The Unseen Bottleneck in Your Bottling Line: Are Your Components Holding You Back?

In the high-speed, high-stakes world of beverage and liquid product bottling, efficiency is everything. Production managers focus on optimizing line speed, minimizing changeover times, and ensuring flawless operation. However, from our extensive experience at NHK Group, we know that the most significant threats to uptime and hygiene often hide in plain sight: the standard, non-specialized components that form the foundation of your equipment.

A single corroded leveling foot or a leaking bearing unit may seem like a minor issue, but these small failures create a domino effect, leading to unscheduled downtime, compromised product safety, and rising maintenance costs. This article explores the critical components that every state-of-the-art bottling line needs to thrive in a demanding, high-washdown environment.

The Core Challenge: Constant Moisture and Aggressive Cleaning

The primary challenge for any bottling line is the constant presence of moisture, combined with aggressive cleaning and sanitation protocols. Standard components, even those made from basic stainless steel, are not engineered to withstand this relentless assault.

Corrosion: Standard steel corrodes, releasing particles that can contaminate your product.

Instability: Inferior leveling feet can lose their position due to vibrations, causing misalignment on the conveyor.

Contamination: Non-sealed bearings are a critical risk, as lubricants can leak out and water can seep in, leading to premature failure and bacterial growth.

Our Solution: Engineering for the Washdown Environment

At NHK Group, we don’t just sell parts; we engineer solutions specifically for these challenges. Our philosophy is simple: every component must be designed to enhance hygiene, maximize durability, and reduce your operational costs. Below, we highlight the essential components we’ve developed for the bottling industry.

