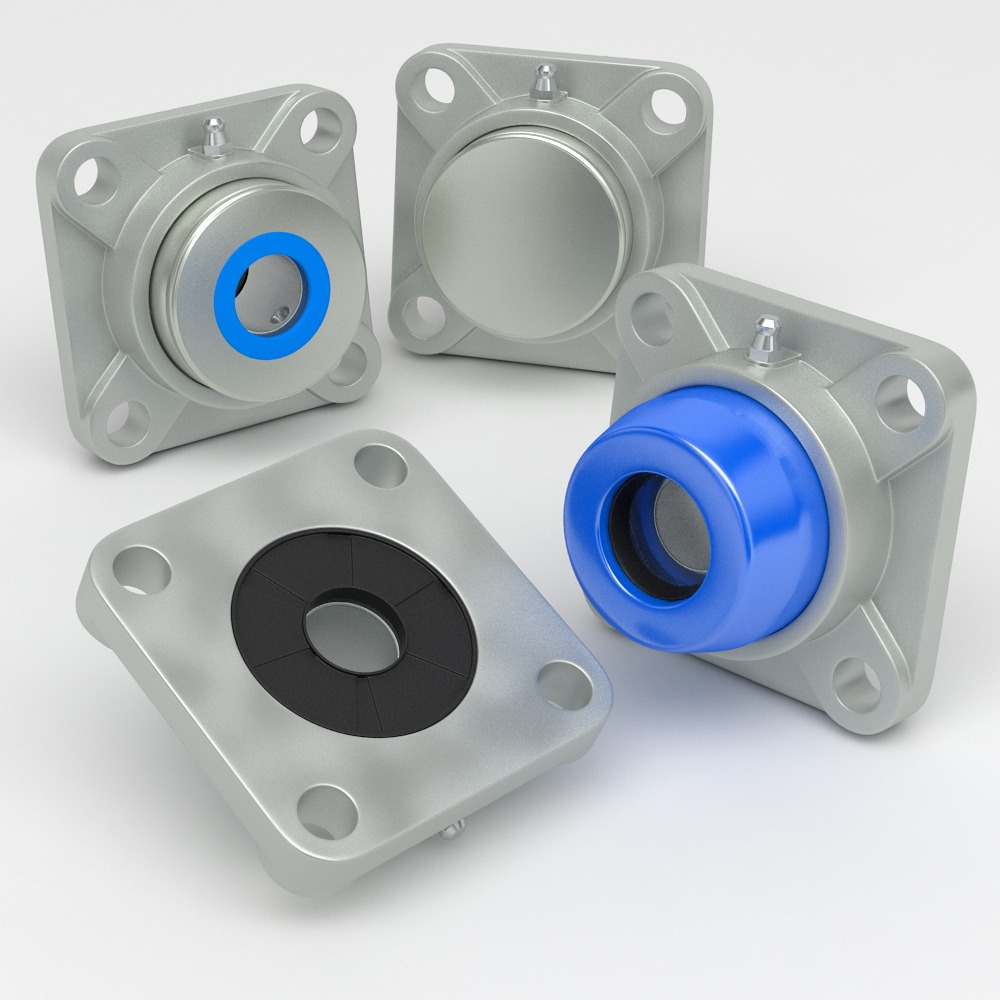

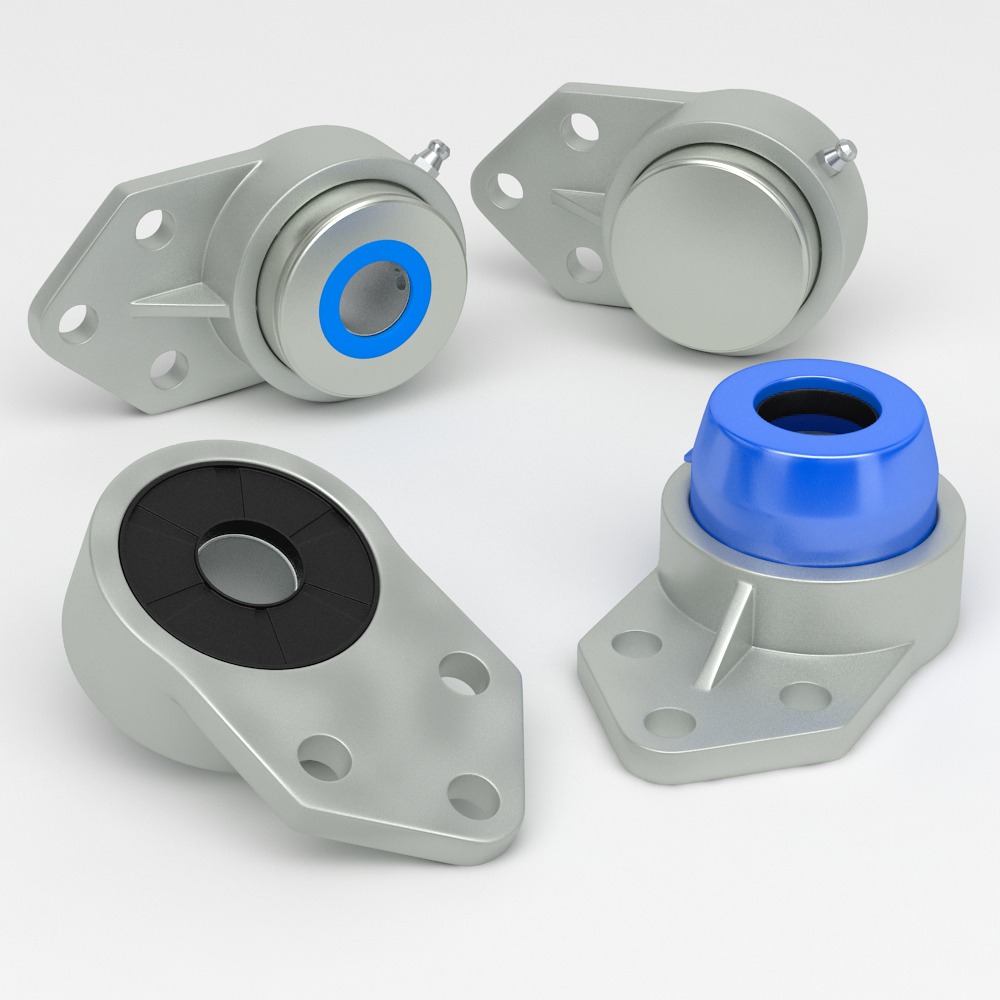

Flange bearing square unit

Flange bearing square units are indispensable in modern industrial applications, ensuring smooth motion and reducing friction in machinery. These units provide excellent load distribution, structural support, and alignment for rotating shafts, making them crucial for equipment across multiple industries. Choosing the right flange bearing square unit requires careful consideration of usage, industries, materials, and expertise. This article explores the essential aspects of these bearing units while emphasizing experience, expertise, authoritativeness, and trustworthiness (E-E-A-T), ensuring reliability in critical applications. Flange bearing square units are integral components in various mechanical systems, providing essential support and alignment for rotating shafts. Their unique design, featuring a square flange, allows for secure attachment to perpendicular surfaces, ensuring stability and efficient load distribution. This article delves into the usage, industries, materials, and the importance of experience, expertise, authoritativeness, and trustworthiness in selecting and applying flange bearing square units. Flange bearing square units are designed to mount bearings securely to a perpendicular surface, facilitating the smooth operation of rotating shafts. The square flange design, typically with four mounting holes, ensures a robust and stable connection, preventing misalignment and reducing wear on the bearing and associated components. This configuration is particularly beneficial in applications where precise alignment and stability are crucial. These bearing units find applications across a diverse range of industries due to their versatility and reliability: The choice of materials in flange bearing square units is critical to their performance and suitability for specific applications: Selecting the appropriate flange bearing square unit requires a deep understanding of the application requirements and the bearing’s specifications. Partnering with reputable manufacturers and suppliers ensures access to high-quality products and expert guidance. Companies like NHK, NSK and SKF are renowned for their expertise and authoritative presence in the bearing industry, offering a wide range of flange bearing units tailored to various applications. Trustworthiness in this context involves relying on established brands and suppliers who adhere to stringent quality standards and provide reliable performance data. This trust is built through years of consistent product quality, innovation, and customer support. Flange bearing square units are vital components in numerous industrial applications, offering reliable support and alignment for rotating shafts. Understanding their usage, the industries they serve, the materials they are made from, and the importance of experience, expertise, authoritativeness, and trustworthiness in their selection and application is crucial for optimal performance and longevity. By partnering with reputable manufacturers and suppliers, industries can ensure the efficient and reliable operation of their machinery and equipment. Flange bearing square units are self-contained bearing housings with a square flange for secure mounting. These units house insert ball bearings, which help reduce friction between moving parts, improving efficiency and longevity. ✔ Secure Shaft Support – Prevents misalignment and enhances machine stability. These features make flange bearing square units ideal for heavy-duty machinery requiring precise and stable rotation under various conditions. Flange