F208 bearing

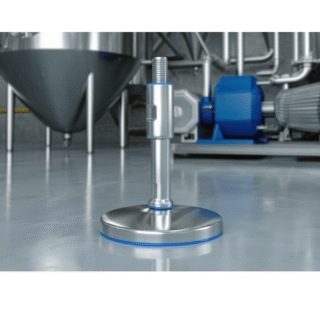

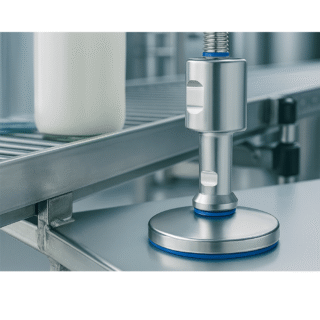

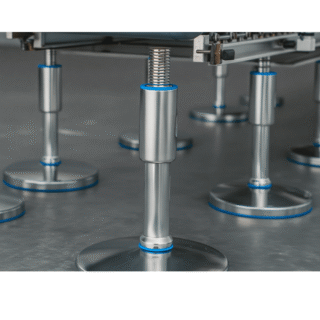

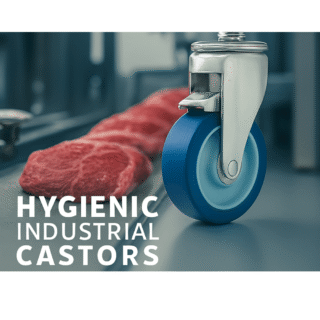

In the world of manufacturing, precision is the cornerstone of success. NHK Machinery Parts understands the critical role that precision plays in the production and processing of food and pharmaceutical products. With a steadfast commitment to sustainable development and growth, we engineer products that not only meet but exceed industry standards. Check out all of our waterproof bearings Creating sustainable and responsible production processes is a multifaceted endeavor. At NHK, we meticulously craft our products to endure the harshest environments while minimizing their environmental impact. As a global leader in sustainable stainless steel components, IP67 waterproof bearing units, levelling castors, and more, we take pride in our role as stewards of the environment. Our journey toward sustainable development commences with the durability of our products. NHK Machinery Parts manufactures items that are built to last and are fully recyclable. We believe in contributing to a circular economy, where resources are conserved and reused, reducing waste and fostering environmental responsibility. At NHK, we proudly stand as leading manufacturers in the industry. Our extensive range of products includes EHEDG levelling feet, IP67 waterproof ball bearing units, industrial castors, and stainless parts designed with the utmost hygiene in mind. We continuously evolve and innovate our product offerings to keep pace with the ever-increasing demands of our valued customers. We comprehend the unique challenges confronted by manufacturers in the food and pharmaceutical processing equipment industry. Hygienic design is a linchpin in ensuring product quality and safety. NHK Group leverages its expertise and vast experience to deliver high-quality, hygienic stainless steel equipment for cutting-edge machine systems. Our offerings encompass levelling castors, conveyor parts, stainless feet, and much more, all meticulously designed to meet and exceed the stringent standards of the food, dairy, beverage, and pharmaceutical processing sectors. At NHK Machinery Parts, we are more than just suppliers; we are your partners in progress. We offer guidance and tailored solutions that align with your specific industry requirements. When you engage with us, you’re not just purchasing products; you’re gaining access to our wealth of experience and expertise. Our product catalog boasts an extensive array of offerings, ranging from EHEDG Stainless Steel Machine Levelling Feet to Hygienic 3A Conveyor Parts in Stainless Steel. We also provide Hygienic Enclosure Parts and Components, Industrial Castors in Hygienic Design, Waterproof IP67 Bearing Houses, and much more. We extend a warm invitation to get in touch with us. Share your unique requirements and challenges with our dedicated team, and let us demonstrate how NHK Machinery Parts can enhance your operations. Simply complete the contact form with your company name, name, email, phone, and message. We are here to assist you in finding the ideal equipment for your specific industry. When you choose NHK Machinery Parts, you are opting for precision, quality, and sustainability. Our products, including the exceptional F208 Bearings, are meticulously engineered to elevate your manufacturing processes, providing the precision and reliability you demand. Experience the NHK difference today and embark on a journey toward manufacturing excellence. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Blocks and Flange Mounted Units is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. Stainless Steel 440 and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.Elevate Your Manufacturing Precision with NHK’s F208 Bearings: Where Quality Meets Excellence

The Pursuit of Sustainability

Sustainability Begins with Durability

Mastering Machinery Parts

Tackling Hygienic Challenges

Your Partner in Progress

Discover Our Vast Range

Connect with Us Today

Choose NHK for Precision

Check out our other articles:

Contact

Understanding Machinery Components & Protection Standards