Potato Washing, Drying and Sorting Machines

The food processing industry is constantly evolving to meet consumer demands for higher-quality, safer, and more consistent products. One area that has seen significant advancements is the processing of potatoes, which involves essential steps such as washing, drying, and sorting. With the growing demand for processed potato products, such as fries, chips, and snacks, efficient and hygienic processing machines have become crucial in ensuring top-tier quality while maintaining productivity. This article explores the importance and benefits of potato washing, drying, and sorting machines in modern food processing operations. Potatoes are a staple in the food industry, used in a variety of products ranging from fresh produce to processed snacks. To ensure potatoes are processed efficiently and hygienically, it’s essential to use specialized machinery that performs washing, drying, and sorting tasks seamlessly. The first step in the potato processing line is washing, which is vital for removing dirt, debris, pesticides, and any residual chemicals from the surface of the potatoes. High-quality potato washing machines are designed to thoroughly clean the potatoes without damaging their skins, ensuring that the final product is of the highest quality. These machines utilize water jets, rotating brushes, and vibrating systems to scrub and rinse potatoes efficiently. Advanced potato washing machines also incorporate features like automatic water recycling systems, reducing water usage and enhancing sustainability. By ensuring a thorough cleaning, these machines help in maintaining food safety standards, as any contaminants on the potatoes can affect the quality and safety of the end product. After washing, it is crucial to dry the potatoes effectively to remove excess moisture. This is particularly important for products like frozen fries and chips, where excess moisture can result in uneven cooking and affect the product’s texture and taste. Potato drying machines are designed to remove moisture while preserving the integrity of the potatoes. They use methods like air drying, centrifugal drying, and heated dryers to reduce moisture content to optimal levels. These machines ensure that potatoes are dried quickly and efficiently, preventing the growth of bacteria and mold while maintaining the desired texture for further processing. In some advanced systems, drying can be done in conjunction with sorting, allowing for a more streamlined operation. Drying machines are often equipped with adjustable settings to ensure that the drying process is customized to the type of potato and the final product requirements, optimizing the overall processing time and cost-efficiency. Sorting is the next crucial step in potato processing, ensuring that only high-quality potatoes proceed to the next stage of production. Automated sorting machines use advanced technologies like optical sensors, weight-based systems, and mechanical sorting methods to classify potatoes based on size, shape, color, and quality. Sorting machines can identify and remove damaged, under-sized, or discolored potatoes, ensuring that only the best potatoes are processed further. This reduces waste, improves product consistency, and increases efficiency by ensuring that only the potatoes that meet the required standards move forward. Additionally, sorting machines contribute to food safety by eliminating potatoes that may be contaminated or not suitable for further processing. The automated sorting process reduces the need for manual labor, increasing productivity and reducing the risk of human error. Investing in high-quality potato washing, drying, and sorting machines offers numerous advantages for food processing businesses. Here are some of the key benefits: By using specialized machines, potato processors can achieve a higher level of consistency and quality in their final products. Potatoes are washed, dried, and sorted to perfection, ensuring that they meet food safety standards and deliver a superior taste, texture, and appearance. Automated washing, drying, and sorting machines speed up the processing time, allowing businesses to handle large volumes of potatoes in a shorter amount of time. This results in increased production capacity, helping businesses meet market demand more effectively and reducing downtime. Though the initial investment in advanced machines can be significant, the long-term cost savings are substantial. Automated systems reduce labor costs, minimize waste, and improve energy efficiency, resulting in a more cost-effective operation overall. With growing concerns about sustainability in food production, modern potato processing machines are designed to be more energy-efficient and environmentally friendly. Water recycling systems in washing machines and energy-efficient drying technologies contribute to a more sustainable production process. Potato washing and drying machines are designed with hygiene in mind, helping to meet strict food safety regulations. These machines are often made from high-quality stainless steel, which is easy to clean and maintain, reducing the risk of contamination during processing. When selecting potato washing, drying, and sorting machines, there are several key features to consider: Potato washing, drying, and sorting machines play a critical role in modern food processing, enhancing efficiency, product quality, and sustainability. By investing in these advanced machines, businesses can meet growing consumer demands for high-quality potato products while optimizing their operations. As the industry continues to innovate, the importance of using specialized equipment to handle potatoes efficiently and hygienically will only increase, making these machines an essential part of any potato processing facility. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Block Units and Direct Mount Bearings is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440 Stainless Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.Optimizing Efficiency in Food Processing

