Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

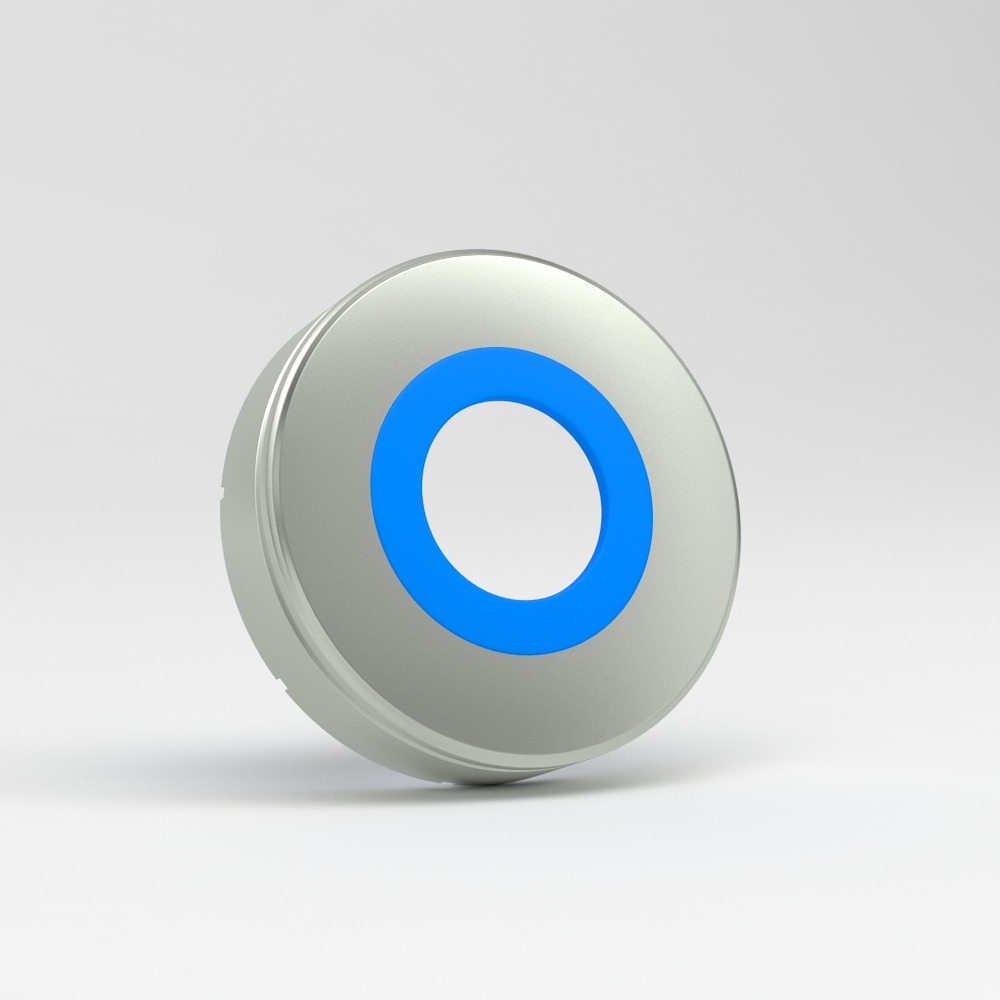

