Long-term cost savings and improve competitive edge

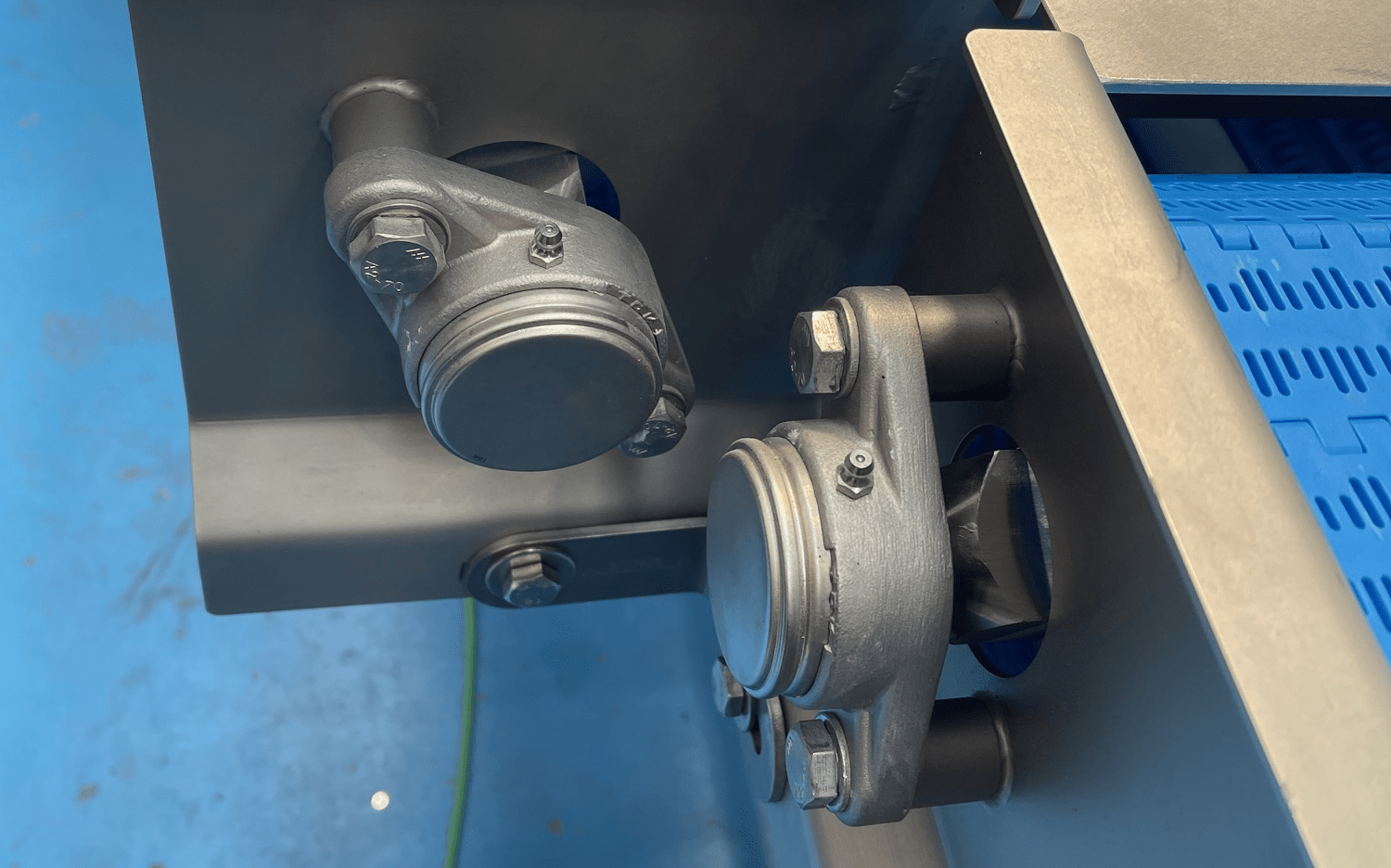

In the modern food and beverage industry, hygiene and safety are paramount. As companies strive to meet strict regulatory standards and consumer expectations, they seek solutions that not only ensure compliance but also offer long-term economic benefits. This is where EHEDG and 3-A SSI certified components and parts come into play. These certifications guarantee that equipment is designed and constructed to meet the highest hygiene standards, leading to significant cost savings and a stronger competitive edge in the marketplace. The European Hygienic Engineering and Design Group (EHEDG) and 3-A Sanitary Standards, Inc. (3-A SSI) are two leading organizations dedicated to promoting hygiene in the design and manufacturing of food processing equipment. EHEDG is a consortium of equipment manufacturers, food industries, research institutes, and public health authorities. It was founded in 1989 with the primary aim of improving hygiene during the processing and packaging of food products. EHEDG certification ensures that equipment is designed to be easily cleaned and sanitized, minimizing the risk of contamination. 3-A SSI, on the other hand, is an American organization that has been setting sanitary standards for dairy and other food processing equipment since 1920. The 3-A symbol is a mark of assurance that equipment meets stringent sanitary standards, is easy to clean, and is constructed using materials that resist bacterial growth. The primary benefit of using EHEDG and 3-A SSI certified components is improved food safety. These certifications ensure that equipment meets rigorous standards for hygiene and sanitation, reducing the risk of contamination and foodborne illnesses. This is crucial for maintaining consumer trust and meeting regulatory requirements. Both EHEDG and 3-A SSI certifications align with international food safety regulations, including those set by the FDA, USDA, and European Commission. By using certified components, companies can ensure compliance with these regulations, avoiding costly fines and potential shutdowns. Certified components are designed for easy cleaning and maintenance, reducing downtime and labor costs associated with cleaning processes. This leads to improved operational efficiency, allowing companies to maximize production and reduce costs. While the initial investment in certified components may be higher, the long-term cost savings are substantial. Reduced maintenance costs, lower risk of contamination-related recalls, and improved equipment lifespan all contribute to significant savings over time. Consumers are increasingly aware of food safety issues and prefer products from companies that prioritize hygiene and safety. By using EHEDG and 3-A SSI certified components, companies can differentiate themselves from competitors and enhance their brand reputation. When integrating EHEDG and 3-A SSI certified components into your production line, consider the following factors: Choose equipment that is specifically designed for your industry and meets the necessary hygiene standards. Consider factors such