Fully threaded leveling feet in the Packaging Industry

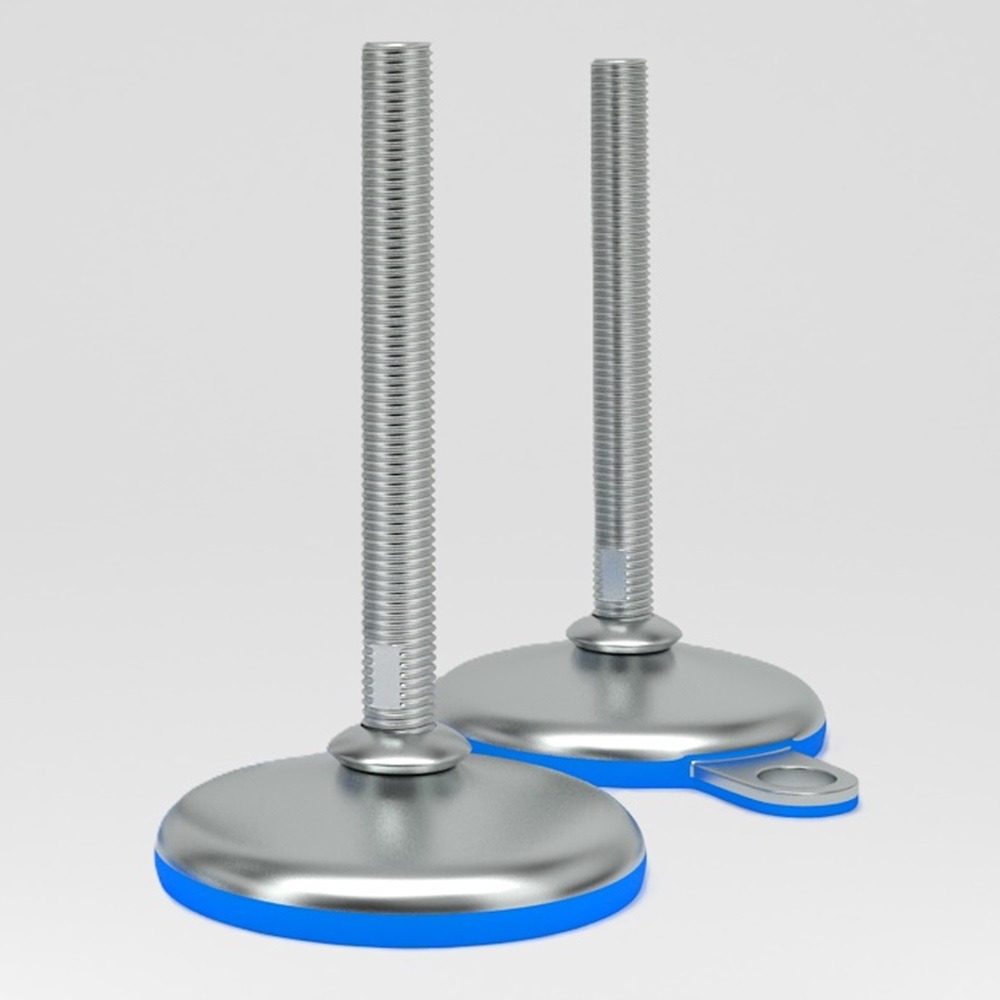

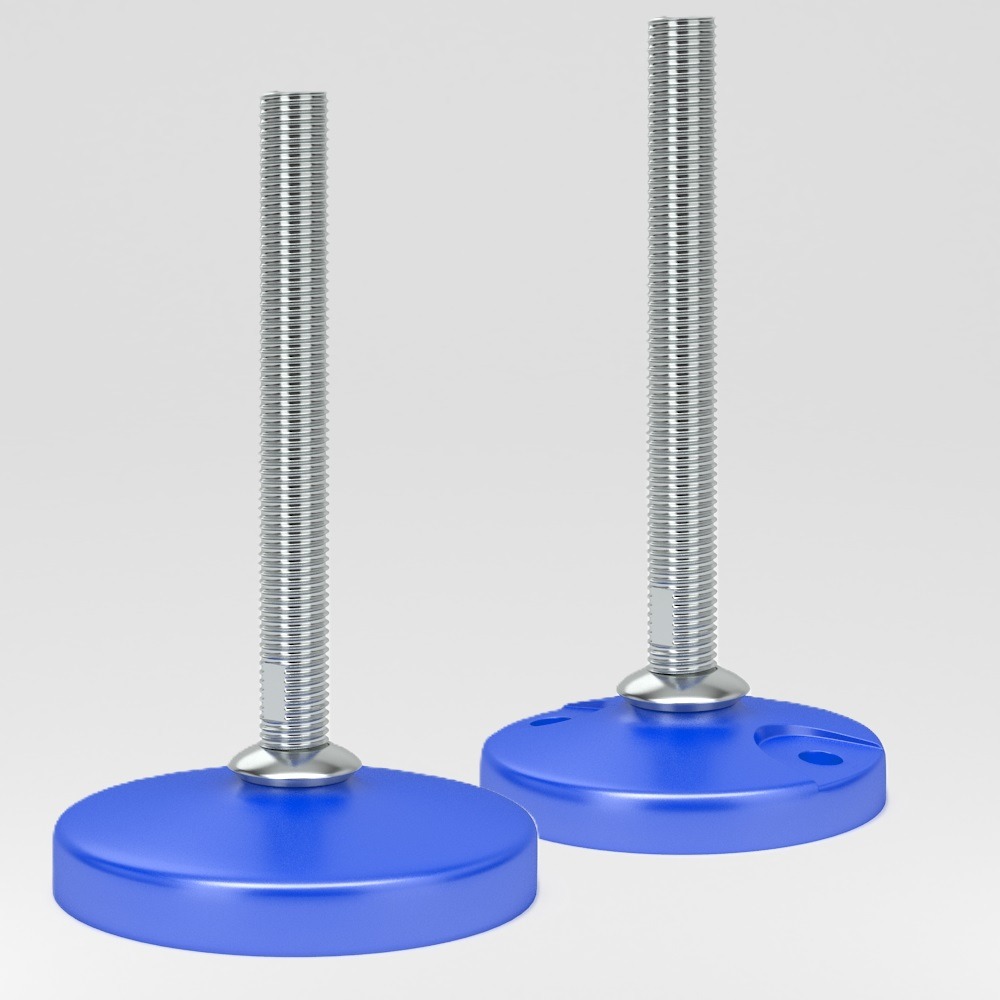

In today’s rapidly evolving industrial landscape, strategic planning and continuous development are crucial for businesses aiming to maintain their competitive edge. In industries such as packaging, food processing, pharmaceuticals, and biotechnology, the integration of highly specialized components like fully threaded leveling feet has become increasingly significant. These components, although seemingly small, play an essential role in ensuring machinery stability, hygiene, and performance. Companies that invest in strategic planning and learning around such technologies are better positioned to achieve operational excellence and maintain compliance with industry regulations. The packaging industry is known for its stringent demands on speed, precision, and quality. As consumer preferences shift towards sustainable and hygienically packaged products, manufacturers must adopt innovative machinery and infrastructure to meet these requirements. Fully threaded leveling feet are an essential part of the equation, ensuring that machinery remains stable, balanced, and easy to clean in the production process. Strategic planning in the packaging industry must consider the implementation of robust machinery components that enhance efficiency and meet the requirements for hygiene and safety. Companies that prioritize leveling systems in their strategic development plans can reduce downtime caused by unstable equipment, improve production speed, and enhance overall product quality. Moreover, fully threaded leveling feet are easily adjustable, allowing for quick realignment of machines when production needs change or when machines are moved. The food processing industry is one of the most regulated sectors due to the critical need for maintaining hygiene and preventing contamination. Fully threaded leveling feet, typically made from stainless steel and designed to be easily sanitized, are ideal for supporting machinery in environments where food safety is a priority. Their resistance to corrosion and ease of cleaning make them a preferred choice in food production settings. Development in the food processing industry involves not only adopting new technologies but also investing in employee training and machinery upgrades to meet evolving regulations. As food companies grow and expand into new markets, the demand for versatile and hygienic machinery components increases. Integrating fully threaded leveling feet into development plans ensures machinery remains stable, compliant with