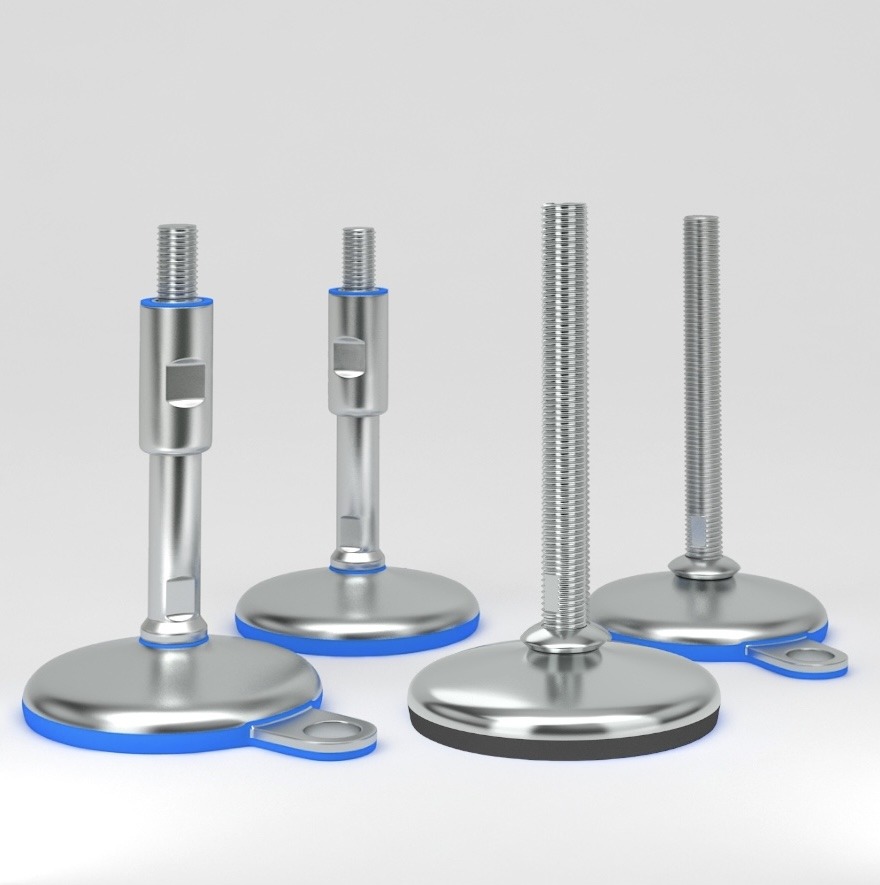

Leveling Feet in Stainless Steel across sanitary Industries

As global demand for high-quality, efficient packaging and processing solutions rises, businesses are turning to strategic innovations in equipment to maintain their competitive edge. One critical, yet often overlooked, component in this machinery ecosystem is the stainless steel leveling foot. Used to stabilize and elevate equipment, leveling feet contribute significantly to production efficiency, regulatory compliance, and product safety in industries such as food and beverage, pharmaceuticals, and cosmetics. In this article, we explore the importance of stainless steel leveling feet in strategic planning and development for these essential sectors. Stainless steel leveling feet are not merely support components but are vital assets in maintaining equipment stability, particularly in industries where hygiene, stability, and corrosion resistance are top priorities. Engineered to withstand extreme conditions and frequent washdowns, these leveling feet are ideal for equipment in cleanrooms and production environments where contamination control is critical. In the realm of strategic planning, stainless steel leveling feet offer long-term advantages that directly impact a company’s efficiency, safety standards, and regulatory compliance. Stainless steel leveling feet contribute significantly to the efficiency of production lines by providing stability to large machinery, reducing vibration, and minimizing the risk of operational downtime. Strategically implementing these components ensures that equipment remains aligned and operates at optimal performance levels. Furthermore, as equipment becomes heavier and more complex, leveling feet capable of supporting substantial loads prevent unwanted movement and ensure a safer working environment. The durability of stainless steel under challenging environmental conditions extends the lifespan of leveling feet, reducing the frequency of replacement. This translates into substantial cost savings over time, a key element in strategic budgeting and development. Packaging and processing industries often operate in high-humidity, corrosive environments where machinery undergoes regular cleaning with chemicals. Stainless steel leveling feet resist rust and corrosion, making them a cost-effective choice for industries requiring consistent, long-term performance. In industries such as food processing and pharmaceuticals, maintaining hygiene standards is non-negotiable. Leveling feet made from stainless steel are easy to clean, resistant to bacterial growth, and suitable for compliance with strict regulations like those set by the FDA and EU for food safety. These features align with a company’s strategic development goals by ensuring compliance with global standards, reducing the risk of contamination, and supporting positive brand reputation. Different sectors within packaging and processing benefit from stainless steel leveling feet in ways tailored to their specific production and regulatory needs. In food and beverage processing, equipment stability is critical to maintaining consistency in product quality. Stainless steel leveling feet not only support large mixers, fillers, and conveyor systems but also withstand frequent washdowns, which helps in meeting sanitation requirements. This reliability forms the foundation for building consumer trust, as it minimizes the risk of contamination while maintaining high product quality. For the pharmaceutical industry, where precision and contamination