Machine Feet: Performance Across Industries

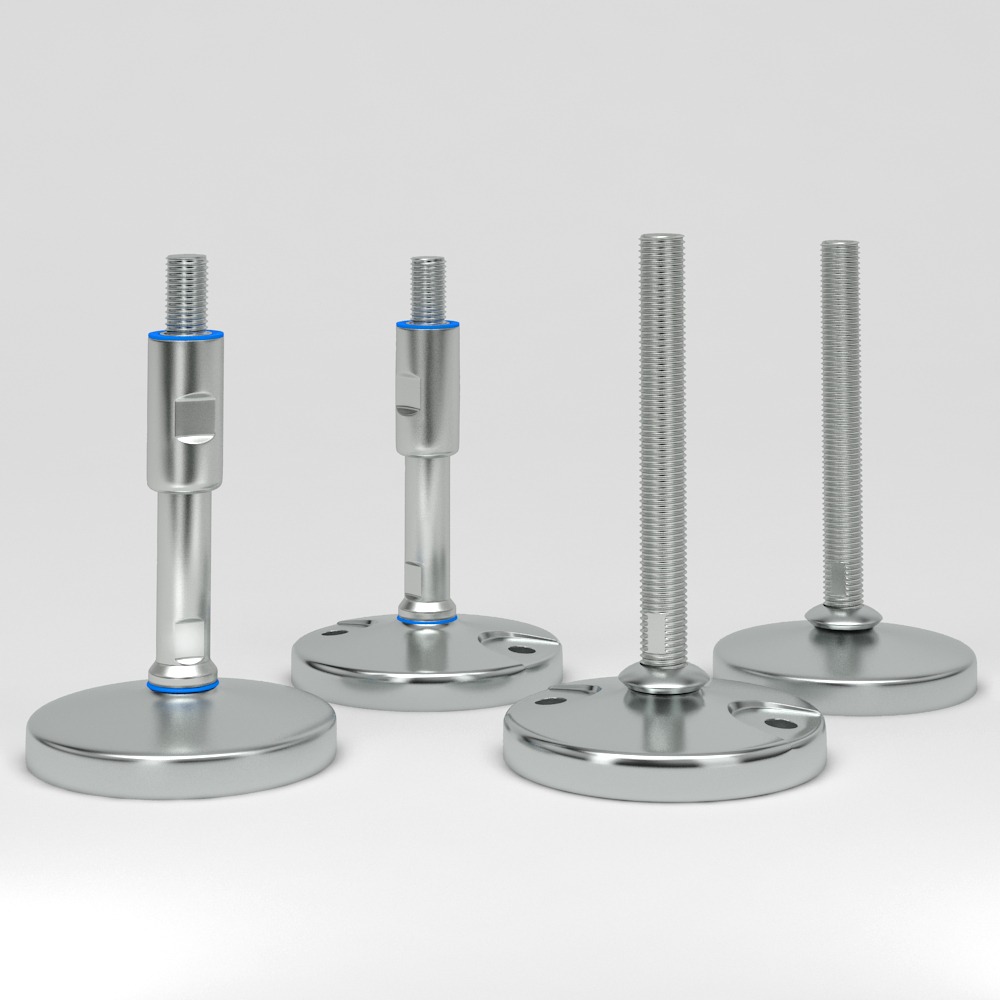

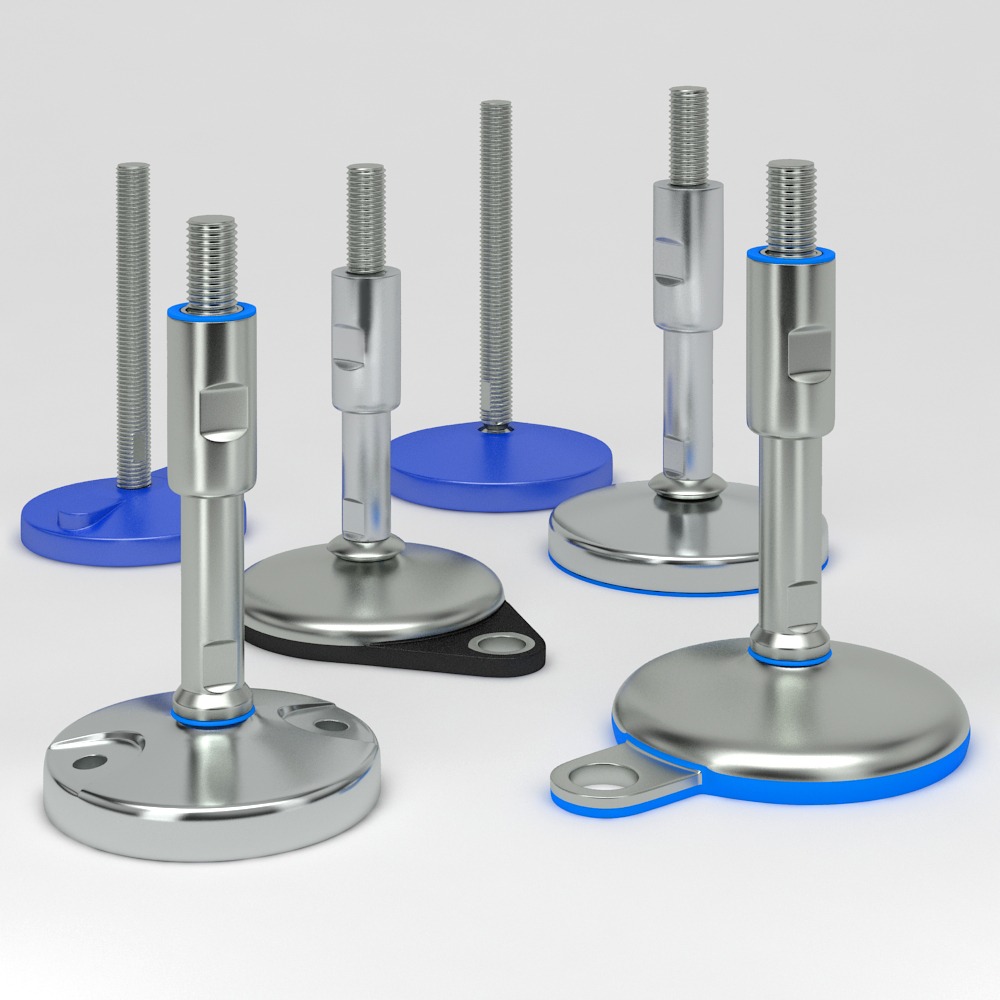

Machine feet are essential components in industrial applications. They ensure that machinery is stable, well-aligned, and safely positioned during operation. These feet, which are typically adjustable, allow for fine-tuning of machine height, ensuring optimal performance and minimizing wear and tear on equipment. In addition to their basic function of leveling, machine feet are used to absorb vibrations, distribute loads evenly, and protect surfaces from damage. Depending on the requirements, they are made from a variety of materials and come in different designs, each suited for specific industrial needs. In this article, we will dive into the usage, industries, and materials of machine feet, providing case studies, expertise from leading manufacturers, and insights on certifications that ensure quality and durability. The primary purpose of machine feet is to maintain stability and alignment. Machines that operate on uneven surfaces or floors can become prone to misalignment, which can affect their operation and lead to costly downtime. Machine feet provide a means to adjust the height of equipment, ensuring they remain level even in challenging environments. In high-speed manufacturing processes, machines often generate vibrations that can cause wear and fatigue over time. Specialized machine feet are designed to absorb these vibrations, which can reduce the mechanical stress on equipment and improve the overall life cycle of machinery. Industrial machines are often heavy and place significant pressure on the surfaces they stand upon. Machine feet help distribute this load evenly, preventing any one area from bearing too much weight. This not only protects the machine but also prevents floor damage, which can be costly to repair. Many machines require precise height adjustments for proper operation. Adjustable machine feet allow operators to easily level machinery, preventing potential problems related to misalignment or instability during production processes. Machine feet are integral to a wide range of industries. Their versatility and adaptability make them essential for maintaining the efficiency of manufacturing processes. Some of the industries that benefit most from machine feet include: In the food industry, hygiene and cleanliness are paramount. Machine feet used in food processing plants are designed to meet high hygienic standards. These feet are often made of stainless steel, which is corrosion-resistant and easy to clean, making them ideal for environments where contamination risks are high. Case Study: A major food production plant in Europe implemented stainless steel machine feet to support its conveyor systems. These machine feet not only helped maintain stable and even loading but also ensured compliance with hygiene standards. The plant saw a 20% reduction in machine downtime due to better stability and ease of cleaning. Pharmaceutical manufacturing involves precise operations, and maintaining the integrity of equipment is crucial. Machine feet in this industry are designed to prevent any instability that could affect the production of sensitive materials like drugs or vaccines. Case Study: A pharmaceutical facility producing injectable solutions replaced their outdated leveling feet with adjustable models made from FDA-approved materials. This upgrade improved the accuracy of their filling machines, resulting in a 15% improvement in production efficiency and a reduction in cross-contamination risks. Automotive production lines rely on heavy machinery that needs to be