health and safety standards, and adaptable to various food processing applications such as sorting, packaging, and assembly. The pharmaceutical industry faces constant challenges with innovation, regulatory compliance, and product safety. With strict regulations like Good Manufacturing Practices (GMP), ensuring machinery stability and cleanliness is vital for operational success. Fully threaded leveling feet provide pharmaceutical manufacturers with the stability needed for precision in drug formulation, tablet pressing, and packaging. Continuous learning is key to the pharmaceutical industry’s success. Companies that invest in training programs for their employees and stay updated with technological advancements are better prepared to respond to changes in regulatory standards and market demands. The use of fully threaded leveling feet in machinery contributes to smoother operations by minimizing vibrations, which is essential in sensitive production processes. Pharmaceutical companies that prioritize learning and upgrading their systems regularly with such components can ensure that their production environments meet the highest standards for safety and precision. The biotechnology industry is characterized by rapid innovation and highly specialized machinery requirements. As biotech firms work on cutting-edge solutions for medicine, agriculture, and environmental science, ensuring that their machinery operates with precision is of utmost importance. Fully threaded leveling feet play a crucial role in stabilizing lab equipment, bioreactors, and production lines. Strategic development in biotechnology involves aligning technological investments with long-term business goals. By incorporating fully threaded leveling feet into machinery, biotech firms can improve the efficiency and reliability of their operations. These components offer the flexibility to quickly adjust equipment in a lab setting, ensuring that sensitive experiments and processes are not disrupted by equipment misalignment. Additionally, biotech firms that invest in leveling feet designed for harsh environments can enhance the durability of their machinery. Fully threaded leveling feet made from corrosion-resistant materials like stainless steel ensure that machinery can withstand exposure to chemicals, high temperatures, and frequent cleaning, which are common in biotech labs and production areas. Strategic planning in industries such as packaging, food processing, pharmaceuticals, and biotechnology must consider both the present needs and future demands of the market. Incorporating fully threaded leveling feet into the machinery infrastructure