Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

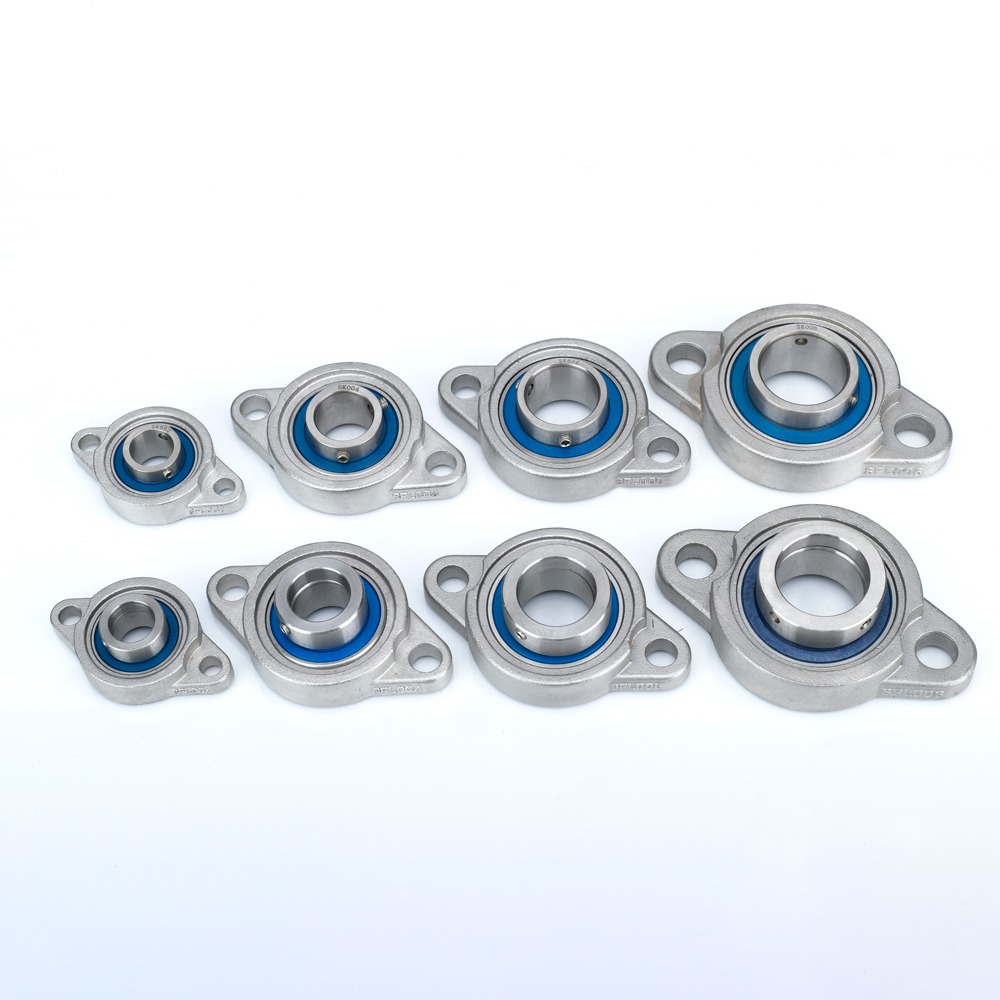

Mini flange bearing unit in stainless steel

Mini stainless steel flange bearing unit

Check out our extensive range of Mini Bearing Units in Stainless Steel

Features and advantages:

Stainless steel housings AISI 304

Stainless steel bearings AISI 440C

Seal: Nitrile rubber (NBR) or FDA approved silicone (Si) rubber

Narrow bearings

No surface coating are required

Set screw lock or eccentric collar lock

Excellent life span

Operating temperature from -30°C to +120°C

Hygienic designed, suitable in food and medical production

The mini stainless steel bearing units in hygienic design are often used in industries such as medical, laboratory and in cleanrooms where the highest level of hygiene is required. The mini stainless steel bearing units improve the overall performance of the food processing equipment, the mini bearing units help to ensure that the equipment runs smoothly and efficiently.

Mini stainless steel flange bearing unit

Mini stainless steel flange bearing units are essential components in various industries, offering reliable performance in demanding environments. Understanding their design, applications, and the importance of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) in selecting these units can ensure optimal performance and longevity.

Understanding Mini Stainless Steel Flange Bearing Units

Mini stainless steel flange bearing units are compact mechanical components designed to support shafts and facilitate smooth rotational or linear movement. They consist of a stainless steel bearing mounted within a flanged housing, allowing for easy installation and secure attachment to machinery or equipment. The use of stainless steel provides excellent corrosion resistance, making these units suitable for applications in harsh or hygienic environments.