perfectly aligned. Machine feet in automotive factories are designed to handle heavy loads and high impact, ensuring that the machinery remains stable during high-speed assembly and testing processes. Case Study: A global automotive manufacturer in North America replaced traditional leveling feet with vibration-damping machine feet in their engine testing area. The result was a 30% reduction in vibration-related issues, which led to a more consistent product quality and fewer defective parts. In electronics manufacturing, precise assembly is key, and equipment must be kept level and stable at all times. Machine feet in this industry are often made from anti-static materials to prevent damage to sensitive components. Case Study: A leading electronics assembly plant upgraded its machinery with anti-vibration, anti-static adjustable feet to protect sensitive equipment from static build-up. This improved the quality of their products and minimized downtime caused by equipment malfunctions. Machine feet are made from various materials, each chosen for its ability to handle specific environmental conditions, loads, and vibration levels. The most common materials used include: Stainless steel is a popular material for machine feet, particularly in industries like food processing, pharmaceuticals, and healthcare, where cleanliness and corrosion resistance are crucial. Stainless steel machine feet are highly durable, easy to clean, and resistant to rust and corrosion. Nylon machine feet are often used in lighter applications, where there is less load-bearing and a need for abrasion resistance. These feet are ideal for indoor environments where hygiene is not as critical, though they may not offer the same level of durability as steel feet in heavy-duty applications. For heavy-duty machinery, cast iron machine feet are often used. Cast iron is ideal for high-load applications, as it can withstand significant pressure without deforming. However, it is less resistant to corrosion, so it is typically used in industrial environments where rusting is not a concern. Rubber is commonly used in machine feet designed to absorb vibrations. Rubber machine feet help reduce noise and vibrations in sensitive environments, making them ideal for manufacturing and lab applications. Rubber also offers anti-slip properties, which are beneficial in preventing machines from shifting during operation. Polyurethane is often chosen for its durability and resistance to wear, tear, and chemicals. It’s a popular choice in industries where exposure to oils, acids, or other harsh substances is common. Polyurethane machine feet also offer good shock absorption, which is valuable in reducing mechanical strain. Several manufacturers are known for producing high-quality machine feet for various industrial applications. These companies ensure that their products meet industry standards and provide the reliability required for high-performance operations. NHK Group is a leading manufacturer known for producing a wide range of machine feet. Their products are designed with advanced materials and technology to ensure long-lasting performance in heavy-duty applications, including automotive and food processing. Conveyor Parts is another reputable manufacturer that specializes in hygienic and durable machine feet. Their products are designed for industries that demand high standards of hygiene, such as food, pharmaceutical, and medical device manufacturing. Conveyor Parts‘s products are certified for their compliance with relevant industry standards. Load Feet specializes in machine feet that provide both high stability and vibration reduction. Their products are widely used