Liquid Processing Equipment: Hidden Contamination Sources in Machine Components

In the world of liquid processing—whether you are producing beverages, dairy products, sauces, or pharmaceuticals—the absolute purity of your product is non-negotiable. Your facility is designed around closed systems, clean-in-place (CIP) protocols, and precise flow control. However, from our extensive experience at NHK Group, we know that a significant risk of contamination often comes from the external support components: the very parts your equipment stands on and moves with.

A standard industrial castor that isn’t fully sealed or a leveling foot with exposed threads can trap residual liquids and cleaning agents, creating a hidden breeding ground for bacteria right on your production floor. This article explores the critical components that every modern liquid processing facility needs to ensure uncompromising hygiene and operational reliability.

The Core Challenge: Constant Wetness, Corrosive Agents, and Aseptic Needs

Liquid processing environments are relentless on machinery components. They must endure:

Permanent Wet Conditions: Constant exposure to the product itself, water, and condensation.

Aggressive Cleaning (CIP): Frequent cycles with hot water, acids, and caustic solutions to sterilize the system.

Cross-Contamination Risks: Any unsealed or hard-to-clean part can harbor microbes that could compromise the next production batch.

Mechanical Stress: The weight of tanks, mixers, and pumps puts enormous strain on support structures.

Our Solution: Engineering for a Liquid-Proof Environment

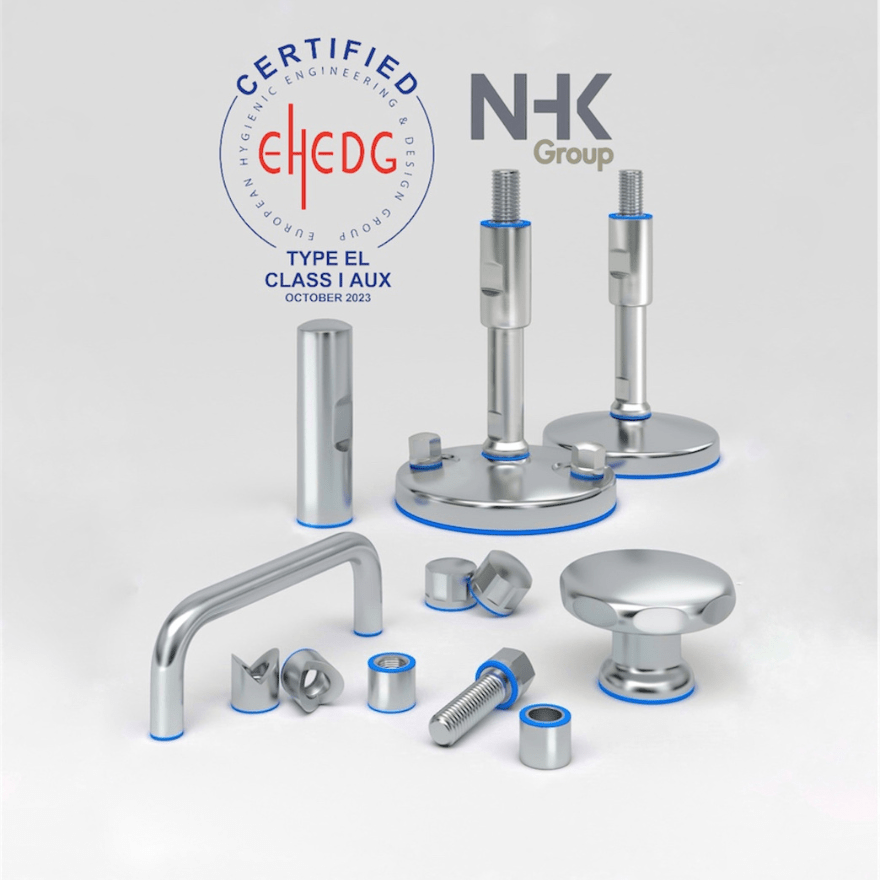

At NHK Group, we don’t just make parts; we engineer hermetically sealed, corrosion-proof solutions designed specifically for these challenges. Our philosophy is that every component must be an impenetrable barrier to contaminants. Here’s how our key products deliver on this promise:

