Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

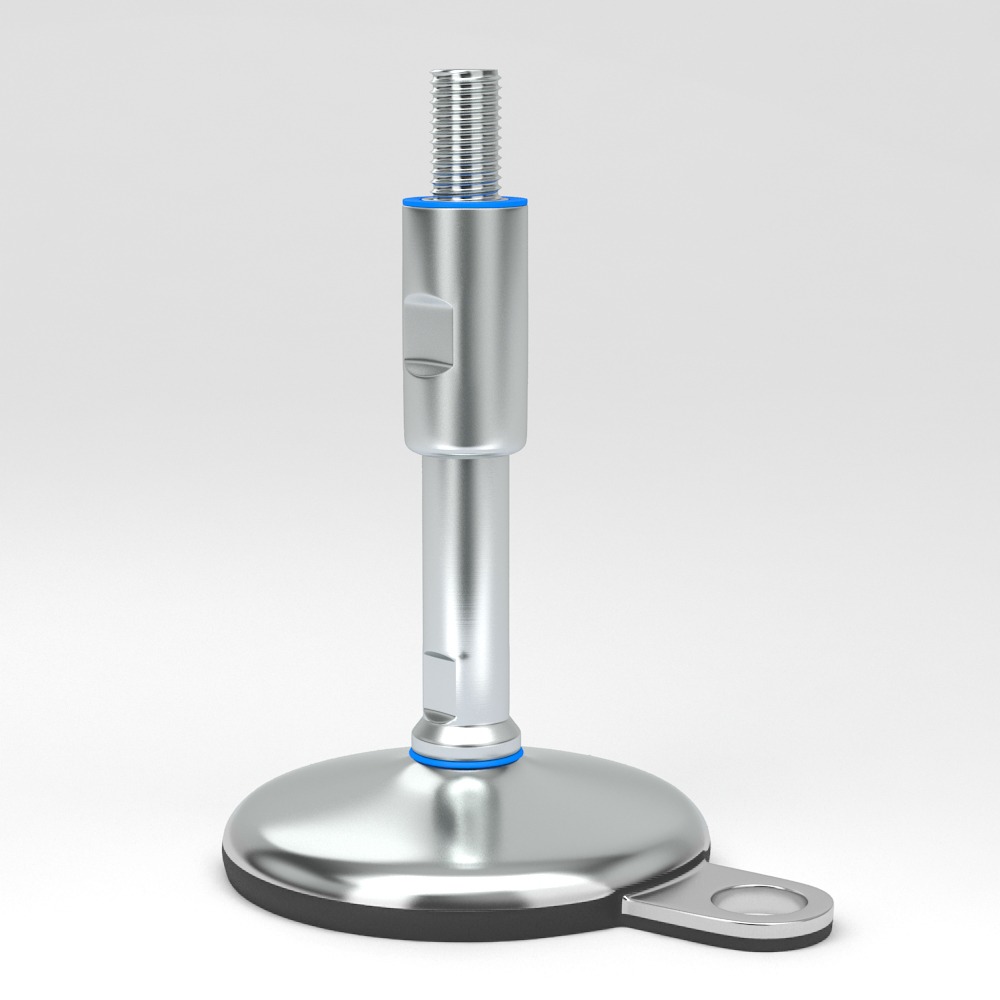

Hygienic machine feet with floor lock plate and sealed protected spindle

Engineered for Uncompromised Industrial Cleanliness

Machine feet in sealed hygienic design with rubber base for vibration reduction and anti-slip properties

Our sealed hygienic machine feet are provided with FDA certificate (FDA CFR 21 177 2600) with unique batch ID number for food safety traceability