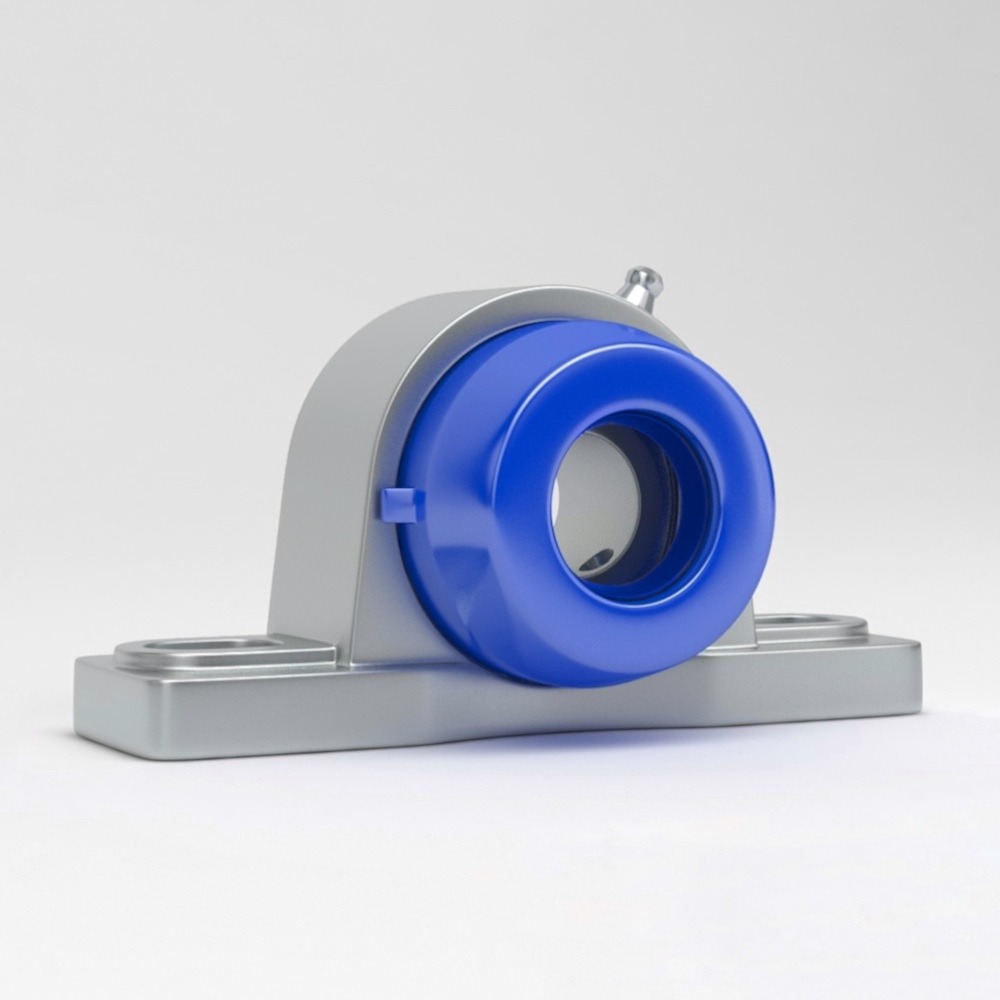

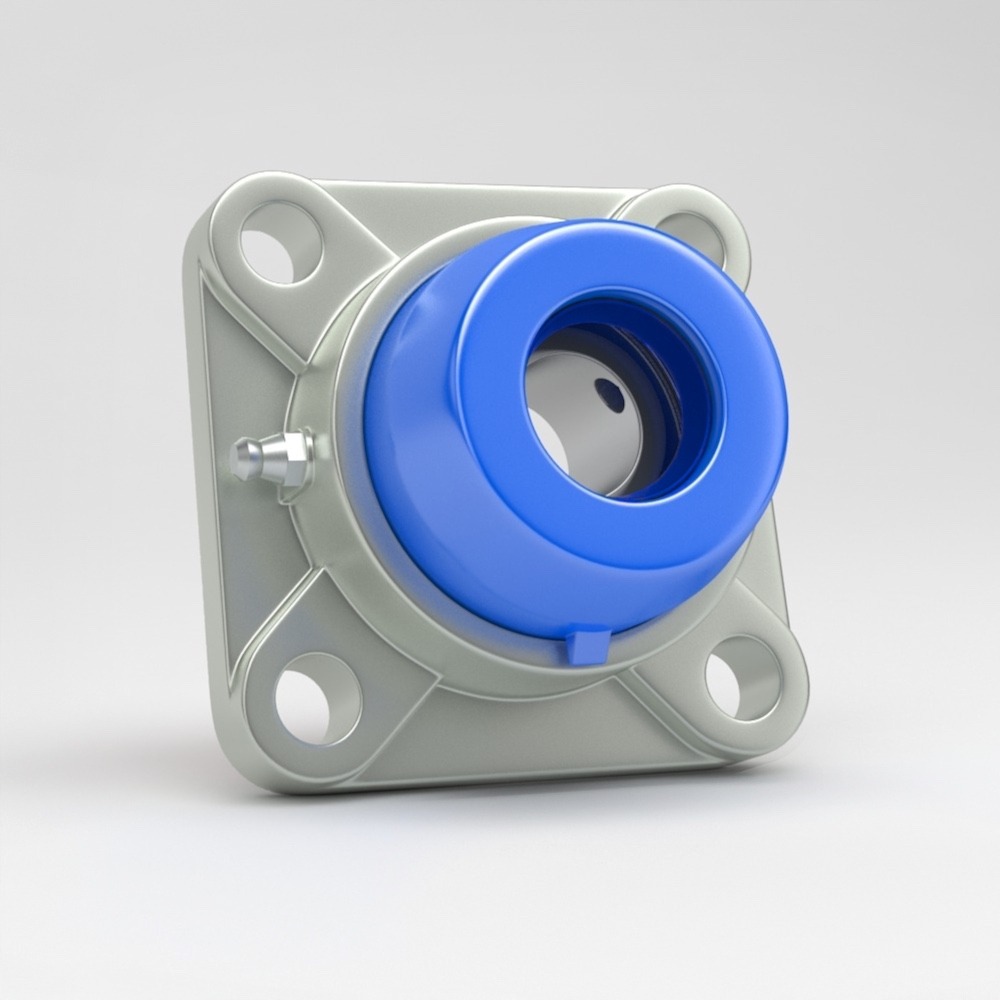

Stainless steel open cover for