EHEDG IP69K Stainless Steel Flange Bearing Units

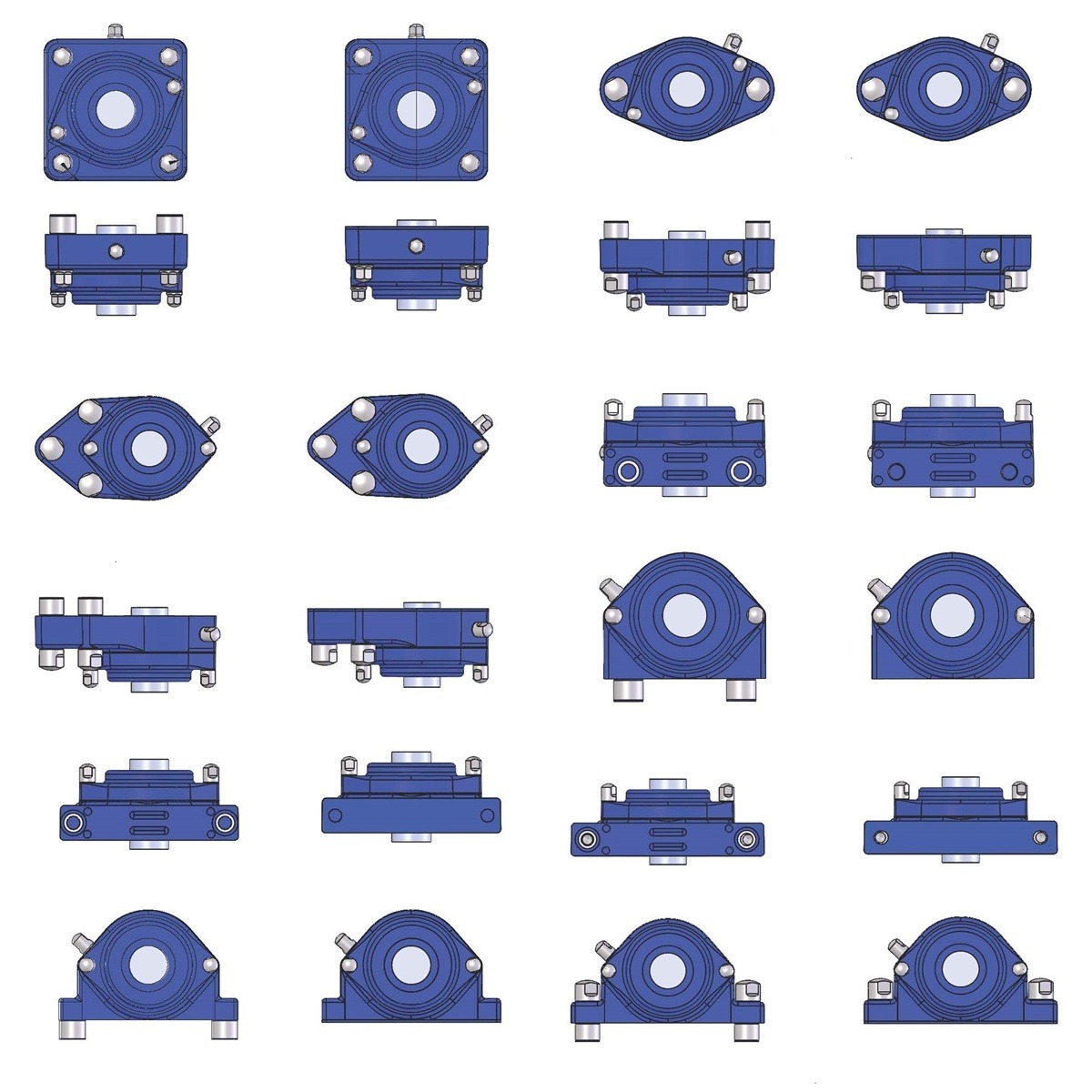

In today’s demanding industrial environments, maintaining the highest standards of hygiene and durability is not just a preference—it’s a necessity. EHEDG IP69K flange bearing units in stainless steel have emerged as a premium solution for industries that require equipment capable of withstanding aggressive cleaning processes without compromising on performance. This comprehensive guide explores the usage, industries served, materials employed, and the unparalleled experience, expertise, authoritativeness, and trustworthiness behind these state-of-the-art units. The world of industrial processing, especially in sectors like food, beverage, pharmaceuticals, and biotechnology, relies on components that combine rigorous hygienic design with robust performance. EHEDG (European Hygienic Engineering & Design Group) standards ensure that equipment meets stringent cleanliness and safety guidelines, while the IP69K rating guarantees resistance to high-pressure wash-downs and extreme conditions. Flange bearing units, when constructed in stainless steel and meeting these standards, become a critical asset for maintaining operational efficiency and safety in environments where contamination control is paramount. As companies continue to prioritize cleanliness and product integrity, understanding the specifics of EHEDG IP69K flange bearing units is crucial. This article dives deep into how these units are used, the industries that depend on them, the superior material qualities of stainless steel, and why decades of experience and unwavering expertise underpin their design and manufacture. EHEDG IP69K flange bearing units are designed with one central purpose: to endure the most severe cleaning processes while maintaining perfect operational functionality. Here’s how their usage benefits modern industries: The applications of EHEDG IP69K flange bearing units in stainless steel are extensive, reaching several high-stakes industries that demand both high hygiene and operational durability: In the food and beverage industry, safety and quality are non-negotiable. Processing equipment must meet strict hygiene standards to prevent contamination and ensure product quality. EHEDG-compliant flange bearing units are integral in: The pharmaceutical sector requires equipment that can be sanitized to the highest standards, given the potential health implications of contamination: In chemical processing, the robustness and chemical resistance of stainless steel, combined with EHEDG and IP69K standards, ensure that equipment can handle corrosive substances without degradation, thus safeguarding both the process and the end product. Industries focused on environmental sustainability and waste treatment benefit from equipment that not only performs efficiently but also meets rigorous cleaning standards. The design of EHEDG IP69K flange bearing units helps reduce contamination risks and supports safe waste handling processes. At the heart of these flange bearing units lies stainless steel—a material renowned for its durability, corrosion resistance, and hygienic properties. Here’s why stainless steel is the material of choice: The design and manufacture of EHEDG IP69K flange bearing units are the culmination of decades of experience in the field of hygienic engineering. Manufacturers have spent years refining their processes to produce units that consistently exceed industry expectations. This accumulated knowledge is evident in every aspect of the product—from the precision of the machining to the reliability of the sealing systems. Companies with a long-standing history in producing sanitary components bring invaluable experience to the table. Their deep understanding of the cleaning challenges and operational stresses faced in modern industrial environments ensures that every flange bearing unit is designed with a focus on longevity, reliability, and ease of maintenance. Over time, their commitment to continuous improvement has resulted in products that are not only compliant with EHEDG standards but also tailored to meet the evolving needs of industries worldwide. Expertise in manufacturing EHEDG IP69K flange bearing units is demonstrated through meticulous design, engineering precision, and adherence to international standards. Key elements