Leveling Feet for Industrial Equipment

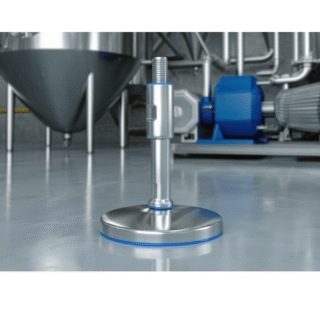

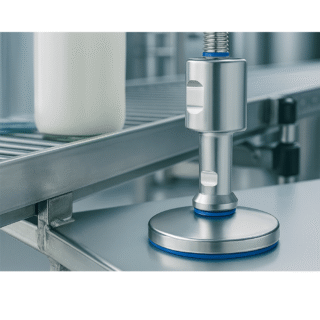

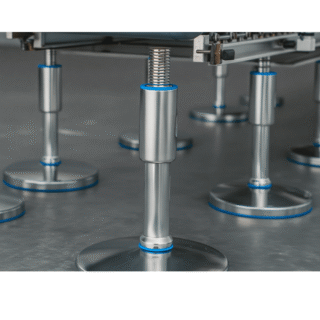

When it comes to maintaining the stability and accuracy of machinery in industrial settings, FPL Steel Group has earned a reputation for offering top-quality leveling hardware. Designed to provide robust solutions for a wide range of sectors, including food processing, pharmaceutical, and biotechnology industries, their products stand out for their durability, ease of maintenance, and hygienic designs. Leveling hardware refers to the components that support and stabilize machinery, ensuring it remains level and firmly positioned during operations. These products are essential for enhancing the precision of industrial processes, reducing vibration, and preventing operational inefficiencies. FPL Steel Group’s range of leveling hardware is crafted from high-quality materials such as stainless steel to offer superior performance in demanding environments. FPL Steel Group has built a reputation for manufacturing high-performance components that meet the strictest standards in industries requiring hygienic and durable solutions. Their leveling hardware products are designed to withstand the stresses of continuous operations while ensuring ease of use and maintenance. Their range of leveling feet, mounts, and accessories ensures that machinery remains securely in place, even in the most demanding environments. From food and beverage production lines to complex pharmaceutical manufacturing setups, FPL Steel Group’s products are engineered to perform under pressure. Leveling hardware from FPL Steel Group is designed for precision. The ability to fine-tune the height and stability of machinery is crucial for maintaining optimal performance. Whether it’s a conveyor system or complex production equipment, their leveling feet provide the necessary adjustments to maintain accuracy in the alignment of machinery. FPL Steel Group prioritizes durability in all their products. Their leveling hardware is constructed from high-quality stainless steel and other corrosion-resistant materials, making them ideal for environments subject to frequent cleaning, humidity, or exposure to chemicals. Whether it’s for a food processing line or pharmaceutical machinery, these components are built to last, ensuring long-term performance. Hygiene is critical in industries such as food processing, pharmaceuticals, and biotechnology. FPL Steel Group understands the importance of sanitary standards in these sectors. Their leveling hardware is designed with easy-to-clean surfaces that prevent contamination and buildup of dirt or bacteria. Smooth finishes and corrosion-resistant coatings ensure that their components are both hygienic and visually appealing. From heavy-duty industrial equipment to lightweight machinery, FPL Steel Group offers leveling hardware solutions that cater to a wide variety of needs. Their components are designed for diverse applications in food manufacturing, pharmaceuticals, biotechnology, and other industries. This versatility ensures that no matter the scale or complexity of the machinery, FPL Steel Group has the right solution. As sustainability becomes an increasingly important concern across industries, FPL Steel Group ensures that its manufacturing processes are efficient and environmentally friendly. The materials used in the production of their leveling hardware are sourced responsibly, and the products are designed to have a long lifespan, reducing the need for frequent replacements. FPL Steel Group’s leveling hardware plays a critical role in a range of industries, ensuring that machinery is both stable and efficient. Some key applications include: In the food industry, maintaining hygiene and operational efficiency is paramount. FPL Steel Group’s leveling feet and mounts are perfect for ensuring that equipment such as mixers, grinders, and packaging machines remain perfectly aligned and stable. Their easy-to-clean designs are well-suited to environments that require regular sanitation, minimizing the risk of contamination. Pharmaceutical manufacturing requires the highest levels of precision and sanitation. FPL Steel Group’s leveling hardware is used in a variety of pharmaceutical equipment, including mixers, grinders, and packaging lines. The ability to adjust the height of machinery with precision ensures that processes such as tablet compression or liquid filling are carried out flawlessly. The biotechnology sector often involves sophisticated equipment that must be precisely calibrated. FPL Steel Group’s leveling hardware is used in laboratory machinery, fermenters, and bioreactors, providing the necessary stability to ensure that experiments and production processes are carried out accurately. In addition to the food, pharmaceutical, and biotechnology industries, FPL Steel Group’s leveling hardware is also widely used in packaging lines, heavy machinery, and other manufacturing environments. The versatility and durability of these products make them ideal for industries that require high performance under continuous operation. FPL Steel Group is a leader in providing leveling hardware that meets the highest standards of precision, durability, and hygiene. Their products are designed to perform in the most demanding environments, ensuring that machinery remains stable, reducing vibrations, and increasing operational efficiency. Every product from FPL Steel Group is crafted with quality in mind. With stringent testing and high manufacturing standards, their leveling hardware is built to provide reliable performance for years. FPL Steel Group is known for its excellent customer support, providing customized solutions to meet specific industrial needs. Their team works closely with clients to understand their requirements and provide tailored solutions for optimal machinery stability. FPL Steel Group’s leveling hardware represents a reliable and high-quality solution for maintaining the stability and efficiency of industrial machinery. With their precision engineering, robust construction, hygienic designs, and versatility across various sectors, their products offer unmatched performance for industries such as food processing, pharmaceuticals, and biotechnology. When it comes to leveling hardware, FPL Steel Group remains a trusted choice for industries around the world. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Block Units and Flange Bearing Units is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440 Grade Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.FPL Steel Group’s Leveling Hardware:

Precision and Durability for Industrial Applications

Get our catalogue here

See our product line here

What is Leveling Hardware?

FPL Steel Group: A Legacy of Innovation and Quality

Key Features of FPL Steel Group’s Leveling Hardware

1. Precision Engineering

2. Durable and Robust Construction

3. Hygienic and Easy to Clean

4. Versatility in Application

5. Sustainability and Environmental Considerations

Applications of FPL Steel Group’s Leveling Hardware

1. Food Processing Industry

2. Pharmaceutical Industry

3. Biotechnology Sector

4. Packaging and Other Industries

Why Choose FPL Steel Group?

Superior Quality

Exceptional Customer Service

FPL Steel Group’s Leveling Hardware

The Ultimate Solution for Industrial Precision and Stability”

Check out our other articles:

Contact

Understanding Machinery Components & Protection Standards