The Hidden Contamination Risk in Your Bakery: Are Your Machine Components Sabotaging Your Hygiene Standards?

In the world of bakery and dough product manufacturing, consistency and quality are king. You perfect your recipes and streamline your production lines to create delicious products for your customers. However, from our extensive experience at NHK Group, we know that a persistent and often invisible threat can compromise both: fine flour dust and sticky dough residue clinging to standard, hard-to-clean machine components.

A single leveling foot with exposed threads or a bearing unit not designed for dusty environments can become a hotspot for mold and bacteria growth, posing a significant risk to your food safety protocols. This article explores the critical components that every modern bakery and dough processing facility needs to overcome these unique challenges.

The Core Challenge: Abrasive Flour Dust and Sticky Residues

Unlike liquid processing, the bakery environment presents a unique set of challenges for equipment:

Abrasive Dust: Fine flour and sugar dust can penetrate standard bearings, causing premature wear and failure.

Sticky Residues: Dough, fillings, and glazes are difficult to clean from standard industrial parts with crevices and sharp corners.

Frequent Cleaning Cycles: Equipment must withstand frequent dry and wet cleaning cycles without corroding or degrading.

High Temperatures: Components near ovens and proofers must be able to handle elevated temperatures.

Our Solution: Engineering for the Bakery Environment

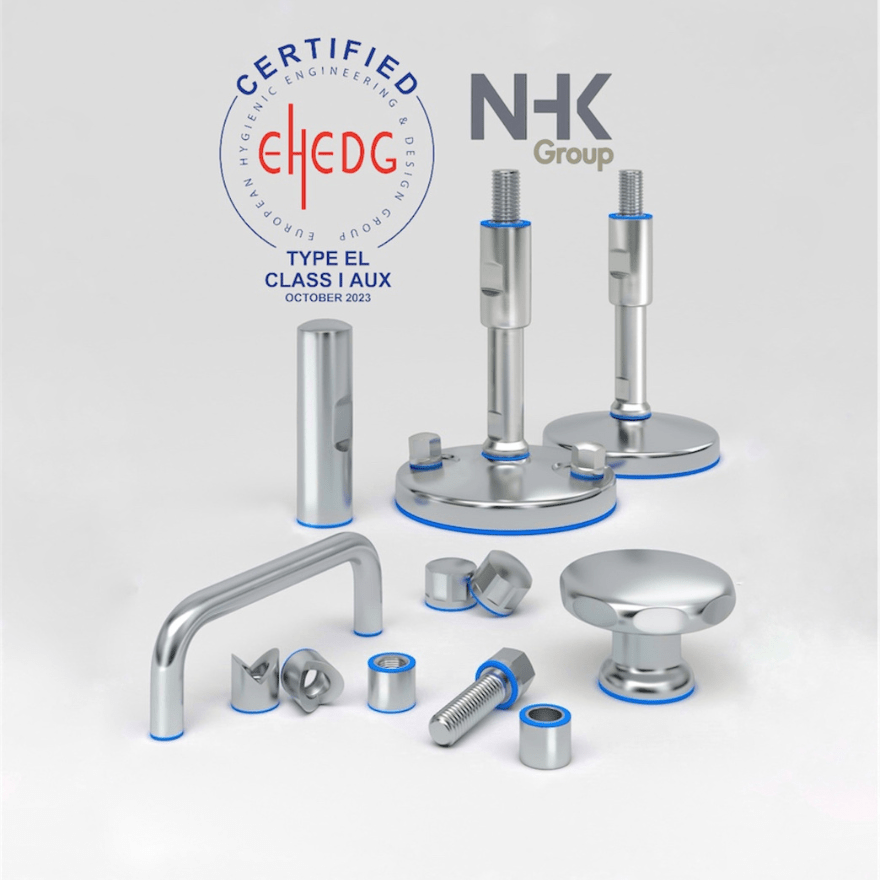

At NHK Group, we engineer our hygienic components to solve these specific problems. Our philosophy is that every part must be designed to be incredibly durable and exceptionally easy to clean. Here’s how our key products meet the demands of dough product manufacturing:

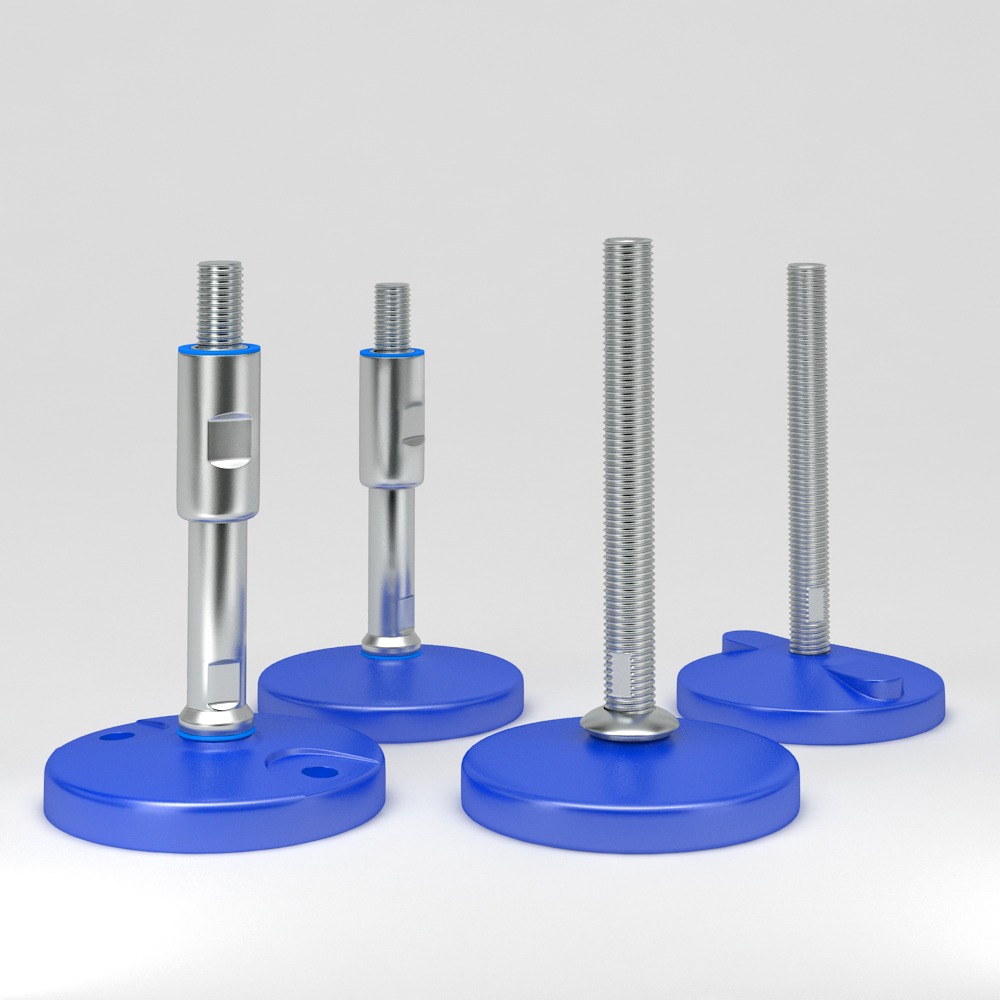

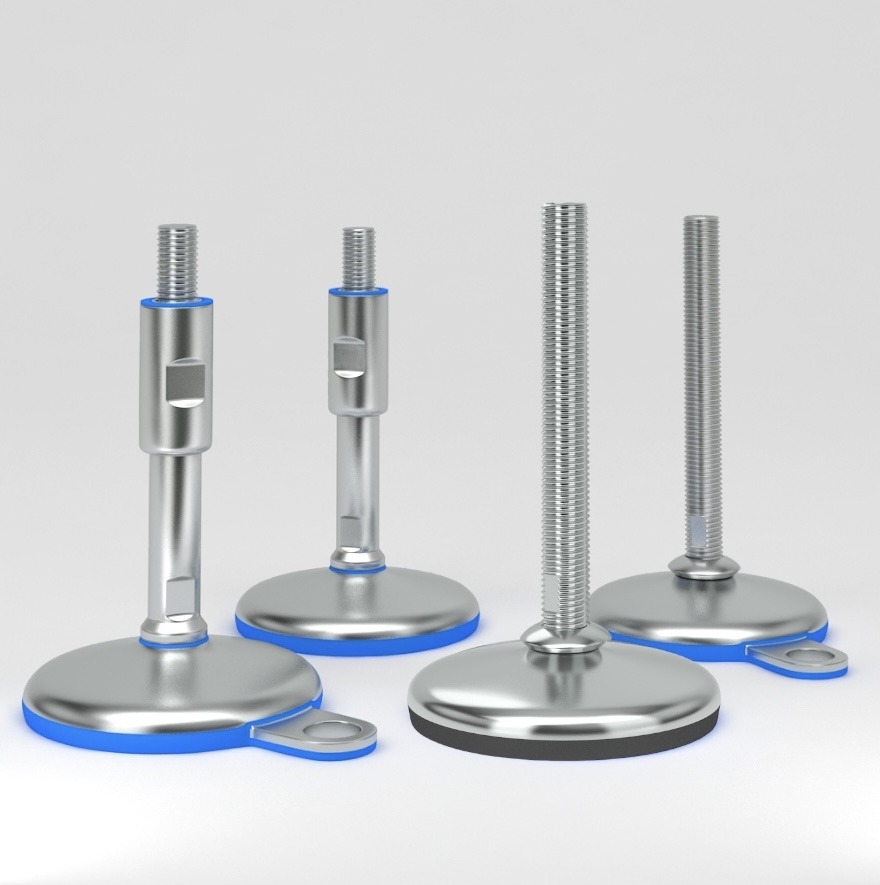

1. The Foundation: Stable and Cleanable Hygienic Levelling Feet

The Challenge: Mixers, dividers, and proofers must be perfectly stable, yet easy to clean underneath to prevent accumulations of old flour and dough.