stainless bearing unit

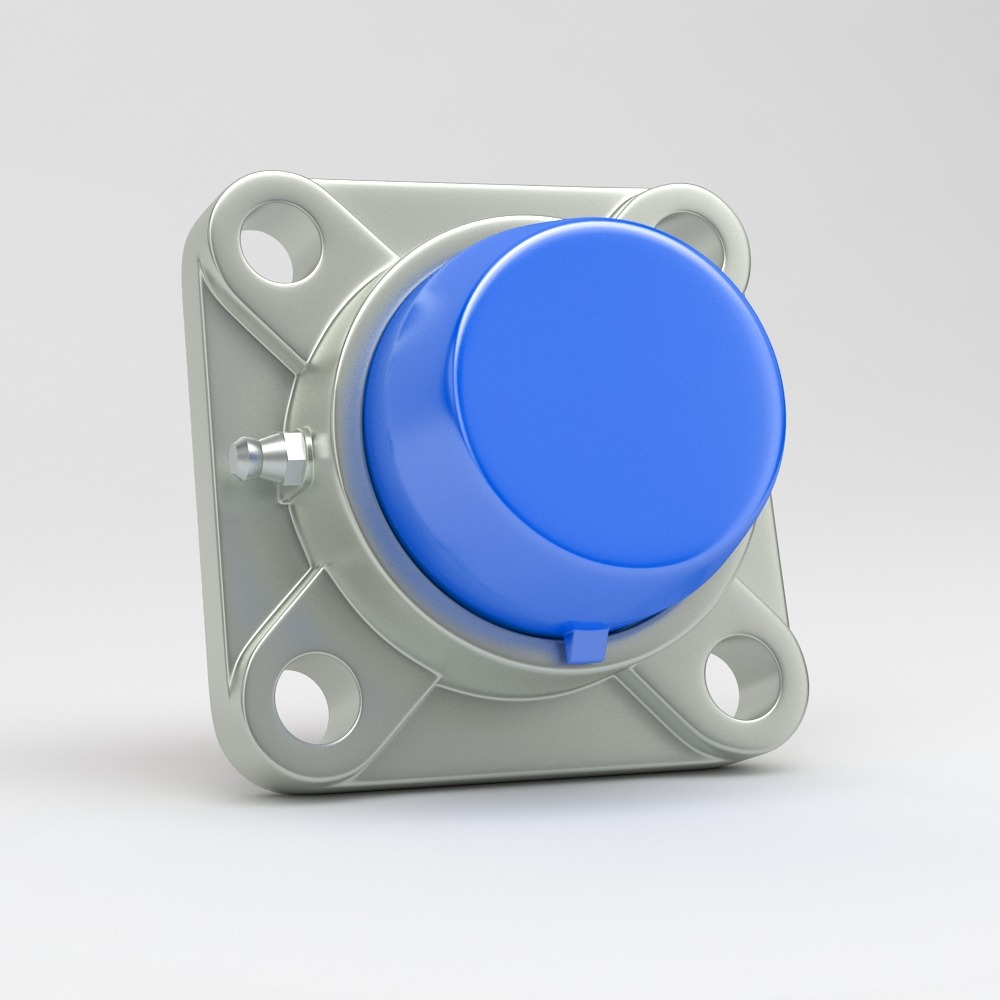

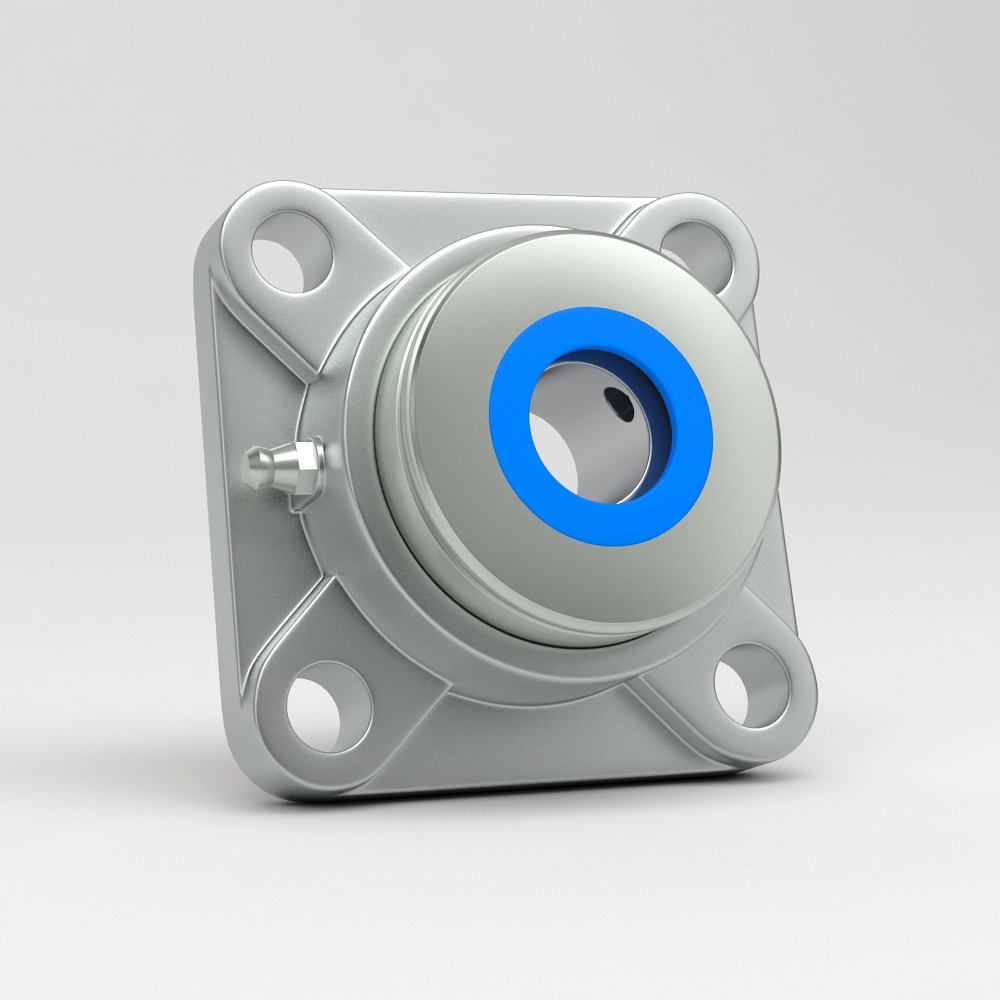

