How to Get 3-A Sanitary Standards Certified

Achieving 3-A Sanitary Standards certification is a crucial step for companies in the food, beverage, and pharmaceutical industries to ensure their products meet rigorous safety and hygiene standards. This certification not only enhances product quality but also builds consumer trust and compliance with regulatory requirements. In this article, we’ll provide a comprehensive guide on how to get 3-A Sanitary Standards certified, including detailed steps, benefits, and real-world case studies. The 3-A Sanitary Standards are a set of guidelines designed to ensure the hygienic design and operation of equipment used in the production of food, beverages, and pharmaceuticals. These standards are established by the 3-A Sanitary Standards, Inc. (3-A SSI) and are widely recognized in the industry for promoting public health and safety. Getting certified to these standards can significantly improve your company’s reputation and operational efficiency. 3-A Sanitary Standards are voluntary guidelines that focus on the design, fabrication, and cleanability of equipment used in the dairy, food, and pharmaceutical industries. They are aimed at preventing contamination and ensuring product safety. Before starting the certification process, it’s essential to thoroughly understand the 3-A Sanitary Standards relevant to your industry. These standards can be accessed through the 3-A SSI website or purchased as needed. Perform a detailed gap analysis to compare your current equipment and processes with the 3-A standards. Identify areas that need improvement or modification to meet the certification criteria. Based on the gap analysis, design and implement the necessary changes to your equipment and processes. This may involve modifying existing equipment or investing in new compliant equipment. Ensure that your team is adequately trained on the new standards and processes. Maintain thorough documentation of all changes, training sessions, and compliance measures taken. Once all changes are implemented, schedule an audit with a 3-A SSI-certified third-party inspector. The audit will assess your compliance with the standards and identify any remaining issues. If the audit identifies any non-compliance issues, promptly address them and make the necessary corrections. Once all issues are resolved, a follow-up audit may be required. After passing the audit, you will receive your 3-A Sanitary Standards certification. Display this certification prominently to demonstrate your commitment to safety and hygiene. A dairy processing plant aimed to improve its hygiene standards by achieving 3-A certification. They conducted a gap analysis, upgraded their equipment, and trained their staff. The successful audit led to increased product quality and customer trust. A beverage manufacturing facility faced contamination issues and decided to pursue 3-A certification. By redesigning their cleaning processes and investing in compliant equipment, they not only achieved certification but also reduced downtime and increased production efficiency. A pharmaceutical company sought 3-A certification to meet regulatory requirements and improve public health standards. Through a meticulous gap analysis and implementation of necessary changes, they successfully obtained certification, enhancing their market reputation. A food packaging plant focused on obtaining 3-A certification to boost consumer confidence. By training their staff and upgrading their equipment, they passed the audit and saw a significant increase in sales and customer satisfaction. Achieving 3-A Sanitary Standards certification is a valuable investment for companies in the food, beverage, and pharmaceutical industries. It ensures compliance with stringent hygiene standards, enhances product safety, and builds consumer trust. By following the outlined steps and learning from real-world case studies, your company can successfully navigate the certification process and reap its numerous benefits.

Comprehensive guide

3-A Sanitary Standards

What Are 3-A Sanitary Standards?

Benefits of 3-A Sanitary Standards Certification

Steps to Achieve 3-A Sanitary Standards Certification

1. Understand the Requirements

2. Conduct a Gap Analysis

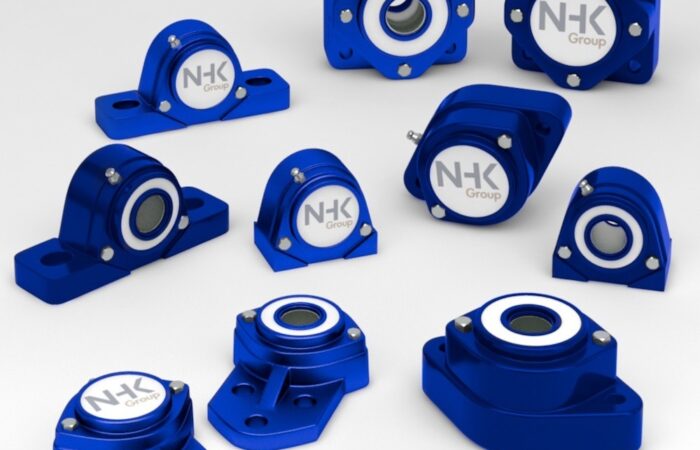

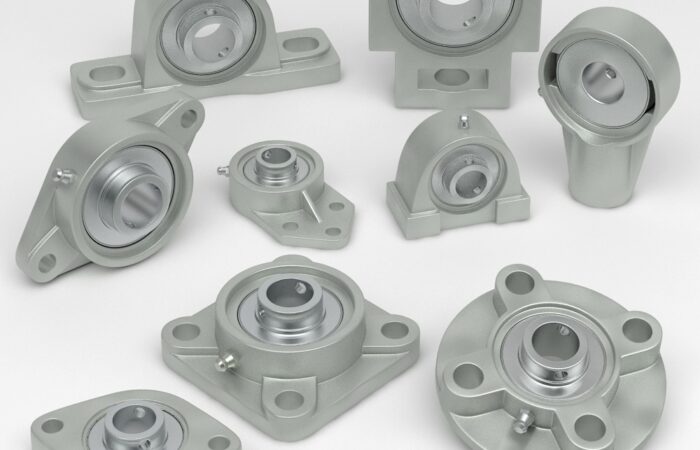

3. Design and Implement Changes

4. Training and Documentation

5. Schedule an Audit

6. Address Audit Findings

7. Obtain Certification

Case Studies

Case Study 1: Dairy Processing Plant

Case Study 2: Beverage Manufacturing Facility

Case Study 3: Pharmaceutical Company

Case Study 4: Food Packaging Plant

Understanding 3-A Sanitary Standards

Contact

Articles