can help companies address several critical challenges—namely, machinery stability, hygiene, and adaptability. Development and learning play a pivotal role in keeping companies competitive. In addition to investing in the right equipment, organizations must ensure that their workforce is trained to operate and maintain the machinery efficiently. This learning component is critical to adapting to new industry standards, improving productivity, and fostering innovation within the company. The adoption of fully threaded leveling feet supports this strategic planning by reducing the need for constant maintenance and minimizing machine downtime. Companies that recognize the importance of continuous learning and development are better equipped to maximize the advantages offered by such machinery components. Fully threaded leveling feet may seem like a minor detail in the broader picture of industrial operations, but their impact is significant in ensuring machinery stability, compliance with industry standards, and adaptability across various sectors. For businesses in the packaging, food processing, pharmaceutical, and biotechnology industries, strategic planning, development, and learning focused on integrating these components into machinery can lead to operational improvements, increased efficiency, and long-term success. By prioritizing investment in components like fully threaded leveling feet, companies can create a strong foundation for their machinery infrastructure. This not only helps meet current regulatory requirements but also prepares them for future growth and market challenges. Through continuous learning and development, businesses can stay at the forefront of innovation, ensuring that their operations remain efficient, safe, and compliant with industry standards. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Bearing Housings and Flange Bearing Units is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440 Stainless Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.Strategic Planning, Development, and Learning in the Packaging, Food Processing, Pharmaceutical, and Biotechnology Industries Using Fully Threaded Leveling Feet

Strategic Planning in the Packaging Industry

Enhancing Development in the Food Processing Industry

Continuous Learning in the Pharmaceutical Industry

Strategic Development in the Biotechnology Industry

Aligning Strategic Planning and Learning

Strategic Planning, Development, and Learning with Fully Threaded Leveling Feet in the Packaging, Food Processing, Pharmaceutical, and Biotechnology Industries

Contact

Understanding Machinery Components & Protection Standards