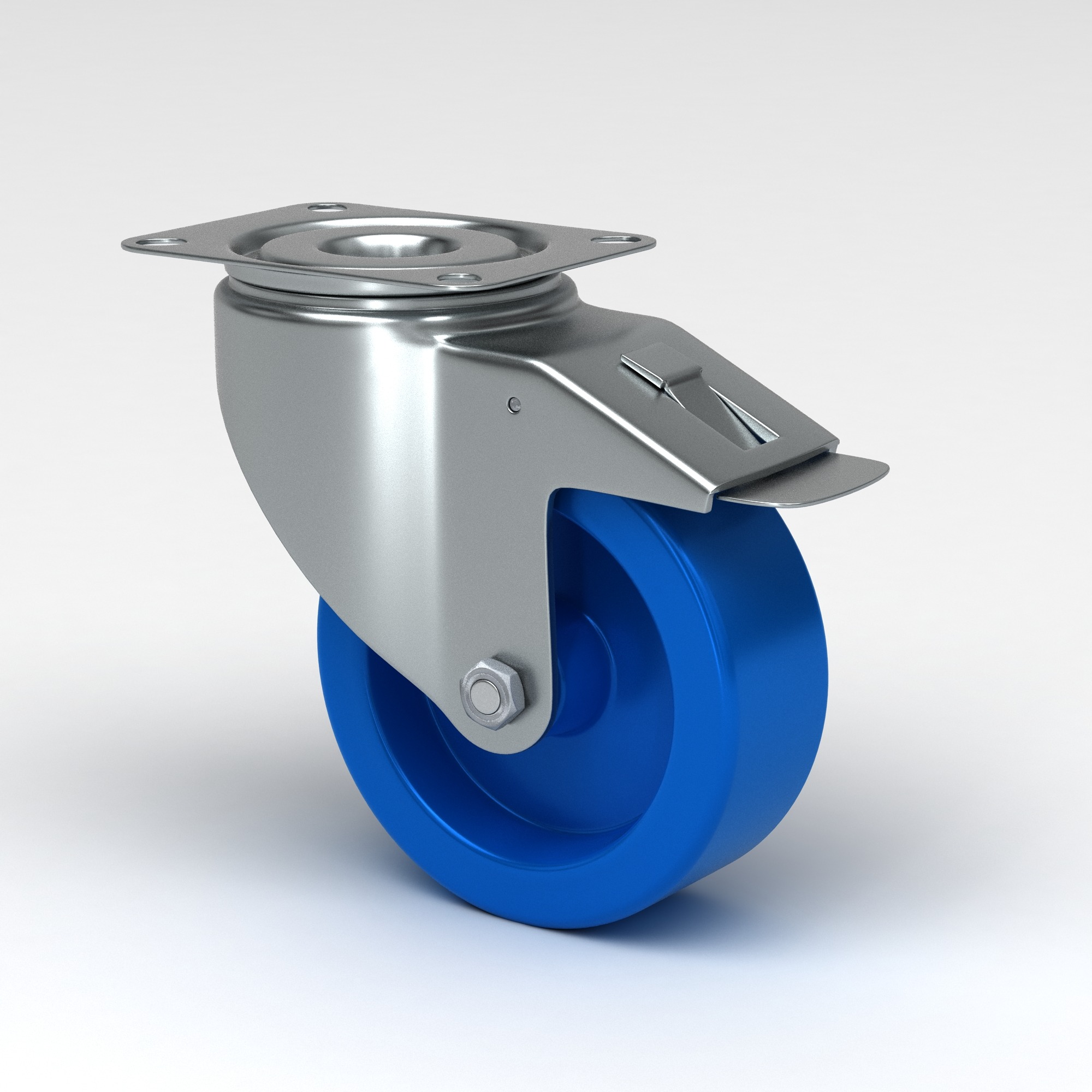

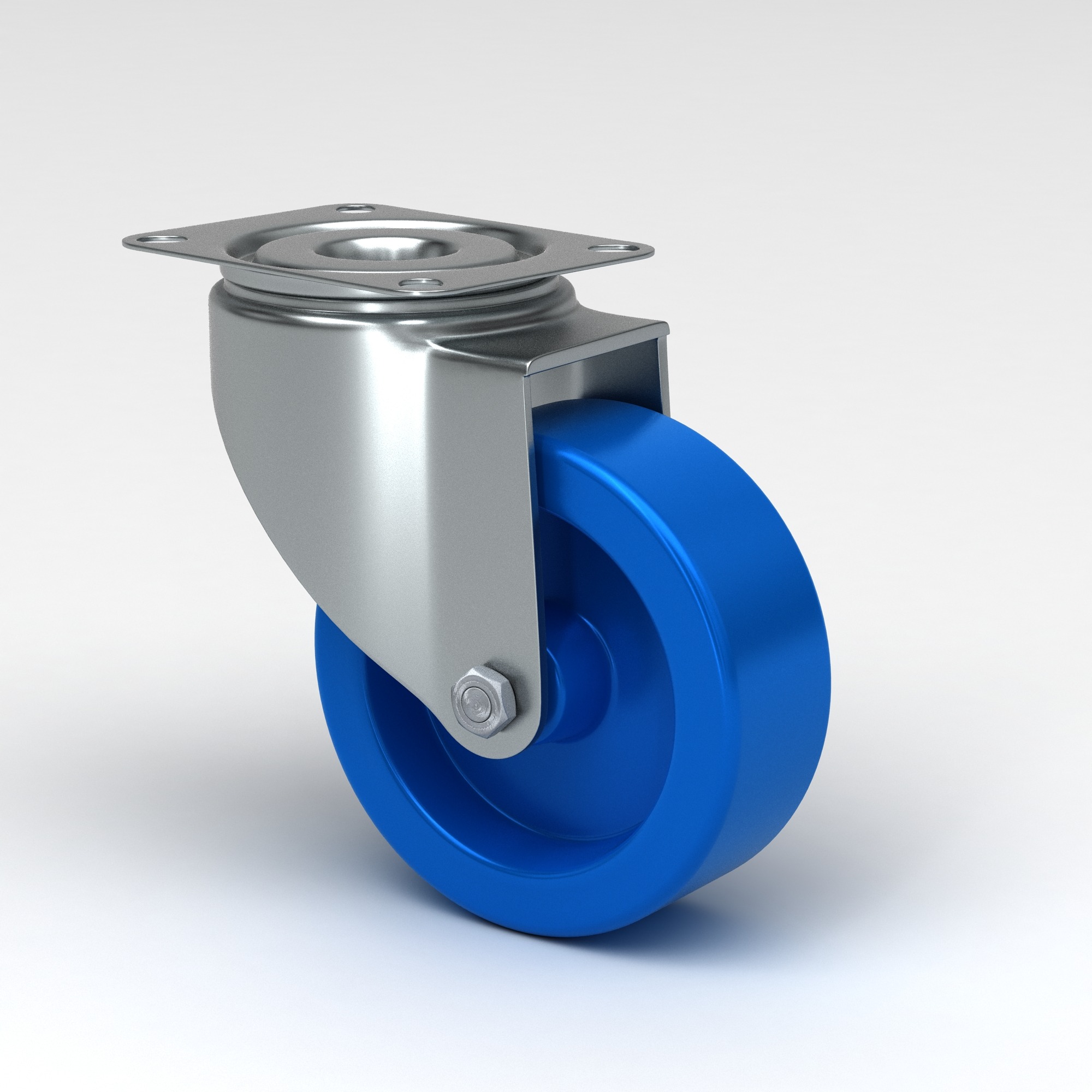

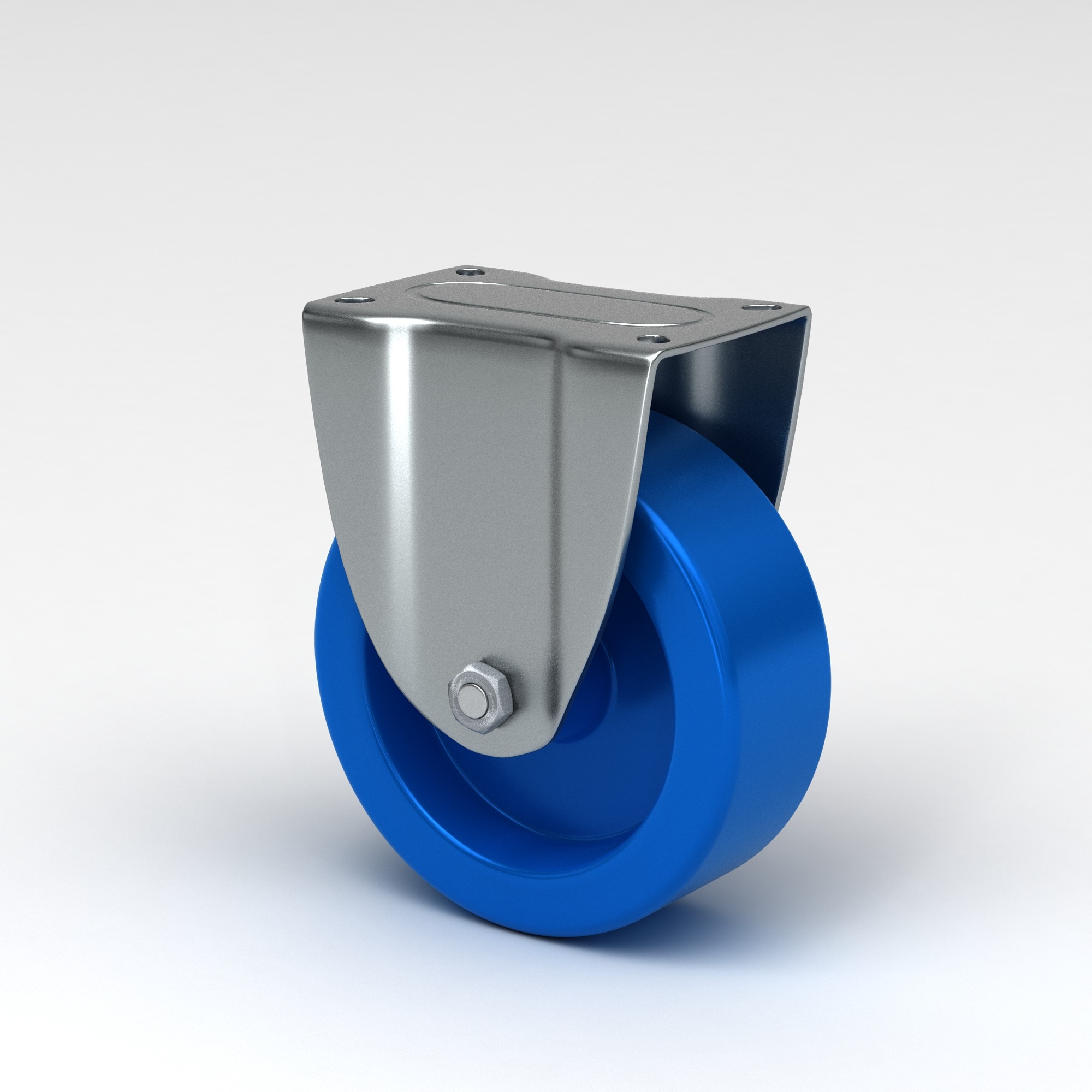

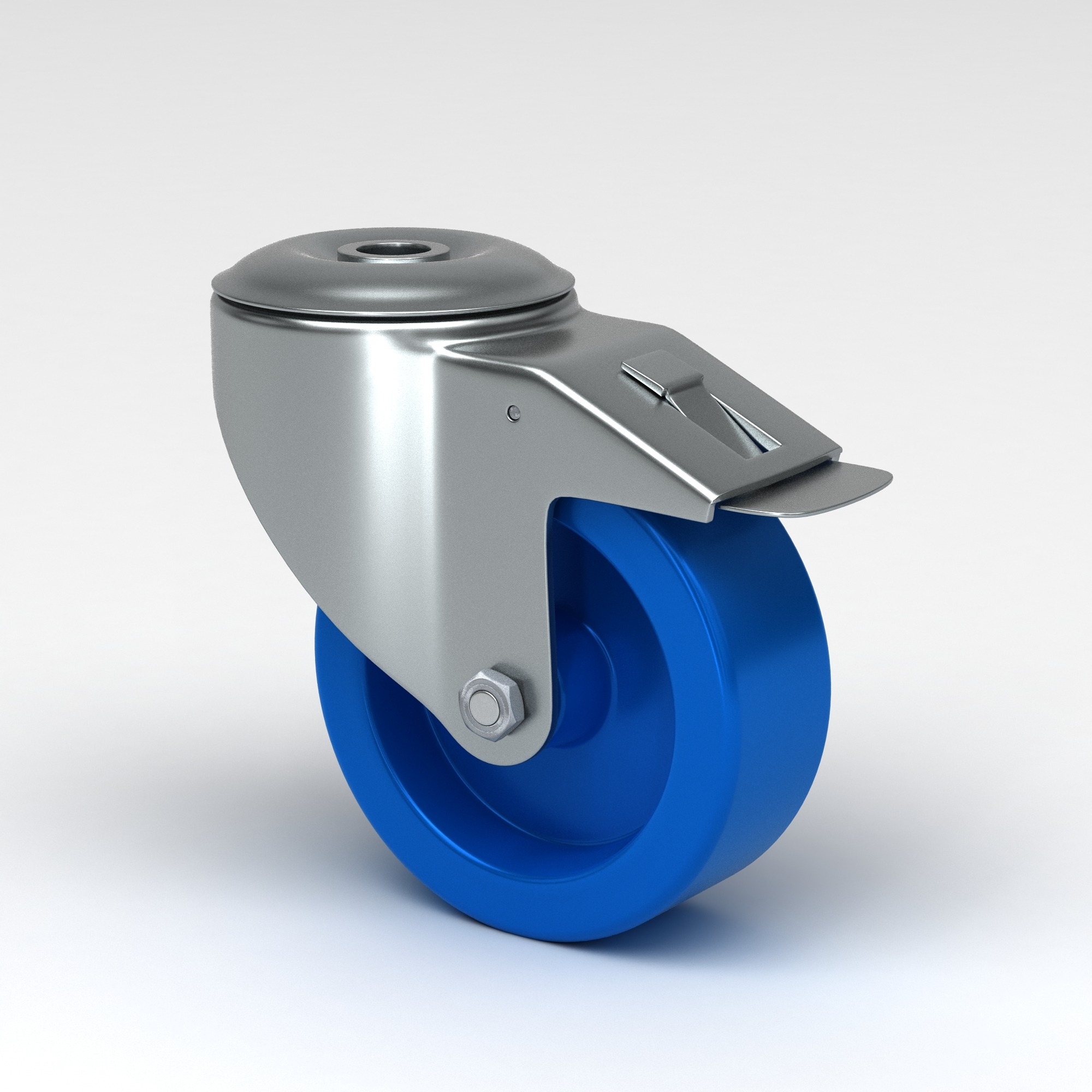

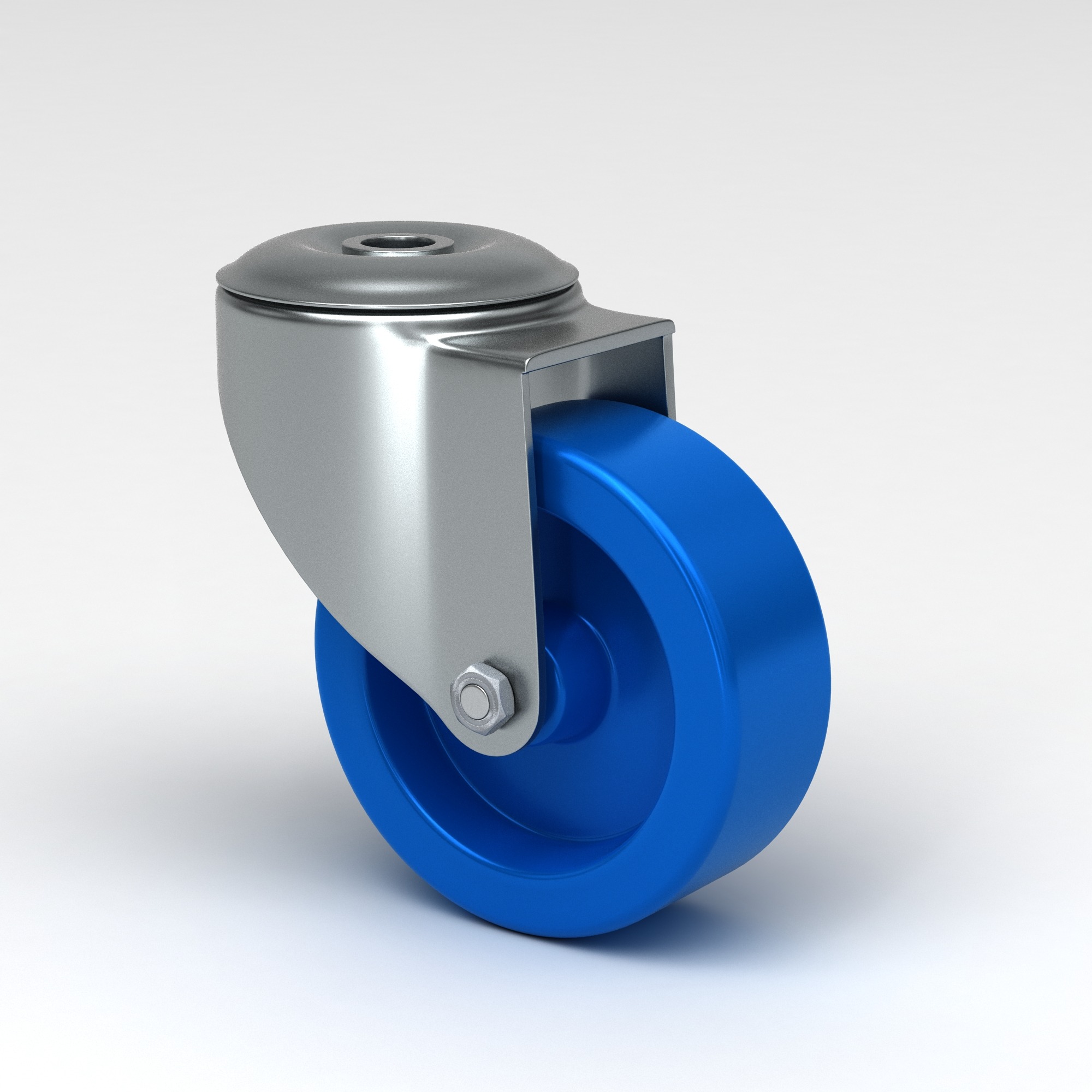

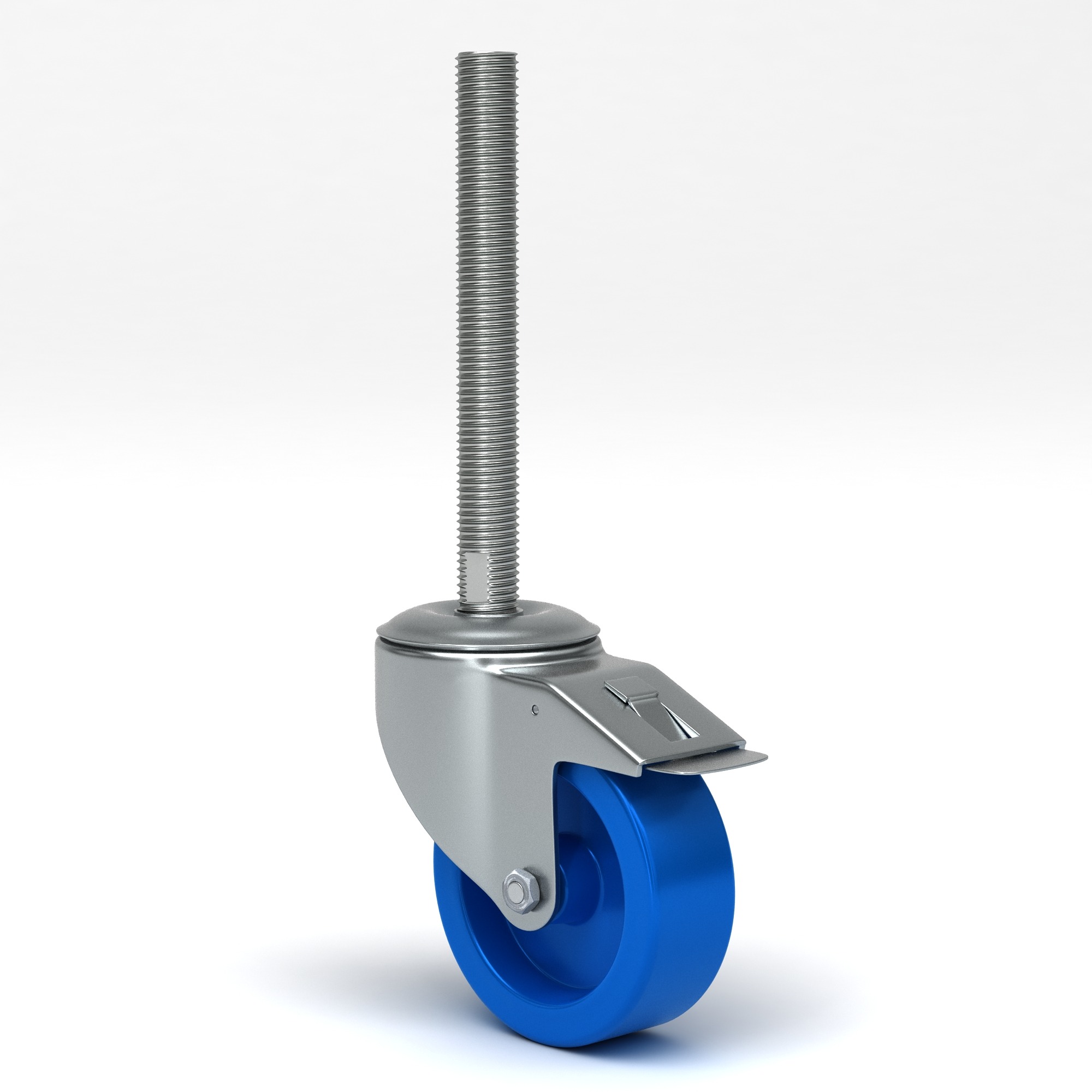

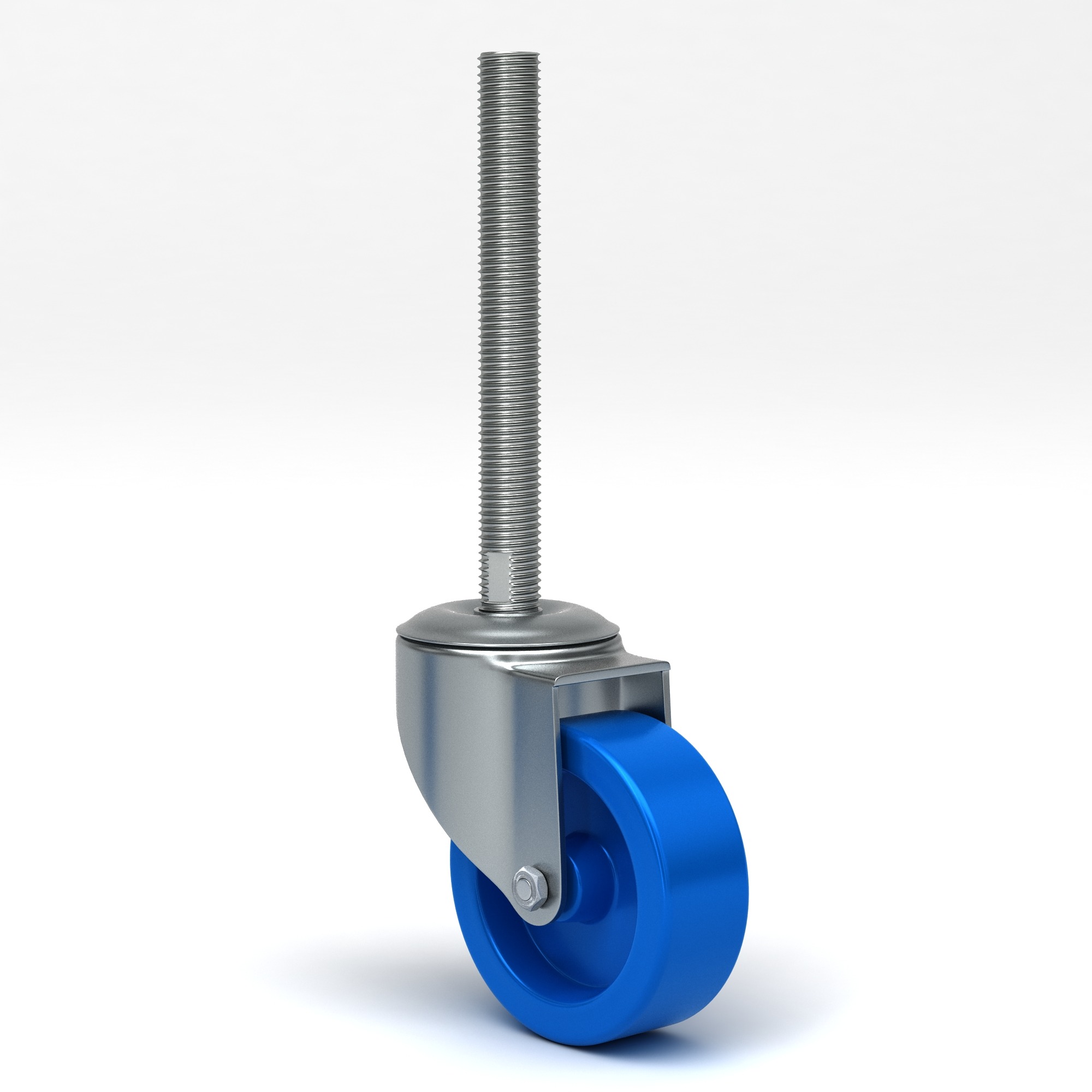

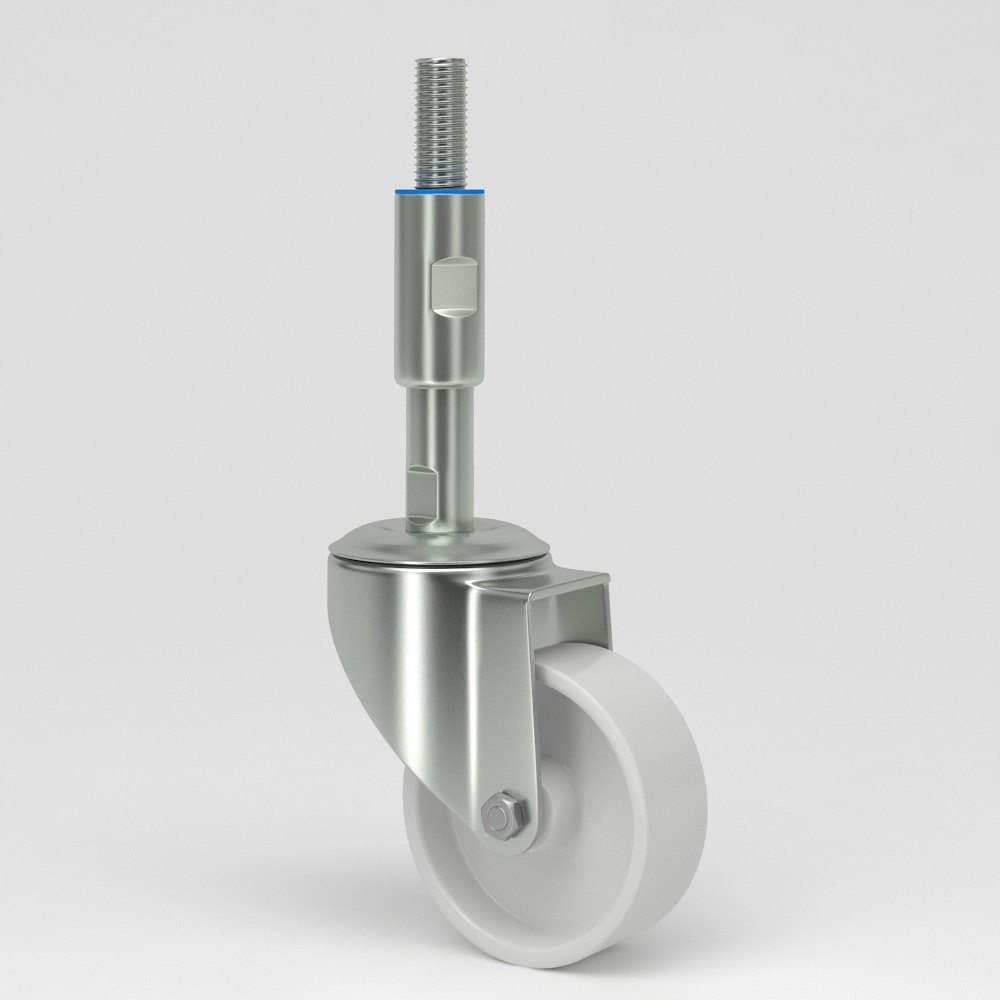

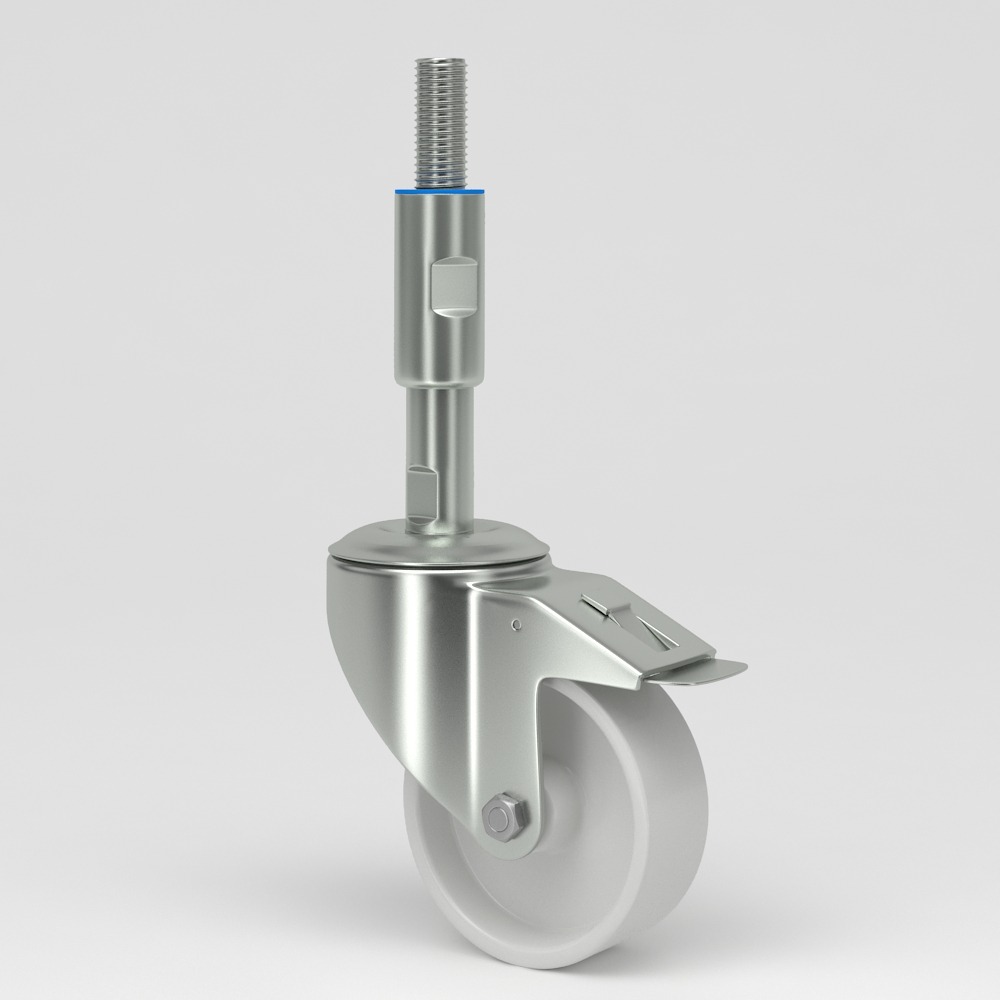

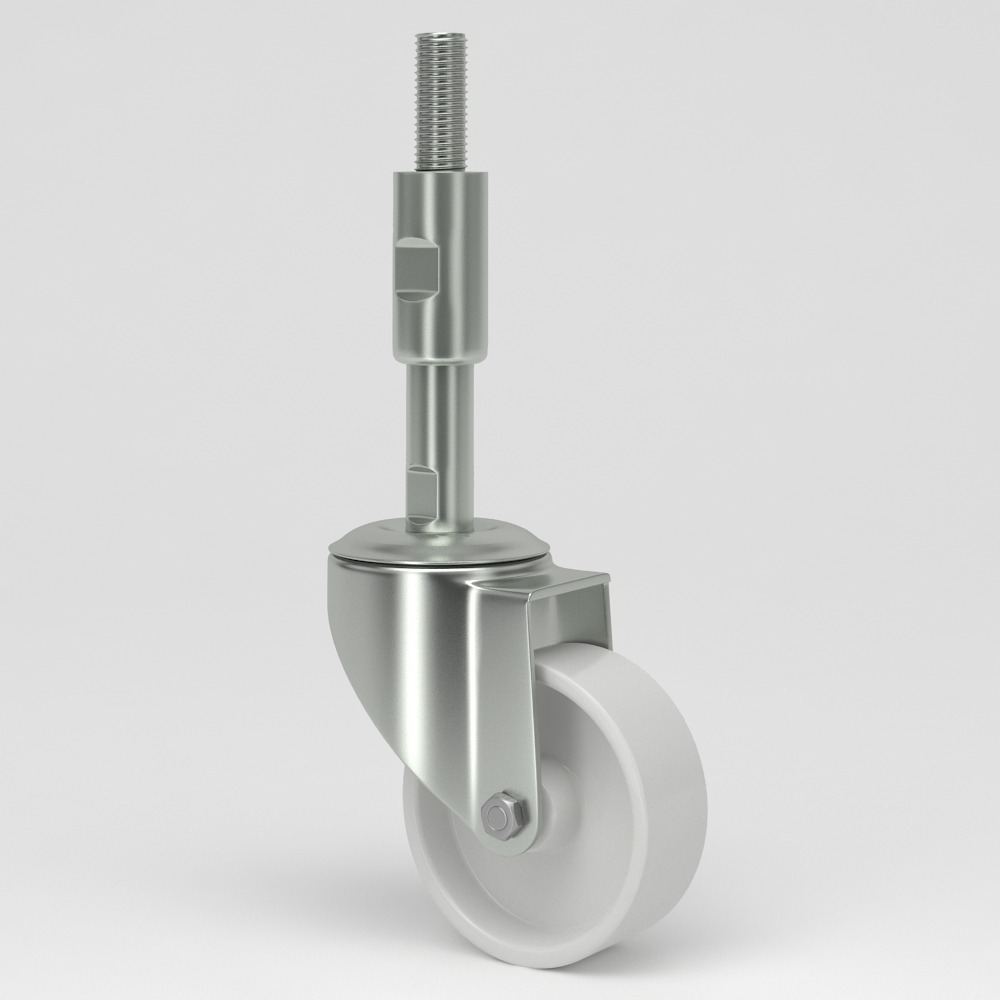

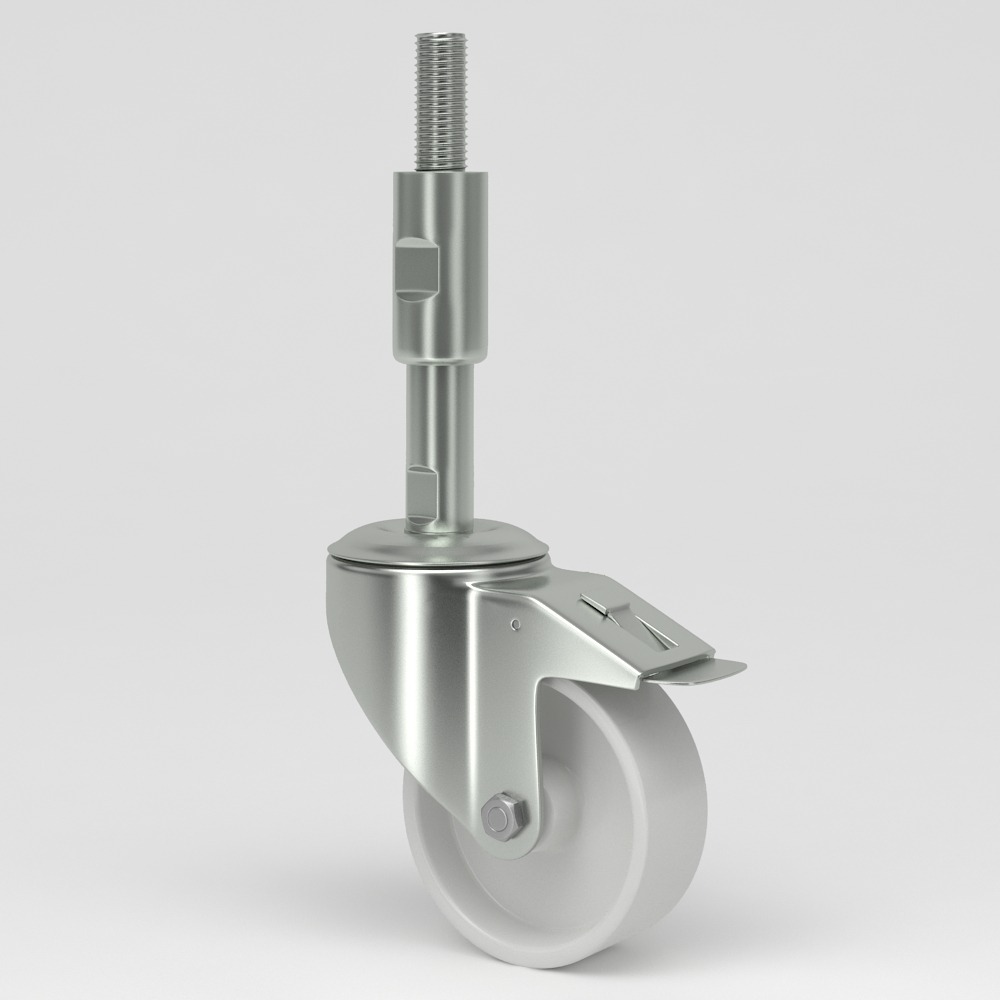

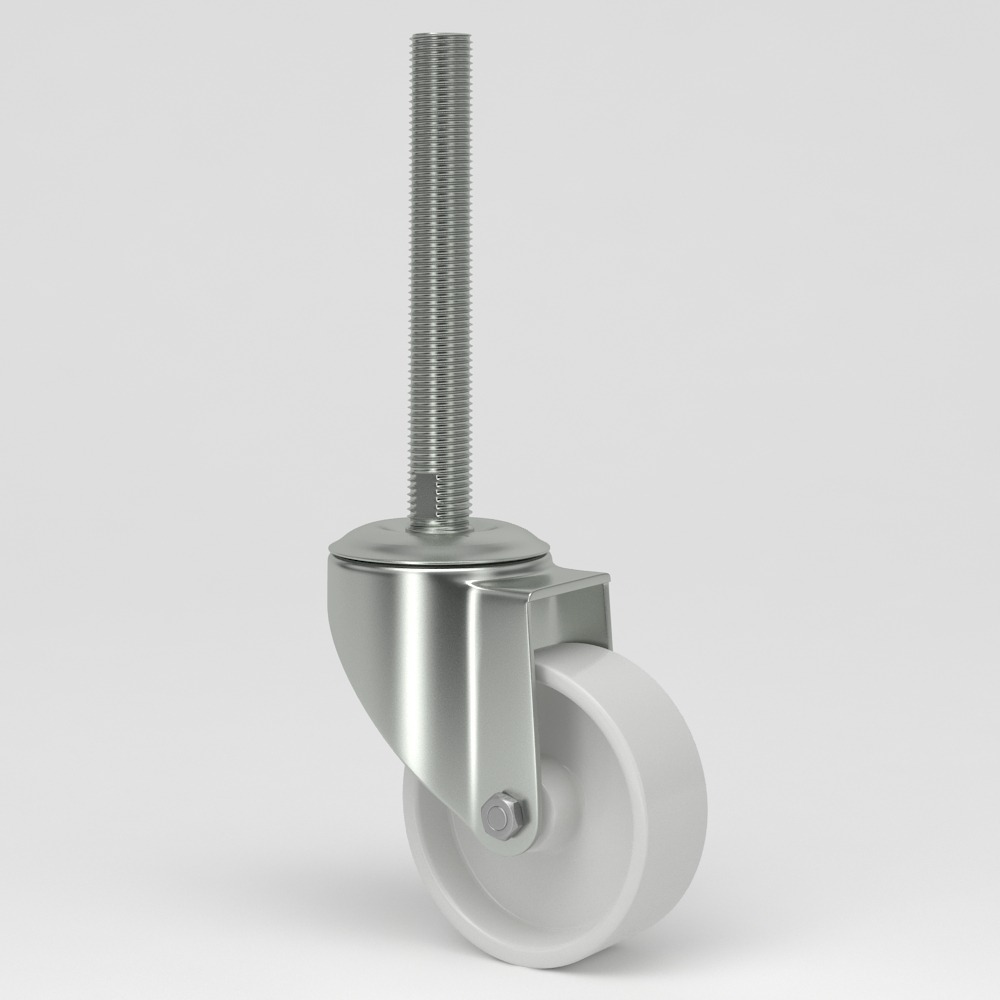

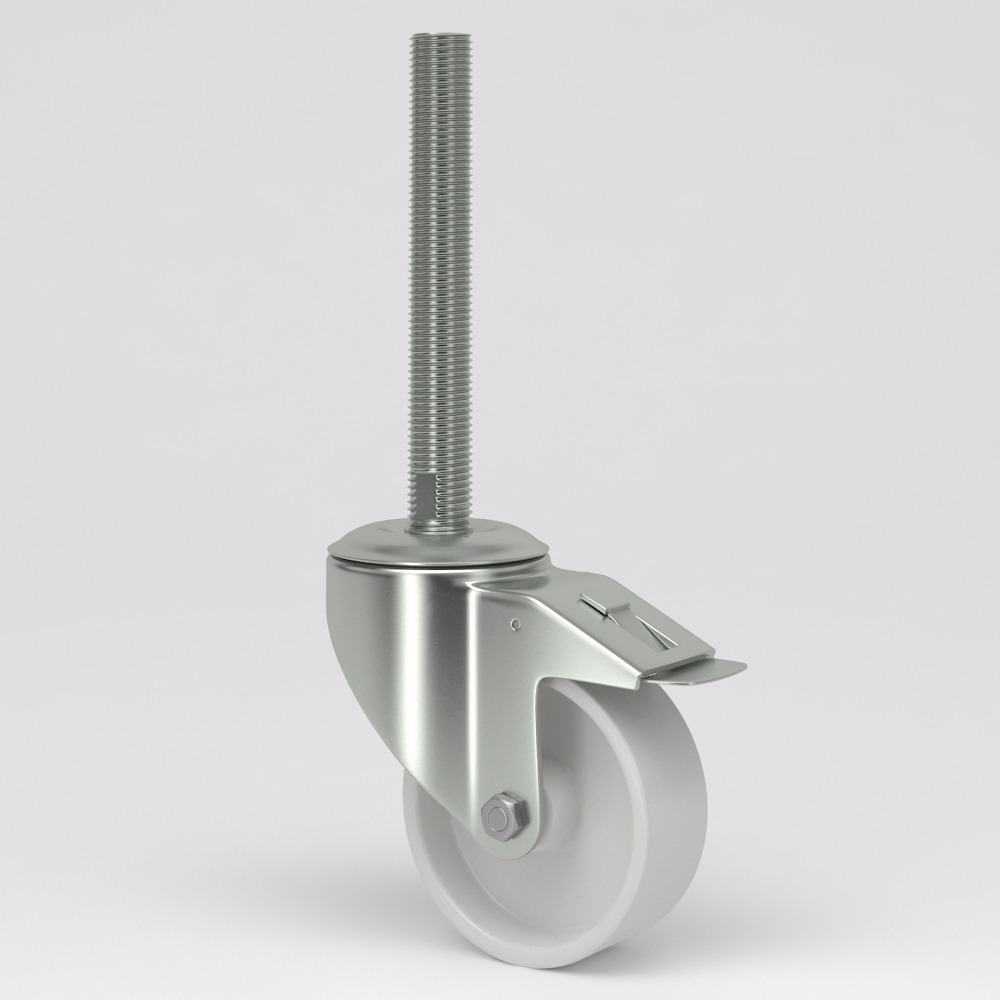

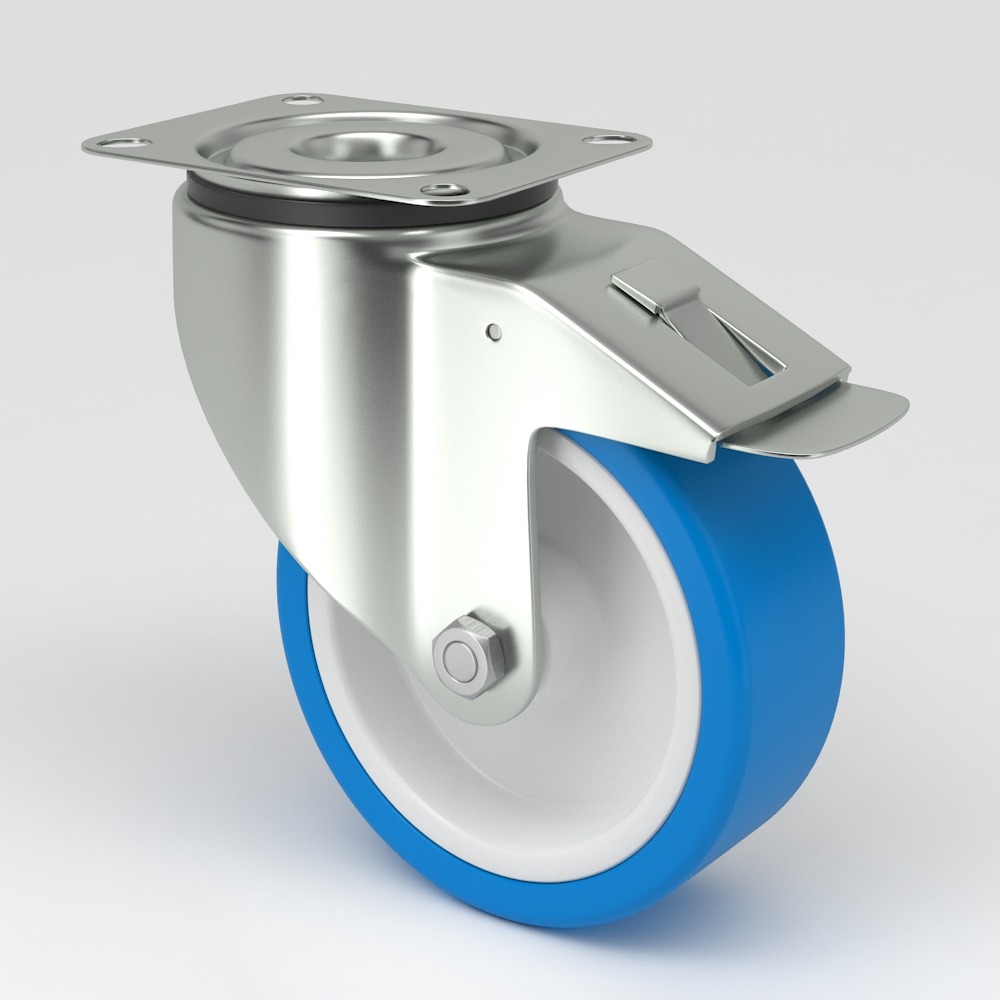

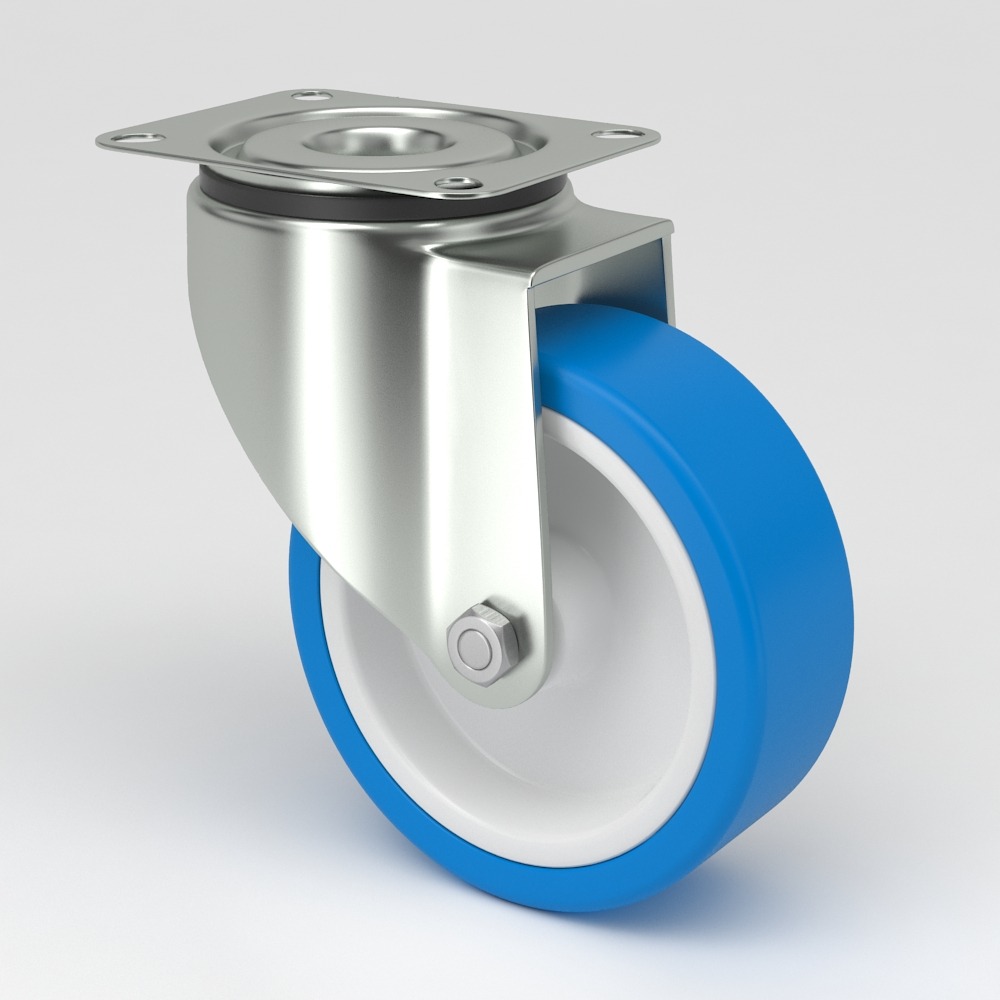

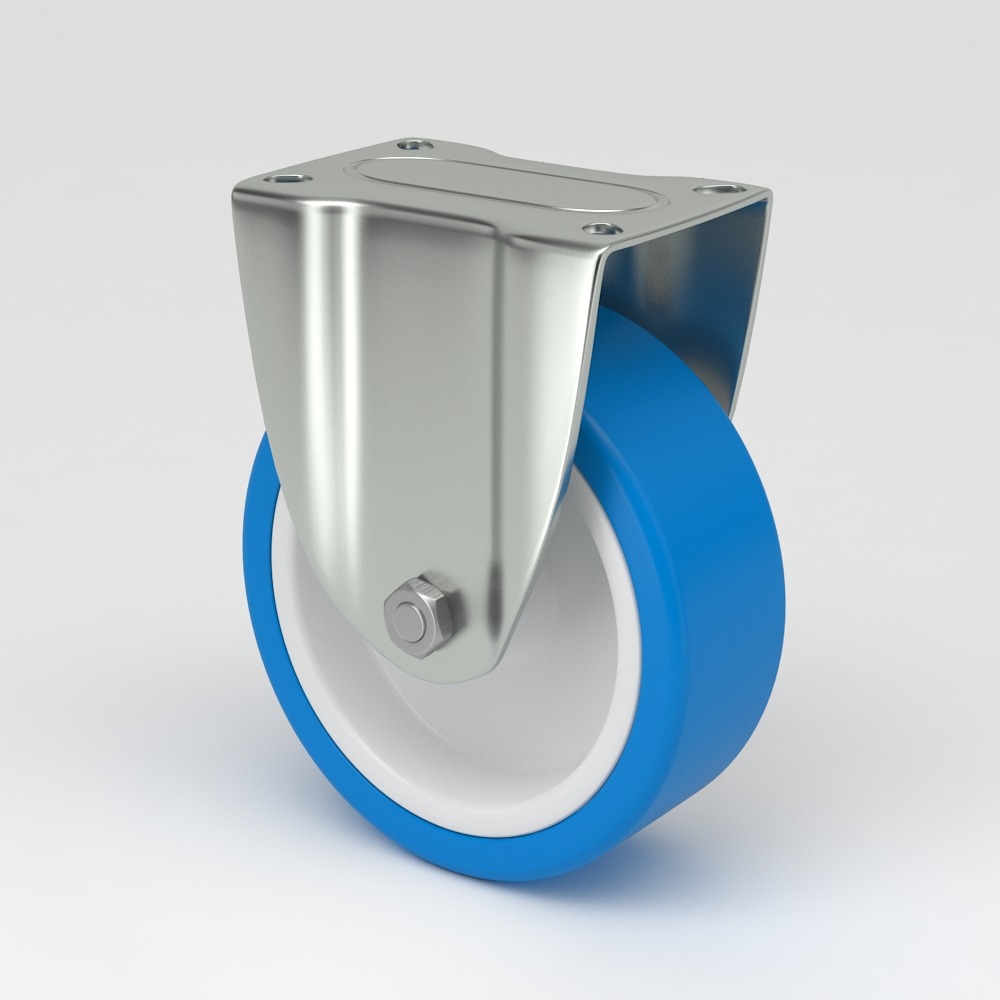

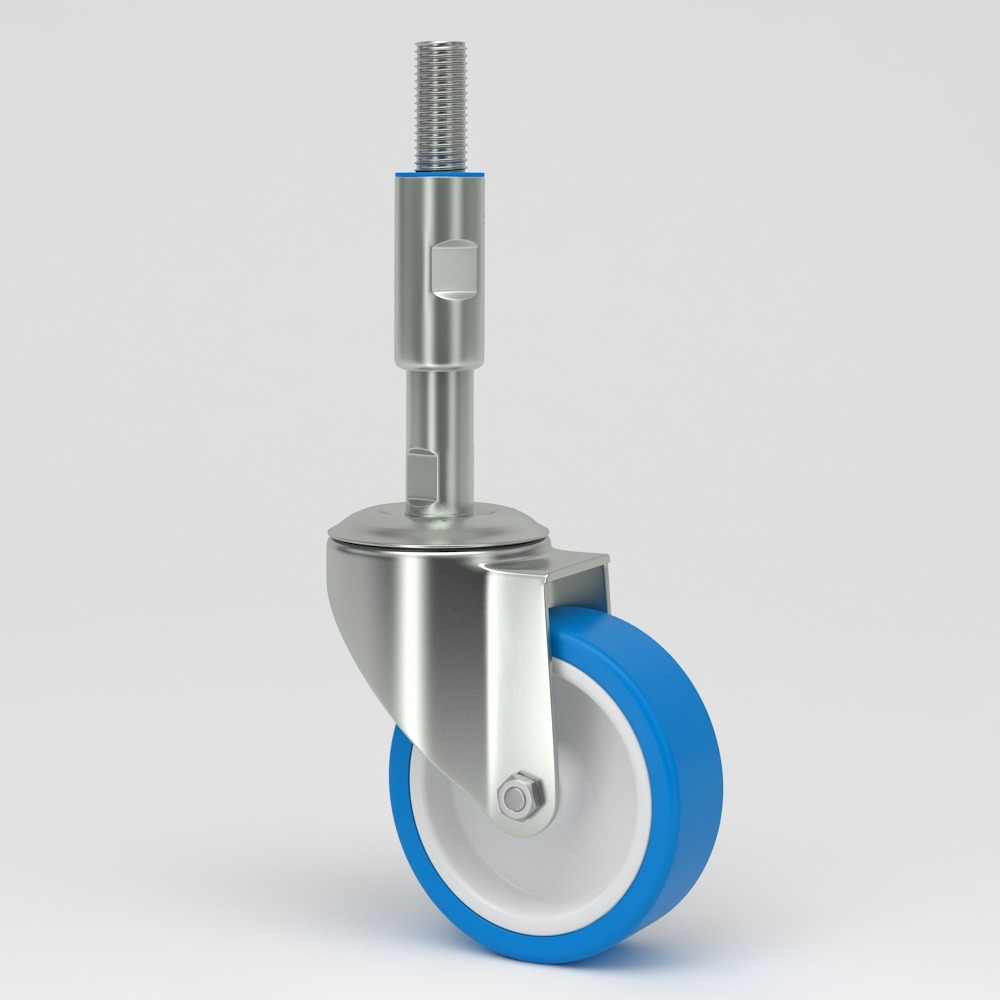

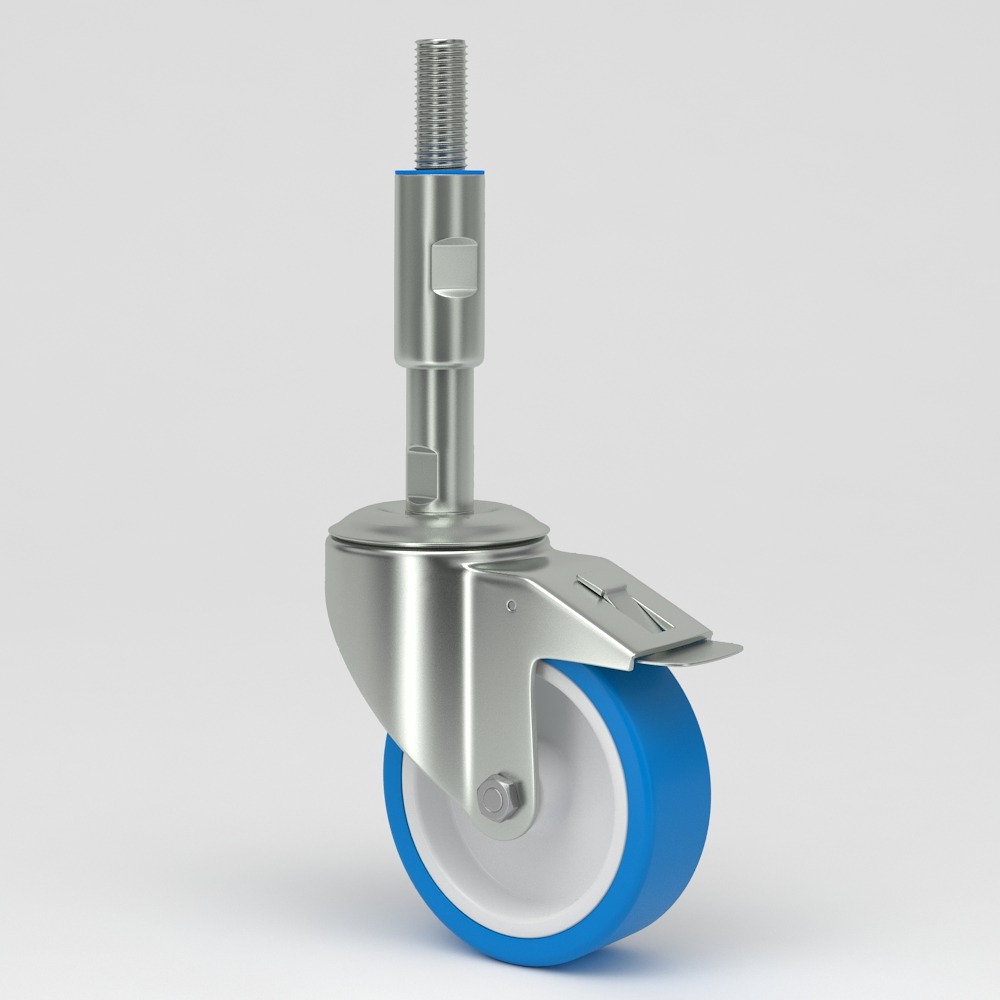

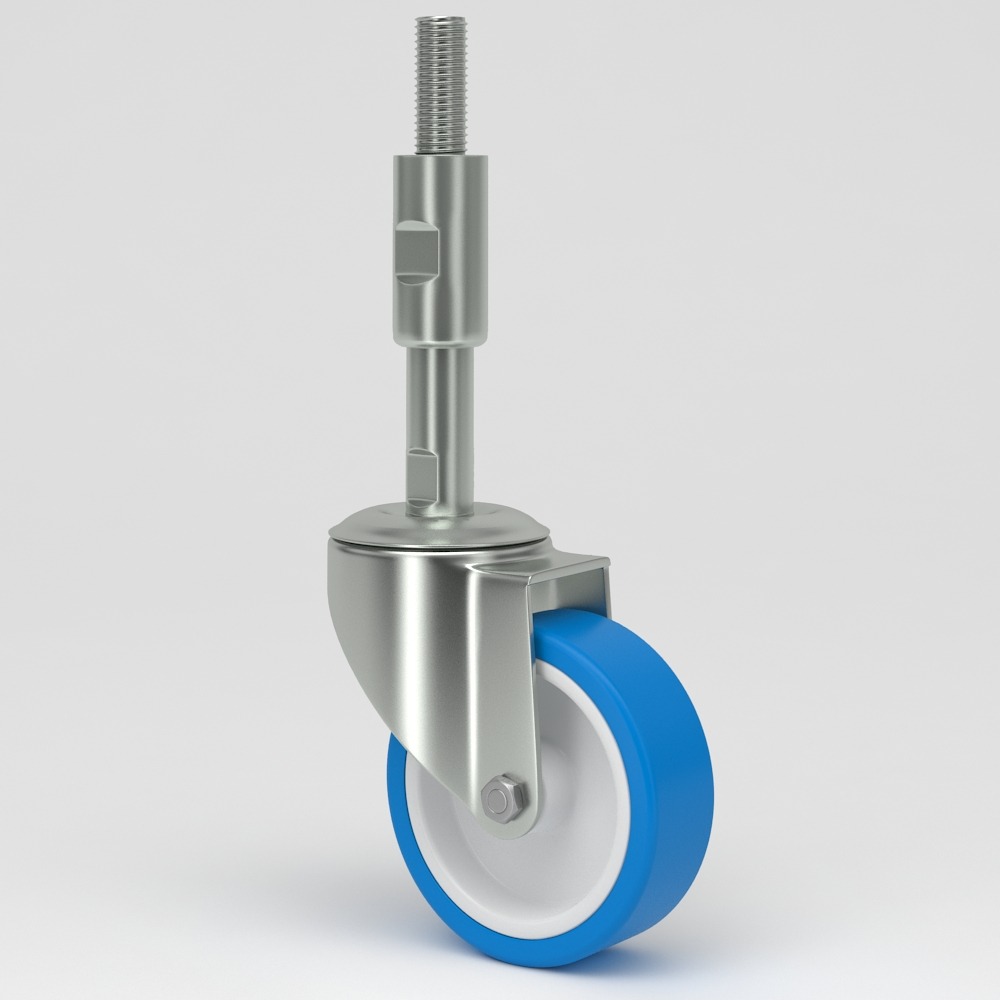

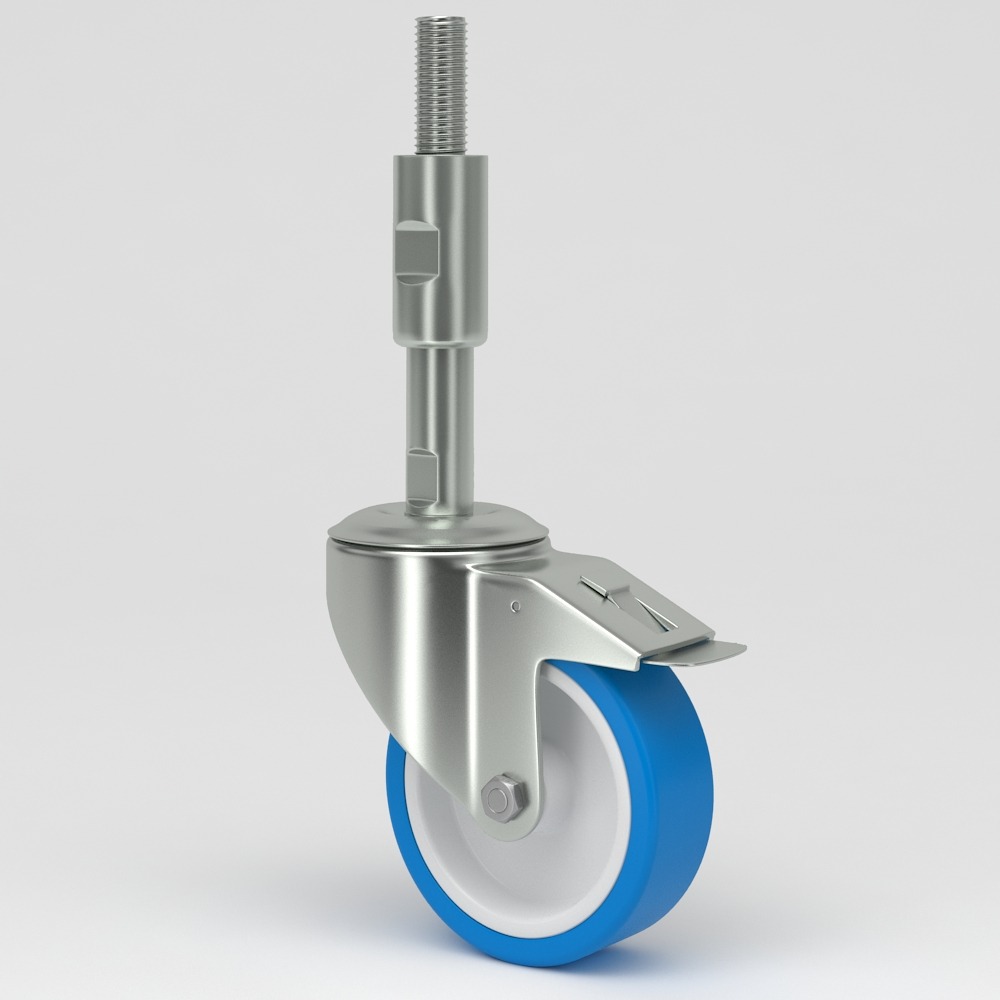

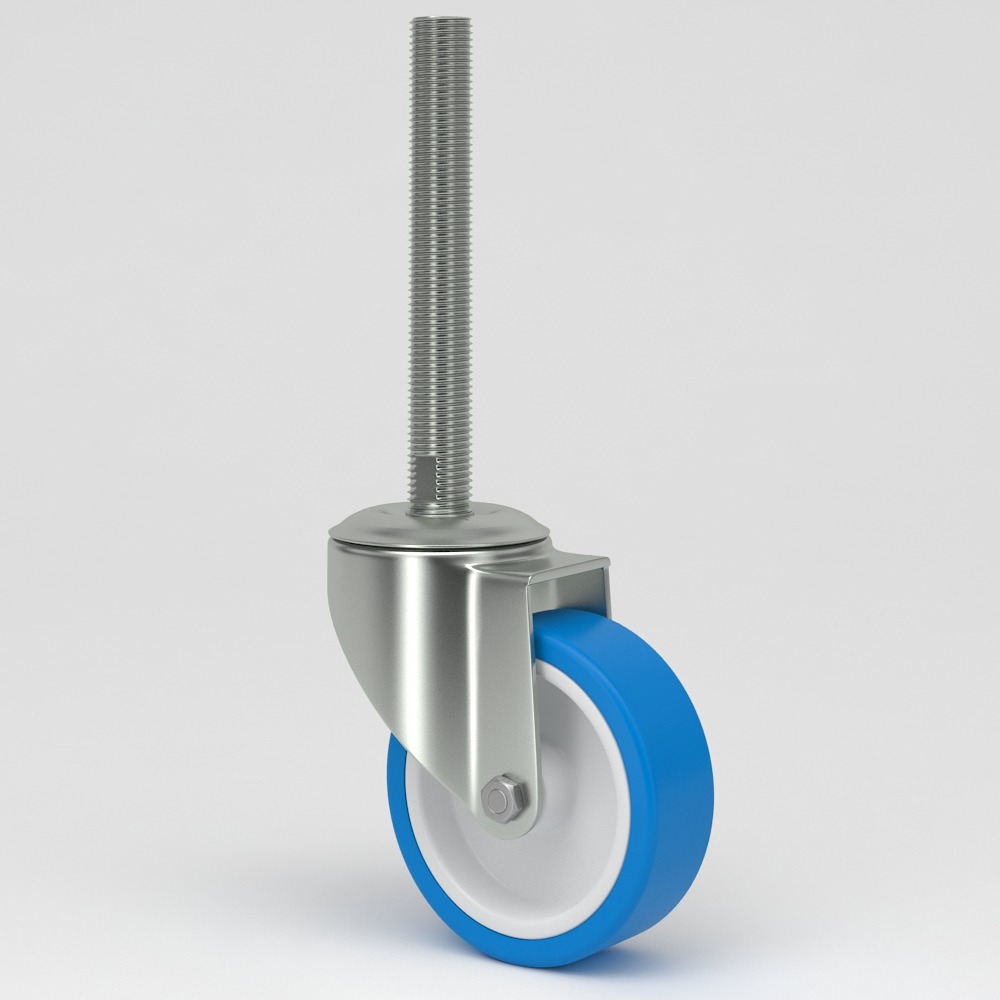

