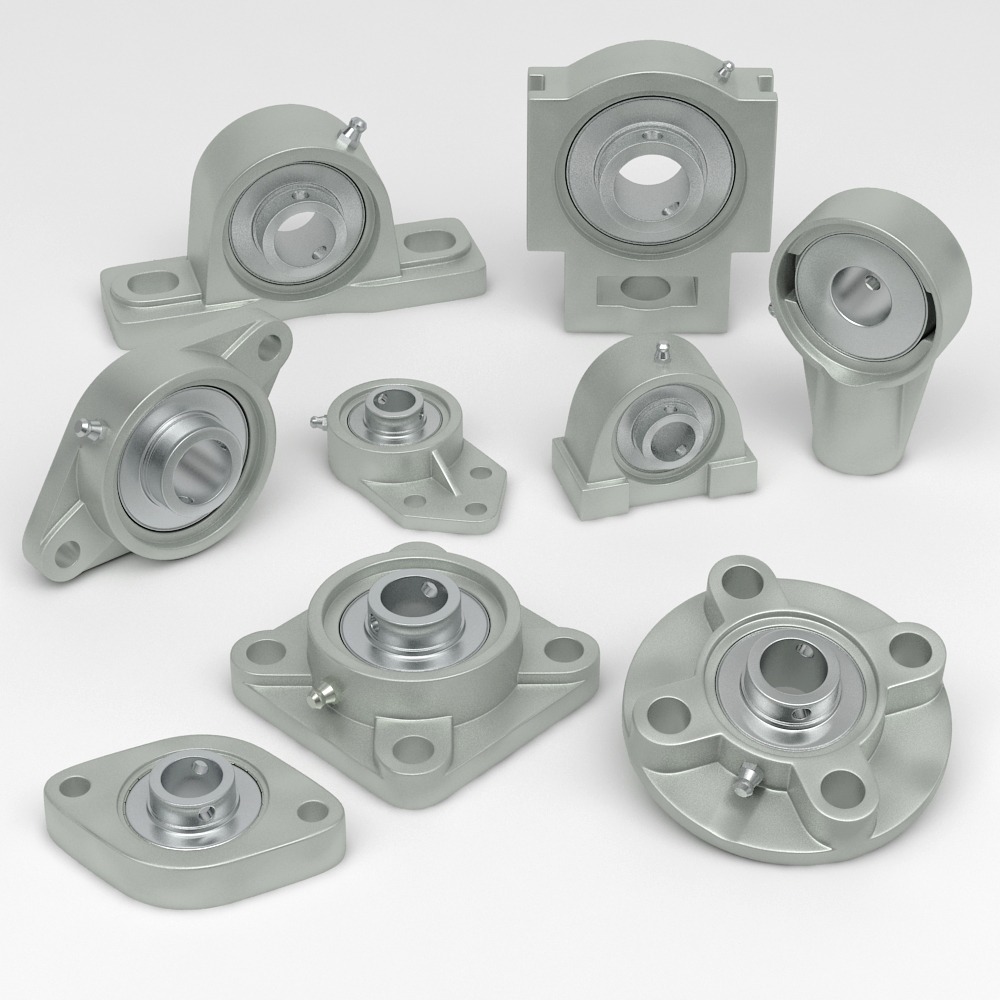

Heavy Duty Pillow Block and Flange Bearing Units

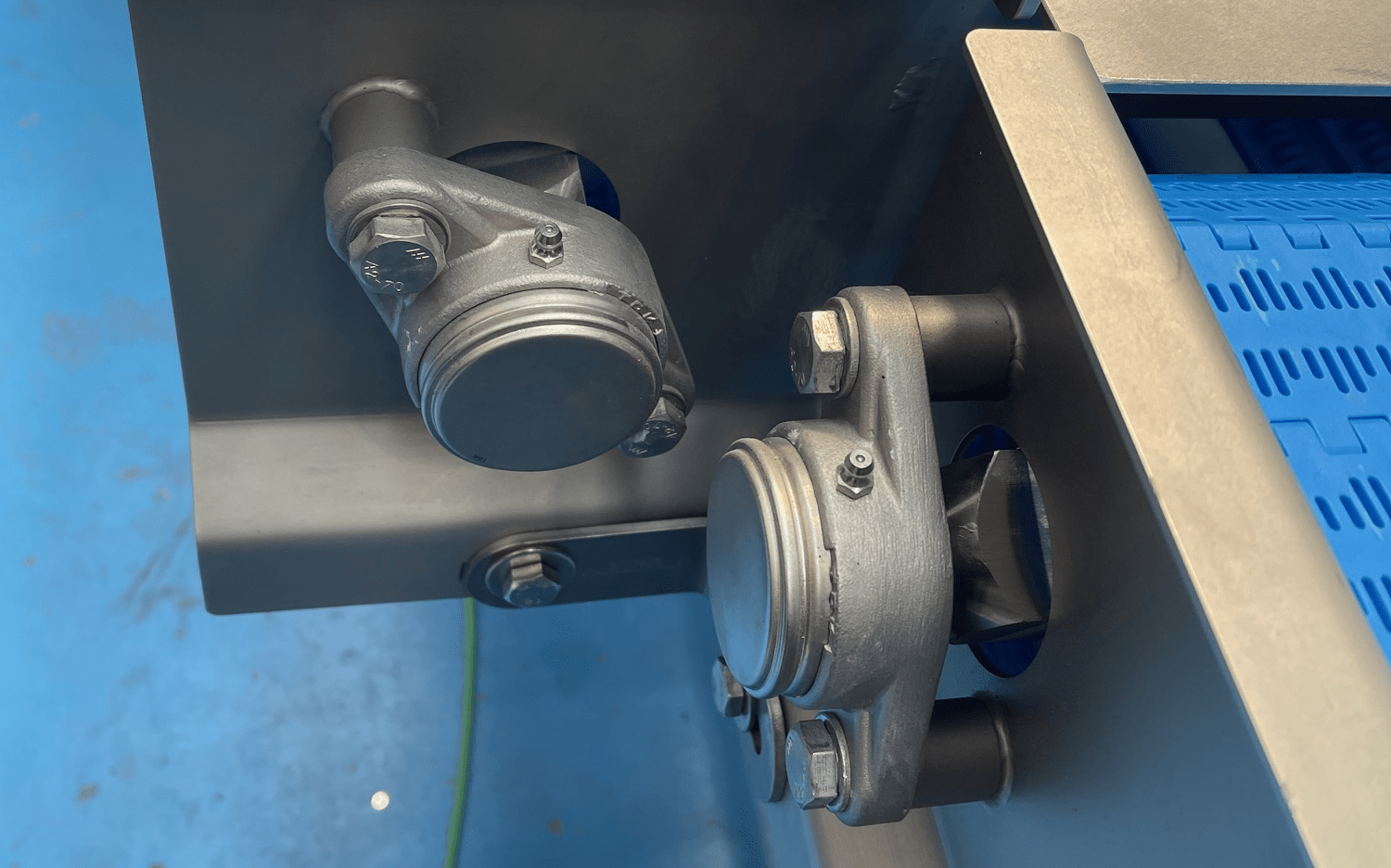

In the world of industrial machinery, reliability and efficiency are paramount. Among the critical components that contribute to these attributes are heavy-duty pillow block and flange bearing units. These bearing units play a vital role in ensuring smooth and efficient operations across various industries, from manufacturing and construction to agriculture and transportation. This article delves into the intricacies of these essential components, highlighting their significance, applications, and the advantages they offer. Pillow Block Bearing Units: Pillow block bearing units are robust components designed to support a rotating shaft while allowing it to move freely. These units are mounted on a base and typically consist of a housing and an insert bearing. The design of pillow blocks provides excellent support and stability, making them ideal for applications where the shaft is parallel to the mounting surface. They are often used in conveyor systems, agricultural machinery, and packaging equipment. Flange Bearing Units: Flange bearing units, on the other hand, are designed for applications where the shaft is perpendicular to the mounting surface. These units come in various shapes, including square, round, and oval flanges, providing flexibility in installation. Flange bearing units are commonly used in industries like automotive, aerospace, and food processing, where precise shaft alignment and support are crucial. Heavy-duty pillow block and flange bearing units are engineered to withstand extreme conditions and heavy loads. They are constructed using high-quality materials such as cast iron or stainless steel, ensuring durability and longevity. These units are capable of handling significant radial and axial loads, making them suitable for applications that involve high-speed rotation and heavy machinery. One of the key advantages of heavy-duty bearing units is their ability to reduce vibration and noise. The design of these units minimizes friction and wear, ensuring smooth and quiet operation. This is particularly important in industries where noise reduction is critical, such as in manufacturing plants and automotive assembly lines. By providing reliable support and reducing friction, heavy-duty pillow block and flange bearing units enhance the overall performance and efficiency of machinery. They contribute to reduced energy