced Stability

Incorporating floor lock holes into the footplate design allows for secure anchoring of machinery and equipment. These mounting holes enable the equipment to be bolted directly to the floor, providing enhanced stability during operation. This feature is particularly beneficial in environments with heavy machinery or where vibrations are a concern, as it prevents movement and potential accidents. Moreover, securing equipment reduces the risk of tipping or shifting, contributing to a safer workplace.

Benefits of Protected Spindles

The protected spindle design is a critical aspect of maintaining hygiene. By covering the spindle with a sleeve, the design prevents the ingress of contaminants into the threads. This protection not only enhances cleanliness but also extends the lifespan of the leveling feet by reducing wear and tear. The low-friction washer between the spindle and footplate ensures smooth adjustment, facilitating precise leveling of equipment.

Optimize Cleanliness and Achieve Hygienic Excellence

Stainless steel feet with hygienic designs, floor lock holes, and protected spindles are indispensable in industries where cleanliness and stability are critical. These features collectively ensure that equipment remains securely in place while adhering to the highest hygiene standards, thereby safeguarding product quality and workplace safety.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Ensuring Cleanliness and Stability

Designed for heavy load in harsh environments under tough conditions

Hygienic stainless steel feet can be applied with rubber pad for vibration reduction and anti-slip properties

Our hygienic stainless steel feet are provided with FDA certificate (FDA CFR 21 177 2600) with unique batch ID number for food safety traceability

Sanitary solid base with floor lock holes stainless steel feet with protected spindle

The spindles are smooth at the end towards the base and the threads are protected by a sleeve to ensure easy cleaning.

The sleeve also functions as a nut.

Hygienic stainless steel feet have a rounded, hygienic design which makes it easy to clean and is for suitable for demanding sanitary applications.

Hygienic stainless steel feet can cope with up to 10 degree slopes on floors and equipment.

Materials

Hygienic stainless steel feet rubber pad with FDA Certificate according to FDA CFR 21 177 2600.

Base plate material description:

Stainless steel Aisi 304 or Aisi 316

Spindle material description:

Stainless steel A2-70 or A4-70

Rubber base material description:

NBR Rubber (Nitrile rubber CAS no. 9005-98-5)

FDA Certificate according to FDA CFR 21 177 2600

All materials are highly resistant to chemicals and commonly applied cleaning agents and to resistant oils and fats.

Stainless steel solid base feet Sizes

Hygienic stainless steel feet base are available in a wide range, giving the optimal flexibility and choice.

| Base Size | Base Diameter D |

|---|---|

| HSF 79 | 78 mm |

| HSF 99 | 98 mm |

| HSF 119 | 118 mm |

| HSF 139 | 138 mm |

| HSF 159 | 158 mm |

| HSF 179 | 178 mm |

| HSF 199 | 198 mm |

| HSF 249 | 248 mm |

| HSF 299 | 298 mm |

For other Base Diameter D, please contact us

Nominal load depend on the spindle threads

For rubber pad, suffix “R” is added to numbers. ex.: HSF79-LC-M16-L140-R

Hygienic stainless steel feet spindles and sleeves are available in a wide range, giving the optimal flexibility and choice.

Stainless steel solid base feet spindle

| EHSF Spindle and sleeve diameter | ||||||

| M16 | M20 | M24 | M30 | M36 | M42 | M48 |

| EHSF Spindle length (L) and Sleeve length (H) | Adjustment height | |||||

| L=135 mm H=55 mm | Min 80 mm to Max 120 mm | |||||

| L=175 mm H=75 mm | Min 100 mm to Max 160 mm | |||||

| L=215 mm H=95 mm | Min 120 mm to Max 200 mm | |||||

| L=255 mm H=115 mm | Min 140 mm to Max 240 mm | |||||

| L=295 mm H=125 mm | Min 180 mm to Max 280 mm | |||||

For other threaded spindle length (L), please contact us

Threads in inch is available upon request

The thread can also be customized according to specific request, ex trapezoid thread etc.

Delivery option

For large orders we offer to supply the base and spindles separate

The advantage is flexibility for the costumer which are using many different sizes of spindles

Stainless steel feet in hygienic design with floor lock holes and protected spindle

In industries where hygiene is paramount, such as food processing and pharmaceuticals, equipment design plays a crucial role in maintaining cleanliness. Stainless steel feet with hygienic designs, featuring floor lock holes and protected spindles, are essential components that enhance both sanitation and stability.

Hygienic Design Features

Stainless steel leveling feet are engineered to meet stringent hygiene standards. These feet are constructed from high-quality stainless steel, offering excellent corrosion resistance and durability. The design includes self-draining surfaces, preventing the accumulation of liquids and reducing the risk of bacterial growth. Additionally, the fully threaded spindles are protected, minimizing exposed threads where contaminants could reside. This design ensures easy cleaning and maintenance, aligning with guidelines from organizations such as USDA, EHEDG, and 3-A.

Floor Lock Holes for Enhanced Stability

Incorporating floor lock holes into the footplate design allows for secure anchoring of machinery and equipment. These mounting holes enable the equipment to be bolted directly to the floor, providing enhanced stability during operation. This feature is particularly beneficial in environments with heavy machinery or where vibrations are a concern, as it prevents movement and potential accidents. Moreover, securing equipment reduces the risk of tipping or shifting, contributing to a safer workplace.

