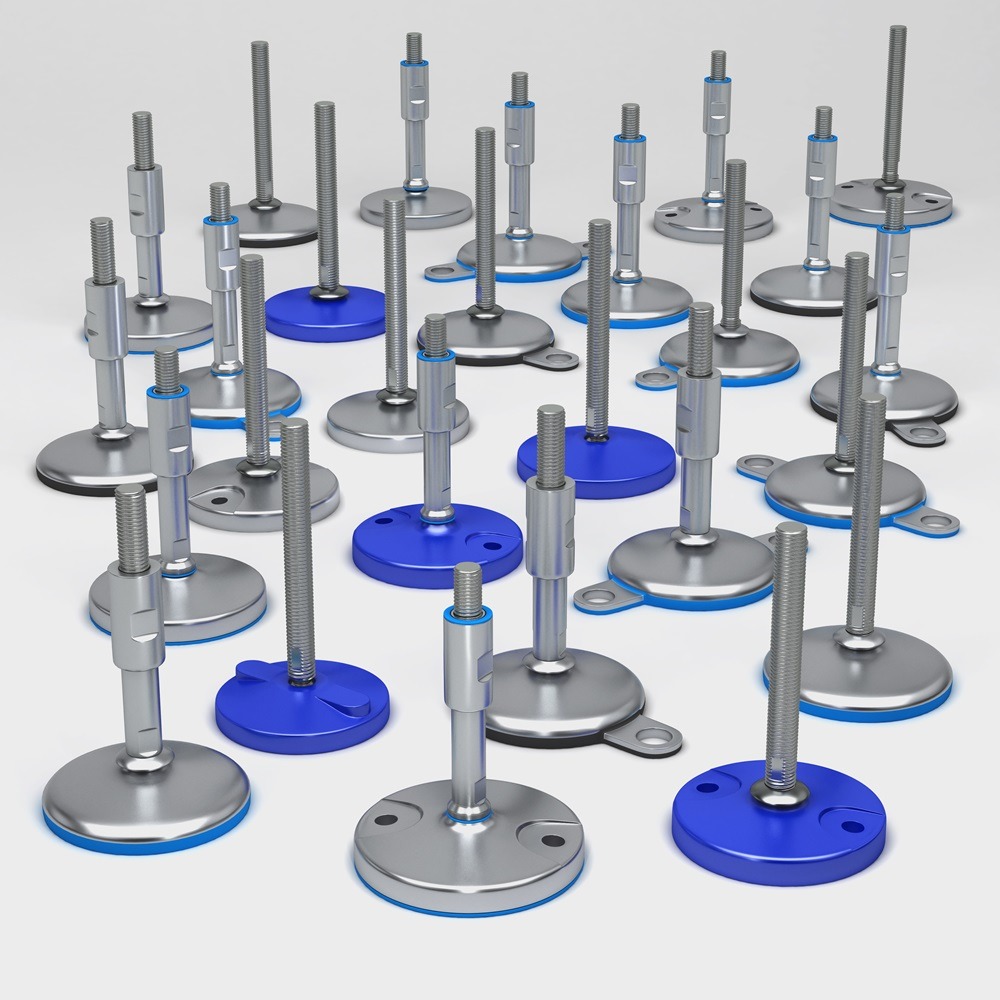

Machine parts in stainless steel hygienic design

In today’s industrial landscape, where stringent hygiene and safety standards are paramount, the demand for machine parts designed with hygiene and efficiency in mind is at an all-time high. Industries such as packaging, food processing, pharmaceuticals, and biotechnology face unique challenges related to contamination risks, production efficiency, and regulatory compliance. The adoption of stainless steel hygienic machine parts plays a critical role in meeting these challenges while enhancing strategic planning and operational development. This article explores the importance of stainless steel hygienic machine parts and how they contribute to the success of these industries. Stainless steel, particularly grades like 304 and 316, is widely recognized for its corrosion resistance, strength, and ability to withstand extreme environments. When it comes to hygienic design, stainless steel becomes an even more vital material due to its ease of cleaning, ability to resist bacterial buildup, and compatibility with cleaning agents used in high-sanitation environments. Hygienic machine parts, such as leveling feet, bearing units, and fasteners, are designed to minimize crevices, sharp corners, and flat surfaces where bacteria, dust, and other contaminants can accumulate. These designs ensure easy and thorough cleaning, reducing downtime for sanitation and maintenance, while adhering to regulatory requirements in industries like food and pharmaceutical manufacturing. The packaging industry is essential in ensuring that products are delivered safely and securely to consumers. Whether it’s food, pharmaceuticals, or biotechnology products, maintaining the integrity of the product during packaging is crucial. Stainless steel hygienic machine parts play a vital role in ensuring packaging machinery operates smoothly and maintains the required cleanliness standards. Strategic planning in the packaging industry revolves around maximizing uptime, ensuring product safety, and adhering to stringent hygiene regulations. Stainless steel machine components, such as hygienic conveyors and leveling feet, help maintain clean production environments, reduce the risk of contamination, and ensure machinery operates efficiently over extended periods. The use of hygienic machine parts in packaging allows companies to meet regulatory requirements set by bodies such as the FDA and ISO. These parts are designed to be robust, corrosion-resistant, and easy to clean, reducing the risk of contamination and ensuring smooth operation in high-speed packaging lines. This contributes to increased productivity, reduced downtime, and lower maintenance costs, making them an essential component in strategic development initiatives. In the food processing industry, hygiene is non-negotiable. Contaminants, bacteria, and allergens must be meticulously controlled to ensure the safety and quality of food products. Stainless steel hygienic machine parts are an integral part of food processing equipment, ensuring easy cleaning, resistance to corrosion, and compliance with food safety standards. Strategic planning in food processing includes optimizing workflows, reducing contamination risks, and ensuring regulatory compliance. By incorporating stainless steel hygienic components into machinery, food processing plants can minimize the risks of bacterial growth and cross-contamination. Components such as IP67 waterproof bearing units, hygienic conveyor systems, and leveling feet all contribute to safer, more efficient operations. Investing in hygienic machine parts ensures that food processing plants can operate continuously without compromising cleanliness. The durable and corrosion-resistant properties of stainless steel ensure long-lasting performance, which reduces the need for frequent part replacements and costly repairs. This investment leads to increased operational efficiency and greater customer trust in the safety and quality of processed foods. The pharmaceutical industry is subject to some of the most rigorous hygiene and safety standards in the world. From drug manufacturing to packaging, every step of the process must