Machine feet in sealed hygienic design features and advantages

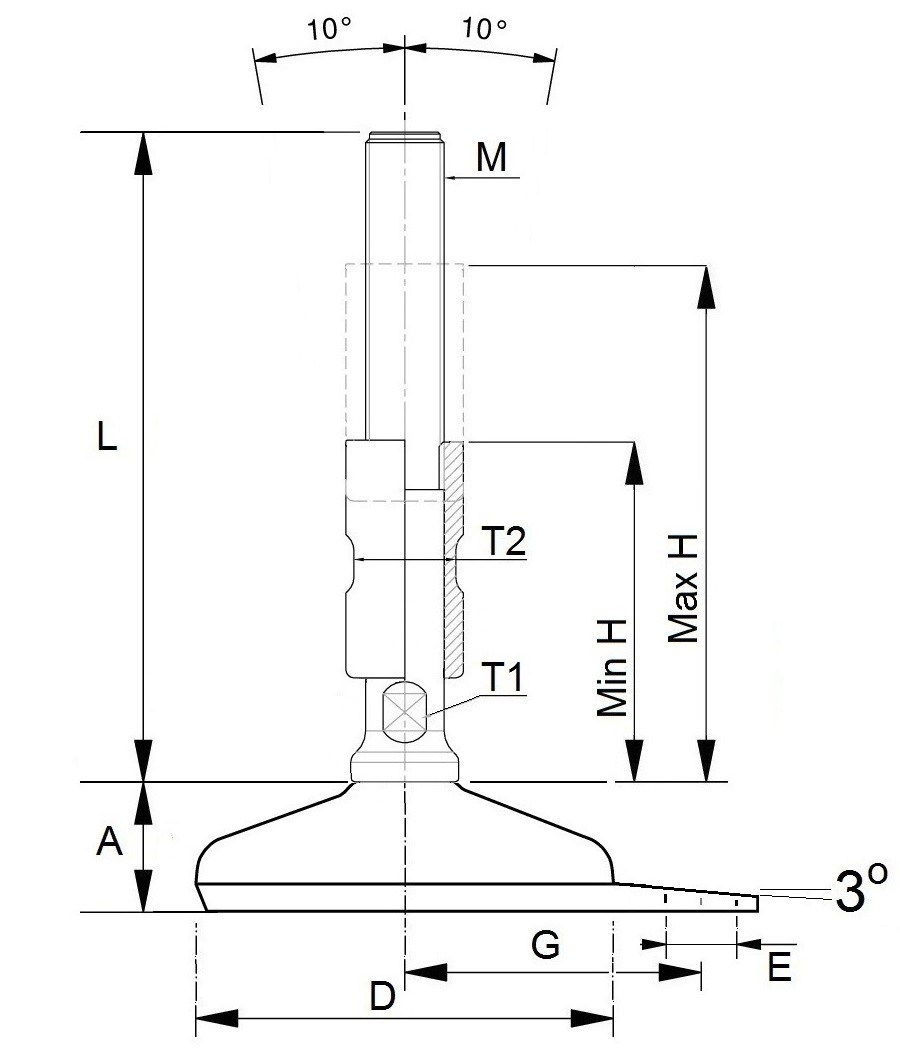

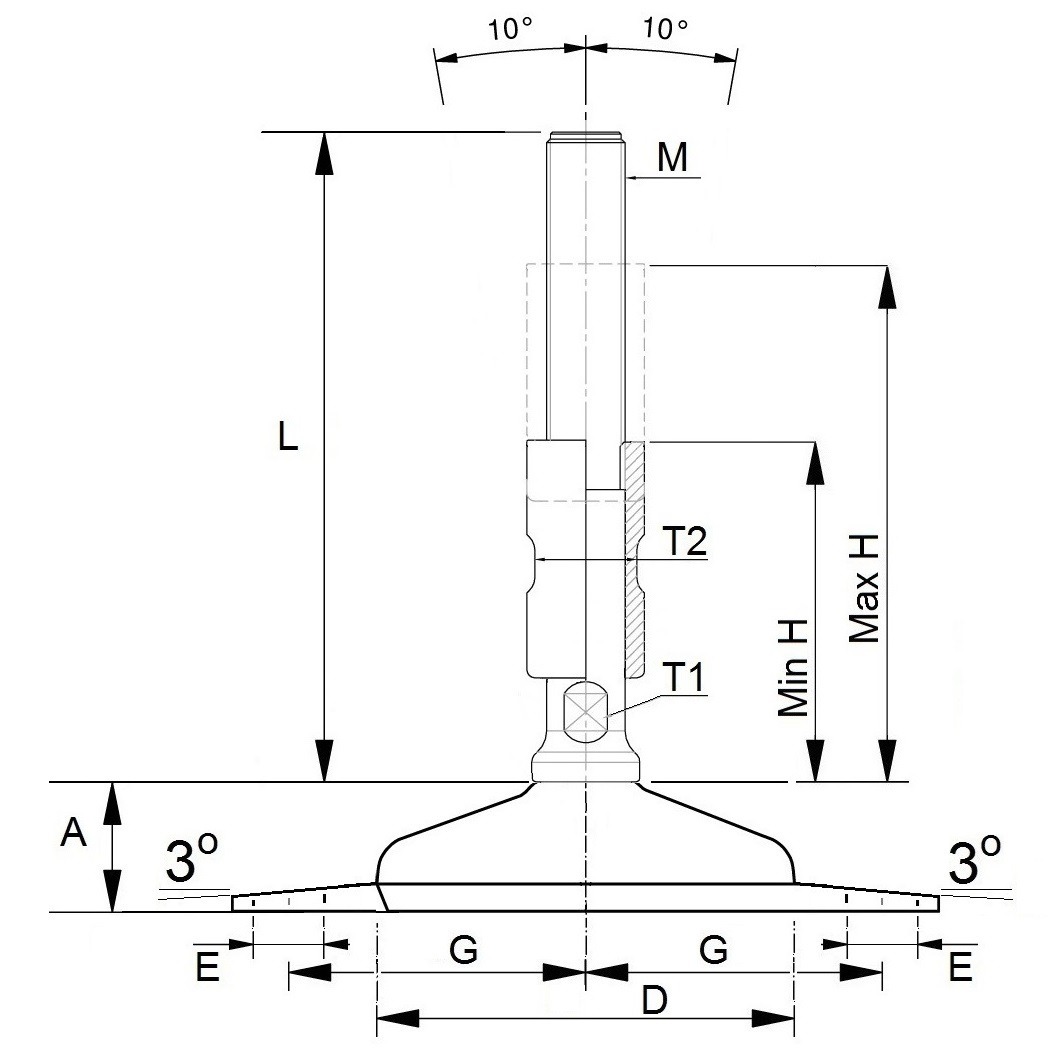

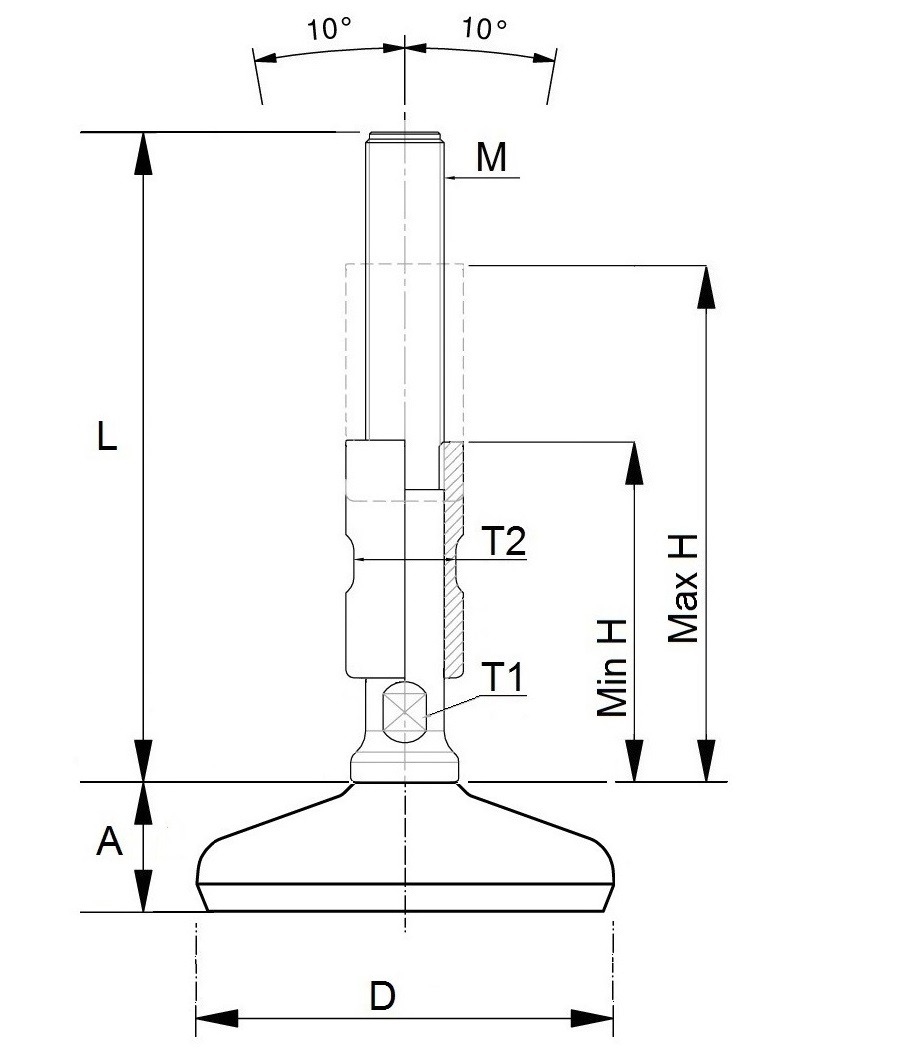

Sealed hygienic machine feet have a rounded, hygienic design which makes it easy to clean.

Sealed hygienic machine feet can cope with up to 10 degree slopes on floors and equipment.

Machine feet in sealed hygienic design materials

Sealed hygienic machine feet vulcanized rubber part with FDA certificate according to FDA CFR 21 177 2600.

Base plate material description:

Stainless steel Aisi 304 or Aisi 316

Spindle material description:

Stainless steel A2-70 or A4-70

Rubber base material description:

NBR Rubber (Nitrile rubber CAS no. 9005-98-5)

FDA Certificate according to FDA CFR 21 177 2600

All materials are highly resistant to chemicals and commonly applied cleaning agents and to resistant oils and fats.

Machine feet in sealed hygienic design sizes

Sealed hygienic machine feet base are available in a wide range, giving the optimal flexibility and choice.

| Base type | Base Diameter D | Nom. Load |

|---|---|---|

| HMF 61 | 60mm | 7.000 N |

| HMF 81 | 80mm | 15.000 N |

| HMF 101 | 100mm | 20.000 N |

| HMF 121 | 120mm | 30.000 N |

Sealed hygienic machine feet spindle with protecting sleeve are available in a wide range, giving the optimal flexibility and choice.

