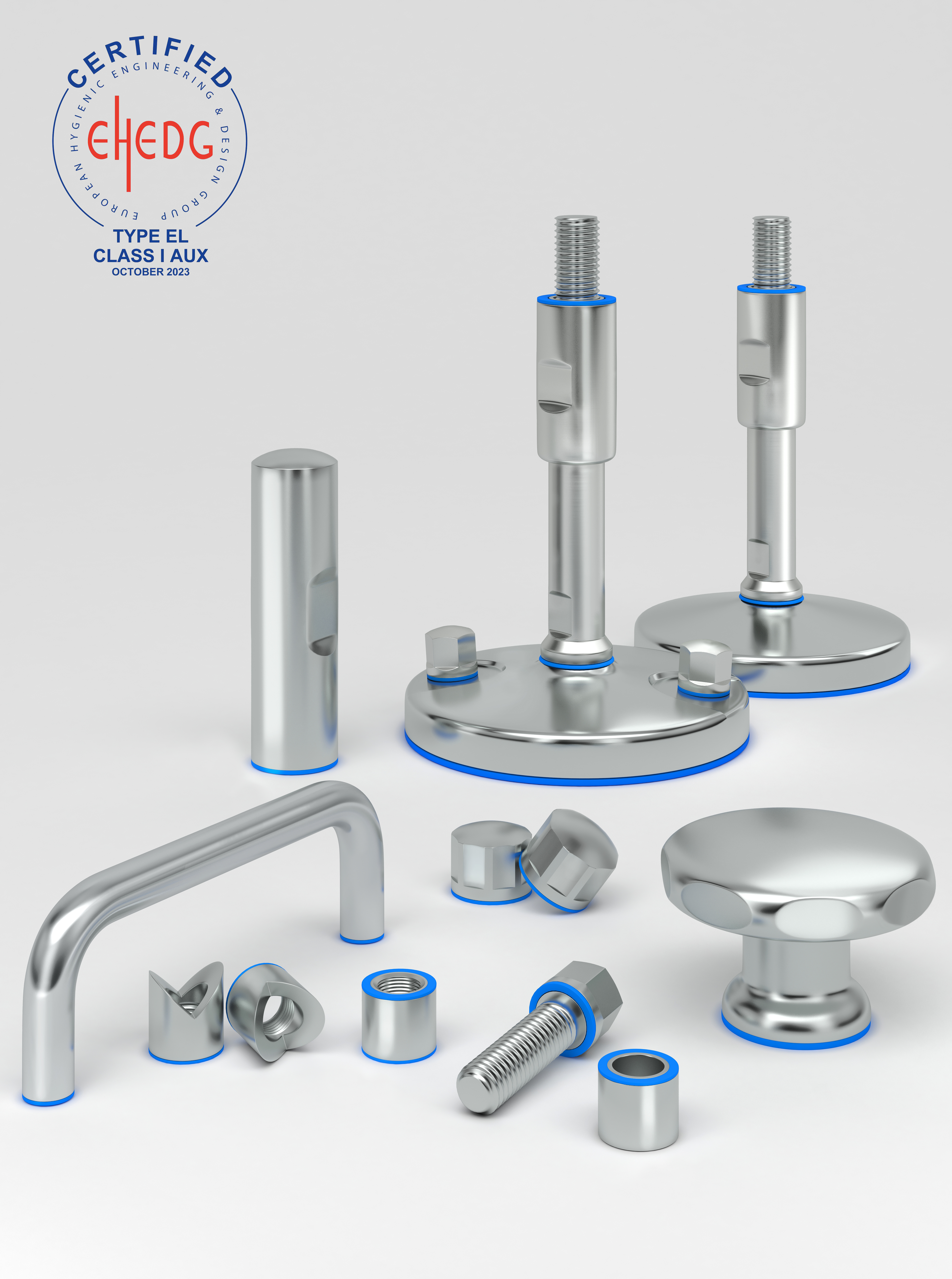

Meets rigorous hygiene and environmental standards

In today’s global marketplace, maintaining the highest levels of hygiene and environmental standards in food production is not only crucial for consumer safety but also for compliance with international regulations. The European Hygienic Engineering & Design Group (EHEDG) and 3-A Sanitary Standards, Inc. (3-A SSI) are two leading organizations that set benchmarks for hygienic design and processing standards. Components and parts certified by these organizations ensure that equipment used in the food and beverage industries meets rigorous hygiene and environmental standards, enhancing food safety and quality. The European Hygienic Engineering & Design Group (EHEDG) is a consortium of equipment manufacturers, food producers, suppliers, research institutes, and public health authorities. Established in 1989, EHEDG aims to improve hygiene during the processing and packaging of food products. The organization provides guidelines and certification for equipment that meets stringent hygienic design criteria, ensuring that food production environments minimize contamination risks and maximize cleanability. 3-A Sanitary Standards, Inc. (3-A SSI) is an American organization that develops sanitary standards and practices for equipment used in the dairy and food industries. Founded in 1920, 3-A SSI works closely with regulatory bodies, equipment manufacturers, and end-users to create and maintain standards that ensure equipment is designed and manufactured to the highest sanitary requirements. The 3-A SSI certification is widely recognized and respected across the food industry, signifying compliance with critical hygiene and safety standards. The primary objective of EHEDG and 3-A SSI certified components is to ensure food safety by minimizing contamination risks. Equipment that meets these standards is designed to be easily cleanable, reducing the likelihood of microbial growth and cross-contamination. This is particularly important in industries such as dairy, meat processing, and beverage production, where the risk of contamination can have severe health implications. Certified components contribute to maintaining the quality of food products. By ensuring that equipment is free from contamination and designed for optimal cleanability, food producers can deliver products that meet the highest quality standards. This is essential for building consumer trust and loyalty, as well as for complying with international quality standards. Food manufacturers are required to comply with various national and international regulations concerning hygiene and safety. Using EHEDG and 3-A SSI certified components helps companies meet these regulatory requirements, avoiding costly fines and reputational damage. Moreover, certification demonstrates a commitment to industry best practices and can facilitate market access in regions with stringent regulatory frameworks. Certified components are designed with hygiene as a top priority. This includes smooth surfaces, the absence of crevices or dead spaces, and materials that are resistant to corrosion and wear. These design features facilitate easy and effective cleaning, preventing the buildup of contaminants and ensuring that all parts of the equipment can be sanitized efficiently. Materials used in EHEDG and 3-A SSI certified components are carefully selected for their resistance to corrosion, chemical reactivity, and ability to withstand rigorous cleaning processes. Stainless steel is commonly used due to its durability and ease of cleaning. Additionally, seals and gaskets are made from food-grade materials that do not degrade