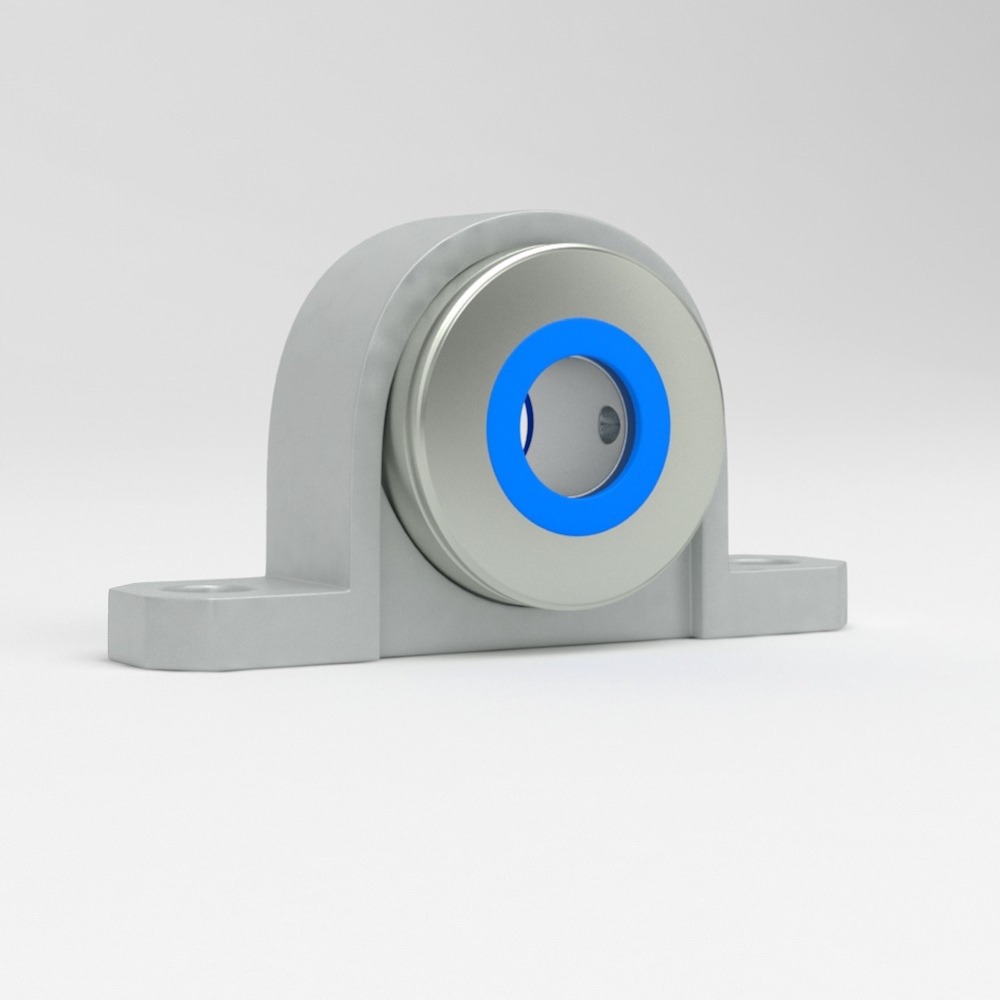

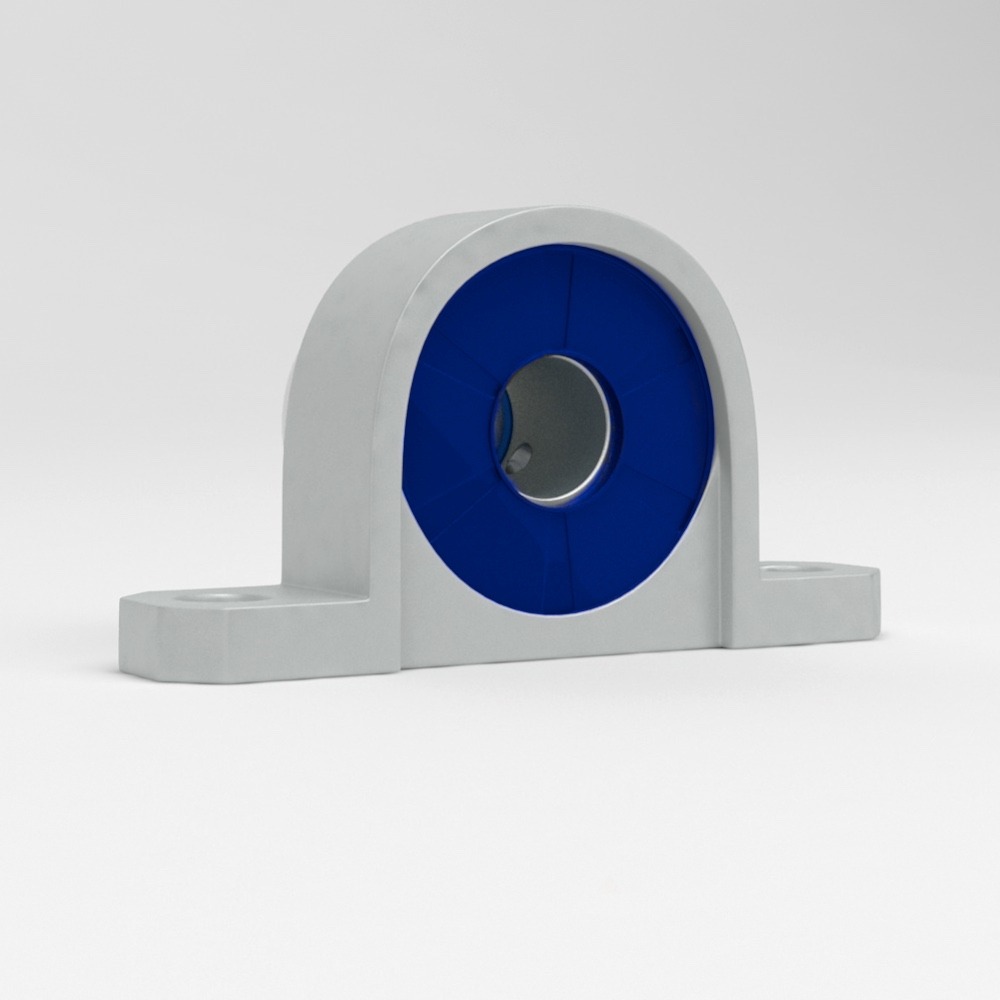

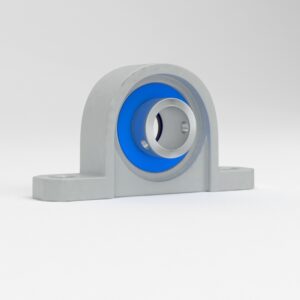

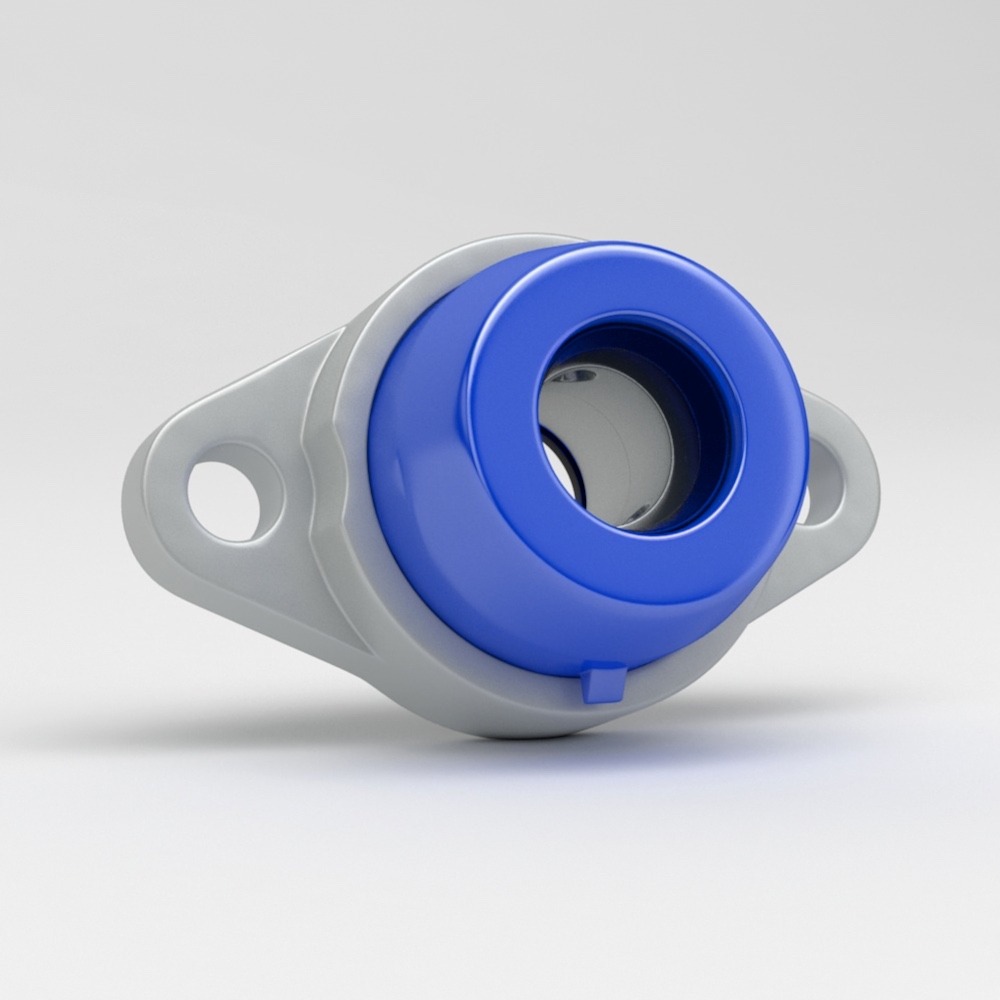

Stainless Mini Bearing Units: A Pinnacle of Efficiency in Food & Pharmaceutical Manufacturing

In the food and pharmaceutical sectors, the quest for efficiency and hygiene is an ongoing journey. Therefore, these compact units have emerged as a game change. We design these units for durability and precision, making them an indispensable asset. This article delves into their role in enhancing productivity.