be executed with precision and cleanliness. Stainless steel hygienic machine parts, such as cleanable bearing units and stainless leveling feet, are designed to minimize contamination risks in pharmaceutical environments. Incorporating hygienic machine parts into strategic planning allows pharmaceutical companies to reduce downtime associated with cleaning and maintenance while ensuring full compliance with regulatory standards such as cGMP (current Good Manufacturing Practices). Hygienic components also ensure that equipment remains functional in sterile and cleanroom environments, supporting high-volume production of pharmaceutical products. By integrating stainless steel hygienic machine parts into pharmaceutical manufacturing equipment, companies can reduce the likelihood of contamination, improve overall equipment reliability, and enhance productivity. These improvements contribute to long-term strategic development goals, such as expanding production capacity and improving operational efficiency while maintaining stringent regulatory compliance. The biotechnology industry requires extreme levels of cleanliness and sterility, particularly in processes involving the manipulation of biological materials. Stainless steel hygienic machine parts are essential for maintaining clean environments that prevent contamination during production. Equipment such as hygienic pumps, clean-in-place (CIP) systems, and stainless steel valves ensures biotech facilities operate within regulatory standards while maintaining operational efficiency. Strategic planning in biotechnology focuses on ensuring that production environments meet strict sanitary guidelines while maximizing operational output. Stainless steel hygienic machine parts help achieve this by facilitating efficient cleaning processes and ensuring machinery operates without interruption, reducing the potential for contamination and costly downtime. The durability and low maintenance requirements of stainless steel hygienic machine parts allow biotech companies to focus on research and production without frequent disruptions for repairs or part replacements. This contributes to the scalability of biotech operations and supports long-term strategic development plans, such as expanding manufacturing capabilities and maintaining compliance with evolving regulatory standards. Stainless steel hygienic machine parts are a critical component in strategic planning and development across the packaging, food processing, pharmaceutical, and biotechnology industries. Their corrosion resistance, ease of cleaning, and compliance with strict hygiene standards make them indispensable for maintaining safe, efficient, and productive operations. By incorporating these components into machinery, companies can reduce contamination risks, enhance operational efficiency, and meet regulatory requirements—ultimately supporting their long-term strategic growth and development goals. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Block Units and Flange Bearings is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440 Stainless Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.Strategic Planning and Development Using Stainless Steel Hygienic Machine Parts in Packaging, Food Processing, Pharmaceutical and Biotechnology Industries

The Importance of Hygienic Design in Stainless Steel Machine Parts

Stainless Steel Hygienic Machine Parts in the Packaging Industry

Strategic Planning and Efficiency in Packaging

Development Benefits of Hygienic Machine Parts in Packaging

Stainless Steel Hygienic Machine Parts in the Food Processing Industry

Ensuring Food Safety with Hygienic Machine Parts

Development Opportunities with Hygienic Machine Parts in Food Processing

Stainless Steel Hygienic Machine Parts in the Pharmaceutical Industry

Meeting Regulatory Standards with Hygienic Machine Parts

Strategic Development in Pharmaceutical Manufacturing

Stainless Steel Hygienic Machine Parts in the Biotechnology Industry

The Role of Hygienic Design in Biotech Manufacturing

Development Advantages of Hygienic Machine Parts in Biotechnology

Machine parts in stainless steel hygienic design

Contact

Understanding Machinery Components & Protection Standards