or leach harmful substances into the food. The design of certified components prioritizes cleanability and accessibility. Equipment is designed to allow for easy disassembly and cleaning, with all surfaces accessible for inspection and maintenance. This ensures that regular cleaning and maintenance can be performed without compromising hygiene standards. Implementing certified components in food processing equipment significantly reduces the risk of contamination. This is achieved through designs that prevent bacterial growth, facilitate effective cleaning, and minimize the potential for product residue to accumulate. Reduced contamination risks lead to fewer product recalls and enhanced consumer safety. Certified components contribute to increased operational efficiency by reducing downtime associated with cleaning and maintenance. Equipment that is easy to clean and maintain can be turned around quickly, ensuring continuous production and minimizing delays. This leads to cost savings and improved productivity for food manufacturers. EHEDG and 3-A SSI certifications also emphasize environmental sustainability. By ensuring that equipment is designed for efficient cleaning and reduced water and chemical usage, these standards contribute to a lower environmental footprint. This is increasingly important as consumers and regulatory bodies demand more sustainable practices from the food industry. To achieve EHEDG certification, equipment manufacturers must undergo a rigorous evaluation process. This includes testing components against EHEDG guidelines and standards, which cover aspects such as material selection, design, and cleanability. Certified components receive the EHEDG certification mark, signifying compliance with the highest hygienic design standards. Similarly, 3-A SSI certification involves a comprehensive assessment of equipment to ensure compliance with 3-A sanitary standards. Manufacturers must submit detailed documentation and undergo inspections to verify that their products meet the required criteria. Once certified, equipment can display the 3-A symbol, indicating adherence to strict sanitary standards. EHEDG and 3-A SSI certified components and parts play a crucial role in maintaining the highest levels of hygiene and environmental standards in the food industry. By ensuring food safety, enhancing product quality, and facilitating regulatory compliance, these certifications provide significant benefits to food manufacturers and consumers alike. As the demand for safe and sustainable food production continues to grow, the importance of certified components in achieving these goals cannot be overstated. Implementing EHEDG and 3-A SSI certified equipment is a strategic investment that ensures the highest levels of safety, quality, and sustainability in food processing. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Bearing Housings and Flange Bearings is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440 Stainless Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.EHEDG and 3-A SSI Certified Components and Parts

Understanding EHEDG and 3-A SSI

What is EHEDG?

What is 3-A SSI?

Importance of Certified Components and Parts

Ensuring Food Safety

Enhancing Product Quality

Regulatory Compliance

Features of EHEDG and 3-A SSI Certified Components

Hygienic Design

Material Selection

Cleanability and Accessibility

Benefits of Implementing Certified Components

Reduced Contamination Risks

Increased Efficiency

Enhanced Sustainability

The Certification Process

EHEDG Certification

3-A SSI Certification

Meets rigorous hygiene and environmental standards

Contact

Understanding Machinery Components & Protection Standards