Optimizing Frozen Vegetable and Berry Processing

The processing of frozen vegetables and berries involves numerous steps to ensure that the final products meet the highest quality standards. Among these, washing, drying, sorting, and grading are critical stages that impact both the quality of the product and the efficiency of the processing operation. In this article, we will explore the role of advanced machines in these processes, their benefits, and how they contribute to the food processing industry’s ongoing evolution. Frozen vegetables and berries are popular for their convenience, extended shelf life, and preserved nutritional value. However, before these products are frozen and packaged, they undergo various stages of processing to ensure they are safe for consumption and aesthetically appealing to consumers. Washing, drying, sorting, and grading are essential processes that must be carried out with precision to meet the required standards. Washing machines for frozen vegetables and berries are designed to clean large batches of raw materials efficiently. They come in various forms, including rotary drum washers, tunnel washers, and bubble washers. The choice of machine depends on the type of product being processed and the level of cleanliness required. Key features include: After washing, drying machines are employed to remove excess moisture. These machines are critical in preventing spoilage and preserving the product’s shelf life. Common drying methods include: Sorting machines are essential for ensuring that only high-quality produce makes it through the processing line. They use advanced technologies to detect defects and ensure uniformity in the products. Some common sorting technologies include: Grading machines help categorize the produce based on predefined quality standards, ensuring that only top-quality items are selected for packaging. These machines typically use: The integration of advanced machines in the washing, drying, sorting, and grading processes offers several benefits to food processors in the frozen vegetable and berry industry: Automation significantly speeds up the processing time compared to manual labor, allowing businesses to handle larger volumes of product in a shorter amount of time. This leads to higher throughput and reduced operational costs. Modern machines are designed to minimize human contact with the produce, reducing the risk of contamination. Advanced cleaning and drying systems ensure that the produce meets safety standards, which is crucial in food processing environments where hygiene is paramount. Sorting and grading machines ensure that only the best quality vegetables and berries make it to the packaging stage. These machines help identify and eliminate defective or substandard products, ensuring uniformity and superior quality in the final product. Energy-efficient machines reduce power consumption, lowering operational costs and environmental impact. Innovations in machine design have made it possible to optimize water and energy use, making the entire processing cycle more sustainable. By reducing manual labor, increasing throughput, and improving product quality, these machines help food processors save on labor costs, reduce waste, and improve overall profitability. The washing, drying, sorting, and grading machines for frozen vegetables and berries are indispensable in modern food processing. By leveraging advanced technology, processors can enhance efficiency, improve product quality, and meet stringent hygiene standards. These machines play a pivotal role in ensuring that the frozen vegetables and berries delivered to consumers are not only safe but also meet the highest quality standards expected by the market. Incorporating the latest equipment into production lines is no longer a luxury but a necessity for businesses aiming to stay competitive in the rapidly evolving food processing industry. As the demand for high-quality frozen vegetables and berries continues to rise, investing in these sophisticated machines is a key strategy for achieving long-term success. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Block Units and Flange Mounted Units is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440C Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.The Role of Washing, Drying, Sorting, and Grading Machines

The Importance of Frozen Vegetable and Berry Processing

Washing, Drying, Sorting and Grading

The washing process removes dirt, pesticides, chemicals, and contaminants that may be present on the surface of vegetables and berries. Machines designed for this task are often equipped with gentle but effective cleaning systems that use water, steam, or a combination of both to clean the raw materials without causing damage.

After washing, it is crucial to remove excess moisture to prevent the growth of bacteria and mold during storage and transport. Drying machines, such as air dryers and centrifugal dryers, help achieve the desired level of dryness while maintaining the integrity of the products.

