Flange bearing units mini stainless steel

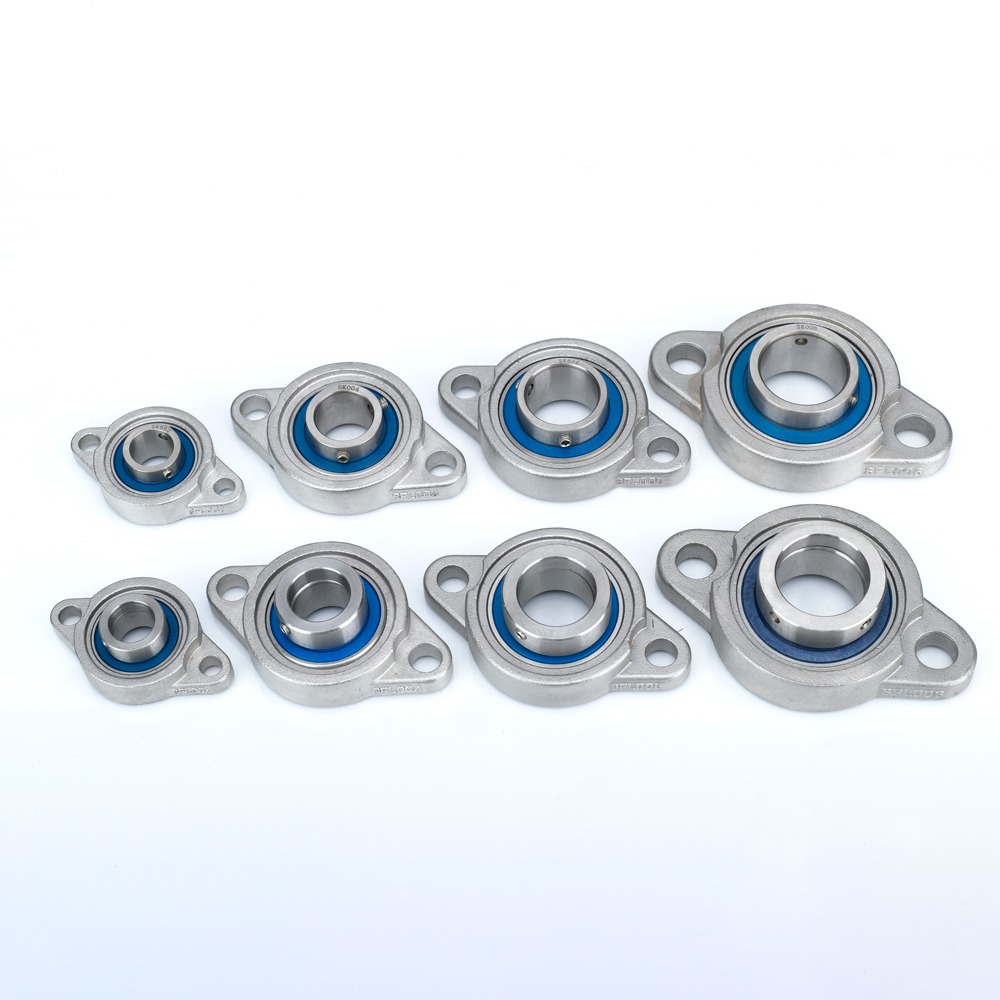

Mini stainless steel flange bearing units play a crucial role in mechanical applications requiring precision, durability, and resistance to corrosion. These compact yet powerful components are widely used across various industries, particularly in environments where hygiene, space constraints, and high performance are essential. In this article, we will explore their usage, industries that benefit from them, and the material properties that make them an excellent choice for demanding applications. Flange bearing units are integral components in various mechanical systems, providing support and reducing friction for rotating shafts. When crafted from stainless steel and designed in miniature sizes, these units offer unique advantages across multiple industries. This article delves into the usage, applicable industries, and materials associated with mini stainless steel flange bearing units. Mini stainless steel flange bearing units are engineered to support shafts while minimizing friction, particularly in compact applications where space is limited. The flange—a protruding rim on the outer ring—facilitates precise positioning within a housing, preventing axial movement and ensuring stability during operation. This design is especially beneficial in applications subject to vibration or thermal expansion, where maintaining the bearing’s position is critical. The choice of materials in manufacturing mini flange bearing units significantly impacts their performance and suitability for specific applications. The flanged design of these bearing units allows for easier mounting and precise alignment in assemblies. The flange helps prevent axial movement, ensuring the bearing remains securely in place during operation. This is particularly advantageous in applications with significant vibration or where thermal expansion of the housing material could lead to a loose fit. Mini stainless steel flange bearing units are versatile components that offer durability, precision, and corrosion resistance across various industries. Their unique design and material properties make them suitable for applications ranging from food processing and pharmaceuticals to aerospace and robotics. By understanding their usage, industry applications, and material advantages, engineers and designers can make informed decisions to enhance the performance and longevity of their mechanical systems. Flange bearing units are designed to support rotating shafts, ensuring smooth motion while distributing loads evenly. The flange design allows for secure mounting onto surfaces, preventing misalignment and reducing stress on connected components. Mini stainless steel flange bearing units are particularly useful in high-speed applications, where vibrations and shocks need to be dampened. Their rigid structure enhances stability, reducing wear and tear on machinery. Industries such as food processing, pharmaceuticals, and marine require components that resist moisture, chemicals, and contaminants. Stainless steel construction ensures durability in such environments while maintaining hygiene and compliance with safety regulations. Unlike larger bearing units, mini flange bearings are compact and lightweight, making them suitable for small machinery and tight spaces. Their design allows