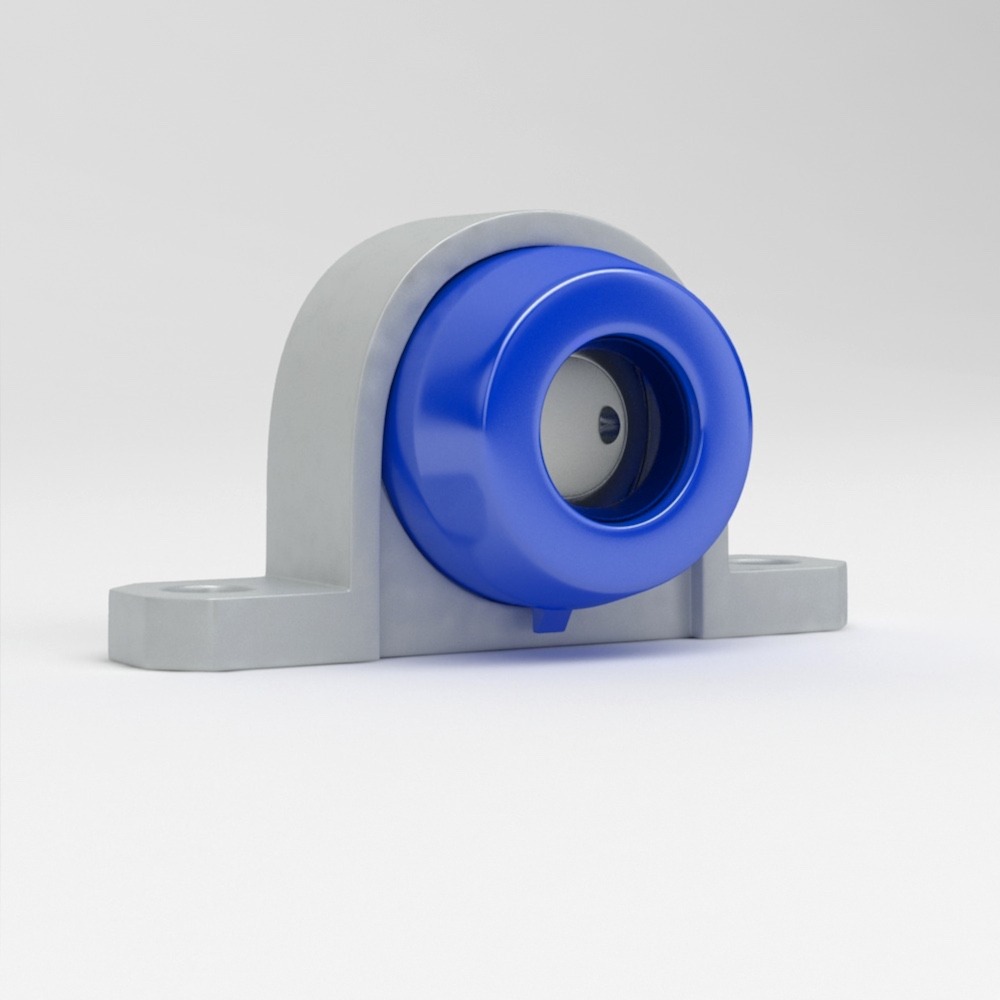

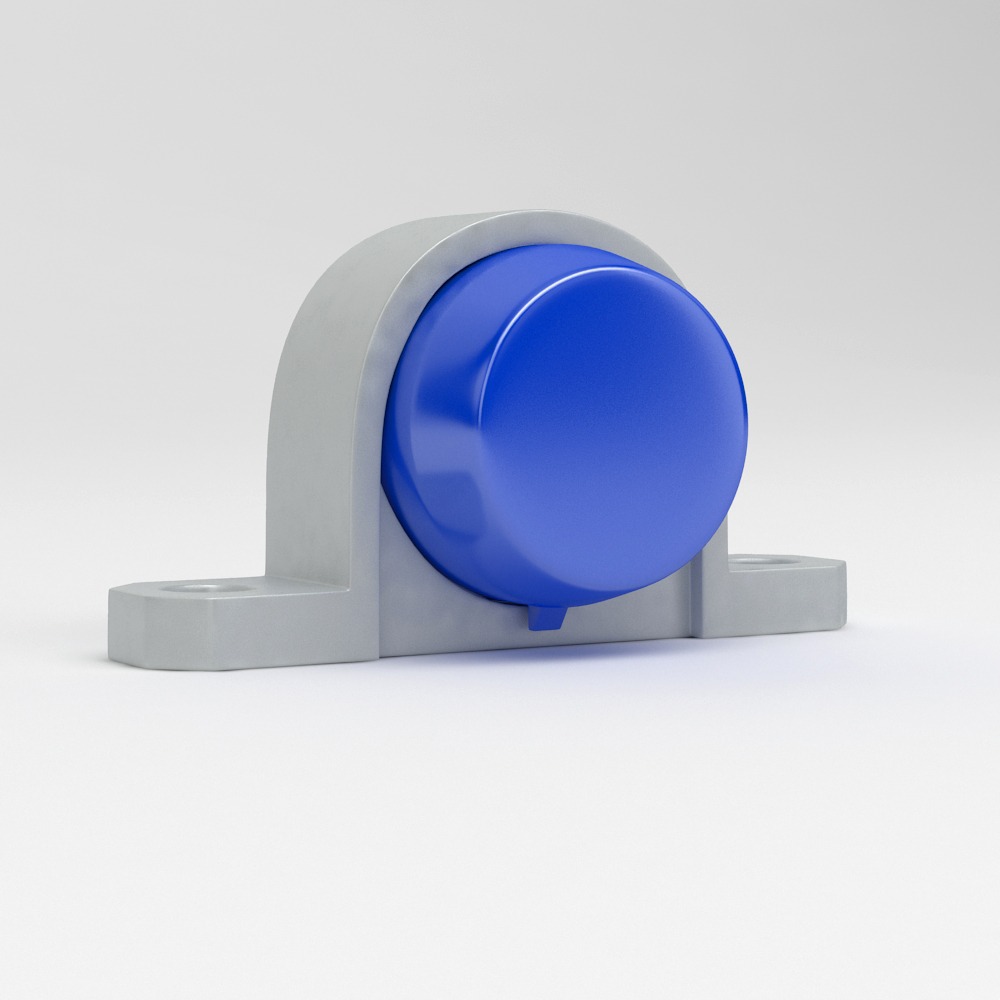

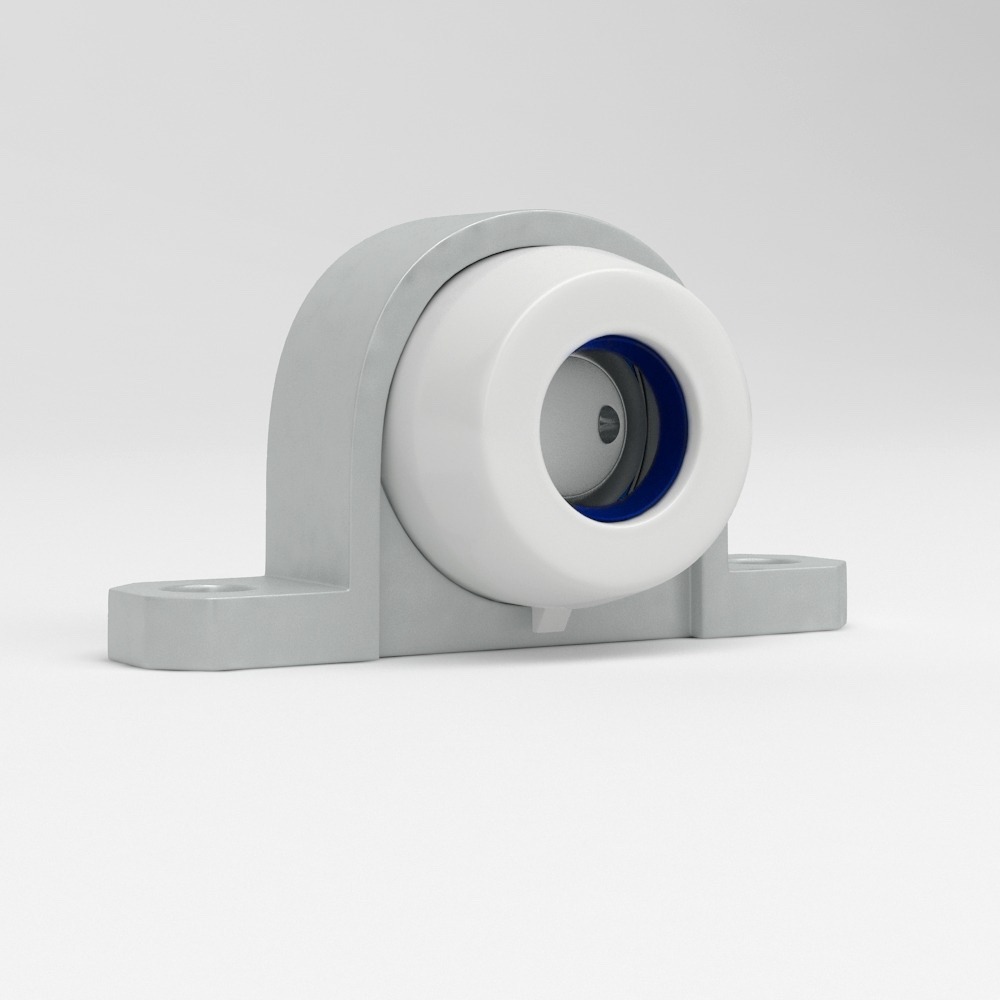

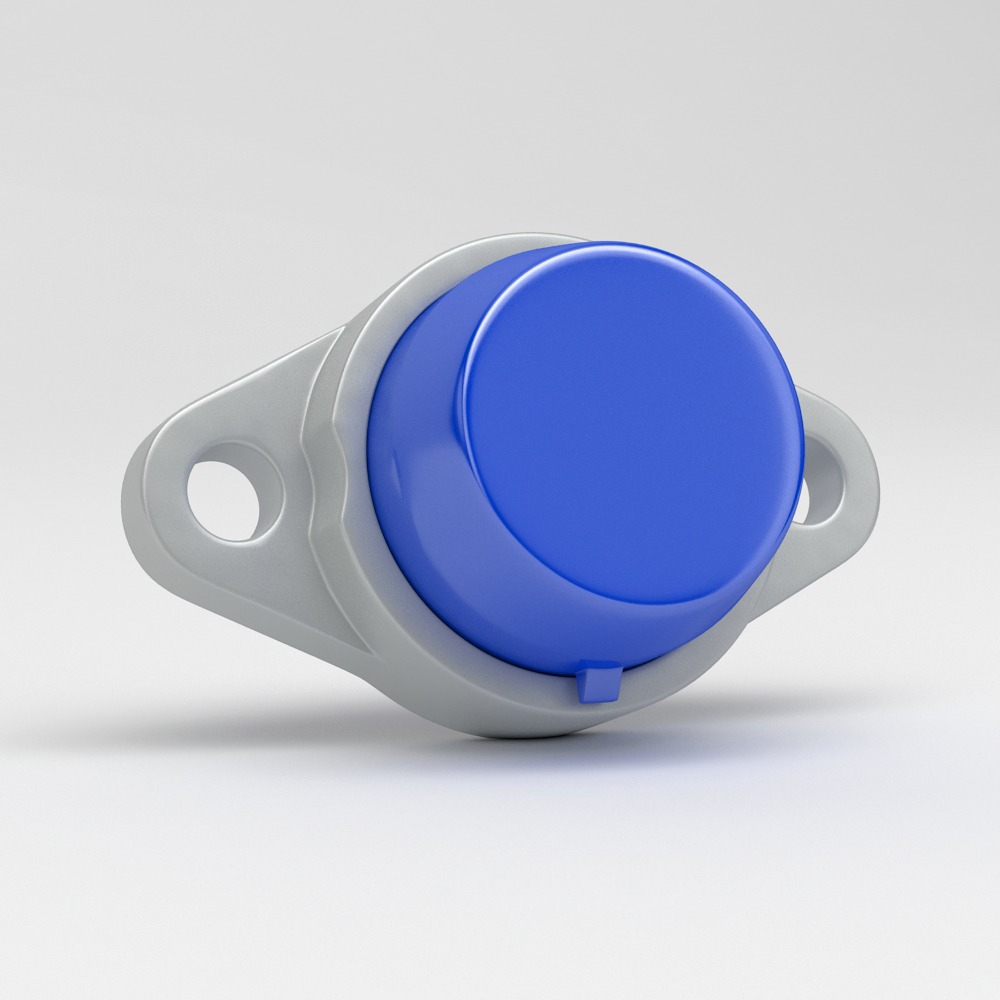

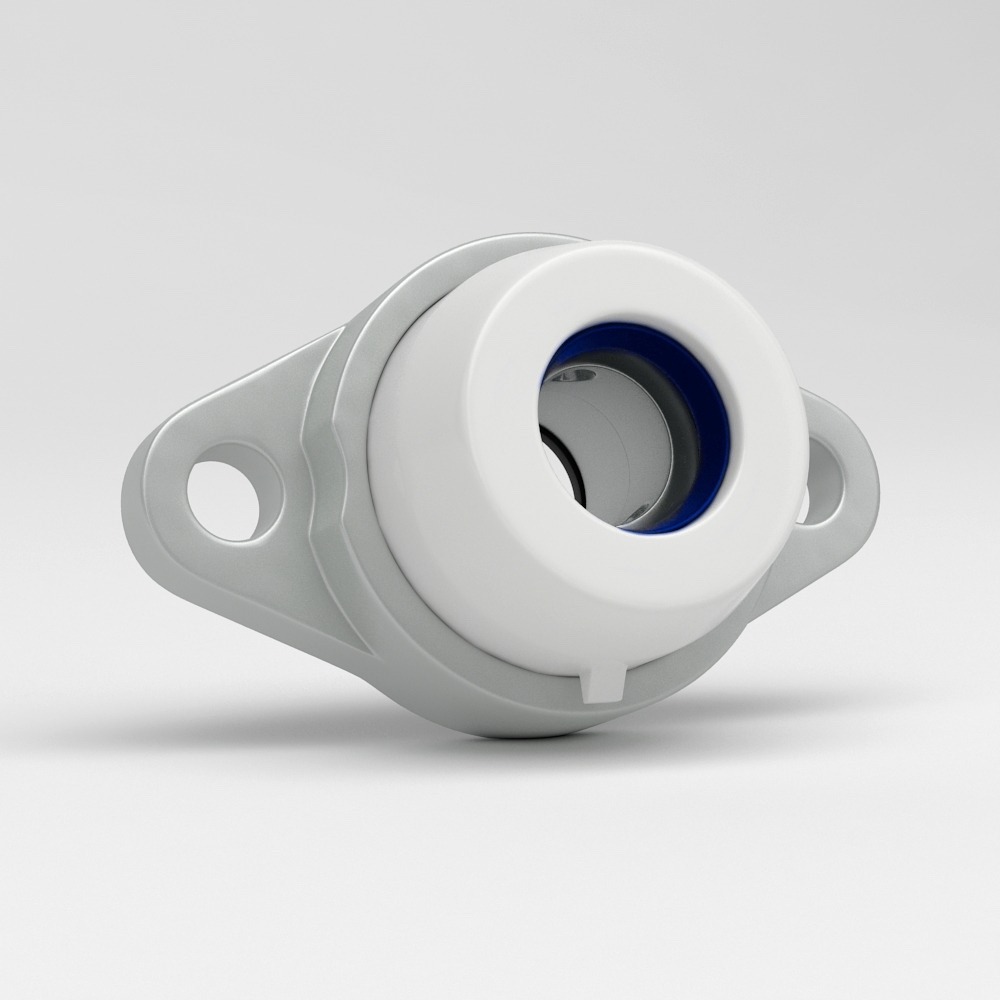

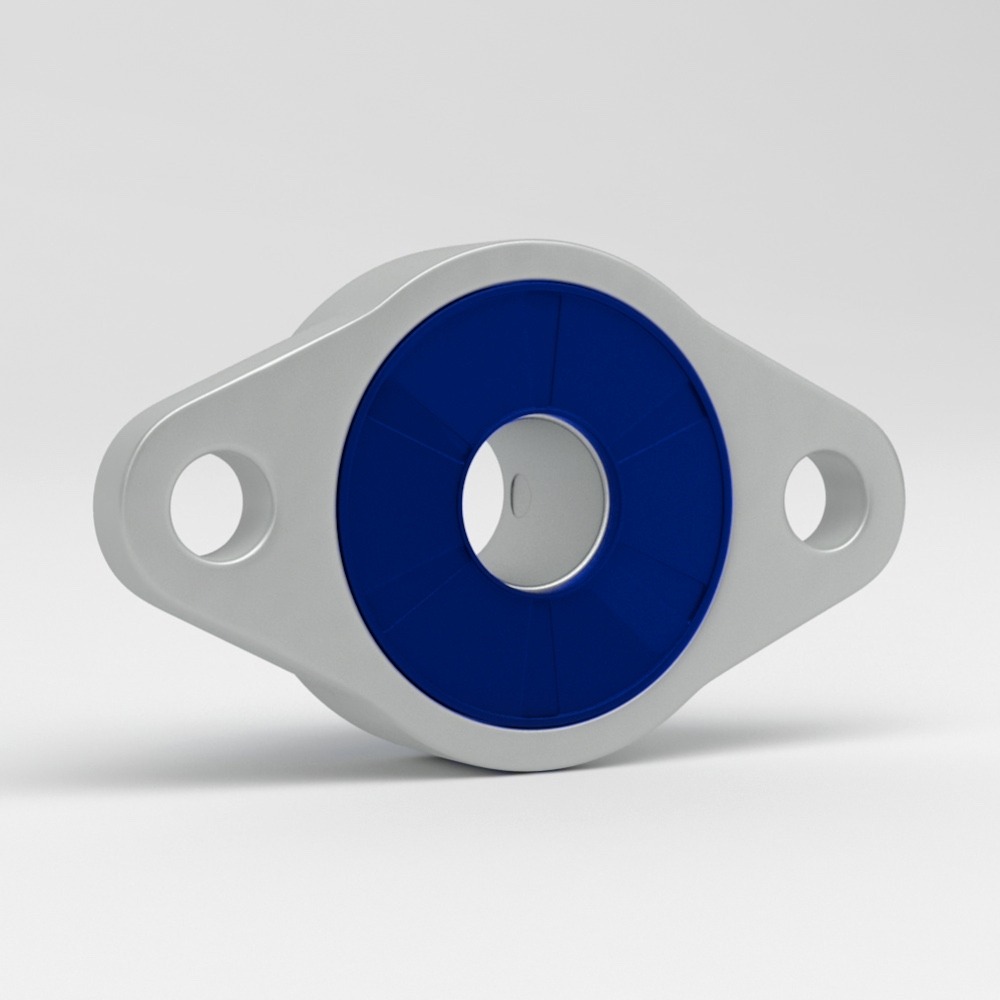

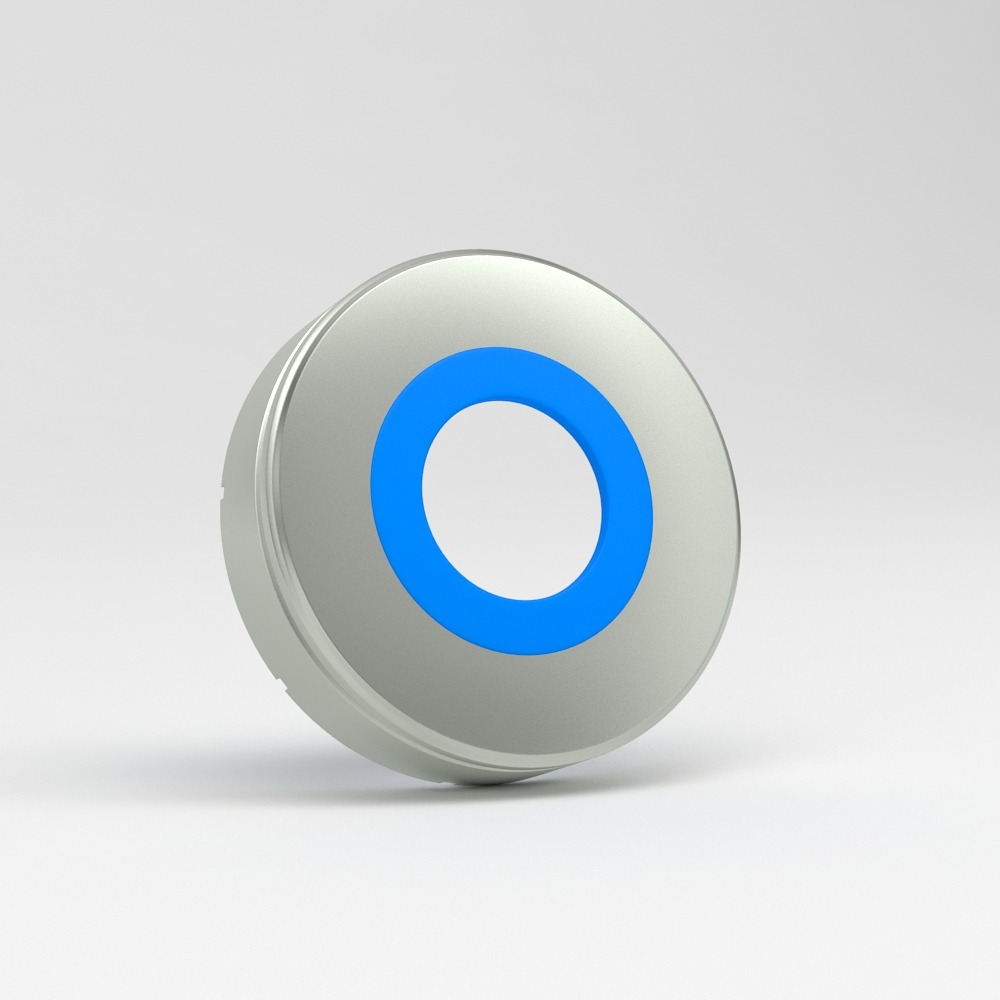

Key Features of Stainless Mini Bearing Units

We meticulously craft our stainless mini bearing units to offer optimal performance under stringent conditions. Specifically, their corrosion-resistant nature, compact design, and easy maintenance are pivotal for optimizing machinery efficiency.

A Deep Dive into the Benefits

Hygiene and Safety