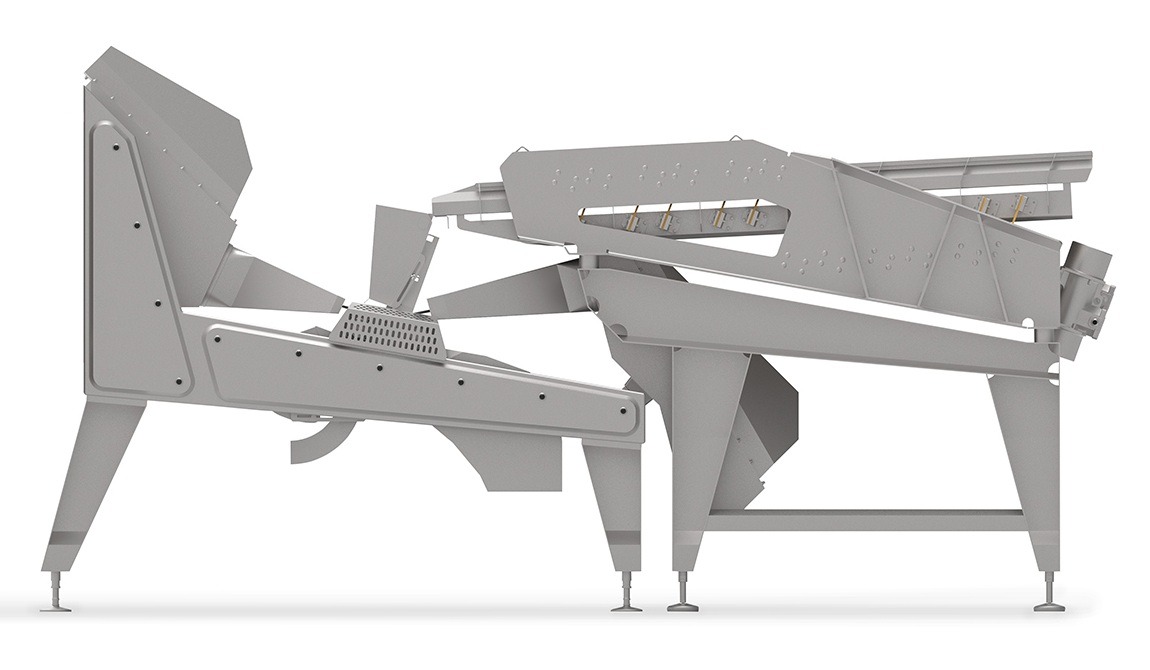

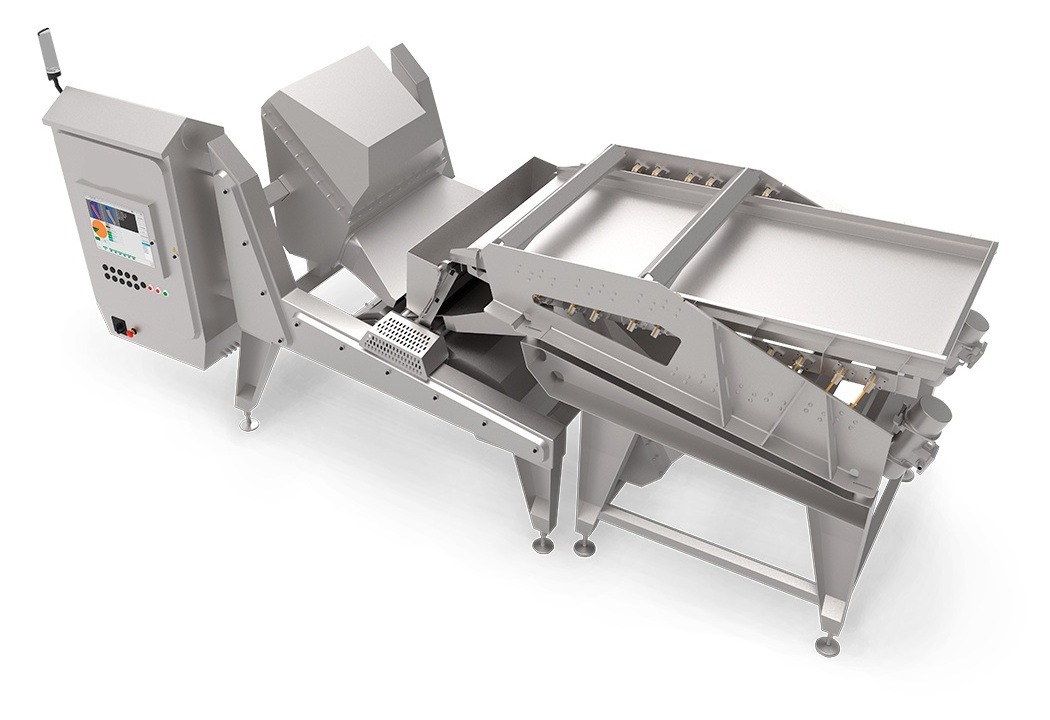

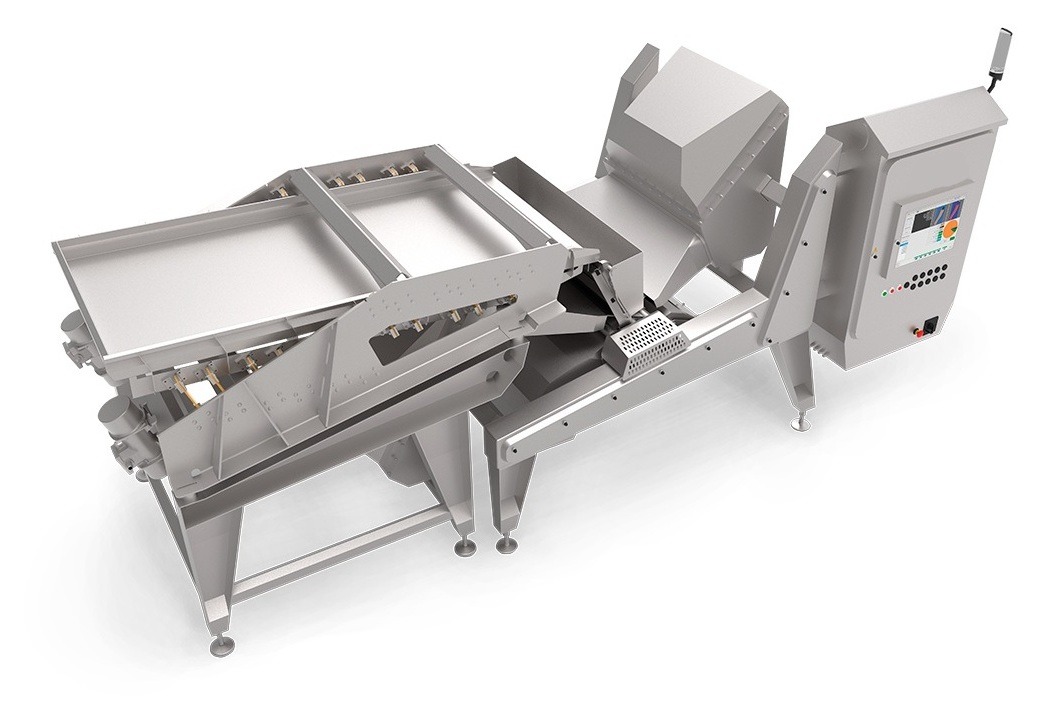

Sorting involves categorizing vegetables and berries based on size, color, shape, and quality. Sorting machines use advanced technology such as optical sensors, infrared cameras, and lasers to accurately identify and separate products that meet quality standards from those that do not.

Grading takes sorting a step further by classifying products into various grades depending on factors such as size and color uniformity. Grading machines help ensure that only the highest quality products are packaged and sent to market, improving consumer satisfaction.Types of Machines Used in Frozen Vegetable and Berry Processing

1. Washing Machines

2. Drying Machines

3. Sorting Machines

4. Grading Machines

Advantages of Using Advanced Machines in Processing

1. Increased Efficiency

2. Improved Hygiene and Safety

3. Enhanced Product Quality

4. Energy Efficiency and Sustainability

5. Cost Savings

Optimizing Frozen Vegetable and Berry Processing

The Role of Washing, Drying, Sorting, and Grading Machines

Get our catalogue here

See our product line here

Contact

Understanding Machinery Components & Protection Standards