easy installation without adding unnecessary bulk to mechanical assemblies. Due to their stainless steel construction and superior lubrication options, mini flange bearings offer extended service life with minimal maintenance. They resist rust and degradation, making them ideal for industries where consistent performance is critical. The food and beverage industry requires machinery components that are hygienic, corrosion-resistant, and easy to clean. Mini stainless steel flange bearings are commonly found in: The ability of these bearings to withstand frequent washdowns and exposure to food-grade cleaning agents makes them indispensable in this sector. Precision and sterility are crucial in pharmaceutical manufacturing and medical device production. Stainless steel flange bearings are used in: Since these bearings are non-toxic, resistant to harsh chemicals, and easy to sterilize, they comply with GMP (Good Manufacturing Practice) standards. The aerospace industry demands lightweight, high-strength components that can endure extreme conditions. Mini stainless steel flange bearings are used in: Their corrosion resistance and ability to perform in high-pressure environments make them ideal for aerospace applications. As automation and robotics advance, there is an increasing demand for miniature bearings with high precision and durability. These bearings are essential in: Their low friction properties ensure smooth motion, reducing energy consumption and enhancing operational efficiency. The marine environment exposes components to saltwater, humidity, and extreme weather conditions. Mini stainless steel flange bearings are used in: With exceptional resistance to saltwater corrosion, these bearings maintain their integrity even in the harshest conditions. The material used in mini flange bearing units significantly impacts their performance, longevity, and resistance to environmental factors. Stainless steel is the material of choice due to its superior properties. The bearing cage holds the rolling elements in place and plays a crucial role in performance and durability. Common materials include: Mini stainless steel flange bearings can be pre-lubricated with specialized food-grade greases, synthetic oils, or dry lubricants depending on the application. Sealed or shielded bearings reduce contaminant ingress, enhancing longevity. To further enhance performance, some bearings undergo passivation or Teflon coatings, which provide: Mini stainless steel flange bearing units are indispensable components in a wide range of industries, from food processing and pharmaceuticals to robotics and aerospace. Their compact size, corrosion resistance, and high load-bearing capacity make them a top choice for precision applications. By understanding their usage, industries, and material properties, businesses can make informed decisions to improve efficiency, safety, and longevity in their mechanical systems. If you’re looking for premium-quality stainless steel mini flange bearings, consider certified and food-safe options that align with your industry’s performance and hygiene requirements. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Block Bearings and Flange Mounted Units is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440C Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.Usage, Industries and Material Composition