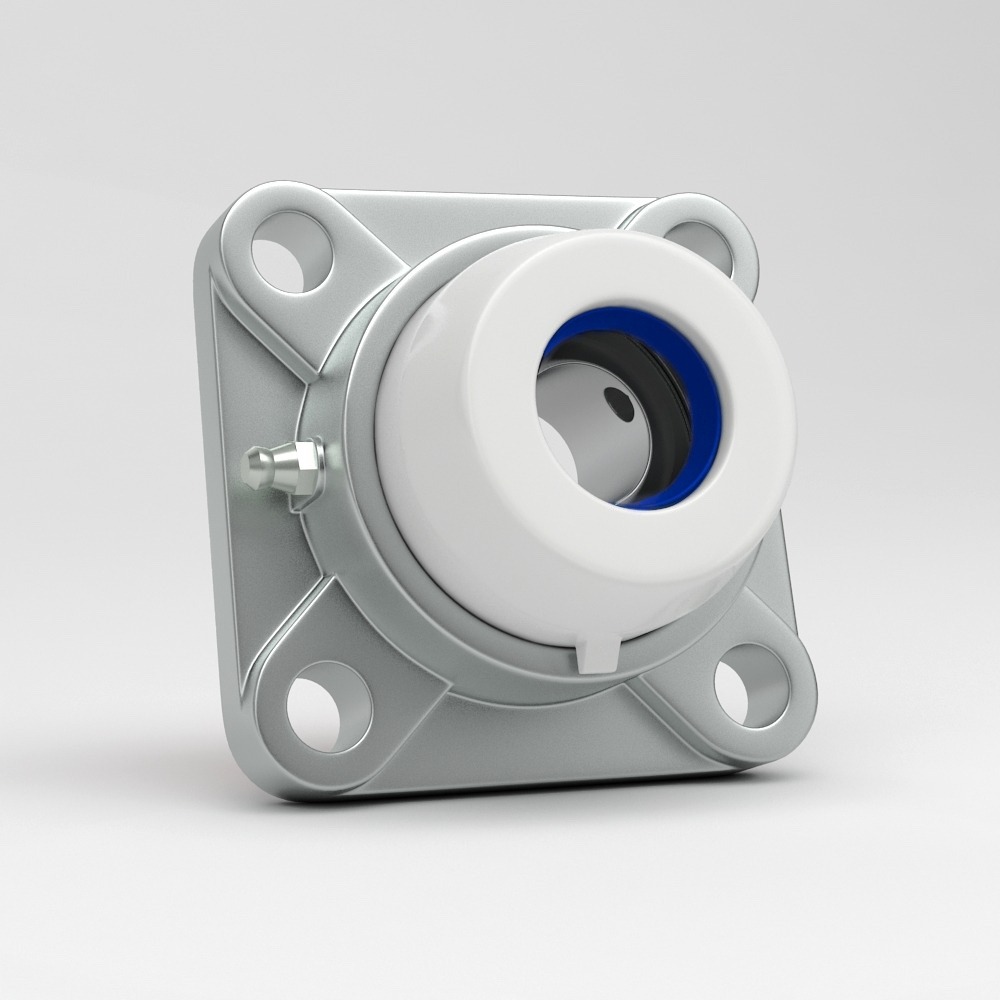

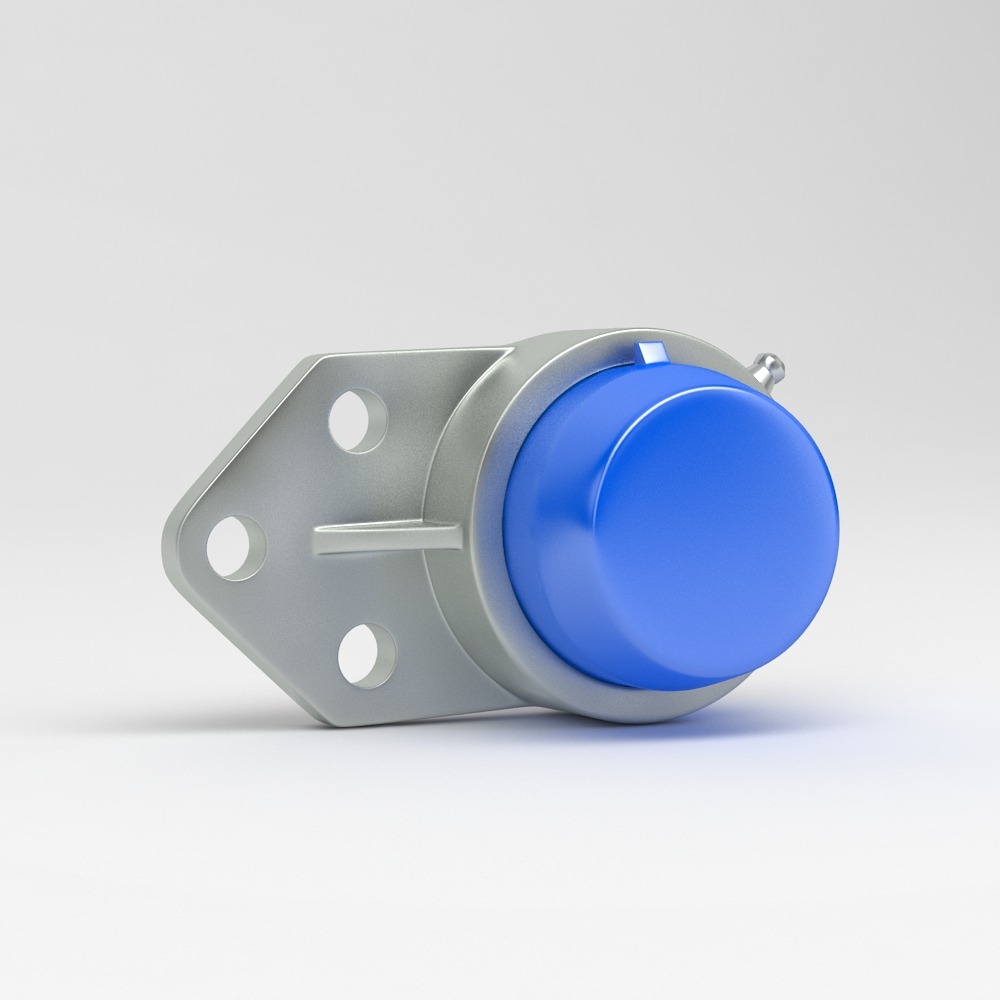

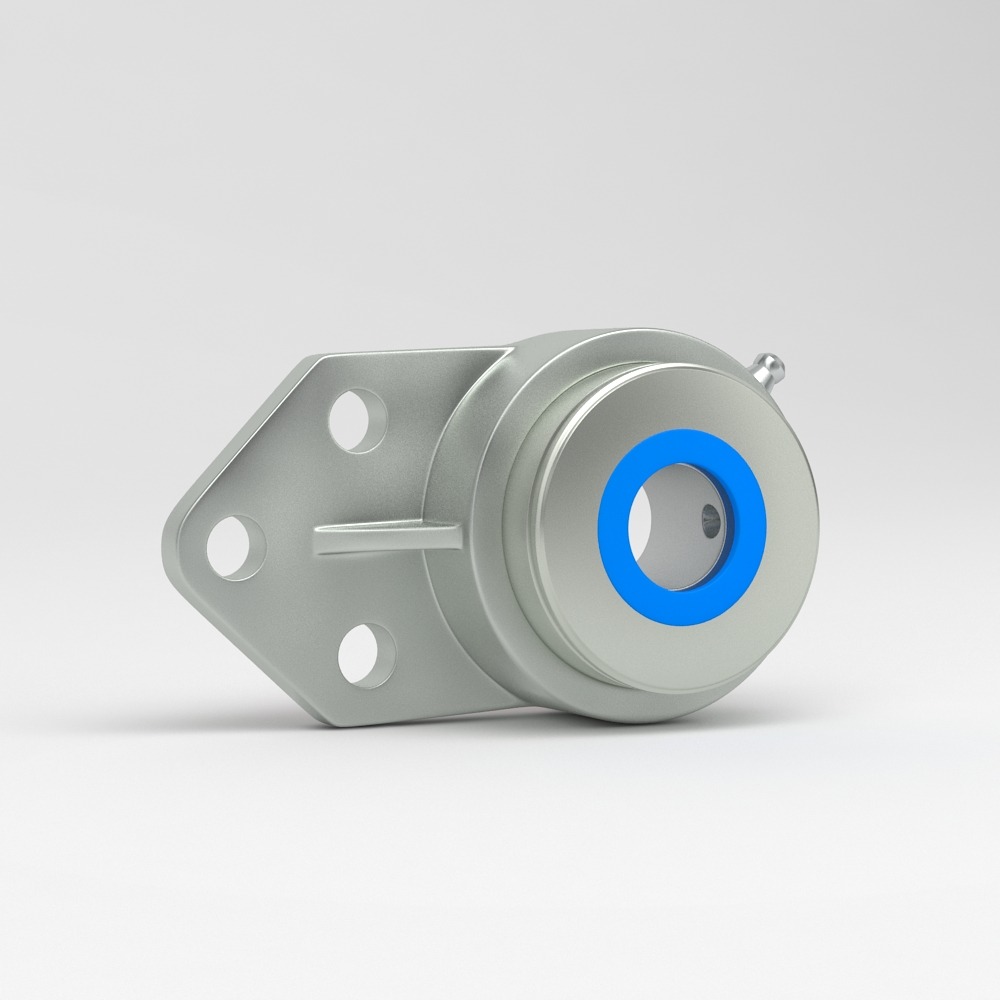