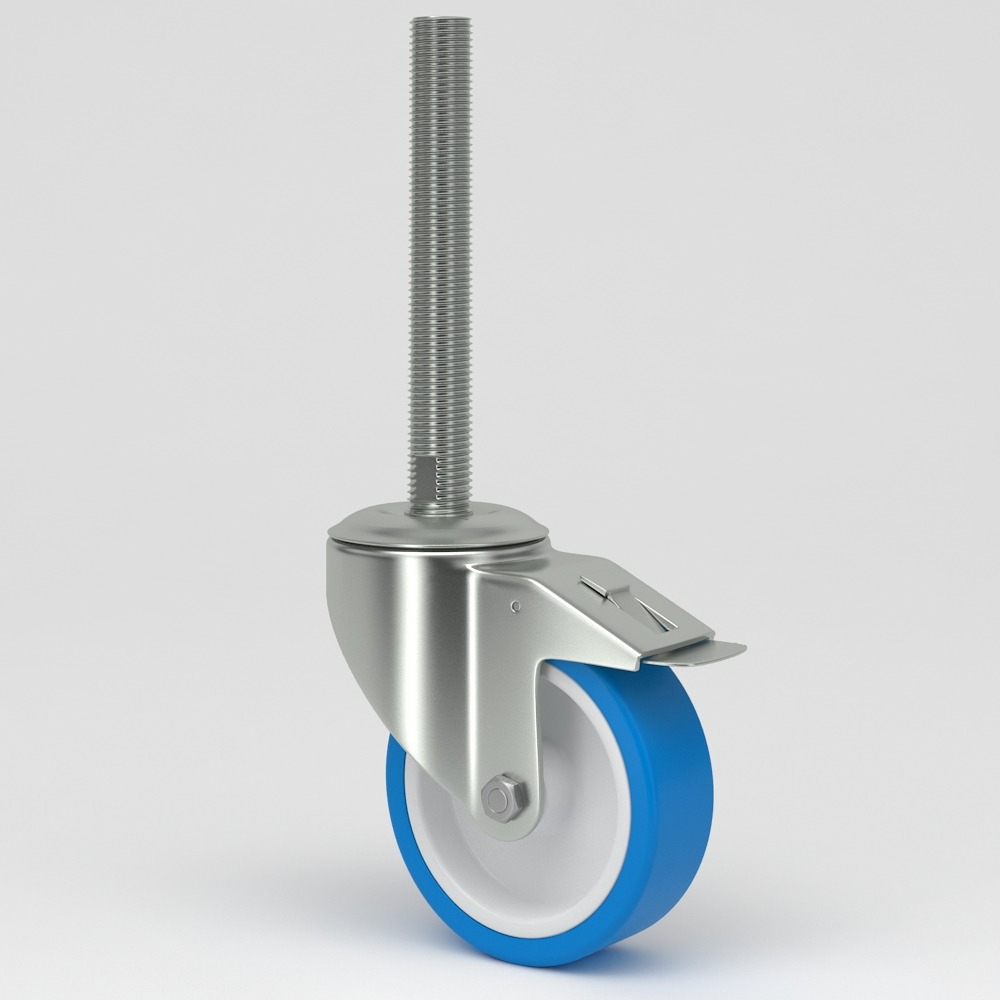

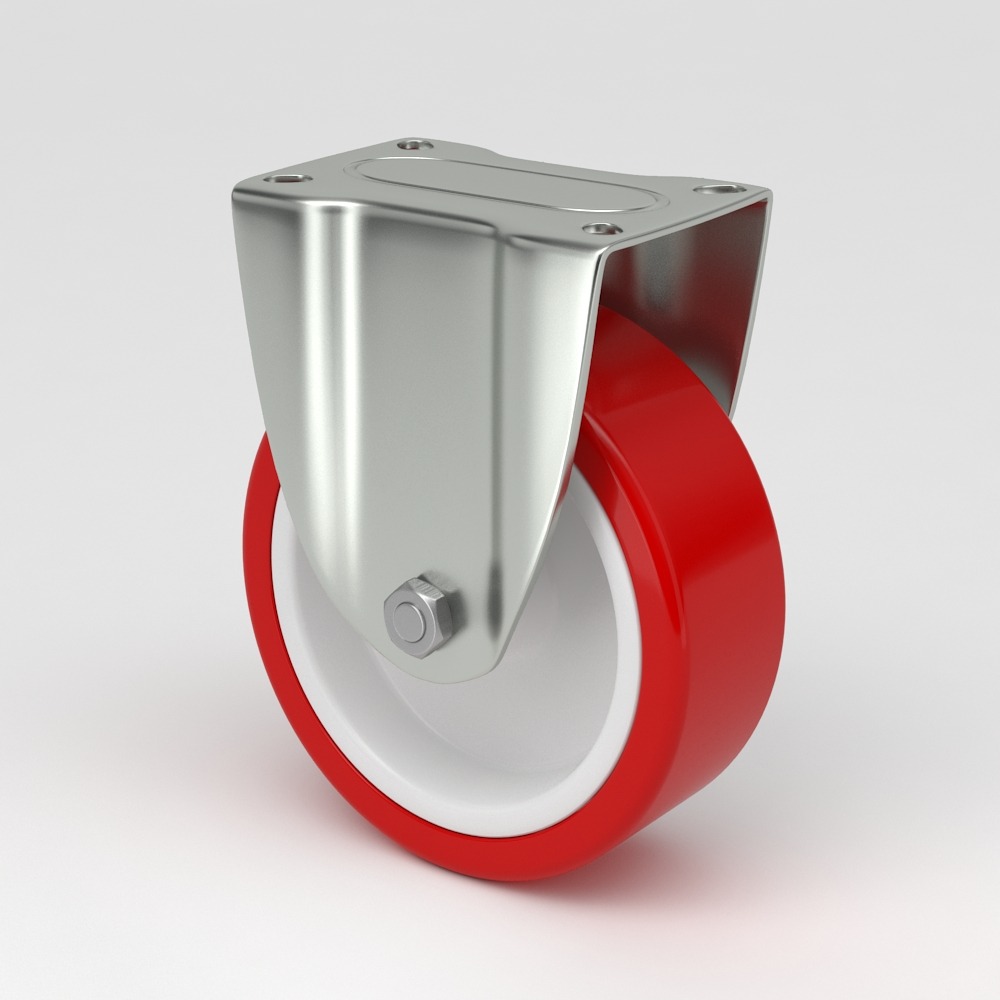

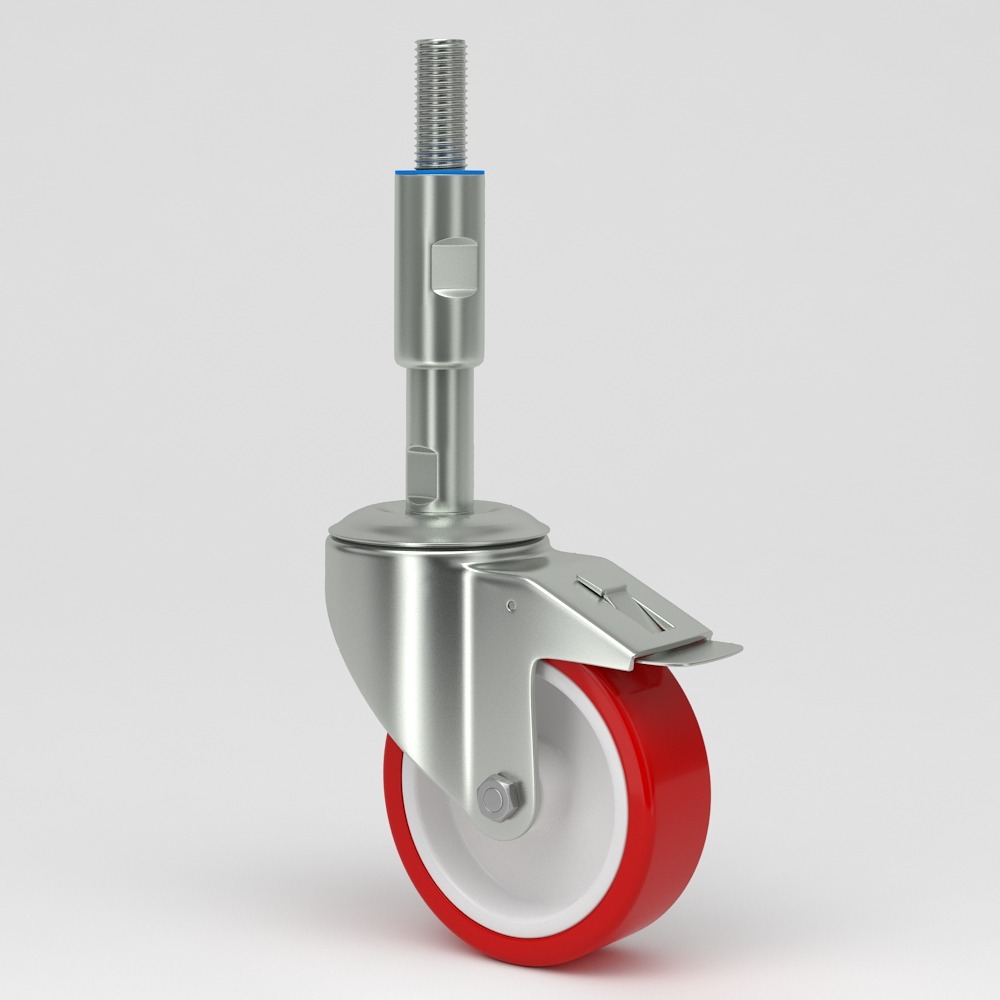

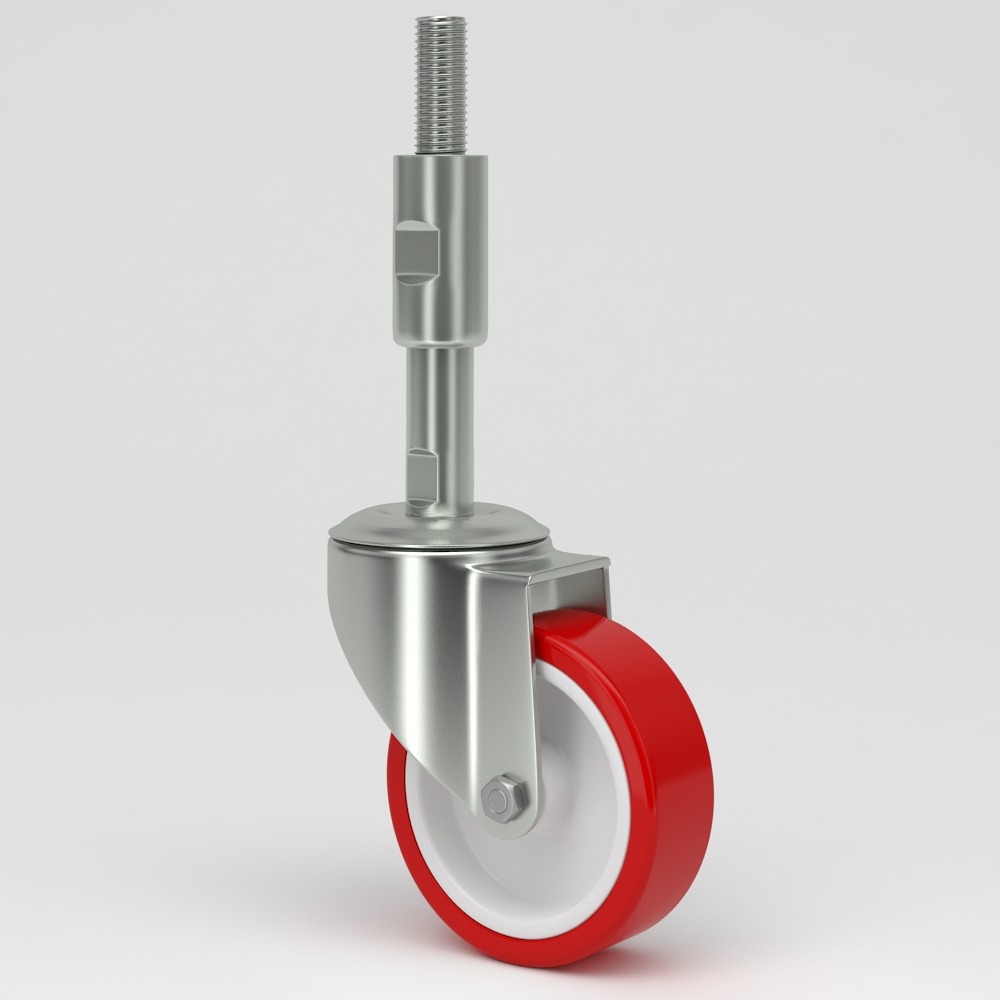

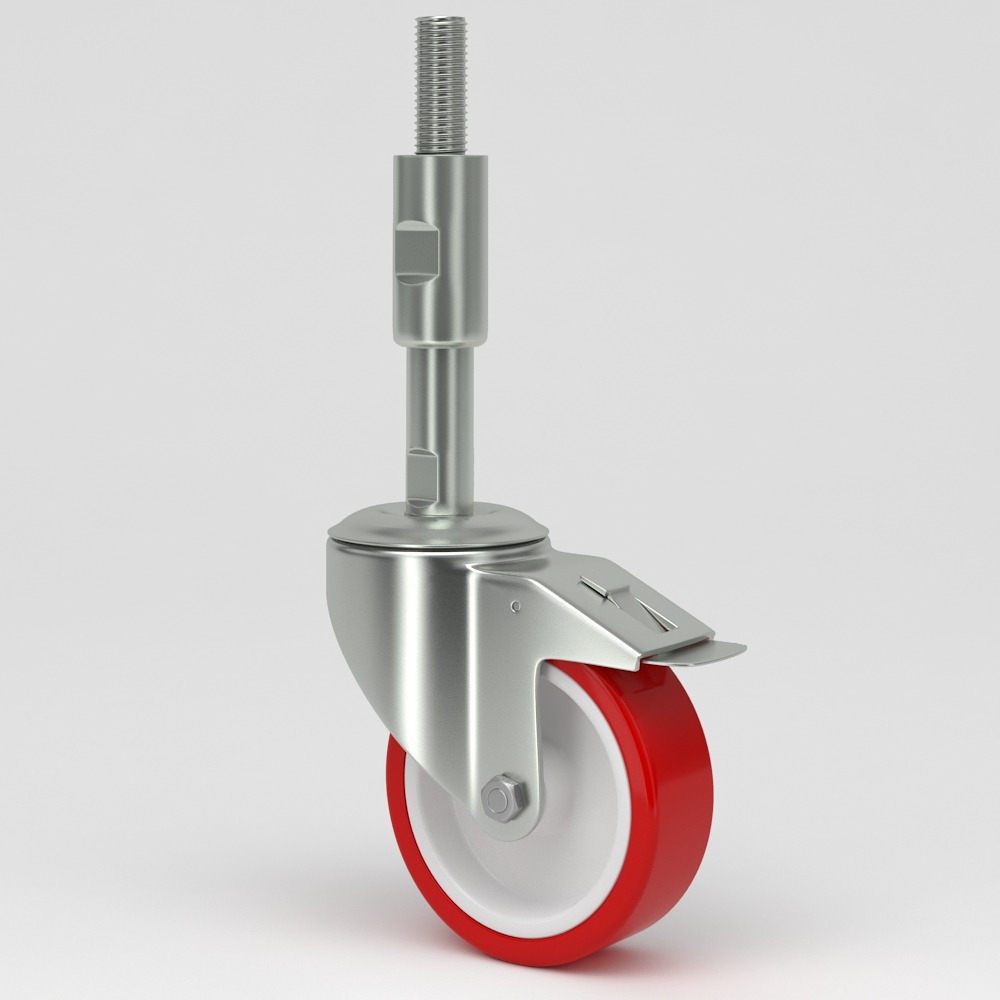

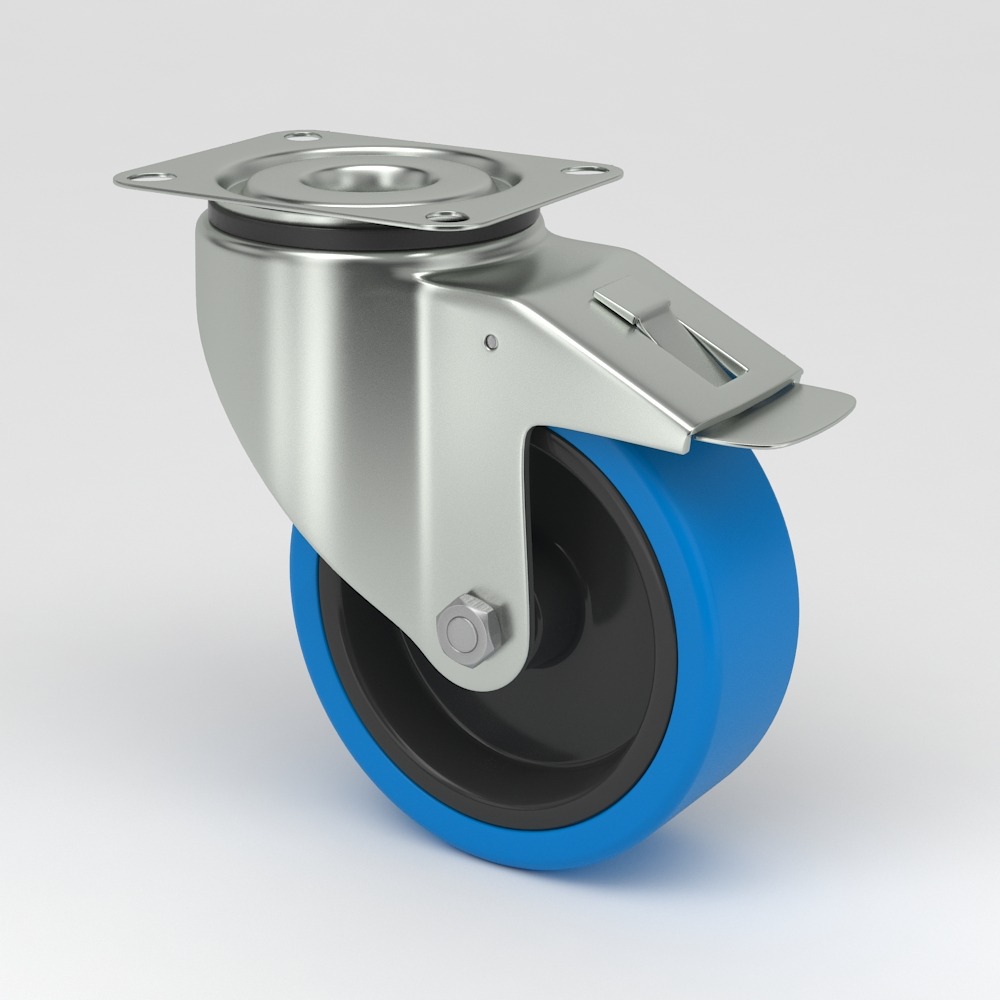

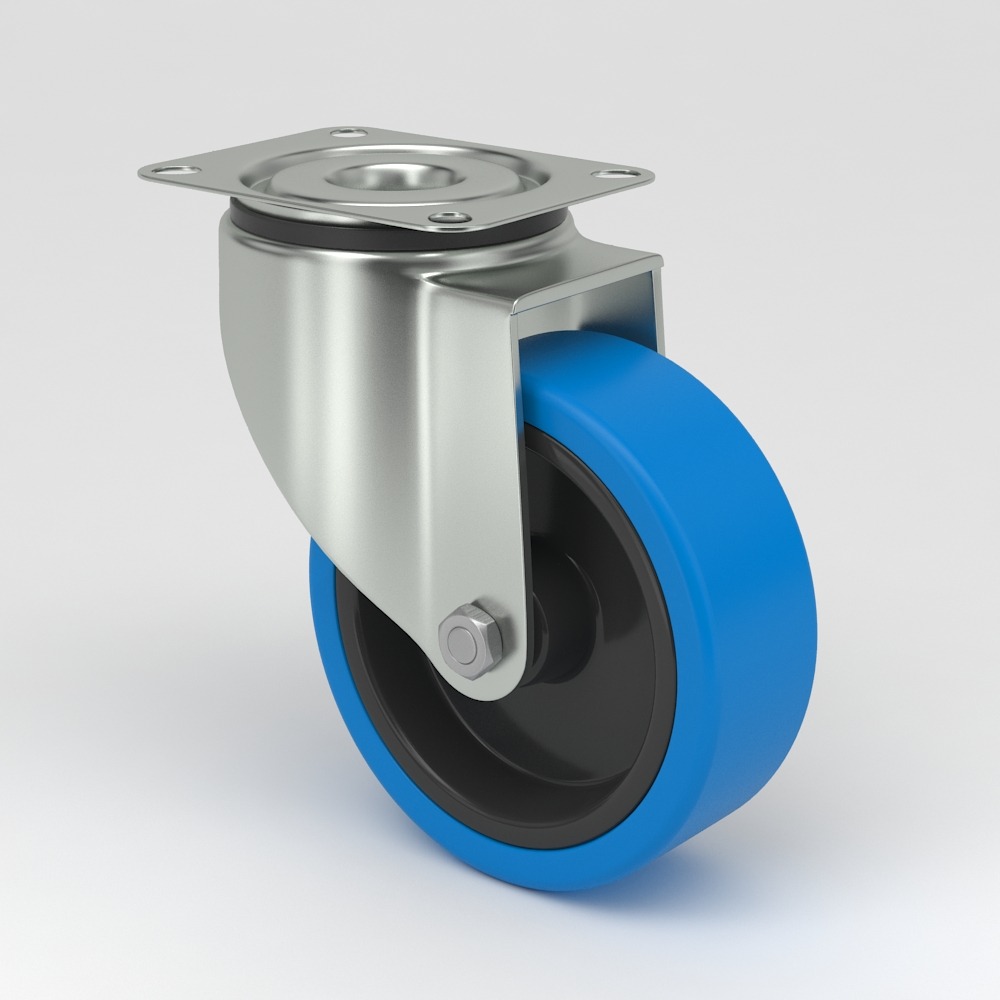

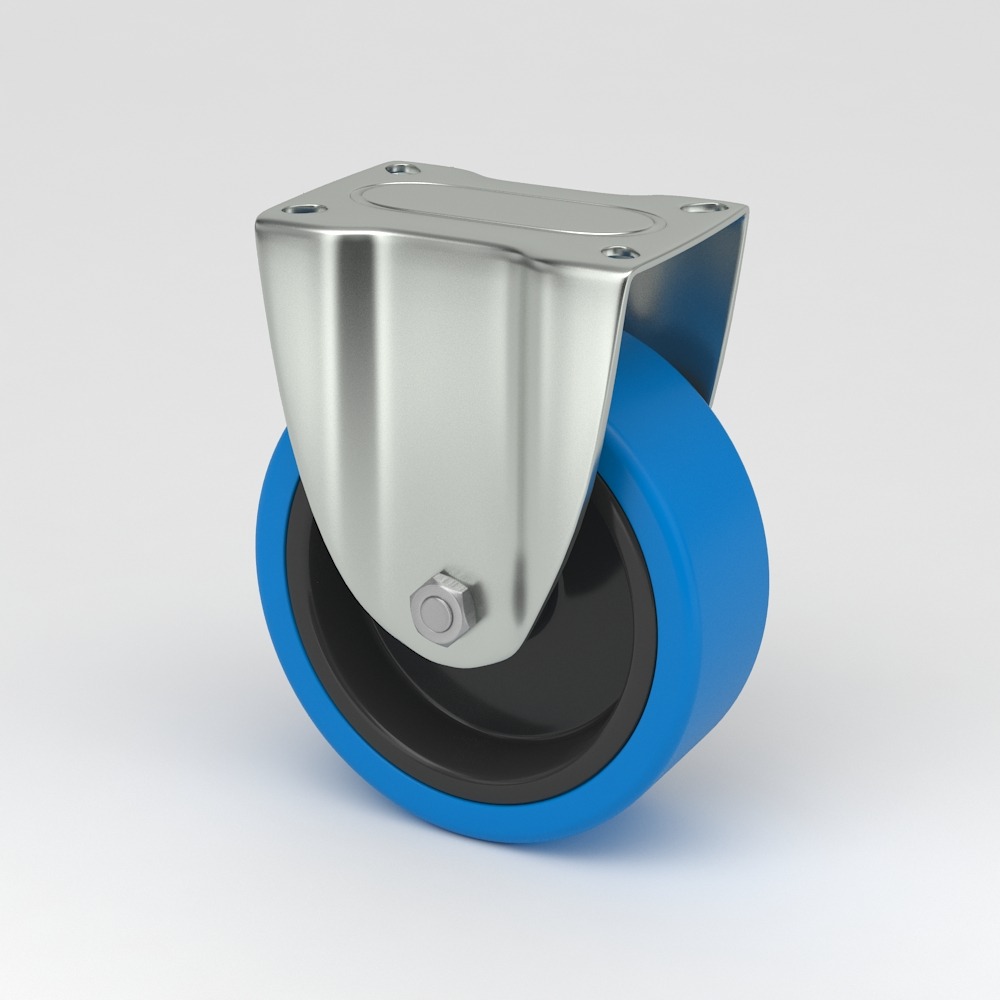

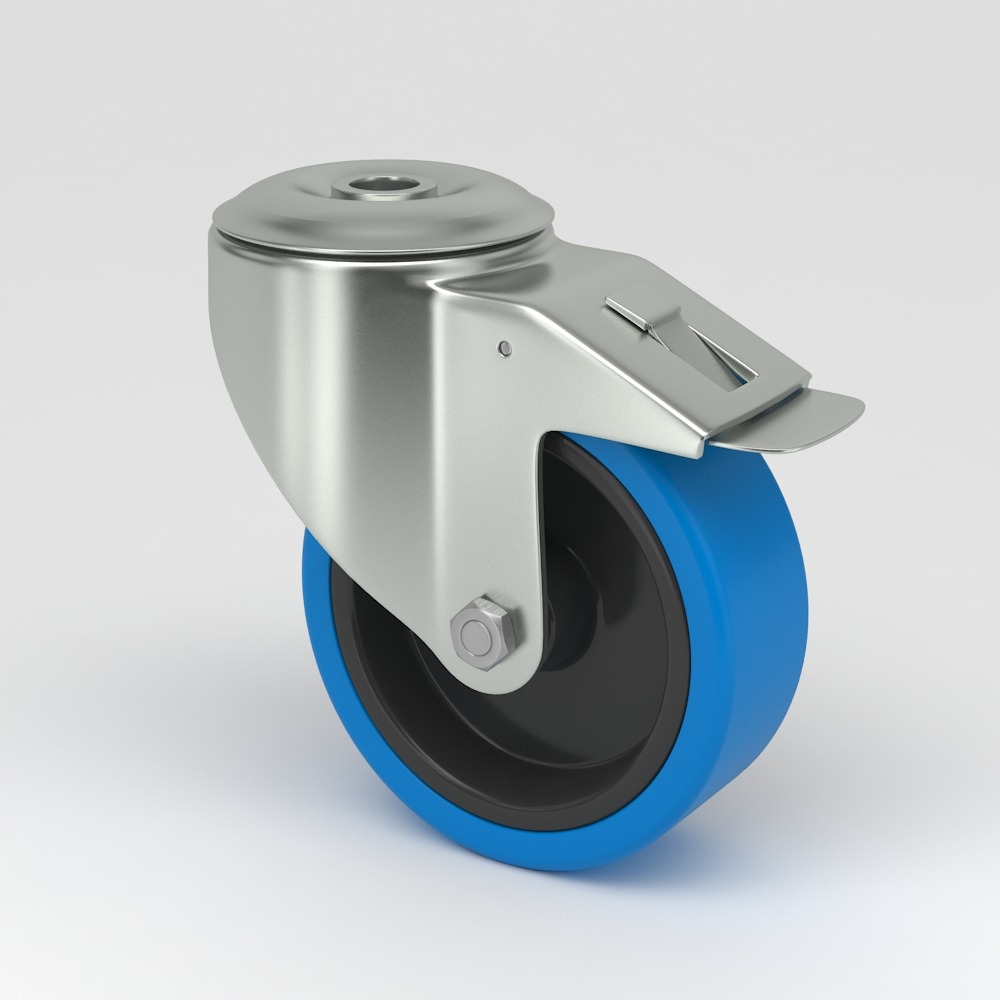

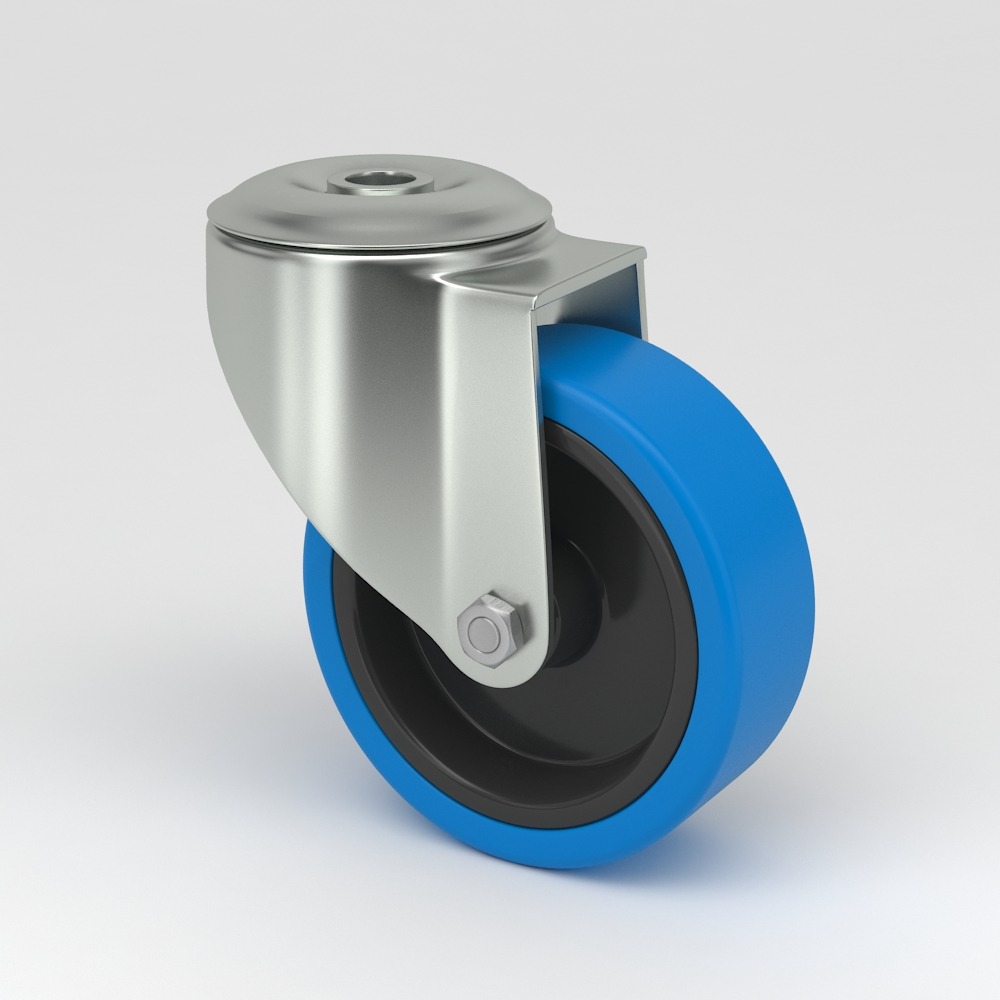

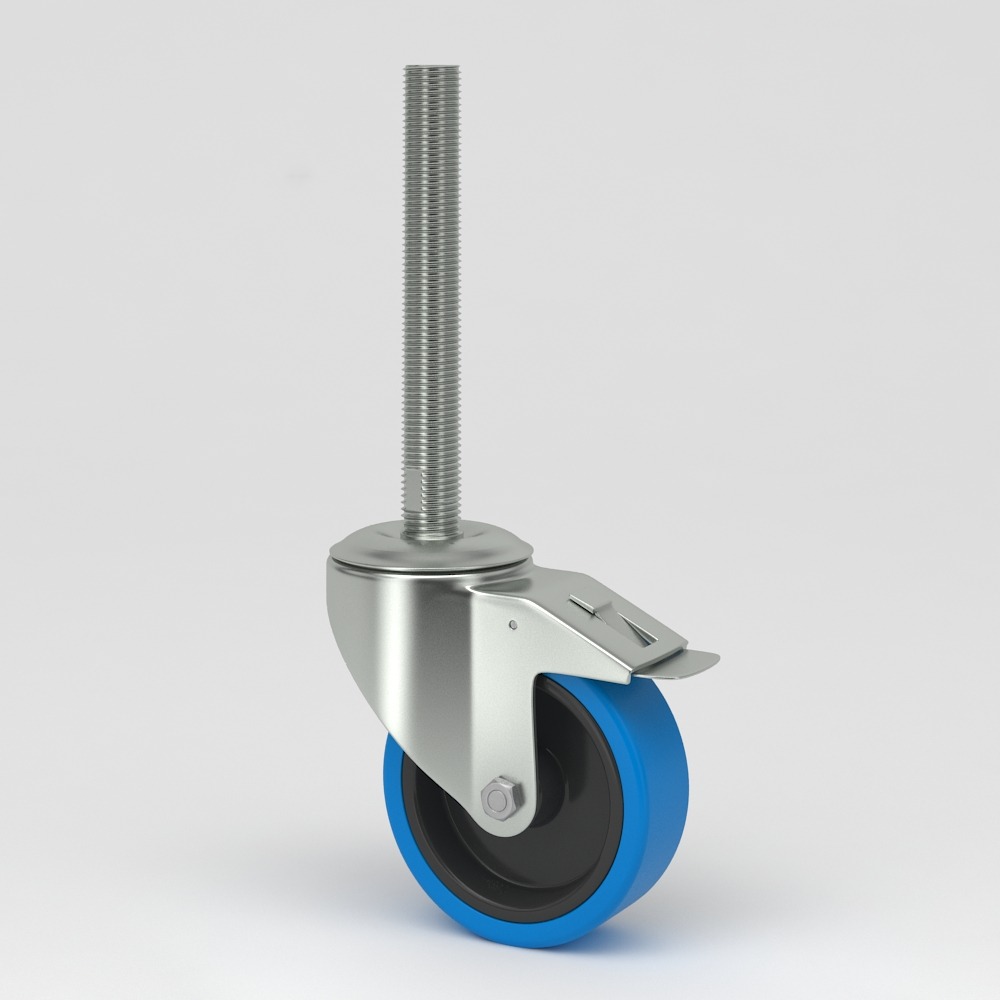

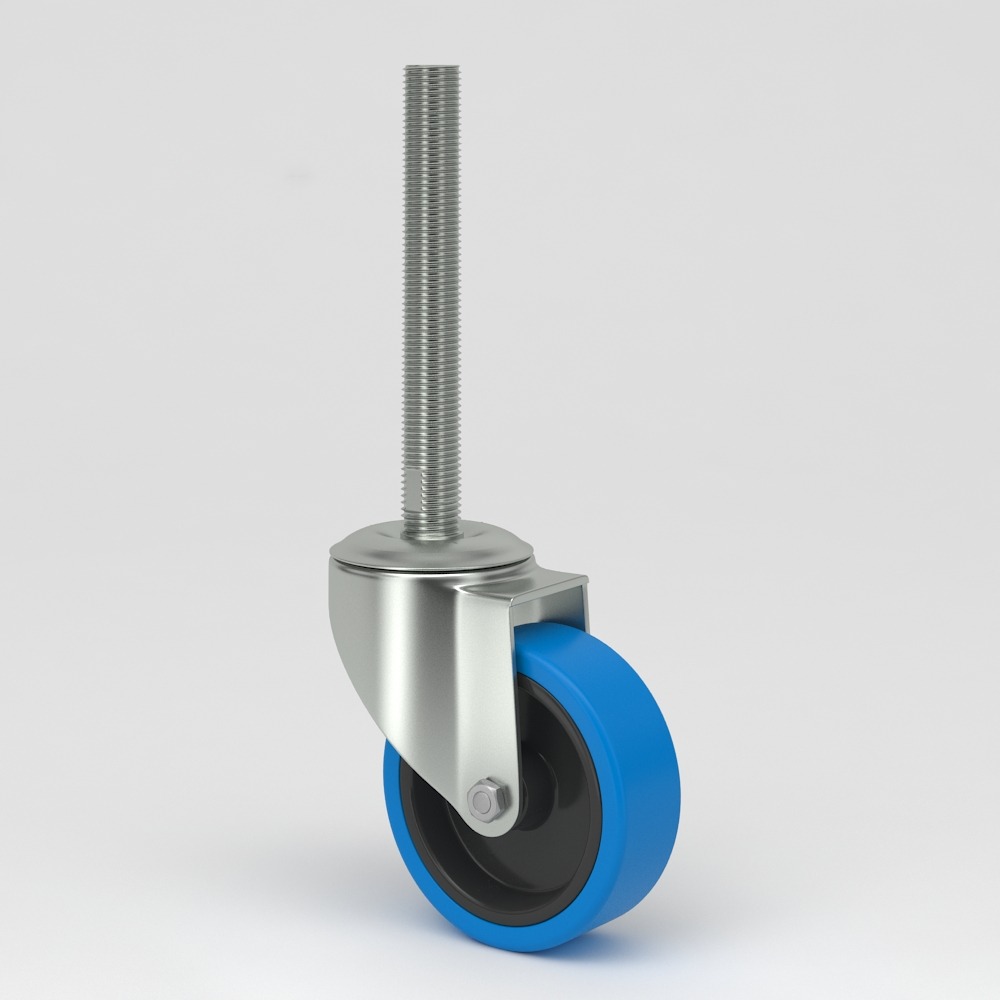

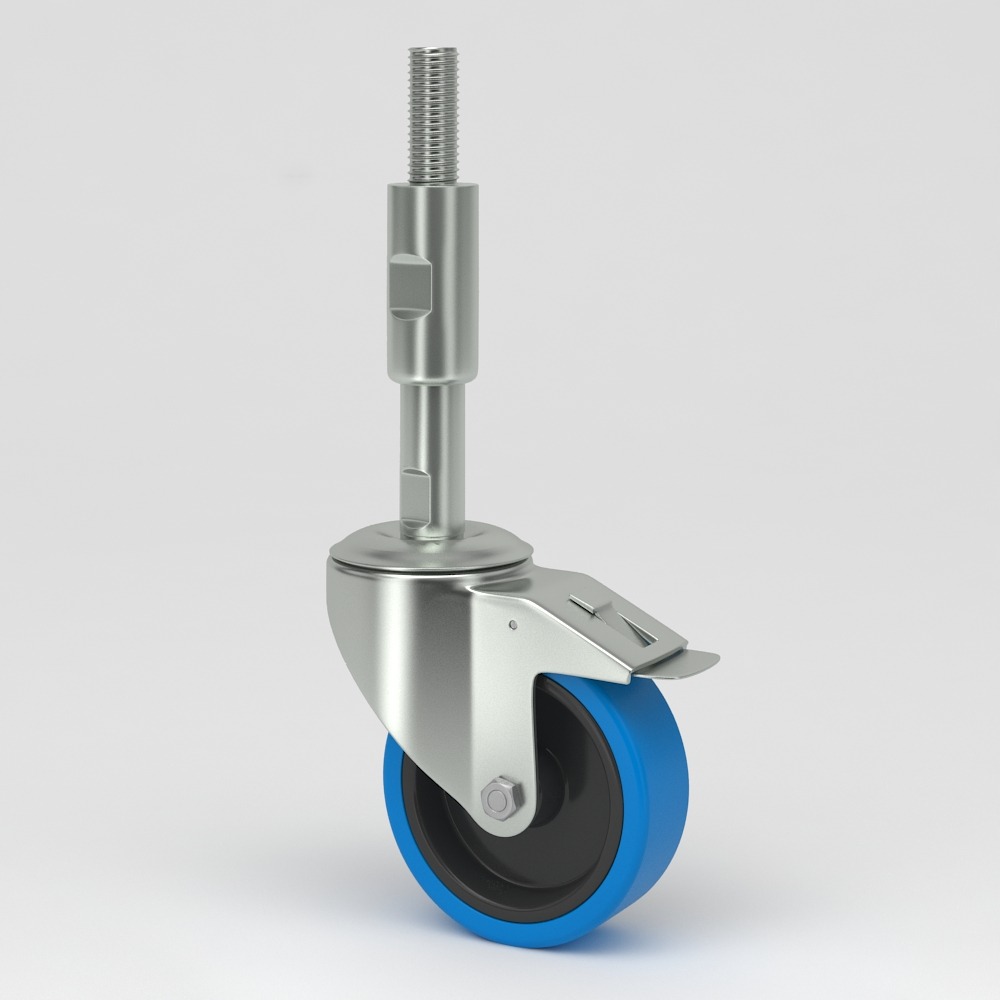

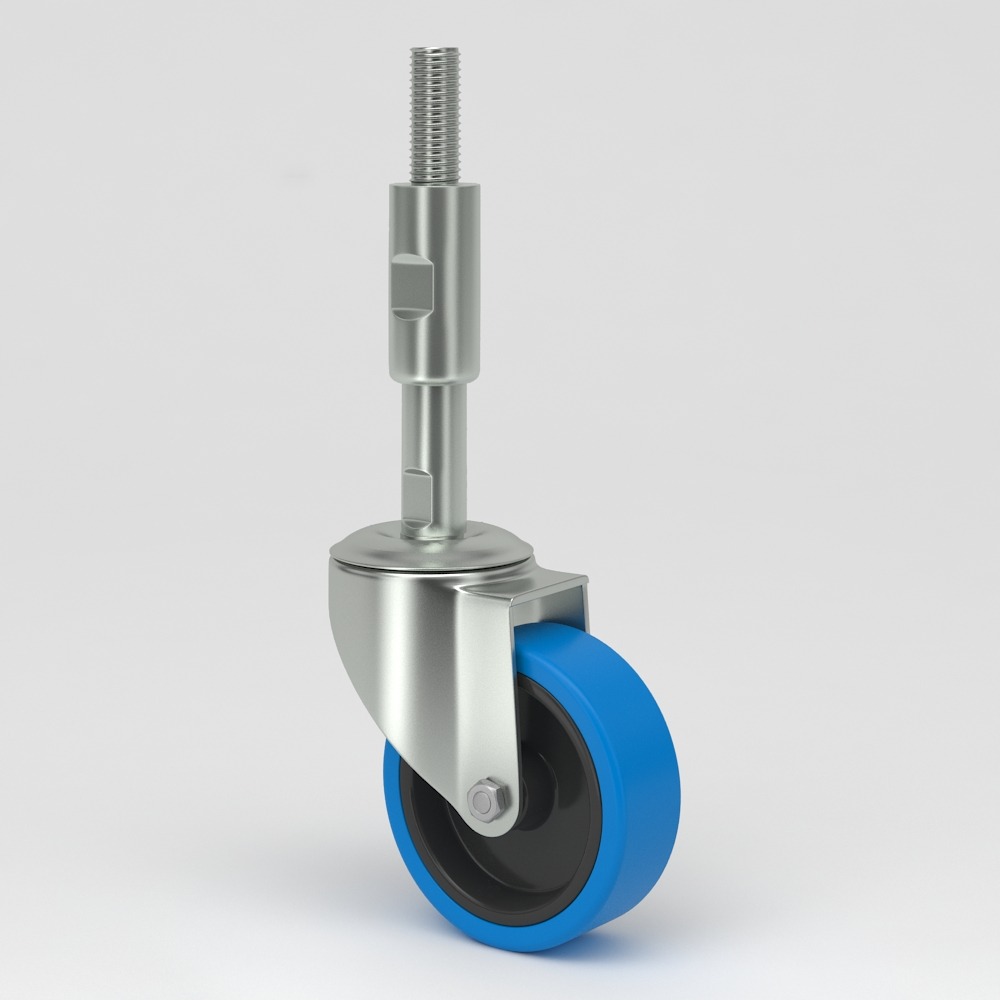

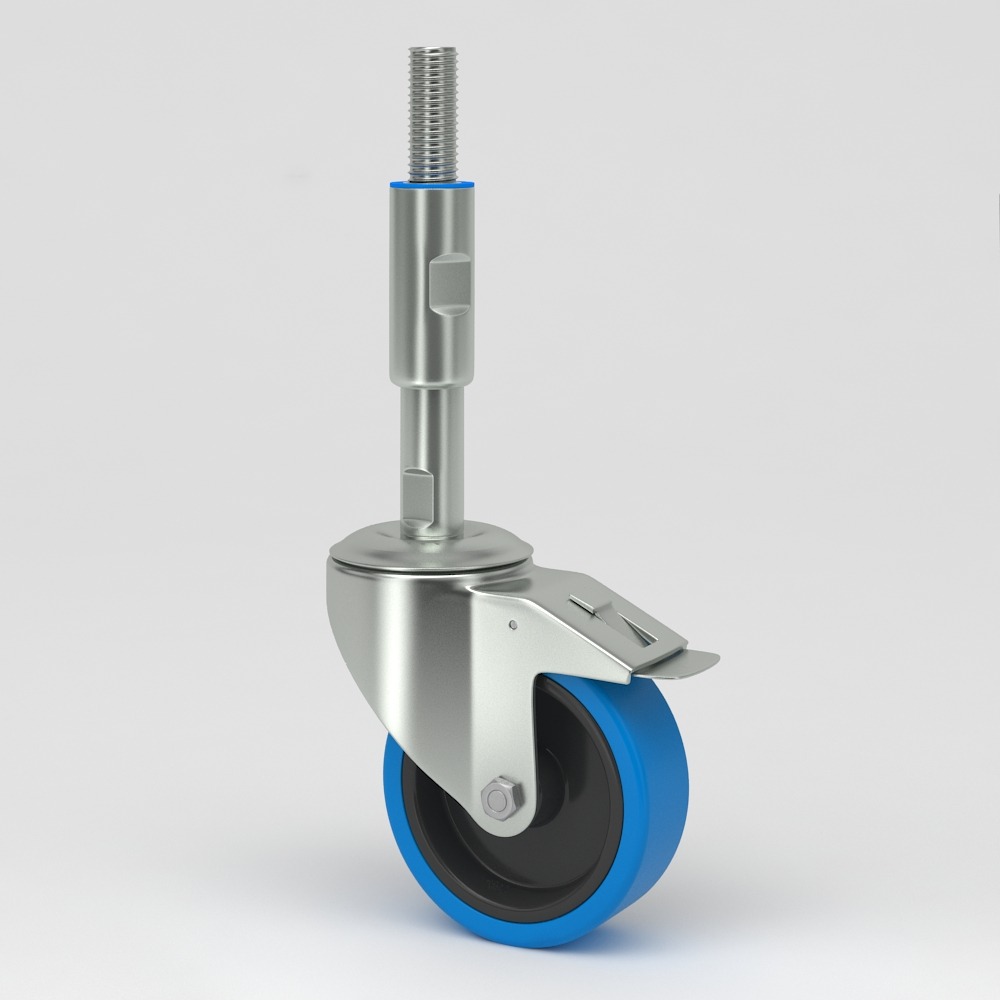

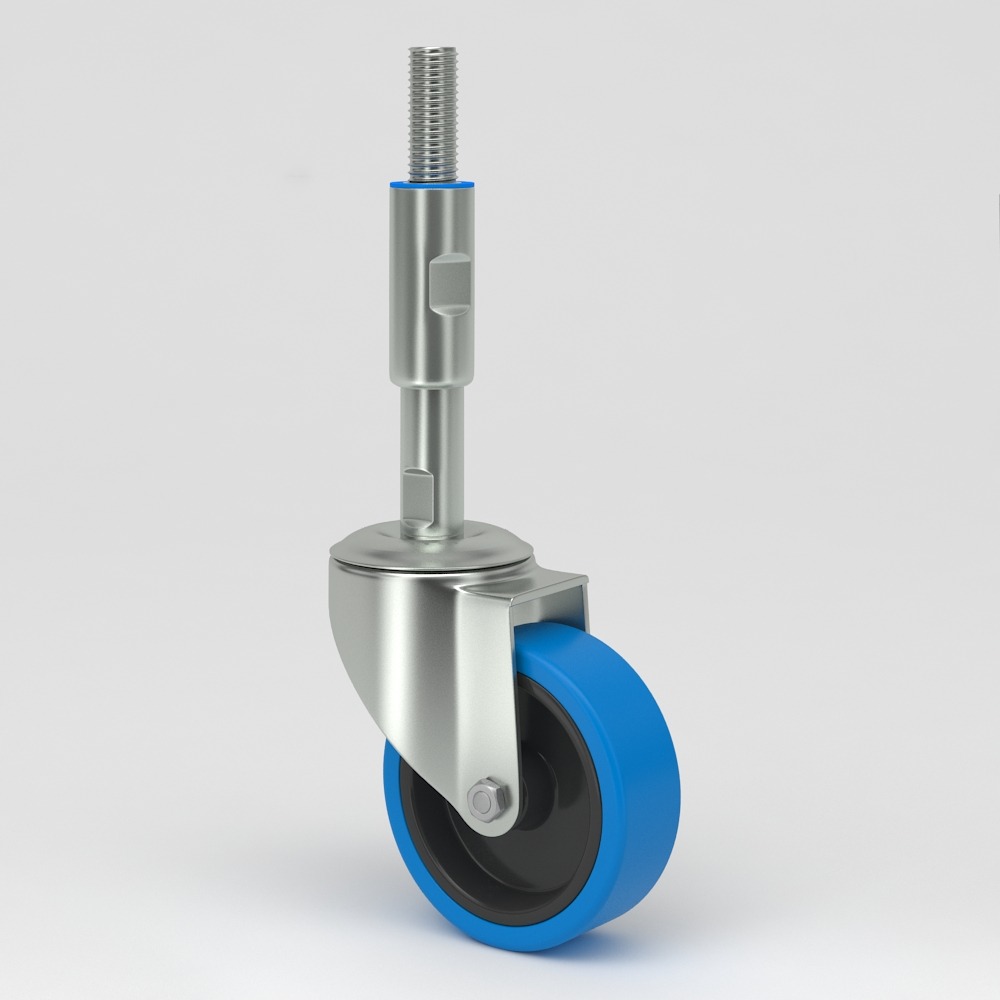

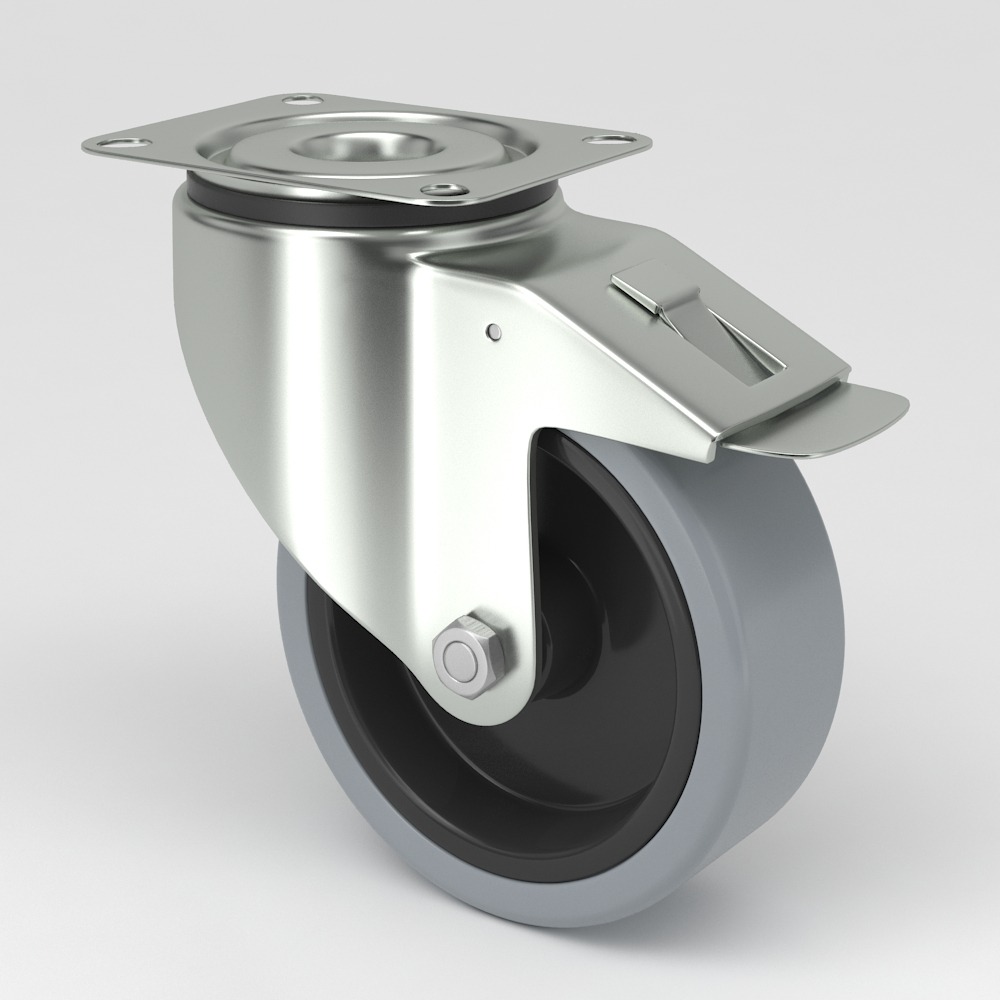

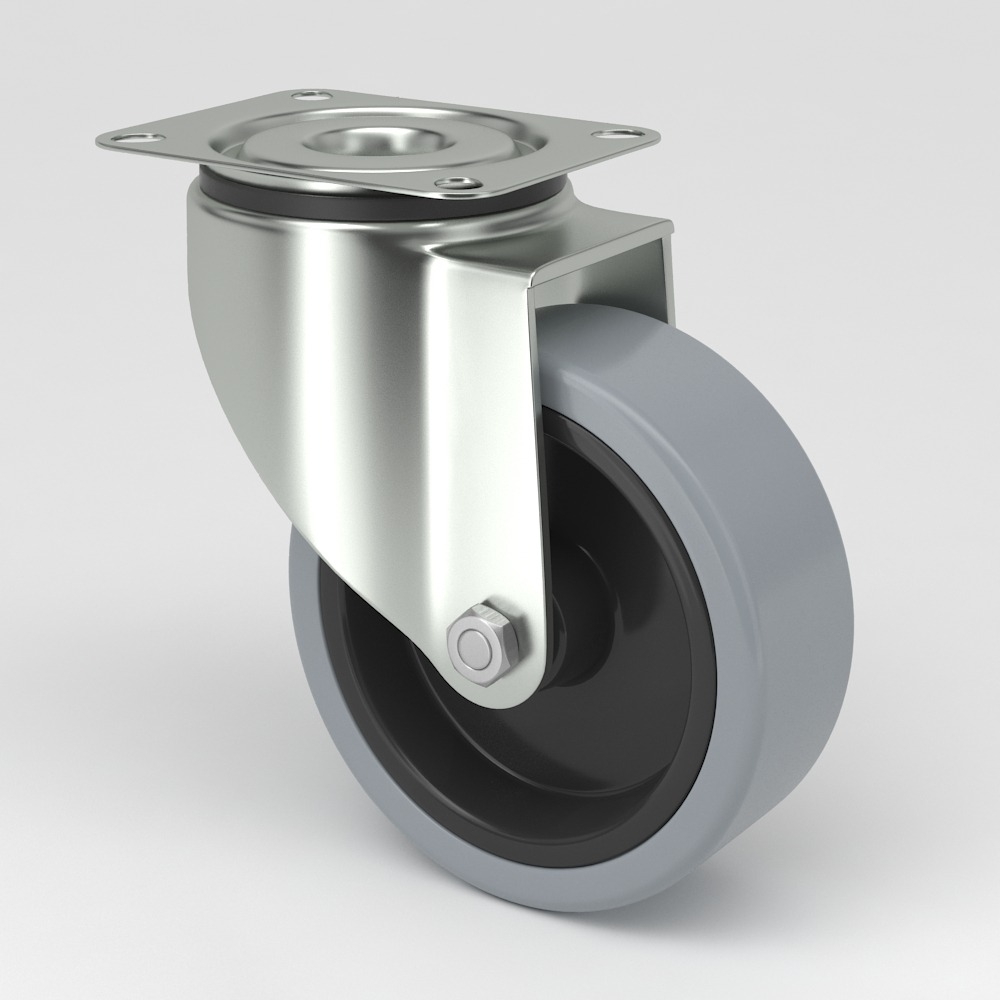

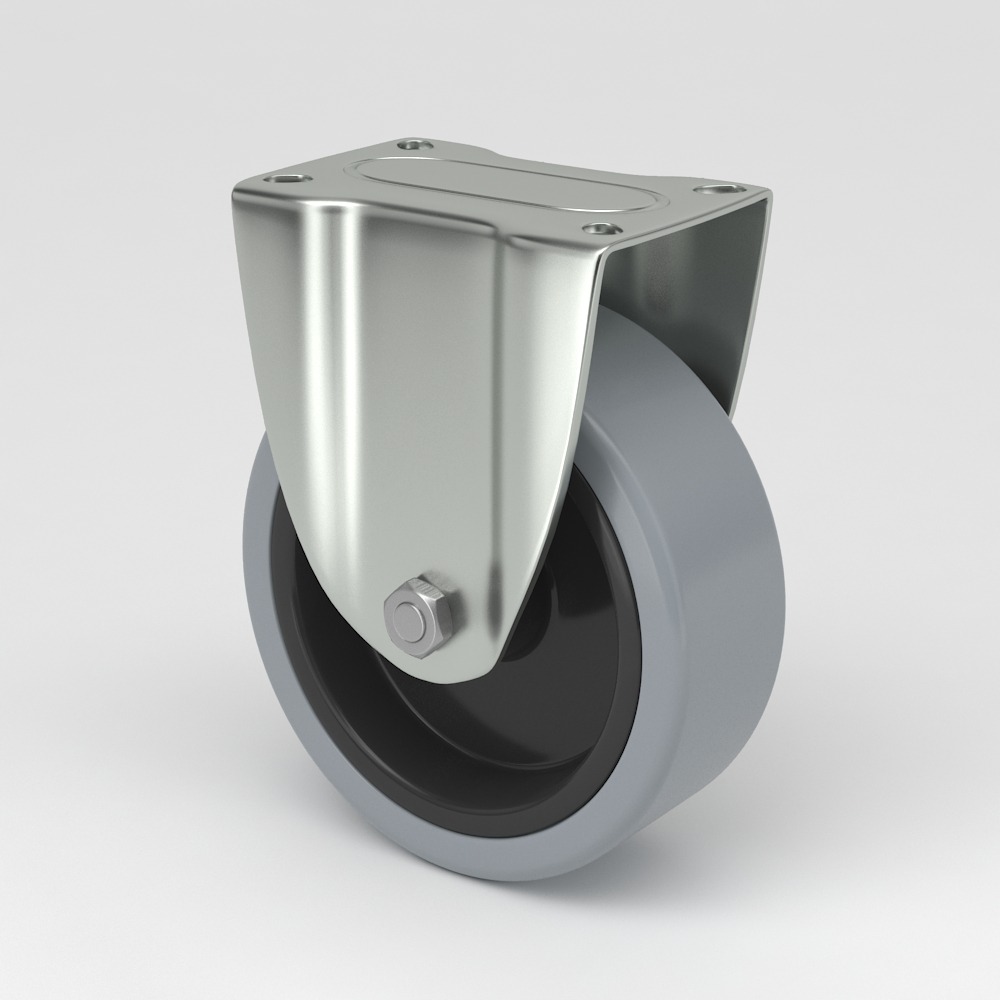

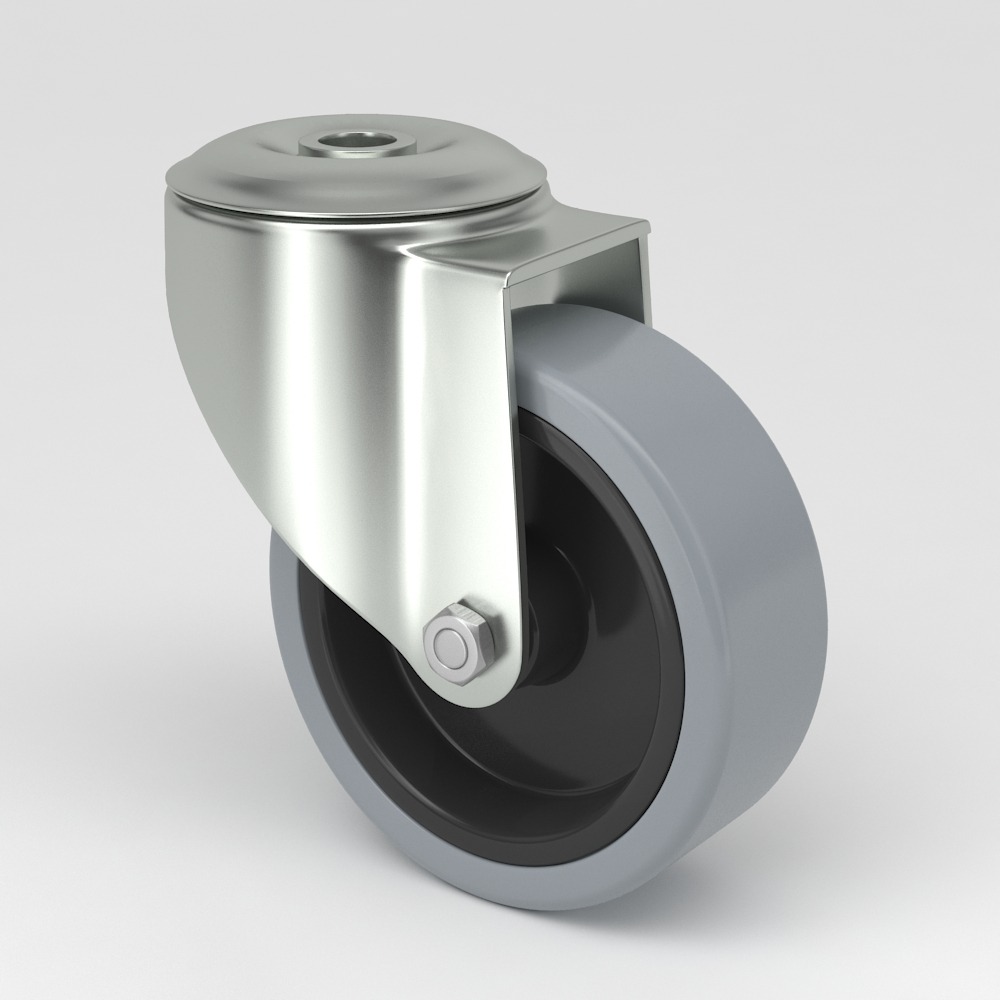

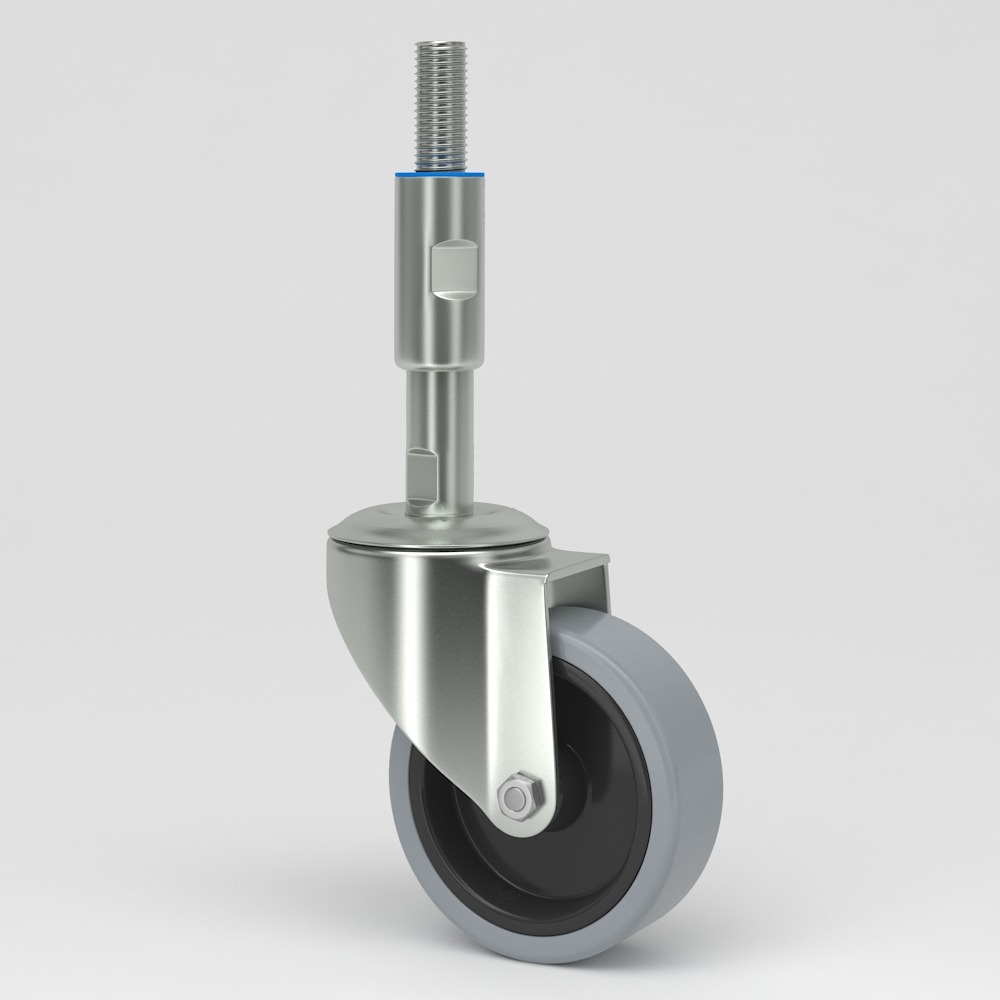