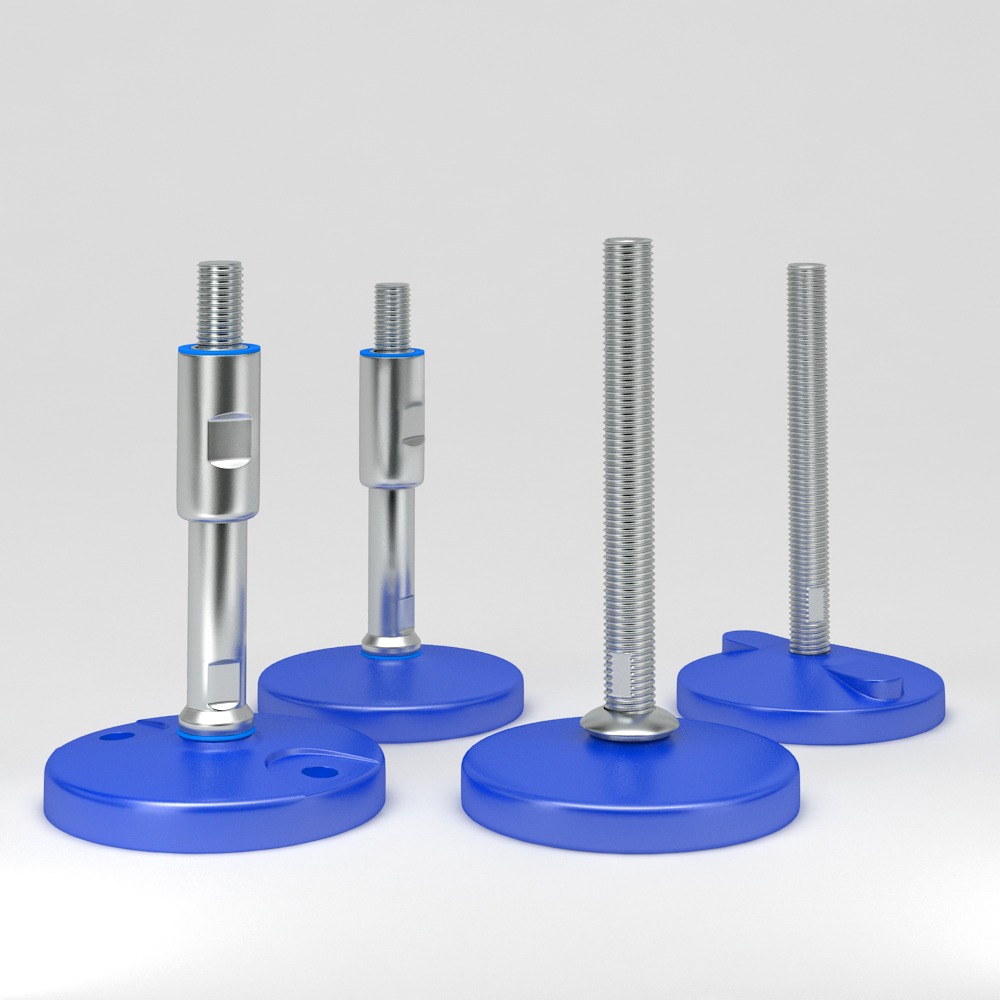

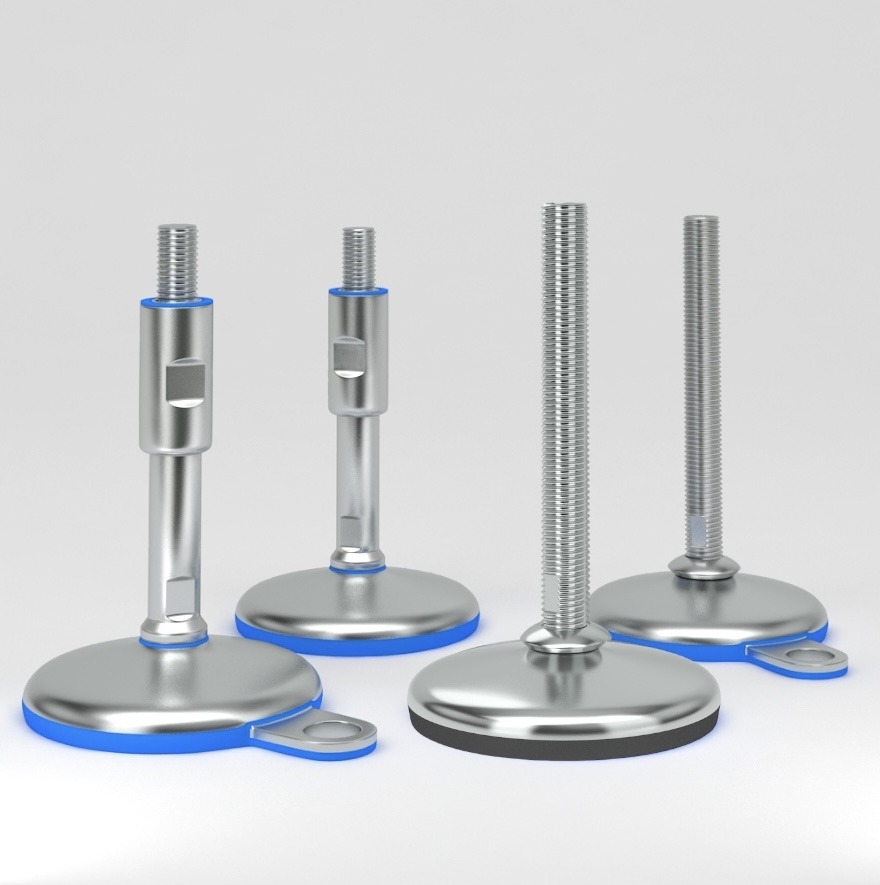

The Foundation: Rock-Solid Stability with Hygienic Levelling Feet

The Challenge: Long conveyor lines require perfect, stable alignment that won’t s

Our Solution: Our hygienic levelling feet are the bedrock of a reliable bottling line. We craft them from certified 316L stainless steel for maximum corrosion resistance. Their sealed, self-draining design and smooth, polished surfaces make them incredibly easy to clean and prevent any bacteria buildup, ensuring you meet the strictest food safety standards.

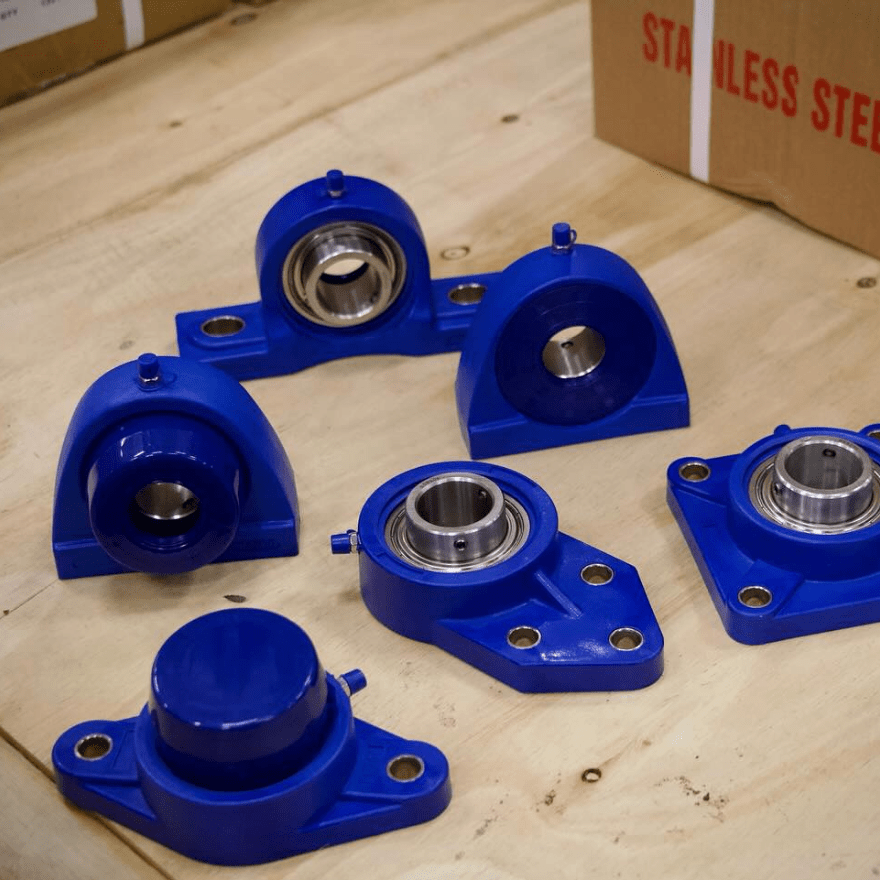

2. Uninterrupted Movement: IP67 Waterproof Bearing House Units

The Challenge: Bearings on conveyors are constantly exposed to water, sugar-based liquids, and harsh detergents, which leads to frequent failure.