| M16 | M20 | M24 | M30 | M36 | M42 | M48 |

| L=135 mm H=55 mm | Min 80 mm to Max 120 mm |

| L=175 mm H=75 mm | Min 100 mm to Max 160 mm |

| L=215 mm H=95 mm | Min 120 mm to Max 200 mm |

| L=255 mm H=115 mm | Min 140 mm to Max 240 mm |

| L=295 mm H=125 mm | Min 180 mm to Max 280 mm |

For other threaded spindle length (L), please contact us

Threads in inch is available upon request

The thread can also be customized according to specific request, ex trapezoid thread etc.

Machine feet in sealed hygienic design delivery option

For large orders we offer to supply the base and spindles separate

The advantage is flexibility for the costumer which are using many different sizes of spindles.

Hygienic machine feet with floor lock plate and sealed protected spindle

Revolutionizing Equipment Hygiene

In today’s fast-paced industrial environment, maintaining equipment hygiene is essential for productivity and safety. Our innovative hygienic machine feet are designed with precision engineering to meet the strictest sanitary standards. This bespoke solution ensures minimal contamination risk and is ideal for industries requiring strict cleanliness protocols.

Innovative Floor Lock Plate Design

The integrated floor lock plate provides exceptional stability and prevents unwanted movement during operation. Its robust design allows the machine to remain securely in place even under high-stress conditions. This feature not only enhances safety but also contributes to a more efficient production process by reducing downtime associated with equipment shifts.

Advanced Sealed Protected Spindle

At the heart of this breakthrough technology lies the sealed protected spindle. The advanced sealing system shields the spindle from dust, moisture, and other contaminants. This protection extends the lifespan of critical components and minimizes maintenance needs. The secure spindle design is essential for achieving optimal performance in environments where hygiene is a top priority.

Enhanced Performance and Durability

By combining hygienic machine feet with a reliable floor lock plate and a sealed protected spindle, businesses can achieve improved operational efficiency and safety. This holistic design approach addresses both performance and durability, ensuring that equipment remains clean and functional over time. The bespoke engineering solutions are tailored to meet the demands of various industrial applications, making them a smart investment for forward-thinking companies committed to maintaining the highest standards of cleanliness and performance.