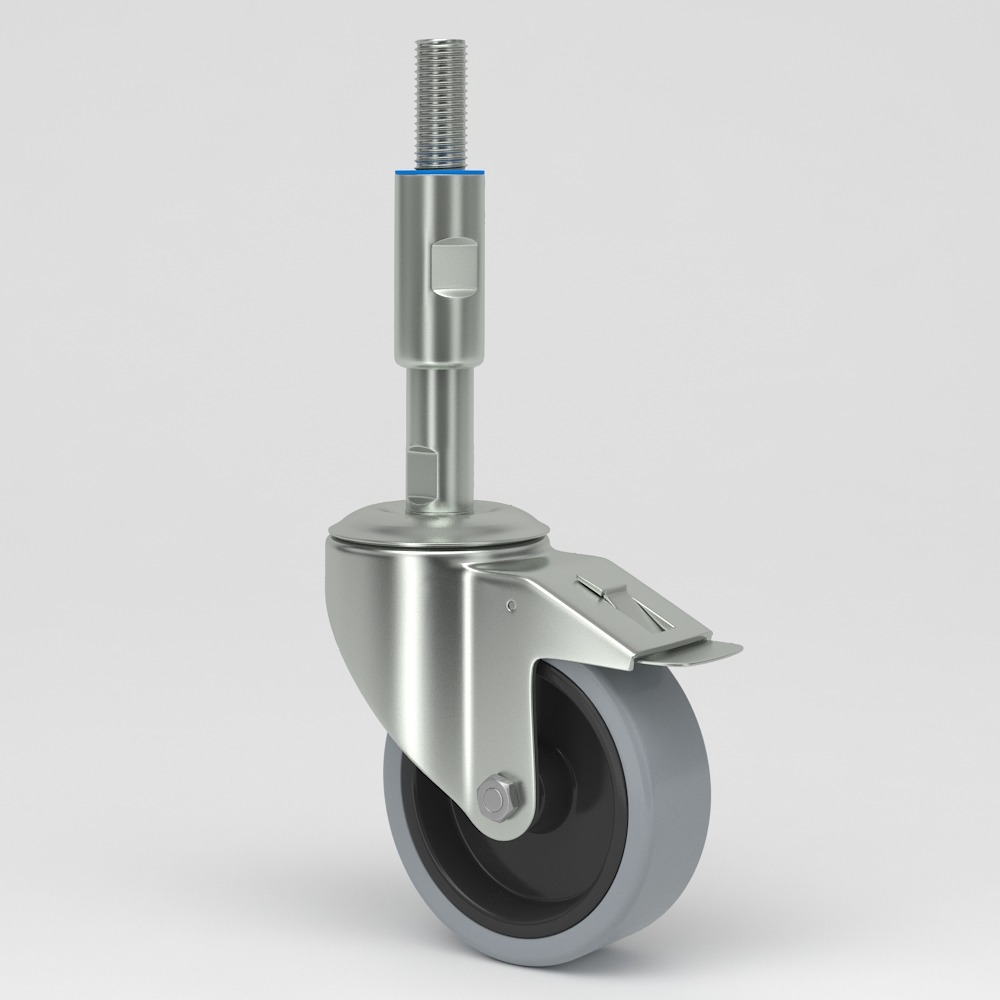

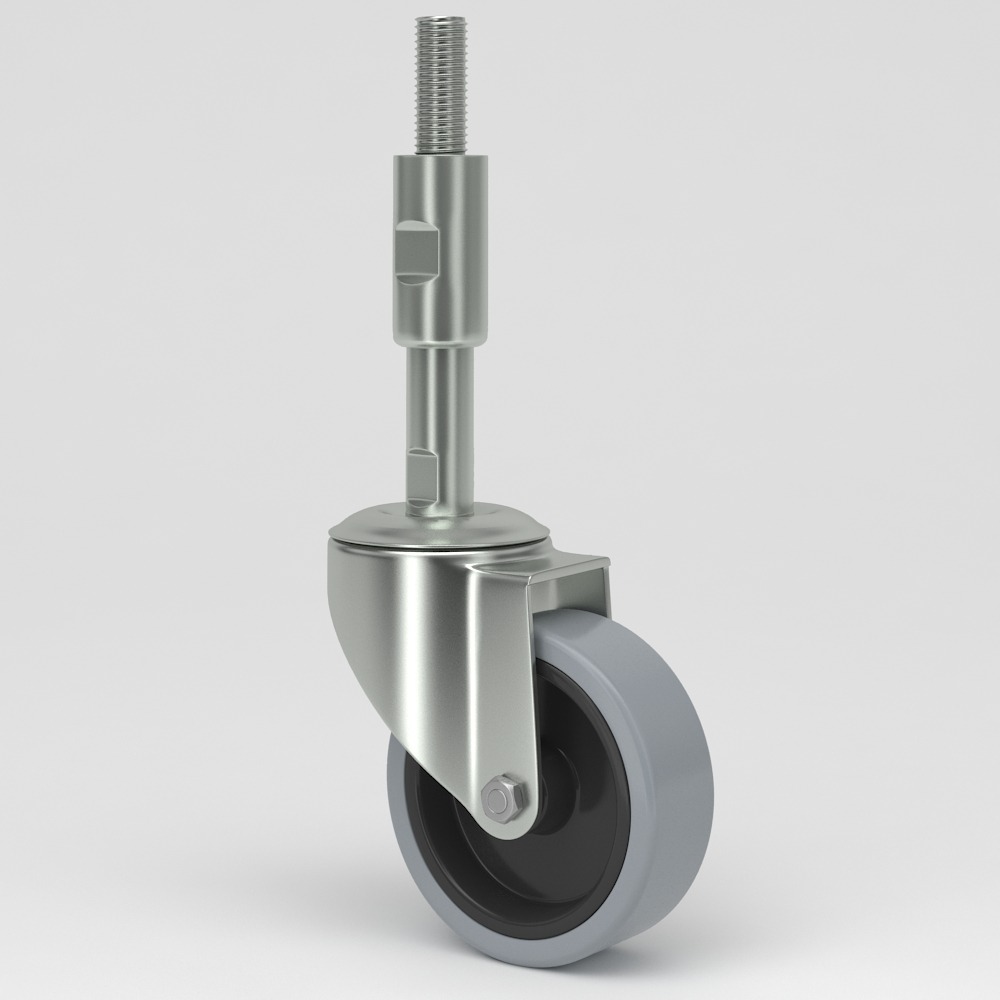

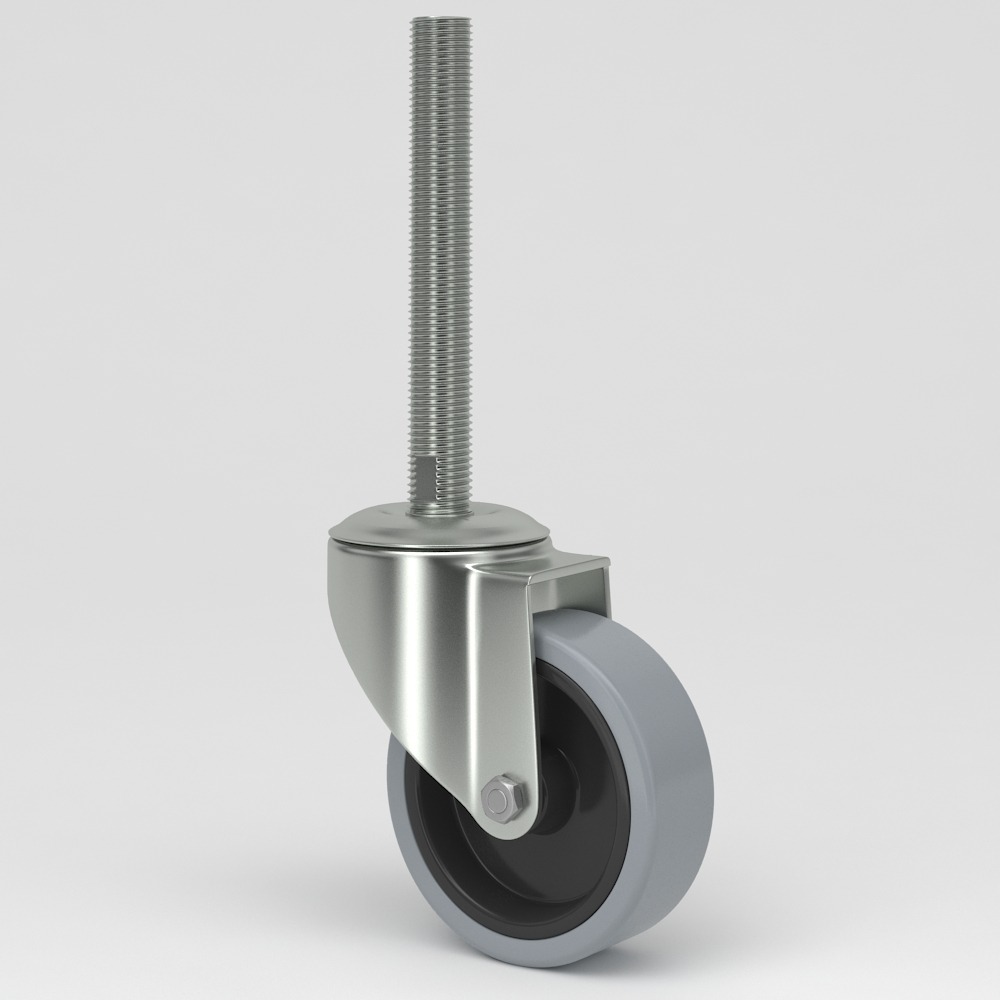

Revolutionizing Industrial Efficiency with Sanitary Industrial Castors

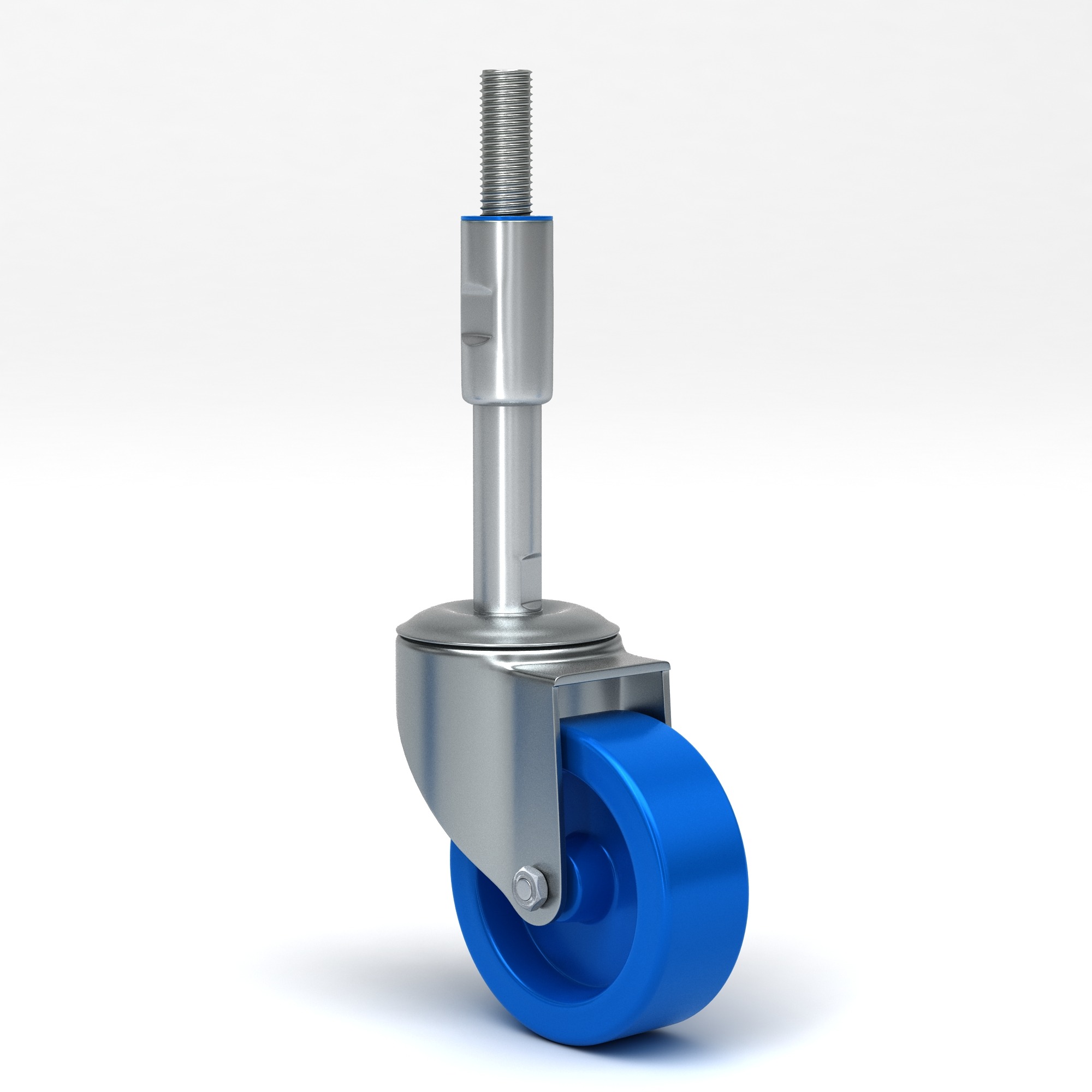

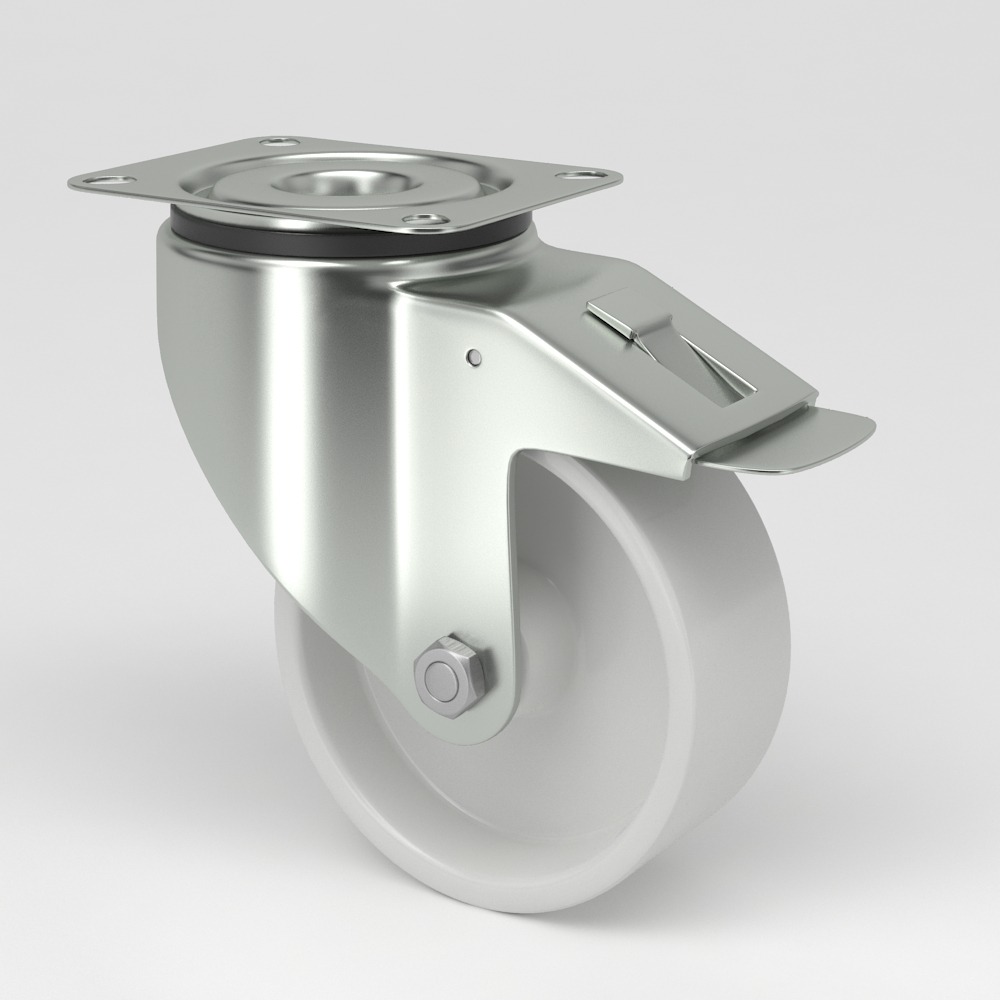

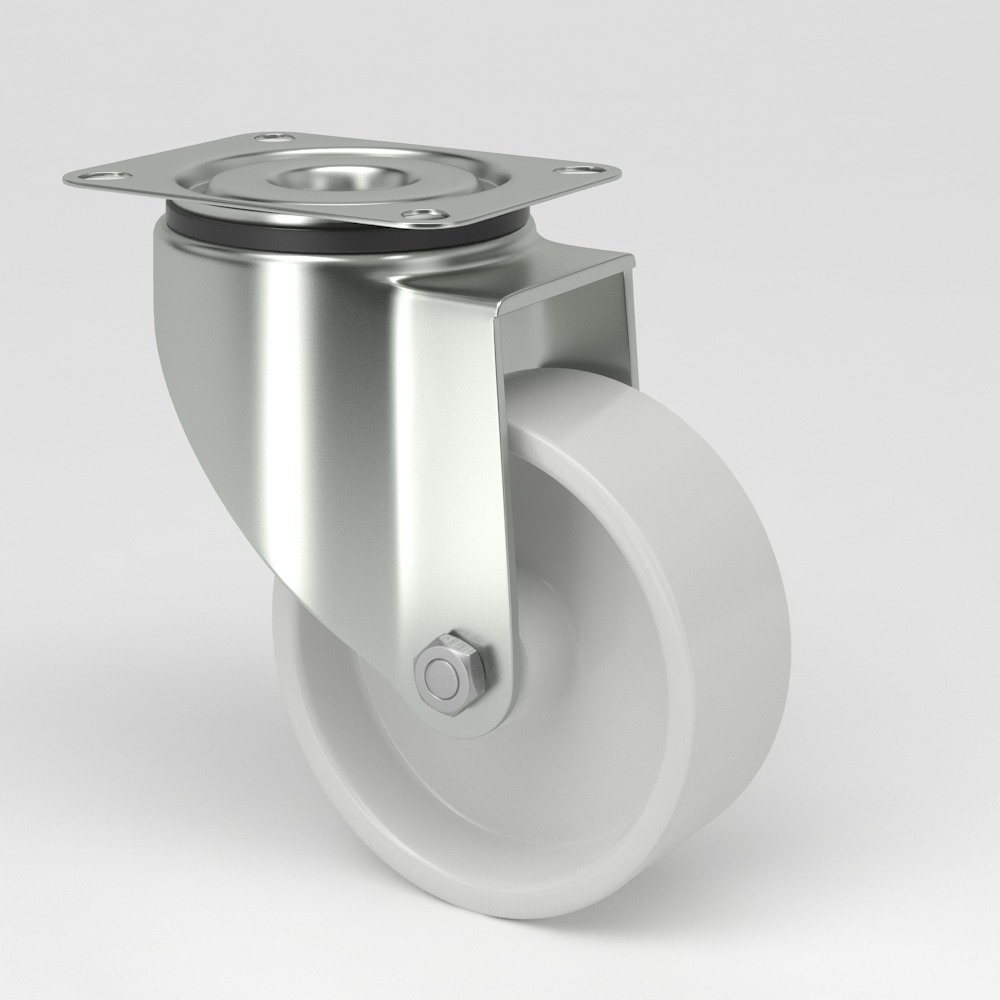

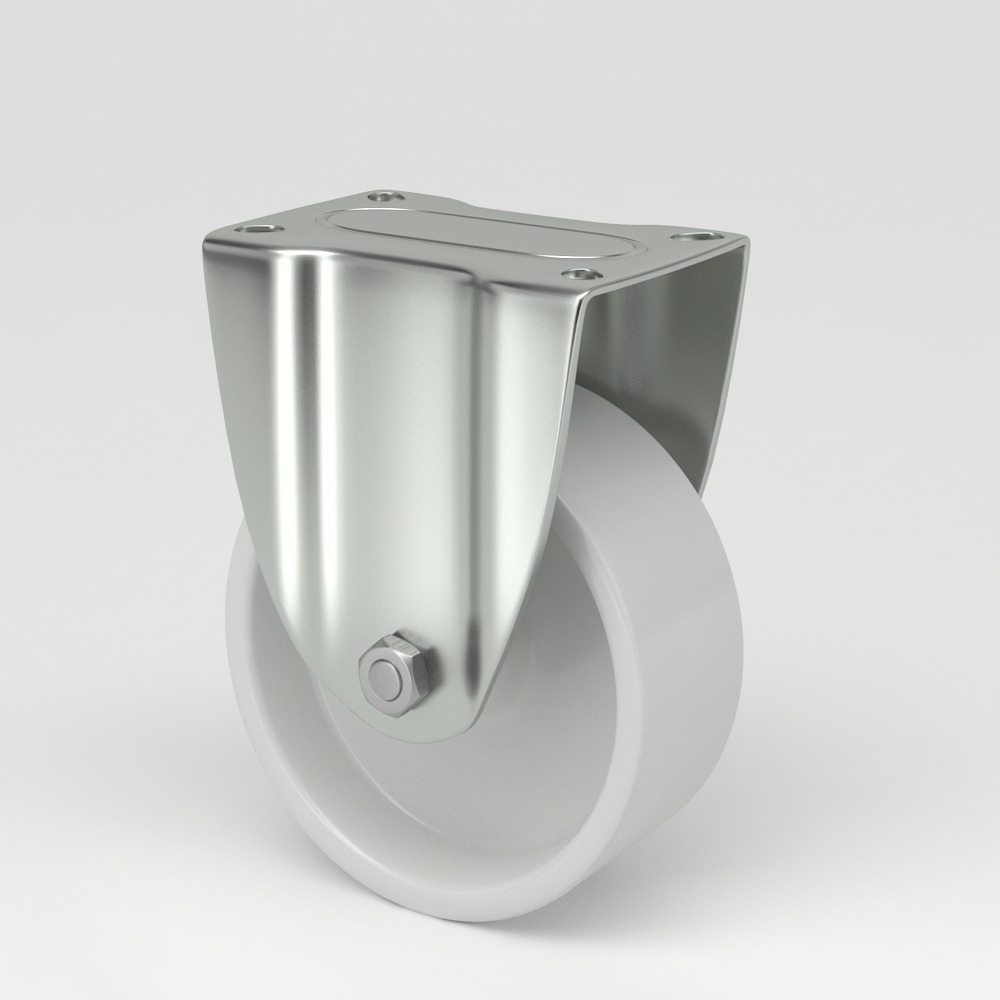

In the complex realm of industrial operations, selecting the right components is pivotal to ensuring not only efficiency but also adherence to stringent hygiene standards. This is particularly true for industries like pharmaceuticals, food processing, and chemicals, where both performance and cleanliness are paramount. Sanitary industrial castors emerge as the unparalleled solution, engineered meticulously to meet and exceed these demanding requirements.

Exceptional Material Resistance