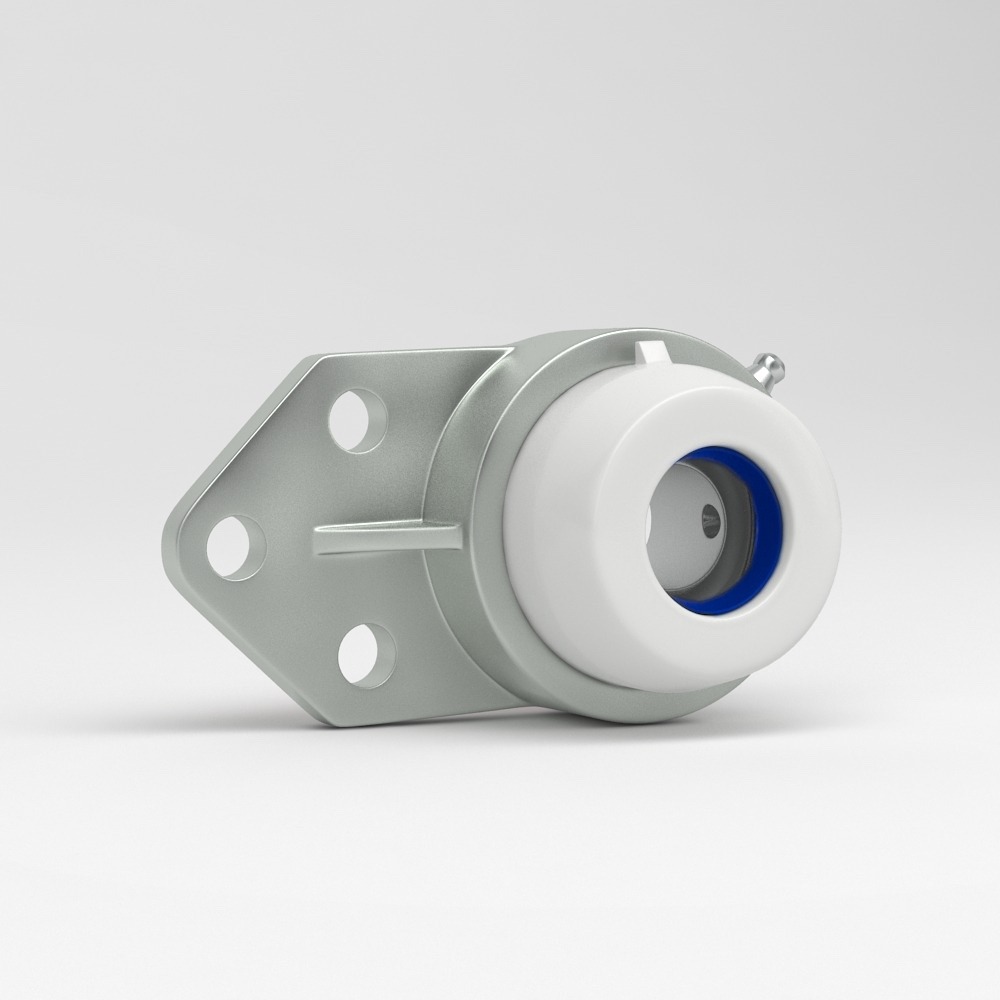

Stainless bearing unit open cover / open cap (CCSS)