in industries like electronics and automotive manufacturing, where precision and stability are critical. NHK Machinery Parts is a trusted manufacturer of machine feet used in various sectors, particularly in the chemical and agricultural industries. Their machine feet are known for their robust construction and resistance to environmental stressors. Machine feet must adhere to various certifications and standards to ensure their quality and safety. Some of the most common certifications for machine feet include: This certification ensures that manufacturers maintain a quality management system that meets international standards for production and customer satisfaction. In industries like food processing and pharmaceuticals, machine feet must meet FDA standards for materials that come into contact with food and medicinal products. FDA-approved materials like stainless steel are often used to ensure hygiene and safety. EHEDG (European Hygienic Engineering & Design Group) certification guarantees that the machine feet are designed to prevent bacterial growth and contamination in food and pharmaceutical production environments. One of the most effective ways to measure the value of machine feet is through customer feedback. “We’ve been using Conveyor Parts machine feet in our pharmaceutical production lines for over five years now, and they’ve exceeded our expectations. The stability and hygienic design have made a noticeable difference in the quality of our operations. We’ve experienced zero downtime related to leveling issues.” – Production Manager, Pharmaceutical Manufacturer “After upgrading our food processing plant with NHK Group adjustable machine feet, we saw a marked improvement in machine alignment and less wear on our equipment. These feet have made a huge difference in our operational efficiency.” – Head of Operations, Food Processing Plant Machine feet are essential components in maintaining the stability, precision, and efficiency of industrial machinery across various sectors. By providing solutions for vibration isolation, load distribution, and height adjustment, they ensure smooth operation and reduce the risk of equipment damage. Leading manufacturers like NHK Group provide high-quality, certified machine feet to meet the diverse needs of industries such as food processing, pharmaceuticals, and automotive manufacturing. Customer feedback highlights the significant improvements in operational efficiency and reliability when using high-quality machine feet, ensuring businesses can trust their machinery for the long haul. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Block Bearings and Flanged Bearings is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440 Grade Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.The Essential Role of Machine Feet in Industrial Efficiency

Machine Feet Usage: Stability and Efficiency

Stability and Alignment

Vibration Isolation

Load Distribution

Height Adjustment

Industries Using Machine Feet

Food Processing

Pharmaceuticals

Automotive Manufacturing

Electronics

Materials Used in Machine Feet

Stainless Steel

Nylon

Cast Iron

Rubber

Polyurethane

Leading Manufacturers of Machine Feet

NHK Group

Conveyor Parts

Load Feet

NHK Machinery Parts

Certifications and Standards

ISO 9001:2015

FDA Approval

EHEDG Certification

Trust and Reliability

Elevating Pharmaceutical Production

How Conveyor Parts Machine Feet Improved Stability and Hygiene

Boosting Operational Efficiency

NHK Group Adjustable Machine Feet Revolutionize Food Processing Plant Performance

Efficiency of industrial machinery

Contact

Understanding Machinery Components & Protection Standards