control are paramount, stainless steel leveling feet provide an additional layer of security. Equipment used in sterile environments requires minimal vibration and absolute stability. These leveling feet are used for equipment such as mixers, tablet presses, and capsule fillers, ensuring minimal vibration during operation, which is crucial for consistency and quality in pharmaceutical production. In the cosmetics sector, packaging and filling equipment must be aligned precisely for products such as lotions, creams, and gels. Leveling feet ensure the stability and alignment necessary for accurate filling, reducing product waste and maintaining brand integrity. Since cosmetics often contain various chemicals, stainless steel leveling feet offer excellent resistance to corrosive agents, extending the life of the equipment and upholding production efficiency. The chemical industry often deals with corrosive substances and extreme temperatures. Here, stainless steel leveling feet ensure machinery stability and provide resistance to both high temperatures and corrosive chemicals. This versatility makes them ideal for strategic development in industries where diverse operational demands require reliable, adaptable equipment components. Strategically planning for the inclusion of durable, hygienic components like stainless steel leveling feet is an integral part of development in high-stakes industries. Here’s how companies can incorporate these components to maximize operational benefits. An equipment audit helps identify areas where stability and hygiene are compromised. This audit assesses equipment that could benefit from enhanced leveling solutions. Strategically addressing these areas ensures smoother operations and lowers maintenance costs over time. High-quality stainless steel leveling feet may come at a higher initial cost, but the long-term benefits far outweigh the expense. Companies should evaluate suppliers based on certifications, such as FDA and NSF, to ensure they meet industry standards for hygiene and durability. As industries evolve, so do their equipment needs. Forward-thinking businesses should consider leveling feet that offer adjustability to adapt to future machinery or changes in floor plans. Planning with future growth in mind saves costs and prevents operational disruptions as production expands or evolves. Selecting the right leveling feet involves evaluating the needs of the specific application. Key considerations include: In today’s competitive packaging and processing industries, strategic planning goes beyond simply acquiring high-performing machinery; it involves every component that keeps equipment operating smoothly, safely, and hygienically. Stainless steel leveling feet are a critical aspect of this strategy, providing stability, longevity, and compliance benefits. By prioritizing durable, corrosion-resistant components, companies can achieve operational efficiency, maintain regulatory compliance, and foster a reputation for quality and reliability. Investing in stainless steel leveling feet is a decision that supports both immediate production needs and long-term growth, making them an essential asset in the strategic development of the packaging and processing sectors. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Bearing Housings and Flange Bearing Units is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440 Stainless Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.The Role of Stainless Steel Leveling Feet in Strategic Planning and Development Across Packaging and Processing Industries