Stainless bearing Unit cover in stainless steel

Cover material: Aisi 304

Oil seal material: NBR Rubber

Oil Seal TC (Double lip)

Open cover for stainless bearing unit available sizes

| Shaft Diameter | Catalog No. |

| Ø20 mm | OCSS 204 |

| Ø25 mm | OCSS 205 |

| Ø30 mm | OCSS 206 |

| Ø35 mm | OCSS 207 |

| Ø40 mm | OCSS 208 |

| Ø45 mm | OCSS 209 |

| Ø50 mm | OCSS 210 |

| Ø55 mm | OCSS 211 |

| Ø60 mm | OCSS 212 |

Open cover for mounted stainless bearing unit

Sealed stainless steel bearing units are engineered to deliver exceptional performance in environments where corrosion resistance, hygiene, and durability are critical. These units combine stainless steel housings and inserts with advanced sealing mechanisms, ensuring reliable operation across various demanding applications.

Key Features and Benefits

Corrosion Resistance: Constructed from high-grade stainless steels, such as AISI 316 for housings and 440C for bearing inserts, these units offer superior resistance to moisture, chemicals, and aggressive cleaning agents, making them ideal for industries like food processing and pharmaceuticals.

Advanced Sealing Solutions: Equipped with robust seals, including metal-backed silicon rubber seals that snap into a groove in the outer race, these bearings effectively prevent contamination ingress, thereby extending operational life.

Hygienic Design: The smooth, solid construction of stainless steel housings minimizes crevices where bacteria can accumulate, facilitating easy cleaning and compliance with stringent hygiene standards.

Maintenance-Free Operation: Many units are pre-lubricated with food-grade solid lubricants, eliminating the need for regular maintenance and reducing the risk of contamination.

Applications

Sealed stainless steel bearing units are particularly suited for applications requiring high corrosion resistance and cleanliness, including:

Food Processing Equipment: Ensuring compliance with hygiene regulations and withstanding frequent washdowns.

Pharmaceutical Machinery: Maintaining sterile conditions and resisting aggressive cleaning agents.

Marine Applications: Providing durability in saltwater environments.

Chemical Processing Plants: Withstanding exposure to corrosive substances.

Enhancing Performance and Durability

Sealed stainless steel bearing units combine robust materials with advanced sealing technologies to deliver reliable, maintenance-free performance in challenging environments. Their design not only enhances durability but also ensures compliance with strict hygiene standards, making them indispensable in various industrial applications.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

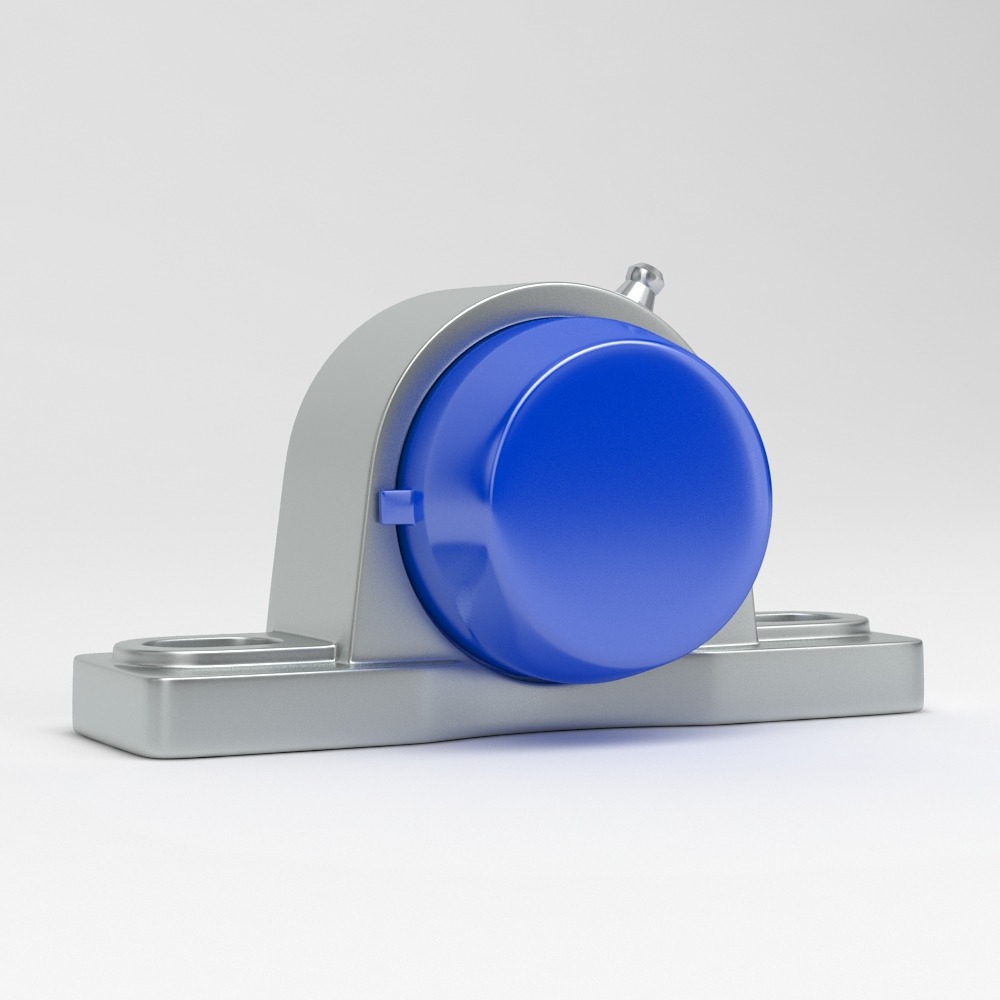

Stainless bearing unit open cover / open cap (CCSS)