Our Solution: We consider our IP67 waterproof bearing house units to be essential for any bottling application. The IP67 rating guarantees they are completely sealed against dust and can withstand high-pressure water jets from any angle. This eliminates the risk of internal corrosion and lubricant leakage, drastically extending the lifespan of your conveyor systems. For less critical areas, our bearing units in IP54 composite housing]offer a

3. Ultimate Mobility: Hygienic Industrial Castors

The Challenge: Mobile tanks, carts, and changeover equipment need to be moved easily while maintaining the highest hygiene standards.

Our Solution: Our Hygienic industrial castors are designed for sterile environments. With sealed bearings and smooth, non-porous materials, they are easy to clean and sanitize. Their robust construction ensures they can handle heavy loads safely, making your operations more flexible and efficient.

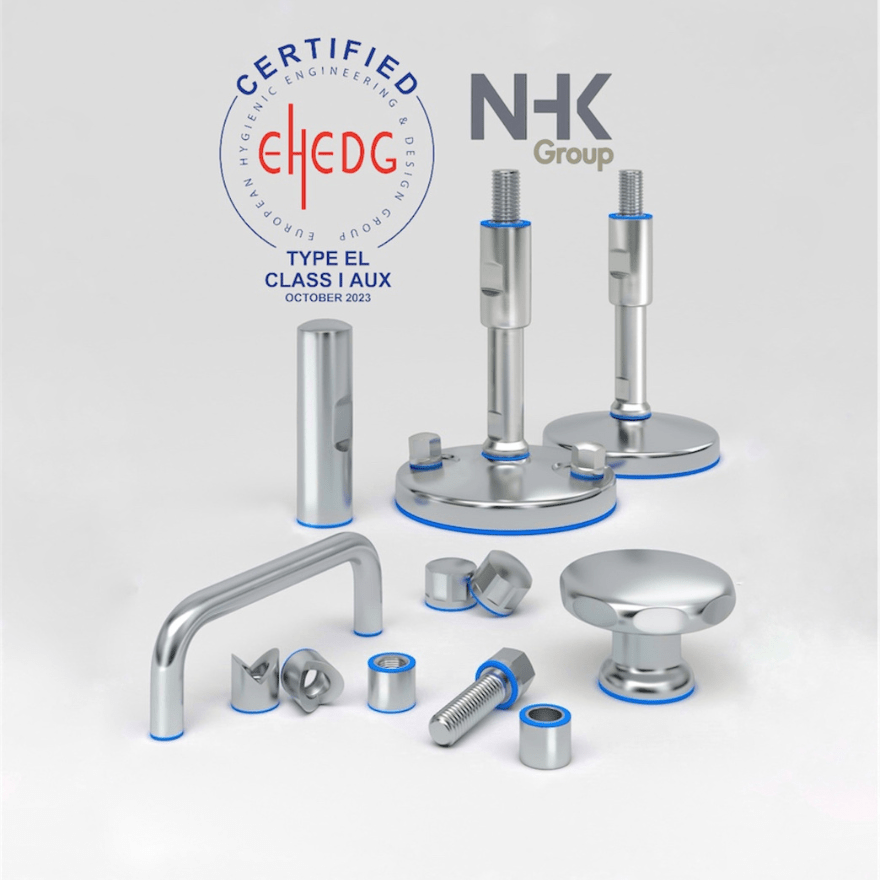

4. System Integrity: Every Detail Matters

The Challenge: A production line is only as strong as its weakest link. Standard handles, bolts, and brackets can also become sources of contamination.

Our Solution: We offer a comprehensive range of Hygienic machinery components in stainless steel. From sealed nuts and bolts to ergonomically designed handles, we ensure that every single part of your line upholds the same uncompromising standard of quality and hygiene.

The Real-World Impact: A Case for Quality

The benefits of upgrading to specialized hygienic components are tangible. **In fact, one of our beverage industry clients reported a 25% reduction in maintenance-relatedIn fact, one of our beverage industry clients reported a 25% reduction in maintenance-related downtime within the first year of retrofitting their main bottling line with our IP67 bearings and hygienic feet. This is a testament to the fact that investing in quality is a direct investment in your productivity.

Conclusion: Build Your Bottling Line on a Foundation of Trust

In the bottling industry, you cannot afford to compromise on hygiene or reliability. Partnering with a specialist manufacturer like NHK Group ensures you receive components that are not just high-quality, but are expertly engineered for the unique challenges of your sector.

Ready to eliminate the hidden bottlenecks in your production line?

Our experts are ready to help you choose the right components for your specific needs.

Contact

Understanding Machinery Components & Protection Standards

Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Block Bearings and Flange Mounted Units is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440C Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.