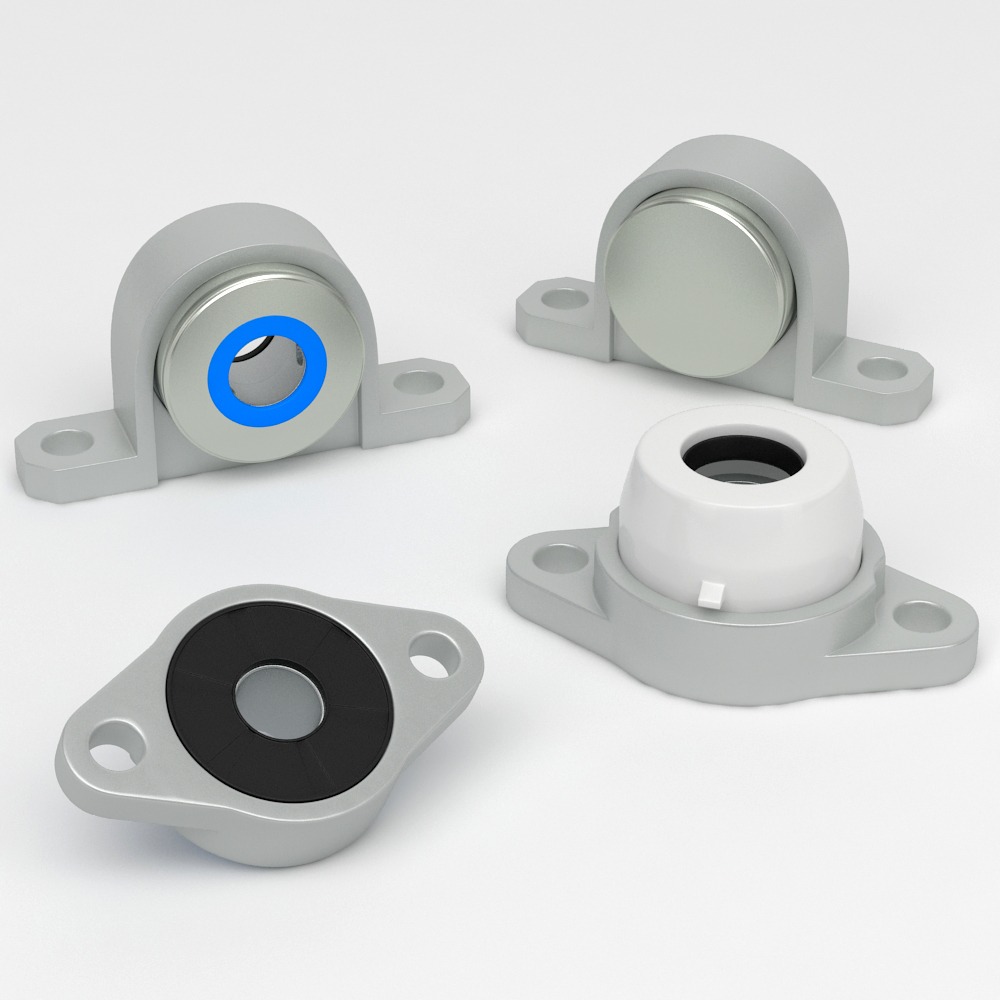

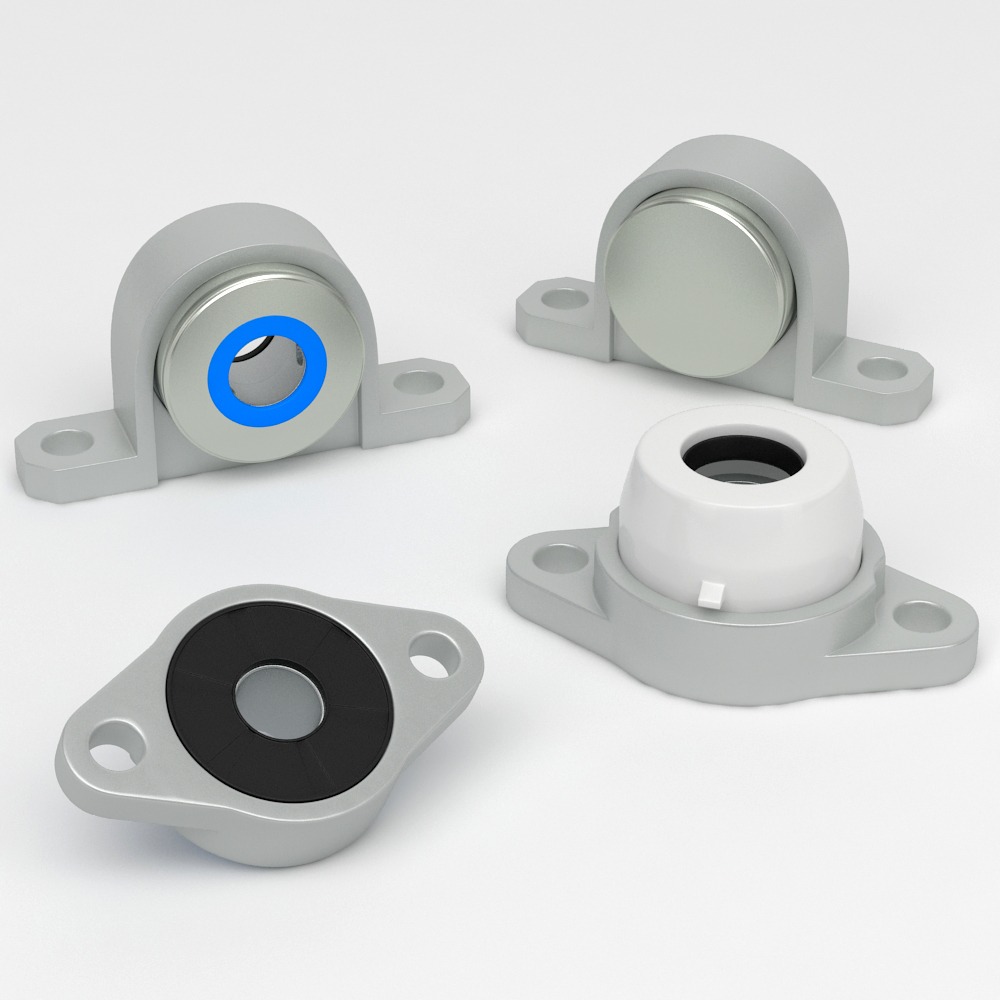

Mini Stainless Steel Flange Bearing Units

Usage of Mini Stainless Steel Flange Bearing Units

Industries Benefiting from Mini Stainless Steel Flange Bearing Units

Materials and Their Advantages

Design Considerations

Usage of Mini Stainless Steel Flange Bearing Units

1. Load Distribution and Shaft Support

2. Vibration and Shock Absorption

3. Corrosion and Contaminant Resistance

4. Compact and Lightweight Design

5. Longevity and Low Maintenance

Industries Benefiting from Mini Stainless Steel Flange Bearing Units

1. Food and Beverage Processing

2. Pharmaceutical and Medical Equipment

3. Aerospace and Defense

4. Robotics and Automation

5. Marine and Offshore Applications

Material Composition and Benefits of Stainless Steel Flange Bearing Units

1. Stainless Steel Grades Used in Mini Flange Bearings

AISI 440C Stainless Steel

AISI 316 Stainless Steel

KS440 or ACD34 Stainless Steel

2. Cage Materials

3. Lubrication and Sealing Options

4. Surface Treatments and Coatings

Precision, Durability and Corrosion Resistance for High-Performance Industries

Contact

Understanding Machinery Components & Protection Standards