In industries where hygiene and safety are paramount, our solutions stand out.. Their corrosion-resistant nature ensures that they do not rust or degrade, preventing contamination and ensuring the purity of food products and pharmaceuticals.

Durability and Reliability

We construct these bearing units from high-quality stainless steel, which makes them renowned for their durability. They withstand extreme temperatures, aggressive cleaning agents, and the wear and tear of continuous operation, ensuring uninterrupted production cycles.

Precision and Efficiency

The compact design of stainless mini bearing units ensures that they fit seamlessly into various machinery without compromising performance. They contribute to the precision and efficiency of equipment, leading to enhanced productivity and reduced downtime.

Applications in Food Processing

In the food processing industry, the role of stainless mini bearing units is critical. They are integral in various stages of production, from processing to packaging, ensuring that machinery operates smoothly and efficiently. Their ability to withstand frequent washdowns and resist corrosion ensures that hygiene standards are uncompromisingly maintained.

Applications in Pharmaceutical Manufacturing

Pharmaceutical manufacturing demands precision, hygiene, and reliability. Stainless mini bearing units deliver on all fronts. They ensure that equipment operates with optimal efficiency and precision, ensuring that the stringent quality standards of pharmaceutical products are met.

Food processing and pharmaceutical manufacturing

As the food and pharma sectors evolve, the indispensability of these compact components becomes evident. They encapsulate the essence of efficiency, durability, and hygiene. By ensuring machinery operates at peak performance and upholding hygiene standards, they become a necessity in the modern manufacturing landscape.

Do you have any questions about our products?

Do you have any questions about our products? You are always welcome to contact us for questions about performance and solutions for your machine or anything else. You can read more about how to contact us here. You can find us in Denmark, the UK, Germany and Hong Kong.

See our other hygienic components and machinery parts

Our product range includes Certified EHEDG standard components, such as Machine leveling feet with solid base plate, Industrial machine leveling feet in stainless steel, Adjustable feet with composite material base plate and Stainless industrial caster Noise reducing castor, alongside IP67 Waterproof bearing house units, Sealed Stainless Steel Bearing Units, Bearing units in IP54 composite housing, Mounted ball bearing house units and Mini Bearing Units in Stainless Steel as well as Hygienic machinery components in stainless steel and Conveyor components and side guides.

All crafted in hygienic stainless steel design for Food and beverage industry, Pharmaceutical manufacturing, Biotechnology industry, Cosmetics and personal care technology, Healthcare and medical device manufacturing, Dairy industry, Pet food processing industry, Meat and poultry processing industry, Seafood processing industry, Fruit and Vegetable processing industry, Snack food processing industry, Frozen food manufacturing industry, Cereal and grain processing industry, Baby food industry, Pastry and dough processing technology industry, Ice cream and frozen dessert industry, Coffee and chocolate processing technology, Sweets and snacks processing industry, Confectionery processing technology industry, production and packaging technology.