Securing Stability and Boosting Efficiency

This advanced solution not only meets rigorous industrial hygiene requirements but also boosts operational reliability and cost-effectiveness, providing a competitive edge in today’s challenging market. Engineered for longevity and ease of maintenance, these components are a testament to quality manufacturing and innovative design.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Engineered for Uncompromised Industrial Cleanliness

Machine feet in sealed hygienic design with rubber base for vibration reduction and anti-slip properties

Our sealed hygienic machine feet are provided with FDA certificate (FDA CFR 21 177 2600) with unique batch ID number for food safety traceability

Machine feet in sealed hygienic design features and advantages

Sealed hygienic machine feet have a rounded, hygienic design which makes it easy to clean.

Sealed hygienic machine feet can cope with up to 10 degree slopes on floors and equipment.

Machine feet in sealed hygienic design materials

Sealed hygienic machine feet vulcanized rubber part with FDA certificate according to FDA CFR 21 177 2600.

Base plate material description:

Stainless steel Aisi 304 or Aisi 316

Spindle material description:

Stainless steel A2-70 or A4-70

Rubber base material description:

NBR Rubber (Nitrile rubber CAS no. 9005-98-5)

FDA Certificate according to FDA CFR 21 177 2600

All materials are highly resistant to chemicals and commonly applied cleaning agents and to resistant oils and fats.

Machine feet in sealed hygienic design sizes

Sealed hygienic machine feet base are available in a wide range, giving the optimal flexibility and choice.

| Base type | Base Diameter D | Nom. Load |

|---|---|---|

| HMF 61 | 60mm | 7.000 N |

| HMF 81 | 80mm | 15.000 N |

| HMF 101 | 100mm | 20.000 N |

| HMF 121 | 120mm | 30.000 N |

Sealed hygienic machine feet spindle with protecting sleeve are available in a wide range, giving the optimal flexibility and choice.

| M16 | M20 | M24 | M30 | M36 | M42 | M48 |

| L=135 mm H=55 mm | Min 80 mm to Max 120 mm |

| L=175 mm H=75 mm | Min 100 mm to Max 160 mm |

| L=215 mm H=95 mm | Min 120 mm to Max 200 mm |

| L=255 mm H=115 mm | Min 140 mm to Max 240 mm |

| L=295 mm H=125 mm | Min 180 mm to Max 280 mm |

For other threaded spindle length (L), please contact us

Threads in inch is available upon request

The thread can also be customized according to specific request, ex trapezoid thread etc.

Machine feet in sealed hygienic design delivery option

For large orders we offer to supply the base and spindles separate

The advantage is flexibility for the costumer which are using many different sizes of spindles.

Hygienic machine feet with floor lock plate and sealed protected spindle

Revolutionizing Equipment Hygiene

In today’s fast-paced industrial environment, maintaining equipment hygiene is essential for productivity and safety. Our innovative hygienic machine feet are designed with precision engineering to meet the strictest sanitary standards. This bespoke solution ensures minimal contamination risk and is ideal for industries requiring strict cleanliness protocols.

Innovative Floor Lock Plate Design

The integrated floor lock plate provides exceptional stability and prevents unwanted movement during operation. Its robust design allows the machine to remain securely in place even under high-stress conditions. This feature not only enhances safety but also contributes to a more efficient production process by reducing downtime associated with equipment shifts.

Advanced Sealed Protected Spindle

At the heart of this breakthrough technology lies the sealed protected spindle. The advanced sealing system shields the spindle from dust, moisture, and other contaminants. This protection extends the lifespan of critical components and minimizes maintenance needs. The secure spindle design is essential for achieving optimal performance in environments where hygiene is a top priority.

Enhanced Performance and Durability

By combining hygienic machine feet with a reliable floor lock plate and a sealed protected spindle, businesses can achieve improved operational efficiency and safety. This holistic design approach addresses both performance and durability, ensuring that equipment remains clean and functional over time. The bespoke engineering solutions are tailored to meet the demands of various industrial applications, making them a smart investment for forward-thinking companies committed to maintaining the highest standards of cleanliness and performance.