bearing square units play a pivotal role in industrial operations, contributing to efficiency, safety, and longevity. Here are some of the most common industries that rely on these components: Flange bearing square units are widely used in food processing conveyor systems, packaging machinery, and filling equipment. Stainless steel bearings with sealed housings prevent contamination, ensuring compliance with strict hygiene standards. In harvesting, sorting, and irrigation systems, these bearing units offer stability in harsh outdoor environments. They are designed to withstand dust, moisture, and heavy loads, essential for farm equipment longevity. Industrial conveyors, automated storage systems, and warehouse equipment depend on square flange bearings to ensure smooth motion and durability, even under continuous operation. Flange bearing square units provide essential rotational support for looms, spinning machines, and dyeing equipment, enabling seamless textile production. In heating, ventilation, and air conditioning (HVAC) systems, these bearings support fans, blowers, and motor shafts, ensuring consistent airflow and energy efficiency. Sterile environments require IP67-rated waterproof and corrosion-resistant bearings, preventing contamination in pharmaceutical, biotech, and chemical production facilities. These industries highlight the versatility and necessity of flange bearing square units in enhancing efficiency, safety, and performance across various applications. The durability and effectiveness of flange bearing square units depend on material selection. Different materials offer specific advantages depending on operating conditions and industry requirements. Selecting the right material ensures longevity, reliability, and compliance with industry standards. When investing in flange bearing square units, it is essential to consider E-E-A-T factors: Manufacturers with decades of experience in the bearing industry understand performance requirements, design improvements, and industry regulations. Established companies such as: are known for producing high-quality flange bearing square units that meet global industrial standards. Industry leaders incorporate advanced engineering, precision manufacturing, and rigorous testing to ensure optimal performance in diverse applications. Key aspects of expertise include: Top manufacturers adhere to global certification standards, ensuring product reliability and safety: To establish trust, leading brands provide: These factors ensure businesses get the right bearing solution tailored to their operational needs. Flange bearing square units are critical for machinery efficiency, reliability, and safety in industries ranging from food processing to material handling and HVAC systems. Choosing the right bearing unit—from selecting the best material to working with experienced manufacturers—ensures longevity and operational excellence. When selecting a flange bearing square unit, always consider: ✔ Industry requirements and operational conditions By prioritizing these aspects, businesses can optimize performance, reduce downtime, and enhance equipment longevity, securing a competitive advantage in their industry. For businesses seeking premium flange bearings, partnering with certified suppliers like NHK, SKF, NTN, NSK and Timken ensures the highest standards in engineering, compliance, and performance. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Blocks and Flange Bearings is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. Stainless Steel 440 and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.A Vital Component for Industrial Efficiency