consumption and maintenance costs, ultimately leading to increased productivity and profitability for businesses. In manufacturing and production environments, heavy-duty bearing units are essential for the smooth operation of conveyor systems, assembly lines, and processing equipment. They ensure that machinery operates efficiently and without interruption, minimizing downtime and maximizing output. The construction and mining industries rely heavily on robust machinery that can withstand harsh conditions and heavy loads. Heavy-duty pillow block and flange bearing units are integral to the operation of equipment such as crushers, loaders, and excavators, providing the necessary support and durability. In the agriculture sector, machinery like harvesters, tractors, and irrigation systems require reliable bearing units to function optimally. Similarly, the food processing industry demands components that can withstand frequent washdowns and exposure to chemicals. Heavy-duty bearing units meet these requirements, ensuring hygiene and reliability. Transportation and logistics companies depend on heavy-duty bearing units for the efficient operation of vehicles, conveyor belts, and material handling equipment. These units contribute to the smooth movement of goods and materials, ensuring timely deliveries and reducing operational costs. When selecting heavy-duty pillow block and flange bearing units, several factors should be considered: The material and construction of bearing units play a crucial role in their performance and longevity. Cast iron and stainless steel are common materials used for heavy-duty applications due to their strength and resistance to corrosion. It’s essential to choose units that can withstand the specific conditions of your application, whether it involves exposure to moisture, chemicals, or extreme temperatures. Understanding the load and speed requirements of your machinery is critical in choosing the right bearing units. Ensure that the selected units can handle the radial and axial loads imposed by the application and can operate at the required speed without compromising performance. Regular maintenance and proper lubrication are essential for the optimal performance of bearing units. Choose units that are easy to maintain and come with lubrication options suitable for your application. Sealed bearing units are often preferred for applications where contaminants are present, as they help prevent dust and debris from entering the bearing. The field of