Key Features and Benefits

- Corrosion Resistance: The stainless steel construction ensures durability and resistance to rust and corrosion, essential for applications in food processing, pharmaceuticals, and marine environments.

- Compact Design: Their miniature size allows for use in applications with limited space without compromising performance.

- Ease of Installation: The flanged design simplifies mounting, providing stability and reducing the risk of misalignment.

- Hygienic Properties: Ideal for industries requiring strict hygiene standards, as stainless steel is easy to clean and does not harbor bacteria.

Applications

These bearing units are versatile and find applications across various industries:

- Food and Beverage Industry: Used in processing and packaging equipment where hygiene and corrosion resistance are paramount.

- Pharmaceuticals: Applied in machinery that requires clean and sterile conditions.

- Marine Applications: Suitable for equipment exposed to saltwater environments due to their corrosion resistance.

- Automotive: Utilized in systems where space is limited, and reliable performance is essential.

The Importance of E-E-A-T in Selecting Bearing Units

When choosing mini stainless steel flange bearing units, considering the principles of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) is crucial:

- Experience: Opt for manufacturers with a proven track record in producing high-quality bearing units. Experience indicates a deep understanding of the product and its applications.

- Expertise: Ensure the manufacturer possesses specialized knowledge in bearing technology and stainless steel applications. Expertise ensures that the products are designed and manufactured to meet specific industry requirements.

- Authoritativeness: Choose suppliers recognized as leaders in the field. Authoritative companies often contribute to industry standards and are cited as reliable sources.

- Trustworthiness: Select manufacturers known for their integrity and quality assurance. Trustworthy companies provide transparent information about their products and stand behind their performance.

By prioritizing E-E-A-T, you can be confident in the quality and reliability of the mini stainless steel flange bearing units you select, ensuring optimal performance in your applications.

Mini stainless steel flange bearing units are vital components in various industries, offering durability, compactness, and ease of installation. By understanding their features and applications and applying the E-E-A-T principles in your selection process, you can ensure the longevity and efficiency of your machinery and equipment.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.

Mini stainless steel flange bearing unit

Check out our extensive range of Mini Bearing Units in Stainless Steel

Features and advantages:

Stainless steel housings AISI 304

Stainless steel bearings AISI 440C

Seal: Nitrile rubber (NBR) or FDA approved silicone (Si) rubber

Narrow bearings

No surface coating are required

Set screw lock or eccentric collar lock

Excellent life span

Operating temperature from -30°C to +120°C

Hygienic designed, suitable in food and medical production

The mini stainless steel bearing units in hygienic design are often used in industries such as medical, laboratory and in cleanrooms where the highest level of hygiene is required. The mini stainless steel bearing units improve the overall performance of the food processing equipment, the mini bearing units help to ensure that the equipment runs smoothly and efficiently.

Mini stainless steel flange bearing unit

Mini stainless steel flange bearing units are essential components in various industries, offering reliable performance in demanding environments. Understanding their design, applications, and the importance of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) in selecting these units can ensure optimal performance and longevity.

Understanding Mini Stainless Steel Flange Bearing Units

Mini stainless steel flange bearing units are compact mechanical components designed to support shafts and facilitate smooth rotational or linear movement. They consist of a stainless steel bearing mounted within a flanged housing, allowing for easy installation and secure attachment to machinery or equipment. The use of stainless steel provides excellent corrosion resistance, making these units suitable for applications in harsh or hygienic environments.

Key Features and Benefits

- Corrosion Resistance: The stainless steel construction ensures durability and resistance to rust and corrosion, essential for applications in food processing, pharmaceuticals, and marine environments.

- Compact Design: Their miniature size allows for use in applications with limited space without compromising performance.

- Ease of Installation: The flanged design simplifies mounting, providing stability and reducing the risk of misalignment.

- Hygienic Properties: Ideal for industries requiring strict hygiene standards, as stainless steel is easy to clean and does not harbor bacteria.

Applications

These bearing units are versatile and find applications across various industries:

- Food and Beverage Industry: Used in processing and packaging equipment where hygiene and corrosion resistance are paramount.

- Pharmaceuticals: Applied in machinery that requires clean and sterile conditions.

- Marine Applications: Suitable for equipment exposed to saltwater environments due to their corrosion resistance.

- Automotive: Utilized in systems where space is limited, and reliable performance is essential.