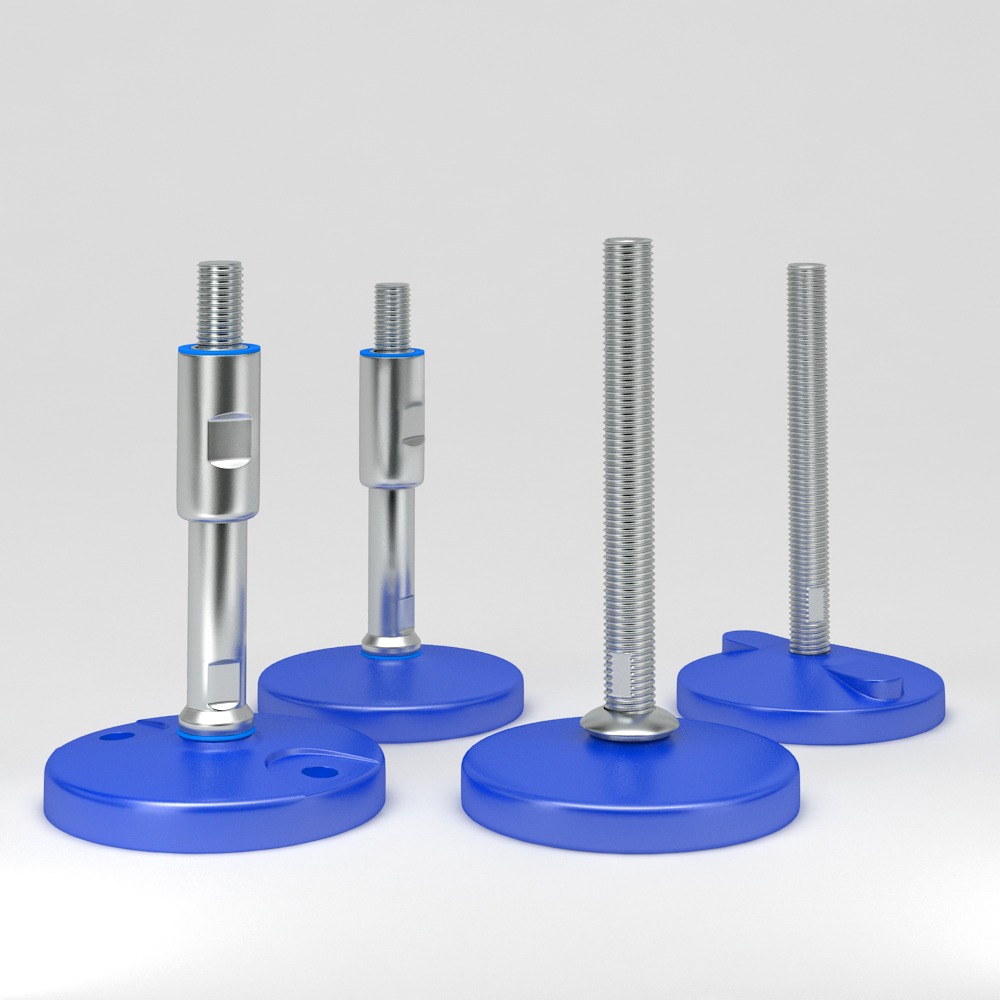

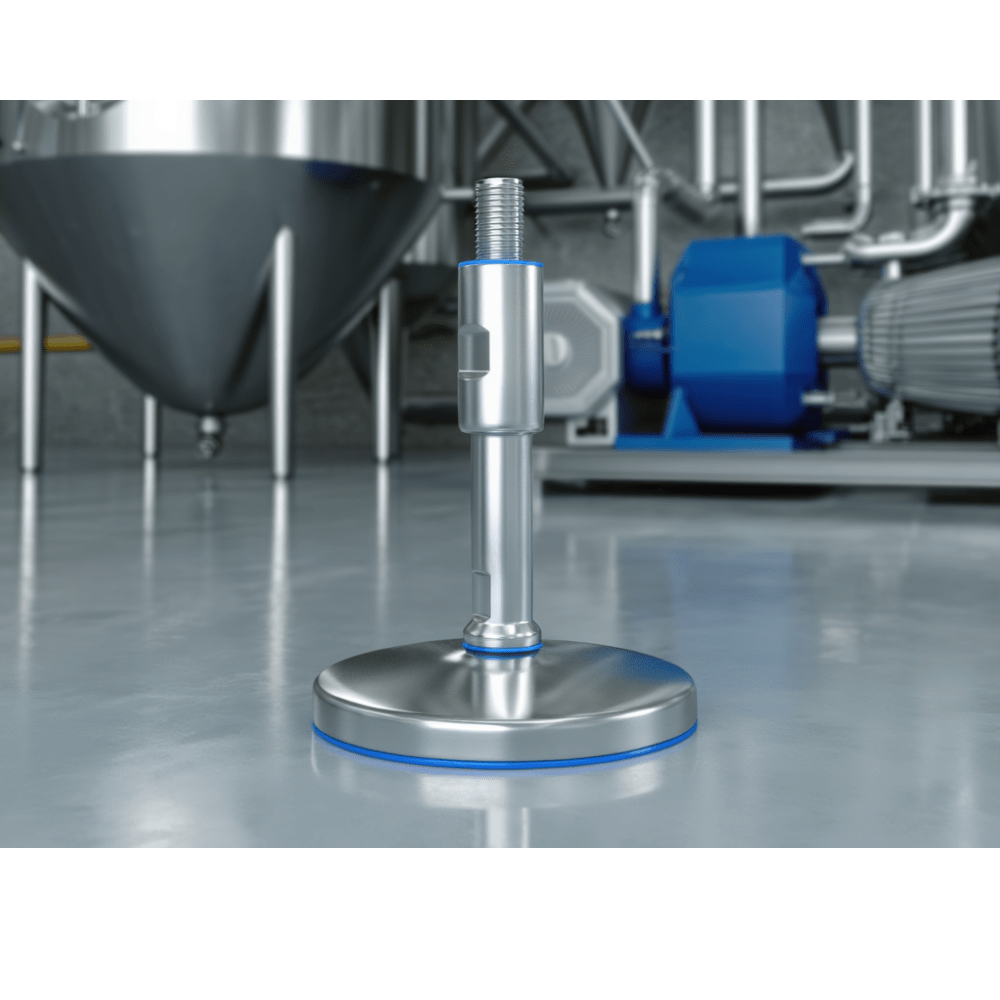

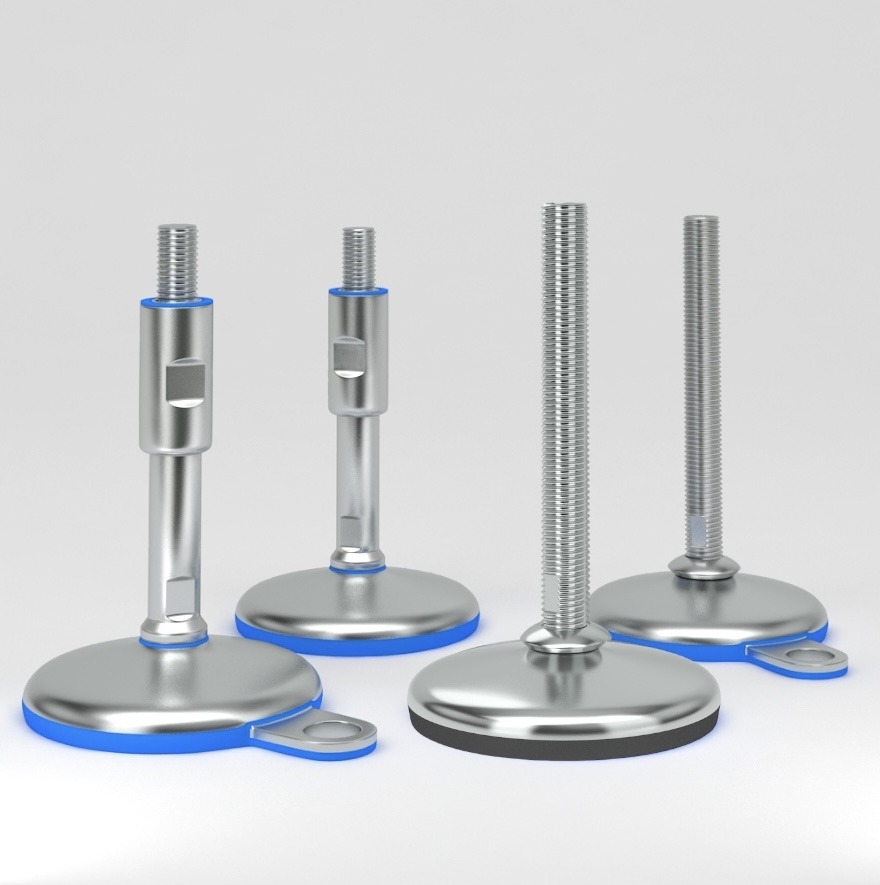

1. The Foundation: Absolute Stability with Hygienic Levelling Feet

The Challenge: Heavy liquid storage tanks, mixers, and filling lines must be perfectly level and stable, with no risk of liquids pooling at the base or seeping into threads.

Our Solution: Our hygienic levelling feet are the bedrock of a sanitary liquid processing setup. We craft them from polished 316L stainless steel for ultimate resistance to corrosive cleaning fluids. Their sealed, self-draining design and fully encapsulated threads are EHEDG certified, guaranteeing they meet the highest standards of cleanability and prevent any risk of contamination.