bearing technology is continually evolving, with manufacturers introducing innovations to enhance performance and efficiency. Some of the notable trends include: Self-lubricating bearings are designed to reduce the need for frequent maintenance and lubrication. These bearings feature a built-in lubrication system that releases lubricant gradually, ensuring consistent performance and reducing downtime. With the advent of the Internet of Things (IoT), smart bearings equipped with sensors and monitoring systems are becoming increasingly popular. These bearings provide real-time data on temperature, vibration, and load, enabling predictive maintenance and reducing the risk of unexpected failures. As industries shift towards sustainability, there is a growing demand for bearing units made from eco-friendly materials. Manufacturers are exploring options such as biodegradable lubricants and recyclable materials to meet this demand and reduce the environmental impact of bearing units. Heavy-duty pillow block and flange bearing units are indispensable components in various industries, providing essential support, durability, and efficiency. As technology continues to advance, these bearing units are evolving to meet the demands of modern machinery and contribute to the success of businesses worldwide. By understanding their applications and selecting the right units for your needs, you can ensure the optimal performance and longevity of your equipment, ultimately leading to increased productivity and profitability. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Blocks and Direct Mount Bearings is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. Type 440 Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.The Backbone of Industrial Machinery

Pillow Block Units vs Flange Bearing Units

Understanding Bearing Units: Pillow Block vs. Flange

The Importance of Heavy Duty Bearing Units

Durability and Load Capacity

Vibration and Noise Reduction

Enhanced Performance and Efficiency

Applications of Heavy Duty Bearing Units

Manufacturing and Production

Construction and Mining

Agriculture and Food Processing

Transportation and Logistics

Choosing the Right Bearing Units

Material and Construction

Load and Speed Requirements

Maintenance and Lubrication

Innovations and Trends in Bearing Technology

Self-Lubricating Bearings

Smart Bearings

Sustainable Materials

Pillow Block Units vs Flange Bearing Units

Contact

Understanding Machinery Components & Protection Standards