Benefits of Protected Spindles

The protected spindle design is a critical aspect of maintaining hygiene. By covering the spindle with a sleeve, the design prevents the ingress of contaminants into the threads. This protection not only enhances cleanliness but also extends the lifespan of the leveling feet by reducing wear and tear. The low-friction washer between the spindle and footplate ensures smooth adjustment, facilitating precise leveling of equipment.

Optimize Cleanliness and Achieve Hygienic Excellence

Stainless steel feet with hygienic designs, floor lock holes, and protected spindles are indispensable in industries where cleanliness and stability are critical. These features collectively ensure that equipment remains securely in place while adhering to the highest hygiene standards, thereby safeguarding product quality and workplace safety.

Ensuring Cleanliness and Stability

Designed for heavy load in harsh environments under tough conditions

Hygienic stainless steel feet can be applied with rubber pad for vibration reduction and anti-slip properties

Our hygienic stainless steel feet are provided with FDA certificate (FDA CFR 21 177 2600) with unique batch ID number for food safety traceability

Sanitary solid base with floor lock holes stainless steel feet with protected spindle

The spindles are smooth at the end towards the base and the threads are protected by a sleeve to ensure easy cleaning.

The sleeve also functions as a nut.

Hygienic stainless steel feet have a rounded, hygienic design which makes it easy to clean and is for suitable for demanding sanitary applications.

Hygienic stainless steel feet can cope with up to 10 degree slopes on floors and equipment.

Materials

Hygienic stainless steel feet rubber pad with FDA Certificate according to FDA CFR 21 177 2600.

Base plate material description:

Stainless steel Aisi 304 or Aisi 316

Spindle material description:

Stainless steel A2-70 or A4-70

Rubber base material description:

NBR Rubber (Nitrile rubber CAS no. 9005-98-5)

FDA Certificate according to FDA CFR 21 177 2600

All materials are highly resistant to chemicals and commonly applied cleaning agents and to resistant oils and fats.

Stainless steel solid base feet Sizes

Hygienic stainless steel feet base are available in a wide range, giving the optimal flexibility and choice.

| Base Size | Base Diameter D |

|---|---|

| HSF 79 | 78 mm |

| HSF 99 | 98 mm |

| HSF 119 | 118 mm |

| HSF 139 | 138 mm |

| HSF 159 | 158 mm |

| HSF 179 | 178 mm |

| HSF 199 | 198 mm |

| HSF 249 | 248 mm |

| HSF 299 | 298 mm |

For other Base Diameter D, please contact us

Nominal load depend on the spindle threads

For rubber pad, suffix “R” is added to numbers. ex.: HSF79-LC-M16-L140-R

Hygienic stainless steel feet spindles and sleeves are available in a wide range, giving the optimal flexibility and choice.

Stainless steel solid base feet spindle

| EHSF Spindle and sleeve diameter | ||||||

| M16 | M20 | M24 | M30 | M36 | M42 | M48 |

| EHSF Spindle length (L) and Sleeve length (H) | Adjustment height | |||||

| L=135 mm H=55 mm | Min 80 mm to Max 120 mm | |||||

| L=175 mm H=75 mm | Min 100 mm to Max 160 mm | |||||

| L=215 mm H=95 mm | Min 120 mm to Max 200 mm | |||||

| L=255 mm H=115 mm | Min 140 mm to Max 240 mm | |||||

| L=295 mm H=125 mm | Min 180 mm to Max 280 mm | |||||

For other threaded spindle length (L), please contact us

Threads in inch is available upon request

The thread can also be customized according to specific request, ex trapezoid thread etc.

Delivery option

For large orders we offer to supply the base and spindles separate

The advantage is flexibility for the costumer which are using many different sizes of spindles

Stainless steel feet in hygienic design with floor lock holes and protected spindle

In industries where hygiene is paramount, such as food processing and pharmaceuticals, equipment design plays a crucial role in maintaining cleanliness. Stainless steel feet with hygienic designs, featuring floor lock holes and protected spindles, are essential components that enhance both sanitation and stability.

Hygienic Design Features

Stainless steel leveling feet are engineered to meet stringent hygiene standards. These feet are constructed from high-quality stainless steel, offering excellent corrosion resistance and durability. The design includes self-draining surfaces, preventing the accumulation of liquids and reducing the risk of bacterial growth. Additionally, the fully threaded spindles are protected, minimizing exposed threads where contaminants could reside. This design ensures easy cleaning and maintenance, aligning with guidelines from organizations such as USDA, EHEDG, and 3-A.

Floor Lock Holes for Enhanced Stability

Incorporating floor lock holes into the footplate design allows for secure anchoring of machinery and equipment. These mounting holes enable the equipment to be bolted directly to the floor, providing enhanced stability during operation. This feature is particularly beneficial in environments with heavy machinery or where vibrations are a concern, as it prevents movement and potential accidents. Moreover, securing equipment reduces the risk of tipping or shifting, contributing to a safer workplace.

Benefits of Protected Spindles

The protected spindle design is a critical aspect of maintaining hygiene. By covering the spindle with a sleeve, the design prevents the ingress of contaminants into the threads. This protection not only enhances cleanliness but also extends the lifespan of the leveling feet by reducing wear and tear. The low-friction washer between the spindle and footplate ensures smooth adjustment, facilitating precise leveling of equipment.

Optimize Cleanliness and Achieve Hygienic Excellence

Stainless steel feet with hygienic designs, floor lock holes, and protected spindles are indispensable in industries where cleanliness and stability are critical. These features collectively ensure that equipment remains securely in place while adhering to the highest hygiene standards, thereby safeguarding product quality and workplace safety.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.