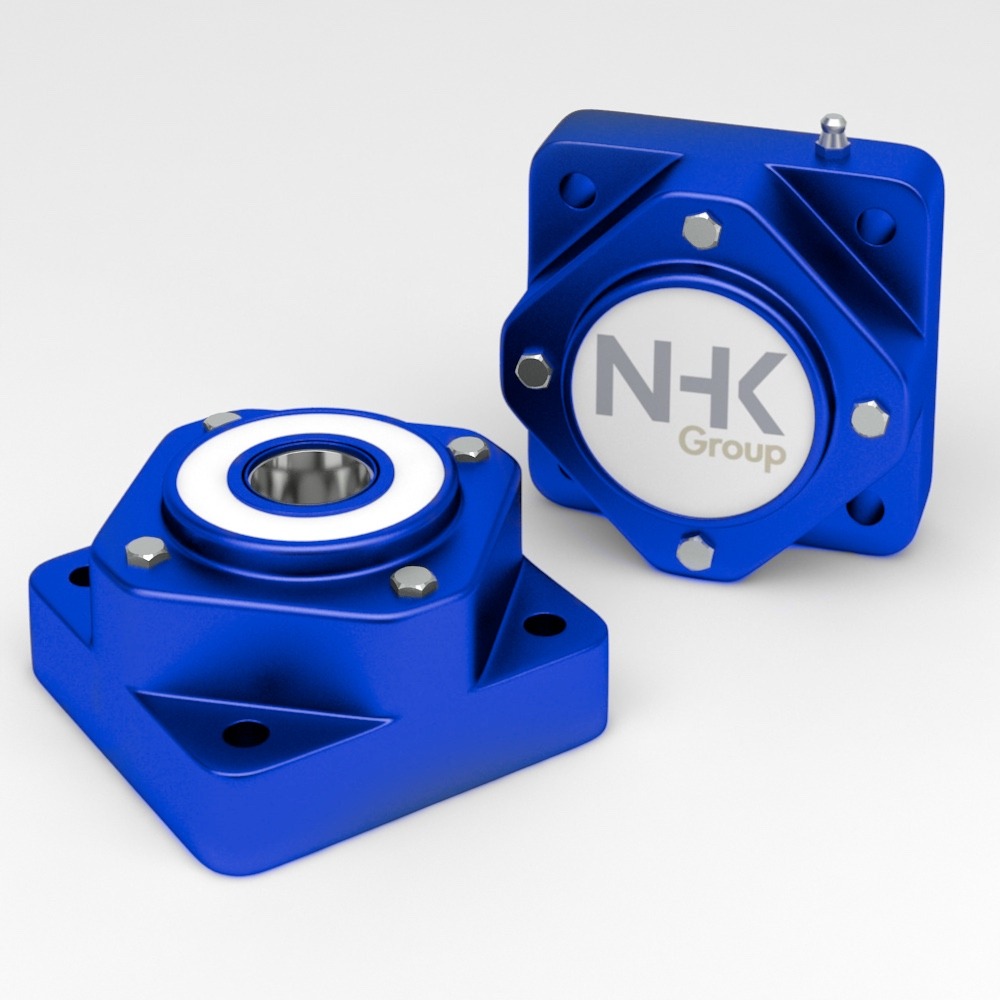