Stainless bearing Unit cover in stainless steel

Cover material: Aisi 304

Oil seal material: NBR Rubber

Oil Seal TC (Double lip)

Open cover for stainless bearing unit available sizes

| Shaft Diameter | Catalog No. |

| Ø20 mm | OCSS 204 |

| Ø25 mm | OCSS 205 |

| Ø30 mm | OCSS 206 |

| Ø35 mm | OCSS 207 |

| Ø40 mm | OCSS 208 |

| Ø45 mm | OCSS 209 |

| Ø50 mm | OCSS 210 |

| Ø55 mm | OCSS 211 |

| Ø60 mm | OCSS 212 |

Open cover for mounted stainless bearing unit

Sealed stainless steel bearing units are engineered to deliver exceptional performance in environments where corrosion resistance, hygiene, and durability are critical. These units combine stainless steel housings and inserts with advanced sealing mechanisms, ensuring reliable operation across various demanding applications.

Key Features and Benefits

Corrosion Resistance: Constructed from high-grade stainless steels, such as AISI 316 for housings and 440C for bearing inserts, these units offer superior resistance to moisture, chemicals, and aggressive cleaning agents, making them ideal for industries like food processing and pharmaceuticals.

Advanced Sealing Solutions: Equipped with robust seals, including metal-backed silicon rubber seals that snap into a groove in the outer race, these bearings effectively prevent contamination ingress, thereby extending operational life.

Hygienic Design: The smooth, solid construction of stainless steel housings minimizes crevices where bacteria can accumulate, facilitating easy cleaning and compliance with stringent hygiene standards.

Maintenance-Free Operation: Many units are pre-lubricated with food-grade solid lubricants, eliminating the need for regular maintenance and reducing the risk of contamination.

Applications

Sealed stainless steel bearing units are particularly suited for applications requiring high corrosion resistance and cleanliness, including:

Food Processing Equipment: Ensuring compliance with hygiene regulations and withstanding frequent washdowns.

Pharmaceutical Machinery: Maintaining sterile conditions and resisting aggressive cleaning agents.

Marine Applications: Providing durability in saltwater environments.

Chemical Processing Plants: Withstanding exposure to corrosive substances.

Enhancing Performance and Durability

Sealed stainless steel bearing units combine robust materials with advanced sealing technologies to deliver reliable, maintenance-free performance in challenging environments. Their design not only enhances durability but also ensures compliance with strict hygiene standards, making them indispensable in various industrial applications.