The Importance of Potato Washing, Drying, and Sorting Machines

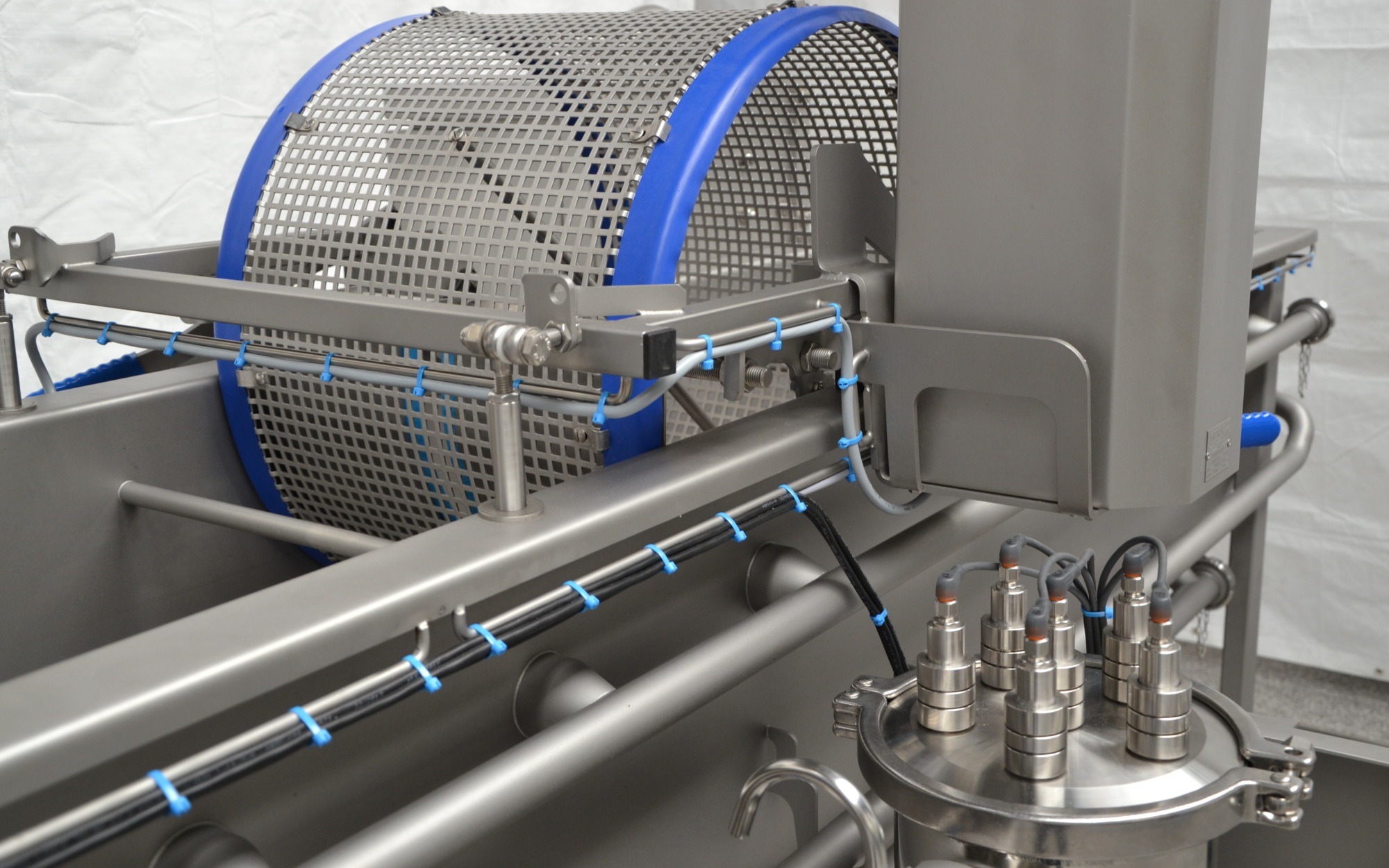

Potato Washing: A Critical First Step

Potato Drying: Enhancing Product Quality and Efficiency

Potato Sorting: Enhancing Consistency and Reducing Waste

Benefits of Using Potato Washing, Drying, and Sorting Machines

1. Improved Product Quality

2. Increased Efficiency

3. Cost Savings

4. Sustainability

5. Hygiene and Food Safety

Key Features to Look for in Potato Washing, Drying, and Sorting Machines

Enhancing Potato Processing Efficiency

The Role of Washing, Drying, and Sorting Machines in Modern Food Production

Contact

Understanding Machinery Components & Protection Standards