Securing Stability and Boosting Efficiency

This advanced solution not only meets rigorous industrial hygiene requirements but also boosts operational reliability and cost-effectiveness, providing a competitive edge in today’s challenging market. Engineered for longevity and ease of maintenance, these components are a testament to quality manufacturing and innovative design.

Engineered for Uncompromised Industrial Cleanliness

Machine feet in sealed hygienic design with rubber base for vibration reduction and anti-slip properties

Our sealed hygienic machine feet are provided with FDA certificate (FDA CFR 21 177 2600) with unique batch ID number for food safety traceability

Machine feet in sealed hygienic design features and advantages

Sealed hygienic machine feet have a rounded, hygienic design which makes it easy to clean.

Sealed hygienic machine feet can cope with up to 10 degree slopes on floors and equipment.

Machine feet in sealed hygienic design materials

Sealed hygienic machine feet vulcanized rubber part with FDA certificate according to FDA CFR 21 177 2600.

Base plate material description:

Stainless steel Aisi 304 or Aisi 316

Spindle material description:

Stainless steel A2-70 or A4-70

Rubber base material description:

NBR Rubber (Nitrile rubber CAS no. 9005-98-5)

FDA Certificate according to FDA CFR 21 177 2600

All materials are highly resistant to chemicals and commonly applied cleaning agents and to resistant oils and fats.

Machine feet in sealed hygienic design sizes

Sealed hygienic machine feet base are available in a wide range, giving the optimal flexibility and choice.

| Base type | Base Diameter D | Nom. Load |

|---|---|---|

| HMF 61 | 60mm | 7.000 N |

| HMF 81 | 80mm | 15.000 N |

| HMF 101 | 100mm | 20.000 N |

| HMF 121 | 120mm | 30.000 N |

Sealed hygienic machine feet spindle with protecting sleeve are available in a wide range, giving the optimal flexibility and choice.

| M16 | M20 | M24 | M30 | M36 | M42 | M48 |

| L=135 mm H=55 mm | Min 80 mm to Max 120 mm |

| L=175 mm H=75 mm | Min 100 mm to Max 160 mm |

| L=215 mm H=95 mm | Min 120 mm to Max 200 mm |

| L=255 mm H=115 mm | Min 140 mm to Max 240 mm |

| L=295 mm H=125 mm | Min 180 mm to Max 280 mm |

For other threaded spindle length (L), please contact us

Threads in inch is available upon request

The thread can also be customized according to specific request, ex trapezoid thread etc.

Machine feet in sealed hygienic design delivery option

For large orders we offer to supply the base and spindles separate

The advantage is flexibility for the costumer which are using many different sizes of spindles.

Hygienic machine feet with floor lock plate and sealed protected spindle

Revolutionizing Equipment Hygiene

In today’s fast-paced industrial environment, maintaining equipment hygiene is essential for productivity and safety. Our innovative hygienic machine feet are designed with precision engineering to meet the strictest sanitary standards. This bespoke solution ensures minimal contamination risk and is ideal for industries requiring strict cleanliness protocols.

Innovative Floor Lock Plate Design

The integrated floor lock plate provides exceptional stability and prevents unwanted movement during operation. Its robust design allows the machine to remain securely in place even under high-stress conditions. This feature not only enhances safety but also contributes to a more efficient production process by reducing downtime associated with equipment shifts.

Advanced Sealed Protected Spindle

At the heart of this breakthrough technology lies the sealed protected spindle. The advanced sealing system shields the spindle from dust, moisture, and other contaminants. This protection extends the lifespan of critical components and minimizes maintenance needs. The secure spindle design is essential for achieving optimal performance in environments where hygiene is a top priority.

Enhanced Performance and Durability

By combining hygienic machine feet with a reliable floor lock plate and a sealed protected spindle, businesses can achieve improved operational efficiency and safety. This holistic design approach addresses both performance and durability, ensuring that equipment remains clean and functional over time. The bespoke engineering solutions are tailored to meet the demands of various industrial applications, making them a smart investment for forward-thinking companies committed to maintaining the highest standards of cleanliness and performance.

Securing Stability and Boosting Efficiency

This advanced solution not only meets rigorous industrial hygiene requirements but also boosts operational reliability and cost-effectiveness, providing a competitive edge in today’s challenging market. Engineered for longevity and ease of maintenance, these components are a testament to quality manufacturing and innovative design.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.