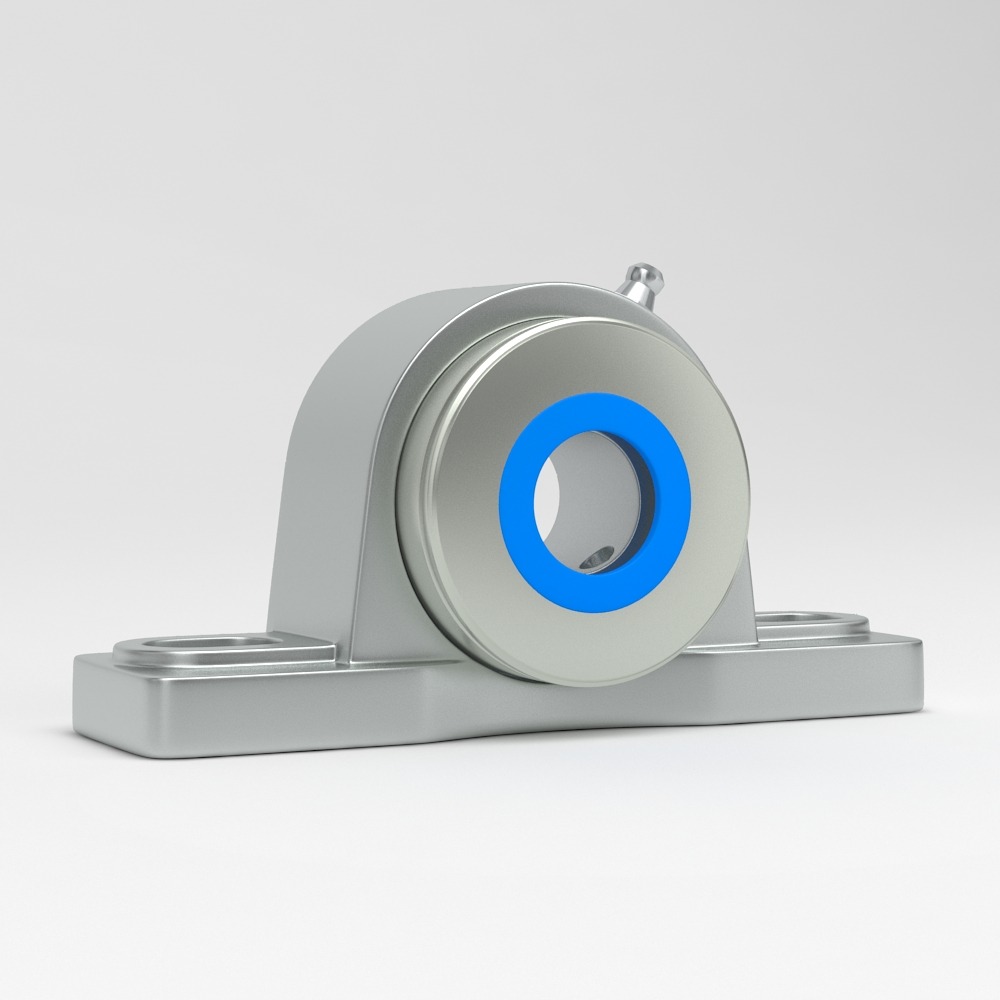

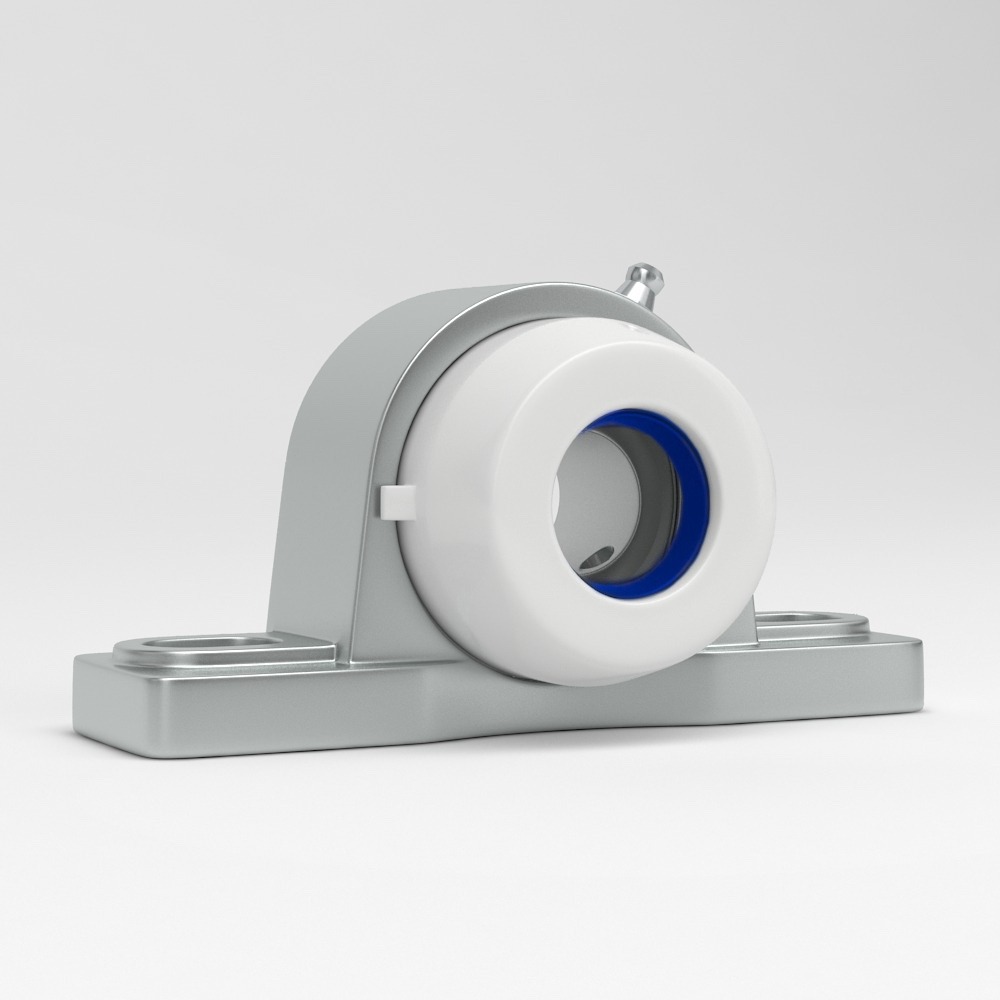

Stainless bearing unit open cover / open cap (CCSS)

Stainless bearing Unit cover in stainless steel

Cover material: Aisi 304

Oil seal material: NBR Rubber

Oil Seal TC (Double lip)

Open cover for stainless bearing unit available sizes

| Shaft Diameter | Catalog No. |

| Ø20 mm | OCSS 204 |

| Ø25 mm | OCSS 205 |

| Ø30 mm | OCSS 206 |

| Ø35 mm | OCSS 207 |

| Ø40 mm | OCSS 208 |

| Ø45 mm | OCSS 209 |

| Ø50 mm | OCSS 210 |

| Ø55 mm | OCSS 211 |

| Ø60 mm | OCSS 212 |

Open cover for mounted stainless bearing unit

Sealed stainless steel bearing units are engineered to deliver exceptional performance in environments where corrosion resistance, hygiene, and durability are critical. These units combine stainless steel housings and inserts with advanced sealing mechanisms, ensuring reliable operation across various demanding applications.

Key Features and Benefits

Corrosion Resistance: Constructed from high-grade stainless steels, such as AISI 316 for housings and 440C for bearing inserts, these units offer superior resistance to moisture, chemicals, and aggressive cleaning agents, making them ideal for industries like food processing and pharmaceuticals.

Advanced Sealing Solutions: Equipped with robust seals, including metal-backed silicon rubber seals that snap into a groove in the outer race, these bearings effectively prevent contamination ingress, thereby extending operational life.

Hygienic Design: The smooth, solid construction of stainless steel housings minimizes crevices where bacteria can accumulate, facilitating easy cleaning and compliance with stringent hygiene standards.

Maintenance-Free Operation: Many units are pre-lubricated with food-grade solid lubricants, eliminating the need for regular maintenance and reducing the risk of contamination.

Applications

Sealed stainless steel bearing units are particularly suited for applications requiring high corrosion resistance and cleanliness, including:

Food Processing Equipment: Ensuring compliance with hygiene regulations and withstanding frequent washdowns.

Pharmaceutical Machinery: Maintaining sterile conditions and resisting aggressive cleaning agents.

Marine Applications: Providing durability in saltwater environments.

Chemical Processing Plants: Withstanding exposure to corrosive substances.

Enhancing Performance and Durability

Sealed stainless steel bearing units combine robust materials with advanced sealing technologies to deliver reliable, maintenance-free performance in challenging environments. Their design not only enhances durability but also ensures compliance with strict hygiene standards, making them indispensable in various industrial applications.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.