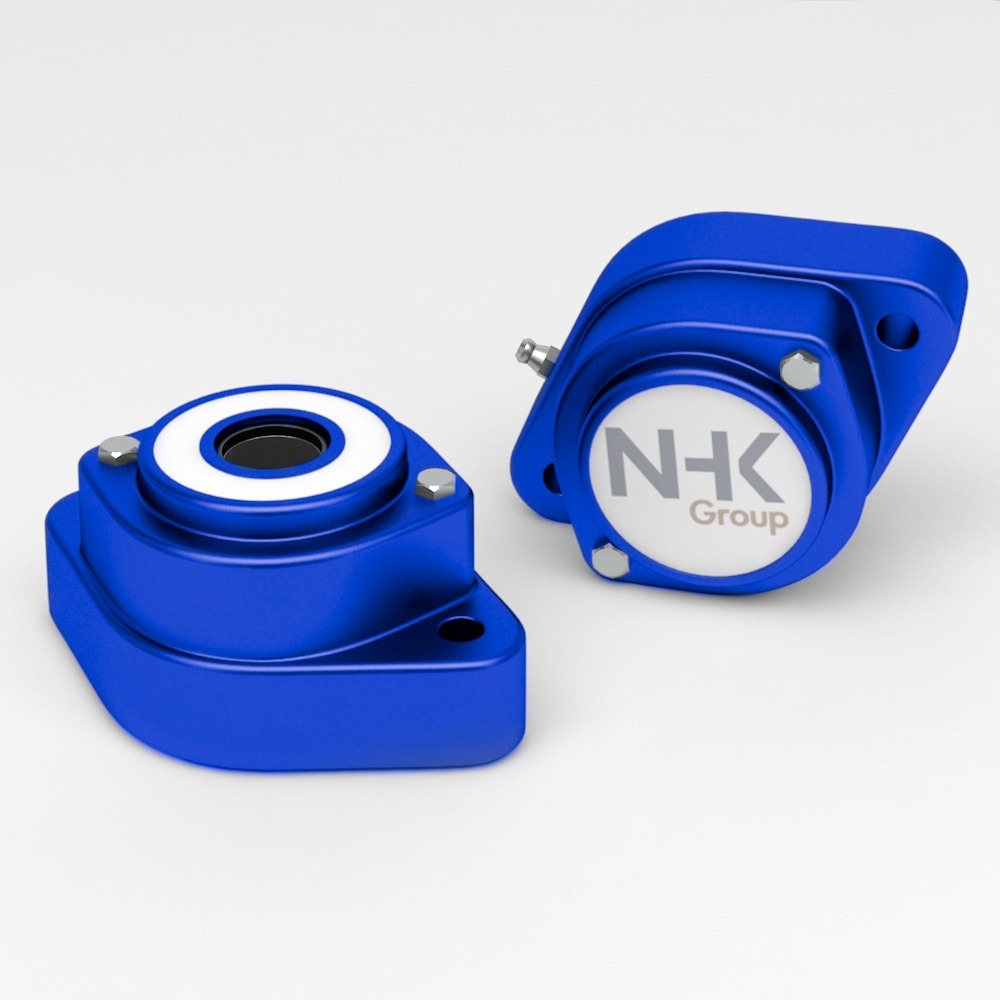

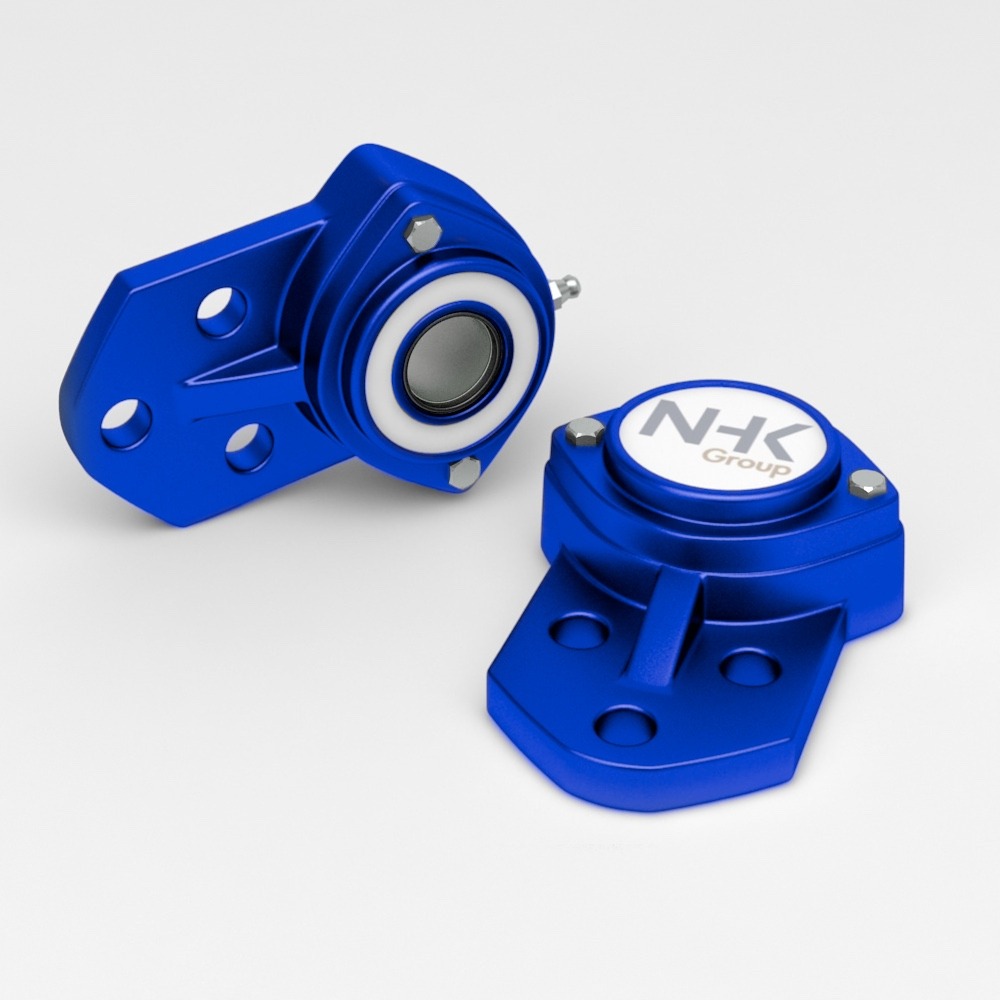