Sanitary industrial castors are designed with a robust construction that withstands the harshest environmental conditions. Crafted from high-quality materials resistant to corrosion, chemicals, and wear, these castors guarantee long-lasting performance. The emphasis is on ensuring that industrial operations are not hindered by the recurrent need for maintenance or replacements, even in the most rigorous use scenarios.

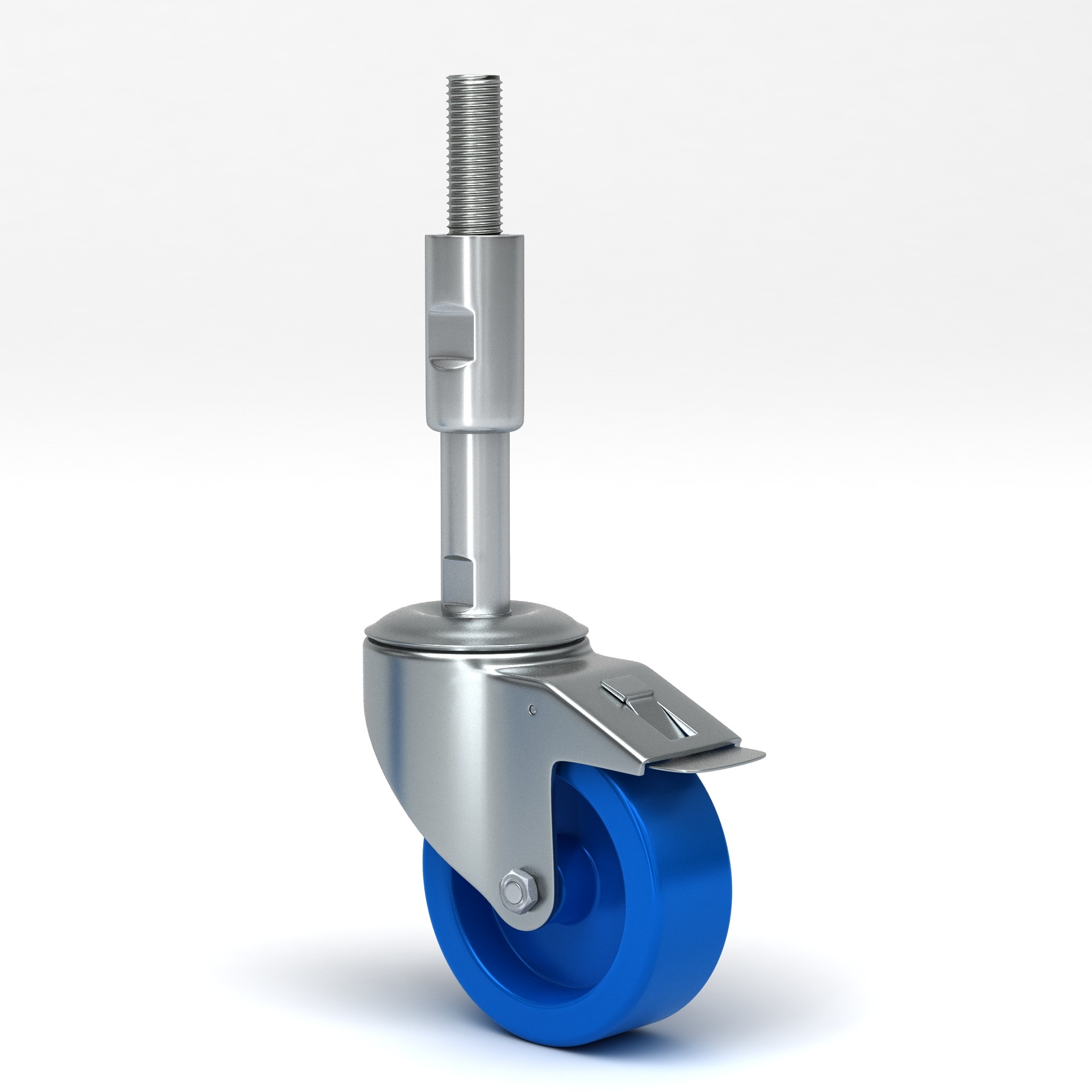

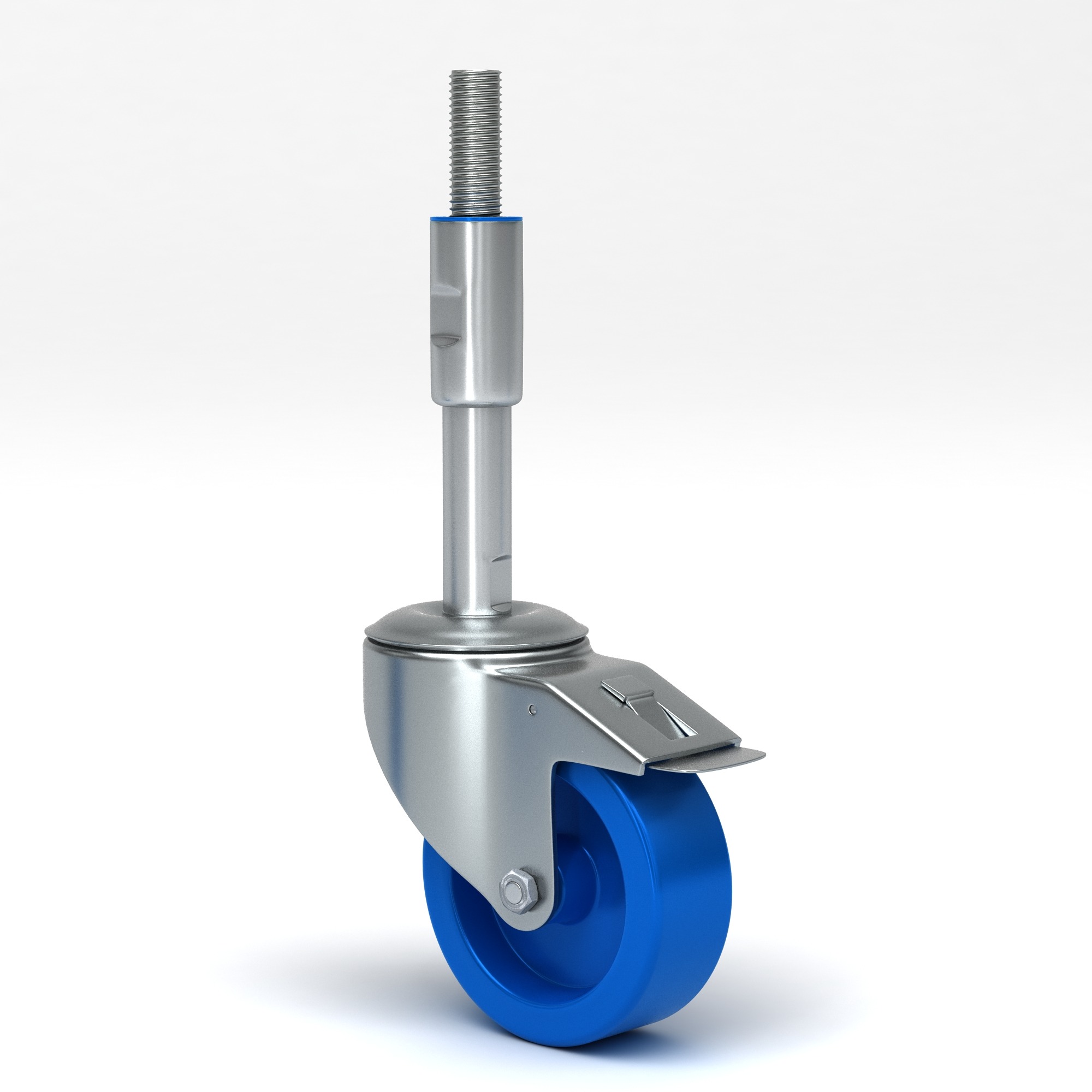

Hygienic and Easy-to-Clean Design

In an environment where cleanliness is as crucial as operational efficiency, sanitary industrial castors shine brightly. Their easy-to-clean design, characterized by smooth surfaces and minimal crevices, ensures that contaminants and bacteria have no room to harbor. The ease of cleaning reduces downtime, ensuring that the wheels of industry keep turning efficiently while upholding the highest standards of hygiene.