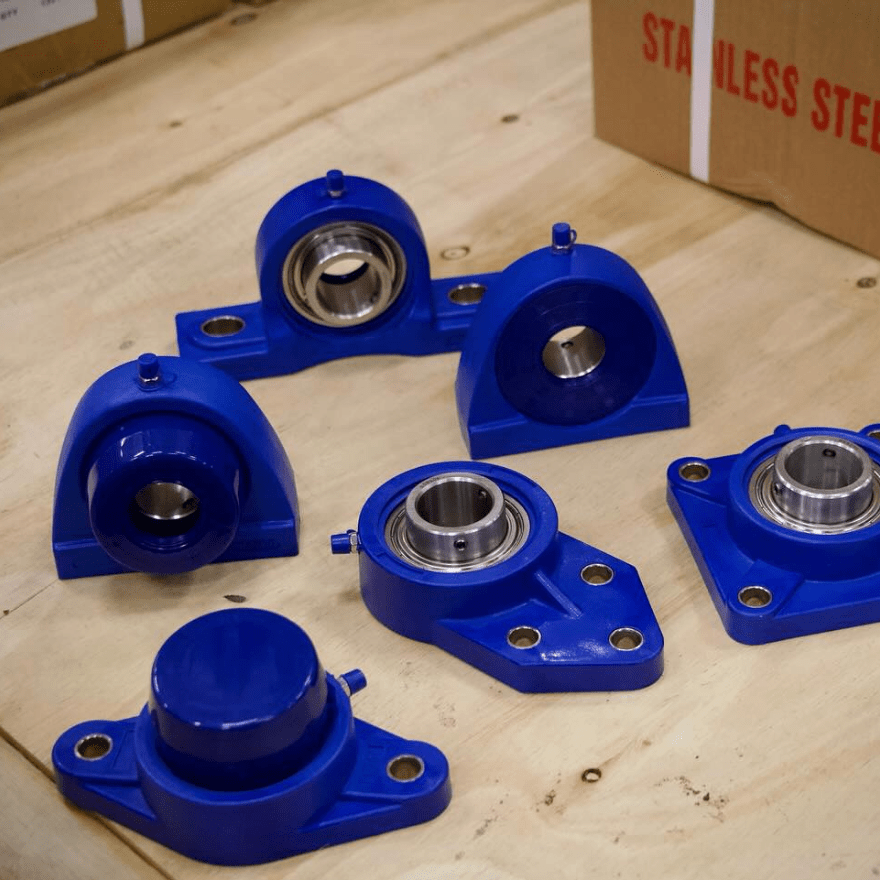

2. Flawless Motion: IP67 Waterproof Bearing House Units

The Challenge: Bearings on pumps, agitators, and conveyors in liquid environments are prime candidates for failure due to fluid ingress, which causes corrosion and lubricant washout.

Our Solution: Our IP67 waterproof bearing house units are an essential specification for any liquid processing line. The IP67 rating ensures a complete, submersible-grade seal that protects the bearing from high-pressure jets and even temporary immersion. This guarantees long, maintenance-free operation and eliminates the risk of lubricant contaminating your product.

3. Sanitary Mobility: Hygienic Industrial Castors

The Challenge: Mobile processing vessels, carts, and tanks must be moved safely and easily across wet floors without becoming a contamination vector.

Our Solution: Our hygienic industrial castors are designed for the most demanding sterile environments. With fully sealed bearings and smooth, non-porous wheels made from FDA-compliant materials, they can be thoroughly cleaned and sanitized, ensuring they uphold the hygienic integrity of your facility.

4. Total System Integrity: Every Detail Engineered for Hygiene

The Challenge: A truly hygienic system has no weak points. Every clamp, handle, and bracket must be designed to the same high standard.

Our Solution: Our comprehensive range of hygienic machinery components in stainless steel provides a complete solution. From sealed nuts to polished stainless steel brackets, we ensure every element of your equipment is designed to prevent contamination and withstand aggressive cleaning protocols.

The Real-World Impact: From Risk Management to Increased Uptime

The benefits of using components truly designed for liquid processing are clear. For example, a major European beverage manufacturer was able to extend the maintenance intervals on their main mixing vessels by 300% simply by switching from standard bearings to our IP67 waterproof units. This translated directly into increased production uptime and significant cost savings.

Conclusion: Build Your Liquid Processing Line on a Foundation of Purity

In the liquid processing industry, product purity is your bond of trust with the consumer. By partnering with a specialist manufacturer like NHK Group, you ensure your facility is built with components that are not just high-quality, but expertly engineered to eliminate contamination risks at every level.

Ready to create a truly liquid-proof and hygienic production environment?

Our experts are ready to help you select the most reliable and compliant components for your needs.

Contact

Understanding Machinery Components & Protection Standards

Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Blocks and Flange Bearing Units is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. Type 440 Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.