Flange Bearing Square Units

Usage of Flange Bearing Square Units

Industries Utilizing Flange Bearing Square Units

Materials Used in Flange Bearing Square Units

Experience, Expertise, Authoritativeness and Trustworthiness (E-E-A-T)

A vital component

Usage of Flange Bearing Square Units

Key Functions:

✔ Load Distribution – Ensures even weight and force distribution, reducing wear.

✔ Shock Absorption – Mitigates vibration and operational stress.

✔ Corrosion Resistance – Often designed with protective materials for harsh environments.

✔ Maintenance Efficiency – Allows for easy replacement and lubrication.Industries That Rely on Flange Bearing Square Units

1. Food and Beverage Processing

2. Agricultural Machinery

3. Material Handling & Logistics

4. Textile Manufacturing

5. HVAC Systems

6. Pharmaceutical and Chemical Processing

Material Selection for Flange Bearing Square Units

Common Materials Used:

Material Key Benefits Cast Iron High strength, cost-effective, suitable for heavy loads. Stainless Steel Corrosion-resistant, ideal for food, beverage, and pharmaceutical applications. Pressed Steel Lightweight, suitable for moderate loads and general applications. Polymer/Plastic Chemical-resistant, non-corrosive, used in hygienic environments. Flange Bearing Square Units

1. Experience: Choosing a Proven Supplier

2. Expertise: Technical Innovation & Engineering Excellence

✔ Load capacity optimization for high-speed operations.

✔ Self-aligning bearing technology to reduce wear.

✔ Advanced sealing mechanisms for dust and moisture resistance.3. Authoritativeness: Compliance with International Standards

4. Trustworthiness: Guaranteed Product Reliability

✔ Comprehensive product warranties

✔ Quality control certifications

✔ Customer support & technical consultationInvesting in High-Quality Flange Bearing Square Units

✔ Material compatibility and durability

✔ Certified suppliers with proven expertise

✔ E-E-A-T principles: Experience, Expertise, Authoritativeness, and Trustworthiness

Contact

Understanding Machinery Components & Protection Standards