The Importance of E-E-A-T in Selecting Bearing Units

When choosing mini stainless steel flange bearing units, considering the principles of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) is crucial:

- Experience: Opt for manufacturers with a proven track record in producing high-quality bearing units. Experience indicates a deep understanding of the product and its applications.

- Expertise: Ensure the manufacturer possesses specialized knowledge in bearing technology and stainless steel applications. Expertise ensures that the products are designed and manufactured to meet specific industry requirements.

- Authoritativeness: Choose suppliers recognized as leaders in the field. Authoritative companies often contribute to industry standards and are cited as reliable sources.

- Trustworthiness: Select manufacturers known for their integrity and quality assurance. Trustworthy companies provide transparent information about their products and stand behind their performance.

By prioritizing E-E-A-T, you can be confident in the quality and reliability of the mini stainless steel flange bearing units you select, ensuring optimal performance in your applications.

Mini stainless steel flange bearing units are vital components in various industries, offering durability, compactness, and ease of installation. By understanding their features and applications and applying the E-E-A-T principles in your selection process, you can ensure the longevity and efficiency of your machinery and equipment.

Mini stainless steel flange bearing unit

Check out our extensive range of Mini Bearing Units in Stainless Steel

Features and advantages:

Stainless steel housings AISI 304

Stainless steel bearings AISI 440C

Seal: Nitrile rubber (NBR) or FDA approved silicone (Si) rubber

Narrow bearings

No surface coating are required

Set screw lock or eccentric collar lock

Excellent life span

Operating temperature from -30°C to +120°C

Hygienic designed, suitable in food and medical production

The mini stainless steel bearing units in hygienic design are often used in industries such as medical, laboratory and in cleanrooms where the highest level of hygiene is required. The mini stainless steel bearing units improve the overall performance of the food processing equipment, the mini bearing units help to ensure that the equipment runs smoothly and efficiently.

Mini stainless steel flange bearing unit

Mini stainless steel flange bearing units are essential components in various industries, offering reliable performance in demanding environments. Understanding their design, applications, and the importance of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) in selecting these units can ensure optimal performance and longevity.

Understanding Mini Stainless Steel Flange Bearing Units

Mini stainless steel flange bearing units are compact mechanical components designed to support shafts and facilitate smooth rotational or linear movement. They consist of a stainless steel bearing mounted within a flanged housing, allowing for easy installation and secure attachment to machinery or equipment. The use of stainless steel provides excellent corrosion resistance, making these units suitable for applications in harsh or hygienic environments.

Key Features and Benefits

- Corrosion Resistance: The stainless steel construction ensures durability and resistance to rust and corrosion, essential for applications in food processing, pharmaceuticals, and marine environments.

- Compact Design: Their miniature size allows for use in applications with limited space without compromising performance.

- Ease of Installation: The flanged design simplifies mounting, providing stability and reducing the risk of misalignment.

- Hygienic Properties: Ideal for industries requiring strict hygiene standards, as stainless steel is easy to clean and does not harbor bacteria.

Applications

These bearing units are versatile and find applications across various industries:

- Food and Beverage Industry: Used in processing and packaging equipment where hygiene and corrosion resistance are paramount.

- Pharmaceuticals: Applied in machinery that requires clean and sterile conditions.

- Marine Applications: Suitable for equipment exposed to saltwater environments due to their corrosion resistance.

- Automotive: Utilized in systems where space is limited, and reliable performance is essential.

The Importance of E-E-A-T in Selecting Bearing Units

When choosing mini stainless steel flange bearing units, considering the principles of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) is crucial:

- Experience: Opt for manufacturers with a proven track record in producing high-quality bearing units. Experience indicates a deep understanding of the product and its applications.

- Expertise: Ensure the manufacturer possesses specialized knowledge in bearing technology and stainless steel applications. Expertise ensures that the products are designed and manufactured to meet specific industry requirements.

- Authoritativeness: Choose suppliers recognized as leaders in the field. Authoritative companies often contribute to industry standards and are cited as reliable sources.

- Trustworthiness: Select manufacturers known for their integrity and quality assurance. Trustworthy companies provide transparent information about their products and stand behind their performance.

By prioritizing E-E-A-T, you can be confident in the quality and reliability of the mini stainless steel flange bearing units you select, ensuring optimal performance in your applications.

Mini stainless steel flange bearing units are vital components in various industries, offering durability, compactness, and ease of installation. By understanding their features and applications and applying the E-E-A-T principles in your selection process, you can ensure the longevity and efficiency of your machinery and equipment.

Contact us

Do you need more information? Get in touch today. We will help you find the right type of machin and levelling foot for your needs.