Our Solution: Our hygienic levelling feet provide a solid, vibration-resistant foundation for your heavy equipment. We craft them from polished 316L stainless steel with sealed, smooth surfaces and encapsulated threads. This hygienic design eliminates “dead spots,” making daily sanitation fast and effective, which is crucial for meeting HACCP standards.

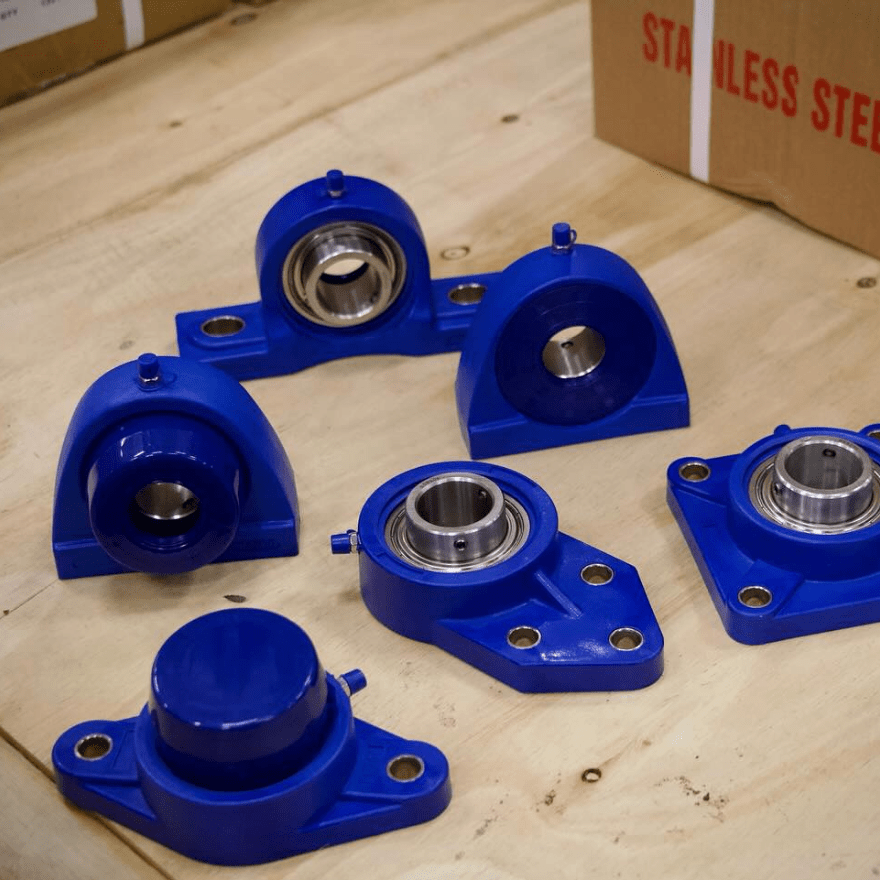

2. Protecting Motion: IP67 Waterproof & Dust-Proof Bearing House Units

The Challenge: Flour dust is the number one enemy of bearings on conveyors, proofers, and packaging lines. It acts like sandpaper, causing rapid wear and failure.

Our Solution: We highly recommend our IP67 waterproof bearing house units for all critical moving parts. The “6” in IP67 signifies that they are completely dust-tight, preventing any abrasive particles from entering the bearing. The “7” means they are also fully waterproof, making them perfect for washdown procedures. This dual protection dramatically increases the lifespan of your equipment.

3. Flexible Operations: Hygienic Industrial Castors

The Challenge: Mobile racks, dough troughs, and ingredient bins need to be moved effortlessly and safely around the bakery, without becoming a source of contamination.

Our Solution: Our hygienic industrial castors are the perfect choice for a dynamic bakery environment. Featuring sealed bearings to protect against flour dust and smooth, non-porous wheels that are easy to clean, they combine robust mobility with the highest standards of hygiene.

4. System-Wide Hygiene: Every Part Matters

The Challenge: To be truly compliant, every component—from handles to side guides—must be designed for cleanliness.

Our Solution: Our comprehensive range of hygienic machinery components in stainless steel ensures your entire production line is easy to clean and maintain. We provide polished, crevice-free parts that prevent dough and flour from accumulating, simplifying your sanitation standard operating procedures (SSOPs).

The Real-World Impact: Less Cleaning, More Production

The benefits of using components truly designed for bakeries are clear. For instance, one of our clients, a large-scale industrial bakery, reduced their daily cleaning time for their main proofing line by 20% after switching to our sealed bearings and hygienic feet. This time saved is now dedicated to production, directly boosting their output.

Conclusion: Build Your Bakery on a Foundation of Reliability

In the competitive bakery market, efficiency and food safety are paramount. Partnering with a specialist manufacturer like NHK Group ensures you receive components that are not just high-quality, but are expertly engineered for the unique challenges of flour dust and dough residue.

Ready to enhance the hygiene and reliability of your production line?

Our experts are ready to help you select the most durable and compliant components for your needs.

Contact

Understanding Machinery Components & Protection Standards

Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Plummer Blocks and Flanged Bearings is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. Stainless Steel 440 and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.