as material compatibility, ease of cleaning, and durability. Ensure that your staff is trained on the proper use and maintenance of certified equipment. This will help maximize the benefits of the investment and ensure compliance with hygiene standards. Conduct regular audits and inspections of your equipment to ensure continued compliance with EHEDG and 3-A SSI standards. This will help identify potential issues before they become costly problems. Stay informed about the latest advancements in hygienic design and continuously improve your processes to maintain a competitive edge. Several companies have successfully implemented EHEDG and 3-A SSI certified components, reaping significant benefits in terms of cost savings and competitive advantage. A leading dairy processing plant in Europe invested in EHEDG certified components for their production line. The result was a 30% reduction in cleaning time and a 20% increase in production efficiency. Additionally, the company reported fewer instances of contamination, leading to a stronger brand reputation and increased market share. An American beverage manufacturer switched to 3-A SSI certified components to comply with new FDA regulations. The transition led to a 25% decrease in maintenance costs and a 15% increase in equipment lifespan. The company also gained a competitive edge by promoting their commitment to food safety, resulting in a 10% increase in sales. Incorporating EHEDG and 3-A SSI certified components and parts into your production processes offers numerous benefits, from enhanced food safety and regulatory compliance to long-term cost savings and a competitive edge. As the food and beverage industry continues to evolve, companies that prioritize hygiene and safety will be better positioned to succeed in the marketplace. By investing in certified components, you are not only ensuring the safety and quality of your products but also setting the stage for sustainable growth and success. Embrace the advantages of EHEDG and 3-A SSI certifications and watch your business thrive in a competitive landscape. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Bearing Housings and Flanged Bearings is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. Type 440 Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.Ensuring Long-Term Cost Savings and Improving Competitive Edge

Understanding EHEDG and 3-A SSI Certifications

EHEDG Certification

3-A SSI Certification

Benefits of Using EHEDG and 3-A SSI Certified Components

1. Enhanced Food Safety

2. Compliance with Regulatory Standards

3. Improved Operational Efficiency

4. Long-Term Cost Savings

5. Competitive Edge in the Marketplace

Key Considerations for Implementing Certified Components

1. Equipment Selection

2. Training and Education

3. Regular Audits and Inspections

4. Continuous Improvement

Case Studies: Success Stories with EHEDG and 3-A SSI Certified Components

Case Study 1: Dairy Processing Plant

Case Study 2: Beverage Manufacturer

EHEDG and 3-A SSI Certified Components and Parts

Ensuring Long-Term Cost Savings and Improving Competitive Edge

Contact

Understanding Machinery Components & Protection Standards