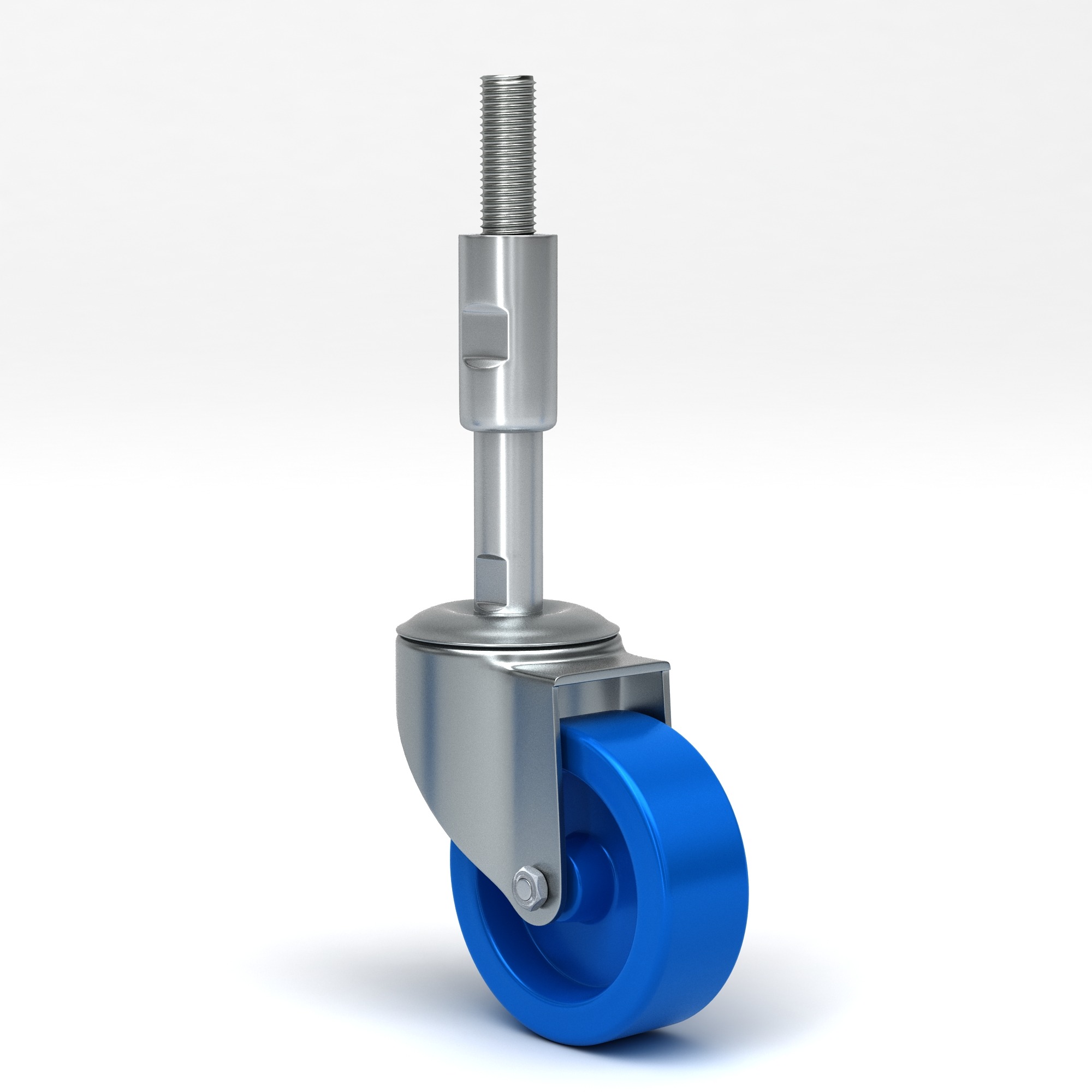

Versatility Meets Customization

Understanding that each industrial setting comes with its unique set of challenges and requirements, the design of these castors is diverse and customizable. Whether it's the need for temperature resistance in a chemical processing plant or enhanced cleanliness in a food processing unit, sanitary industrial castors offer tailored solutions ensuring optimal performance.

Enhancing Mobility and Efficiency

Beyond material resistance and hygiene, the core function of castors is to enhance mobility. Sanitary industrial castors are designed to offer smooth movement, ensuring that the transportation of goods and machinery within the industrial setup is seamless and efficient. The reduction in effort and time spent on movement translates to enhanced productivity and operational efficiency.

