The Unseen Corrosive Threat in Food Preserving: Are Your Machine Components Failing Silently?

In the food preserving industry—from canning and bottling to pickling and freezing—the primary goal is to lock in freshness and ensure long-term product safety. Your processes are designed to be robust and reliable. However, from our deep experience at NHK Group, we know that the very agents you use to preserve food—such as acids (vinegar), brines (salt), and sugars—are relentlessly attacking your equipment.

A standard, non-specialized machine component may look fine on the outside, but corrosion can be eating away at it silently, leading to premature failure, contamination risks, and costly production halts. This article explores the critical components that every modern food preserving facility needs to combat this corrosive threat and uphold the highest standards of hygiene.

The Core Challenge: Aggressive Brines, Acids, and High Temperatures

The food preserving environment is uniquely harsh. Your equipment must withstand:

Chemical Corrosion: Constant exposure to acidic marinades, salty brines, and sugary syrups, which are highly corrosive to standard metals.

Thermal Shock: Rapid temperature changes during pasteurization, sterilization (autoclaving), and cooling cycles.

Intense Washdowns: Daily high-pressure cleaning with aggressive detergents to ensure absolute hygiene.

Standard components made from basic steel or even lower-grade stainless steel (like 304/V2A) will inevitably fail under these conditions.

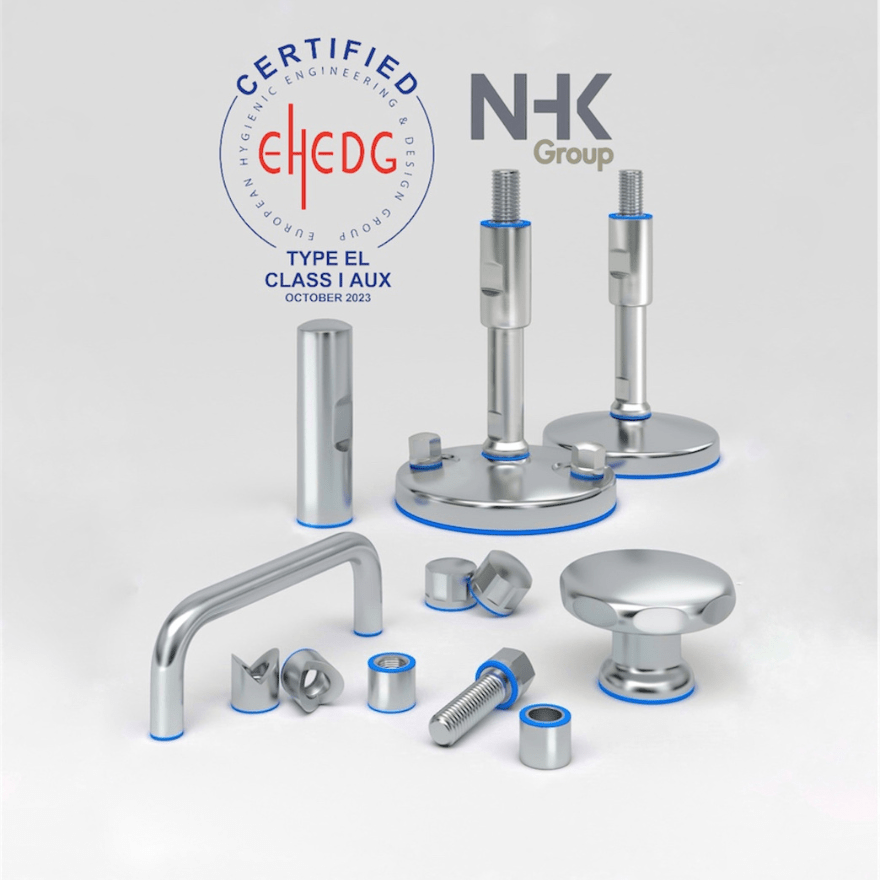

Our Solution: Engineering for Ultimate Corrosion Resistance

At NHK Group, we engineer our hygienic components specifically to thrive in these chemically aggressive and high-temperature environments. Our philosophy is that every part must be a bastion of durability and cleanliness. Here’s how our key products solve the core challenges of your industry:

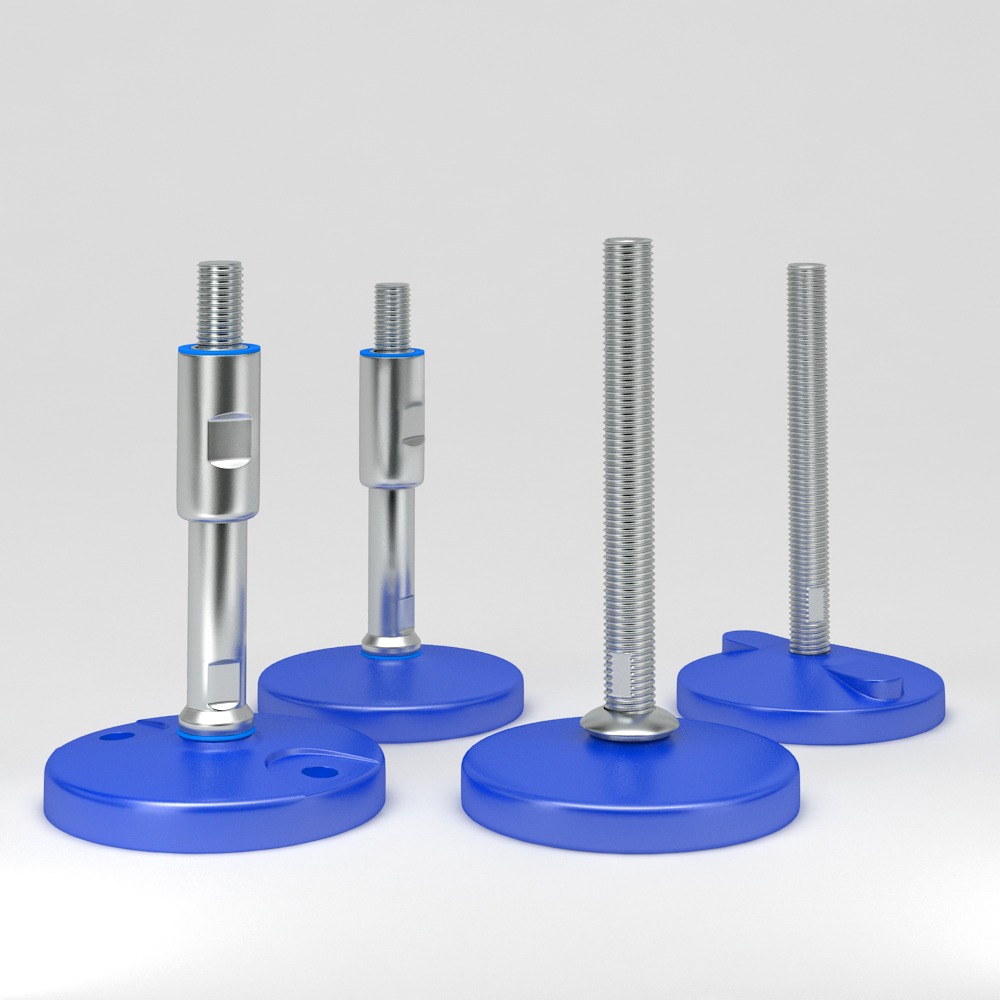

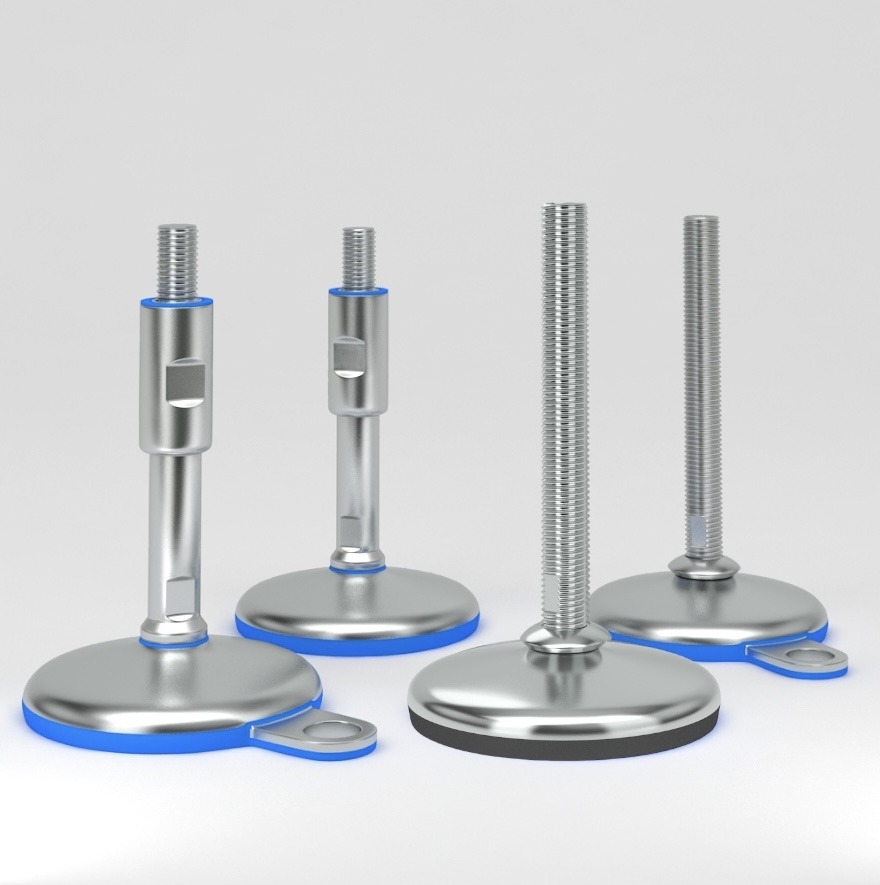

1. The Foundation: Indestructible Hygienic Levelling Feet

The Challenge: Retorts, filling machines, and conveyors must remain perfectly stable despite thermal expansion and corrosive spillage.