include: The authority behind EHEDG IP69K flange bearing units is rooted in strict adherence to internationally recognized standards and certifications. Industry leaders rely on these products because they meet or exceed the benchmarks for hygiene and durability. Manufacturers with a reputation for excellence and compliance provide a level of assurance that is critical in sectors where safety and performance are non-negotiable. Trust is the cornerstone of any industrial component, especially in applications where hygiene and safety are paramount. EHEDG IP69K flange bearing units in stainless steel are trusted by some of the world’s leading companies because: EHEDG IP69K flange bearing units in stainless steel represent the pinnacle of hygienic engineering. They combine robust construction, precision engineering, and advanced material science to meet the rigorous demands of today’s industrial processes. Whether used in food and beverage processing, pharmaceutical production, or chemical handling, these units offer unparalleled performance under extreme cleaning conditions. Their superior design, backed by decades of experience and deep industry expertise, positions them as the trusted choice for companies committed to quality and safety. With the authority of international standards and certifications, and a transparent approach to quality control, manufacturers of these flange bearing units have built a reputation for reliability and excellence that stands as a benchmark in the industry. For companies looking to invest in equipment that not only meets but exceeds stringent hygienic and operational standards, EHEDG IP69K flange bearing units in stainless steel offer a compelling solution. They are a testament to what can be achieved when engineering excellence is combined with a commitment to customer satisfaction and safety. Embracing these units means investing in a future where operational efficiency, hygiene, and durability work in harmony to drive success across critical industries. By understanding the key aspects of usage, the diverse industries they serve, the superior material properties of stainless steel, and the profound expertise behind their creation, decision-makers can confidently select EHEDG IP69K flange bearing units as a critical component of their processing infrastructure. With proven performance, unwavering reliability, and an uncompromising focus on quality, these units not only meet today’s industrial challenges—they are built to lead the way into the future of hygienic engineering. Designed for the toughest environments, EHEDG IP69K stainless steel flange bearing units provide unmatched hygiene, durability, and reliability for critical industries. Engineered to endure high-pressure wash-downs and extreme conditions, these bespoke bearing units set the standard in performance, safety, and cleanliness. Engineered for extreme environments, our EHEDG IP69K stainless steel flange bearing units deliver unmatched hygiene and durability, ensuring seamless performance even under the harshest cleaning protocols. Designed for the critical demands of food, beverage, and pharmaceutical sectors, these bespoke bearing units combine precision engineering with robust material science to guarantee operational excellence and safety. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Bearing Housings and Flanged Bearings is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. Type 440 Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.EHEDG IP69K Flange Bearing Units in Stainless Steel

A Comprehensive Guide

Revolutionizing Hygienic Engineering

EHEDG IP69K Stainless Steel Flange Bearing Units

Engineered for Extreme Environments

Serving Critical Sectors and Industries

Food and Beverage Processing

Pharmaceutical and Biotechnology

Chemical Processing

Environmental and Waste Treatment

The Superiority of Stainless Steel

Decades of Innovation and Experience

Engineering Excellence in Every Detail

Setting the Benchmark in Hygienic Engineering

Building Confidence Through Proven Performance

Optimized for Extreme Cleanliness

The Ultimate Choice for Food, Beverage, and Pharma

Precision & Durability Combined

The Future of IP69K Flange Bearing Solutions

Setting New Standards in Safety: EHEDG-Certified Stainless Steel Bearings

Contact

Understanding Machinery Components & Protection Standards