Understanding the Importance of Stainless Steel Leveling Feet

Strategic Benefits of Using Stainless Steel Leveling Feet

1. Enhanced Operational Efficiency

2. Durability and Cost Savings

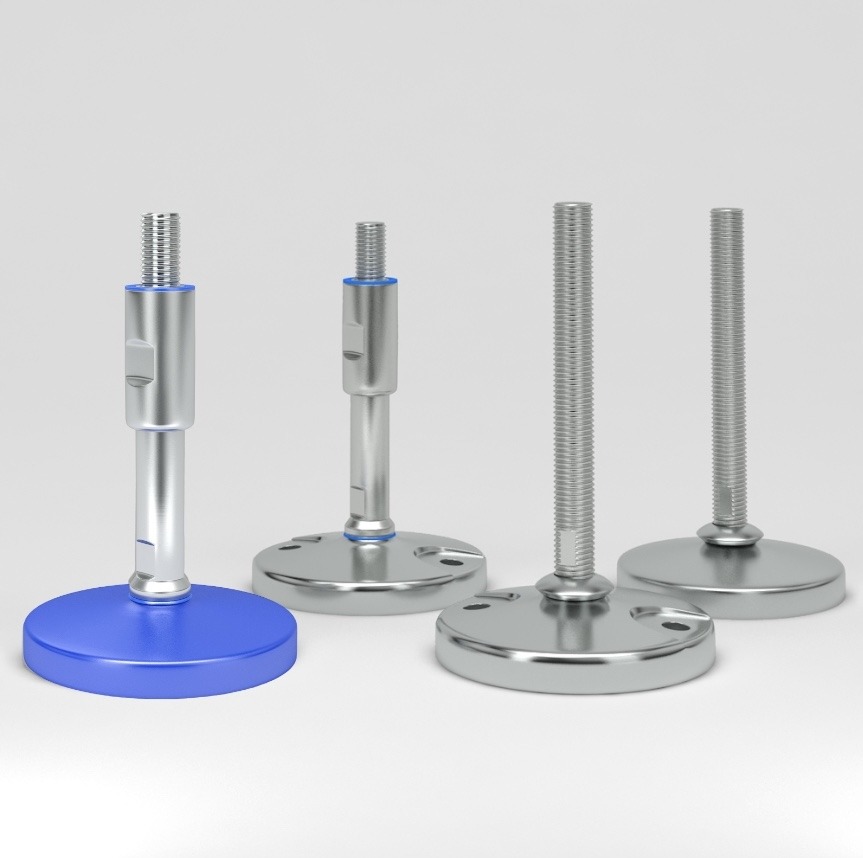

3. Hygienic Design for Compliance with Regulations

Applications of Stainless Steel Leveling Feet Across Industries

Food and Beverage Processing

Pharmaceutical Processing

Cosmetic and Personal Care Industry

Chemical and Industrial Packaging

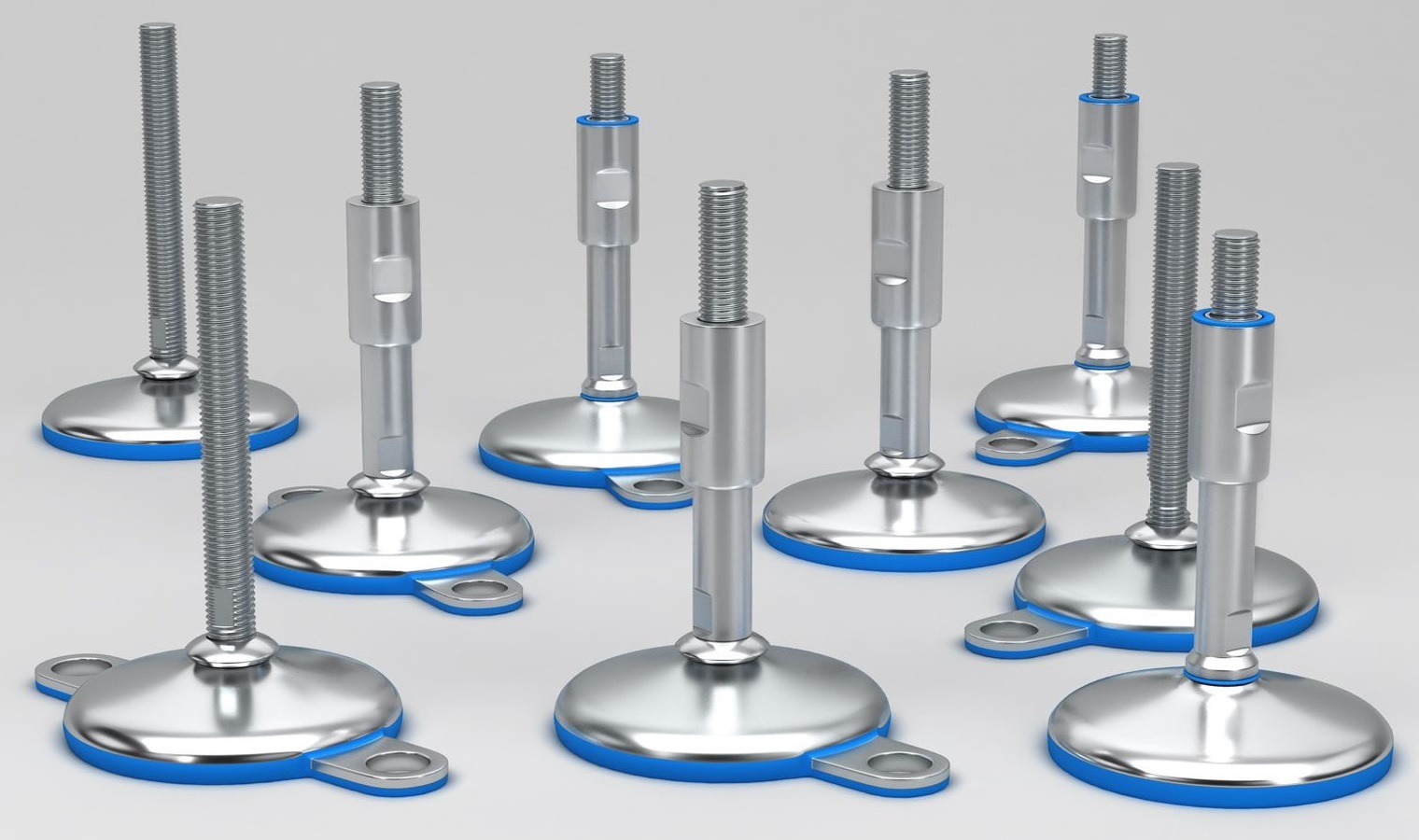

Incorporating Stainless Steel Leveling Feet into Strategic Development

Conducting an Equipment Audit

Investing in High-Quality Leveling Feet

Planning for Future Needs

Selecting the Right Stainless Steel Leveling Feet

Strategic Planning and Development with Stainless Steel Leveling Feet in Packaging and Processing Industries

Contact

Understanding Machinery Components & Protection Standards