Our Solution: Our hygienic levelling feet are the definitive solution. We craft them exclusively from certified 316L stainless steel (V4A), the gold standard for resistance to acids and chlorides. Their robust, sealed design not only withstands extreme loads but also prevents corrosive liquids from penetrating the threads, ensuring a long and maintenance-free service life.

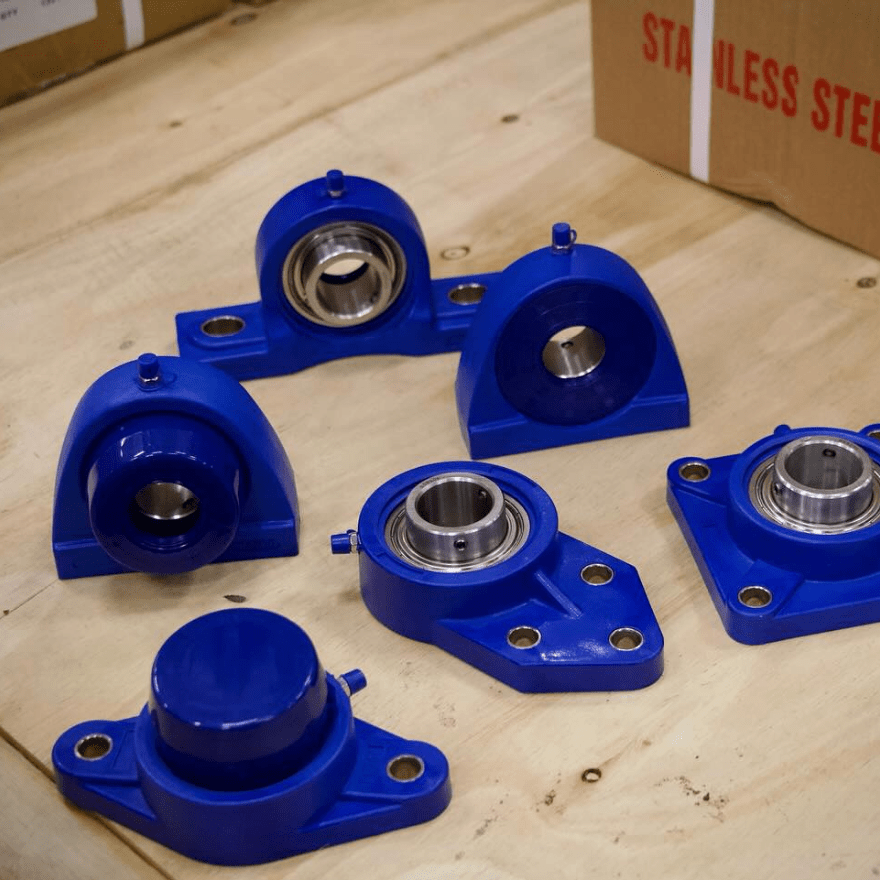

2. Unfailing Motion: IP67 Waterproof Bearing House Units

The Challenge: Bearings on can seamers, conveyors, and processing vessels are extremely vulnerable to failure from corrosive liquids and high-pressure steam cleaning.

Our Solution: We consider our IP67 waterproof bearing house units essential for any food preserving line. Their hermetically sealed, stainless steel enclosures provide complete protection against both liquid ingress and the fine particulate matter common in processing plants. This ensures your line keeps moving without the constant fear of bearing seizure.

3. Sanitary Mobility: Heavy-Duty Hygienic Castors

The Challenge: Mobile carts and tanks used for transporting brines or ingredients must be both incredibly durable and easy to sanitize.

Our Solution: Our hygienic industrial castors are built to last. We construct them from corrosion-proof stainless steel with heat-resistant, non-porous wheels. They are designed to withstand heavy loads and aggressive cleaning, ensuring safe and sanitary mobility throughout your facility.

4. System-Wide Reliability: Total Component Integrity

The Challenge: Every clamp, handle, and bracket must resist the same corrosive forces as the main equipment to prevent weak points in your system.

Our Solution: Our comprehensive range of hygienic machinery components in stainless steel guarantees system-wide durability. We provide every part you need—all crafted from certified 316L stainless steel—to build a production line that is resilient from top to bottom.

The Real-World Impact: From Frequent Replacements to Long-Term Reliability

The return on investment is clear. One of our clients in the vegetable pickling industry reported that they used to replace the leveling feet on their brine tanks every 18 months due to corrosion. After switching to our 316L hygienic feet, the same components have been in service for over five years without any signs of degradation. This is the tangible benefit of investing in the right materials.

Conclusion: Build Your Preserving Line to Last

In the food preserving industry, your equipment’s longevity is directly tied to your profitability. By partnering with a specialist manufacturer like NHK Group, you ensure that you are installing components that are not just compliant, but are expertly engineered to conquer the specific chemical and thermal challenges of your sector.

Ready to build a production line that resists corrosion and minimizes downtime?

Our experts are ready to help you select the most durable and hygienic components for your needs.

Contact

Understanding Machinery Components & Protection Standards

Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Block Bearings and Flange Mounted Units is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440C Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.