Combining Durability, Material Resistance, and Hygienic Excellence for Optimal Performance

Sanitary industrial castors are not just a component but a pivotal element that stands at the intersection of operational efficiency, hygiene, and durability. For industries navigating the complex waters of stringent operational and cleanliness standards, these castors offer a reliable, efficient, and hygienic solution. As we advance into an era where these standards are set to become even more stringent, investing in sanitary industrial castors is a strategic move towards future-proofing industrial operations.

Keywords:

- Sanitary Industrial Castors

- Material Resistance

- Hygienic Design

- Operational Efficiency

- Industrial Applications

- Easy-to-Clean

- Durability

- Food Processing

- Pharmaceutical Industry

- Chemical Processing

Questions and contact

Do you have any questions about our products? You are always welcome to contact us for questions about performance and solutions for your machine or anything else. You can read more about how to contact us here. You can find us in Denmark, the UK, Germany and Hong Kong.

See our other hygienic components and machinery parts

Our product range includes Certified EHEDG standard components, such as Machine leveling feet with solid base plate, Industrial machine leveling feet in stainless steel, Adjustable feet with composite material base plate and Stainless industrial caster Noise reducing castor, alongside IP67 Waterproof bearing house units, Sealed Stainless Steel Bearing Units, Bearing units in IP54 composite housing, Mounted ball bearing house units and Mini Bearing Units in Stainless Steel as well as Hygienic machinery components in stainless steel and Conveyor components and side guides, all crafted in hygienic stainless steel design for Food and beverage industry, Pharmaceutical manufacturing, Biotechnology industry, Cosmetics and personal care technology, Healthcare and medical device manufacturing, Dairy industry, Pet food processing industry, Meat and poultry processing industry, Seafood processing industry, Fruit and Vegetable processing industry, Snack food processing industry, Frozen food manufacturing industry, Cereal and grain processing industry, Baby food industry, Pastry and dough processing technology industry, Ice cream and frozen dessert industry, Coffee and chocolate processing technology, Sweets and snacks processing industry, Confectionery processing technology industry, production and packaging technology.