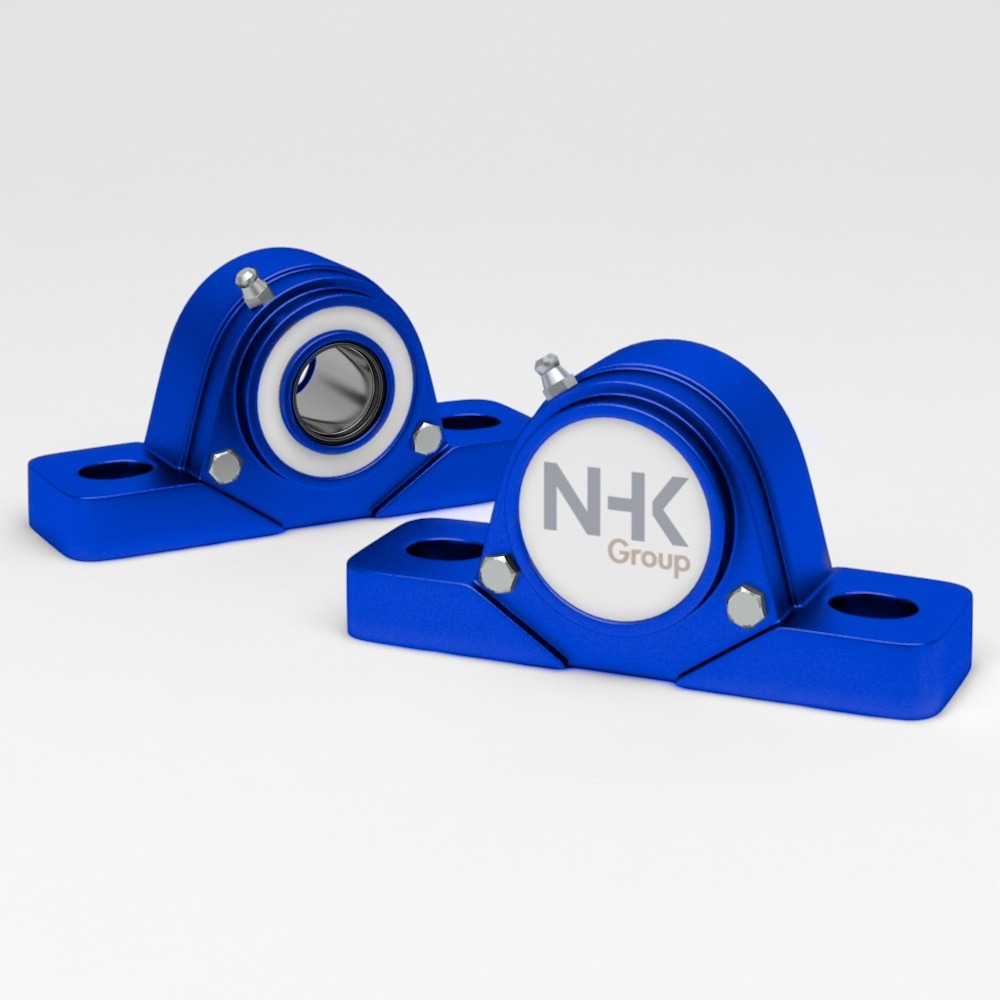

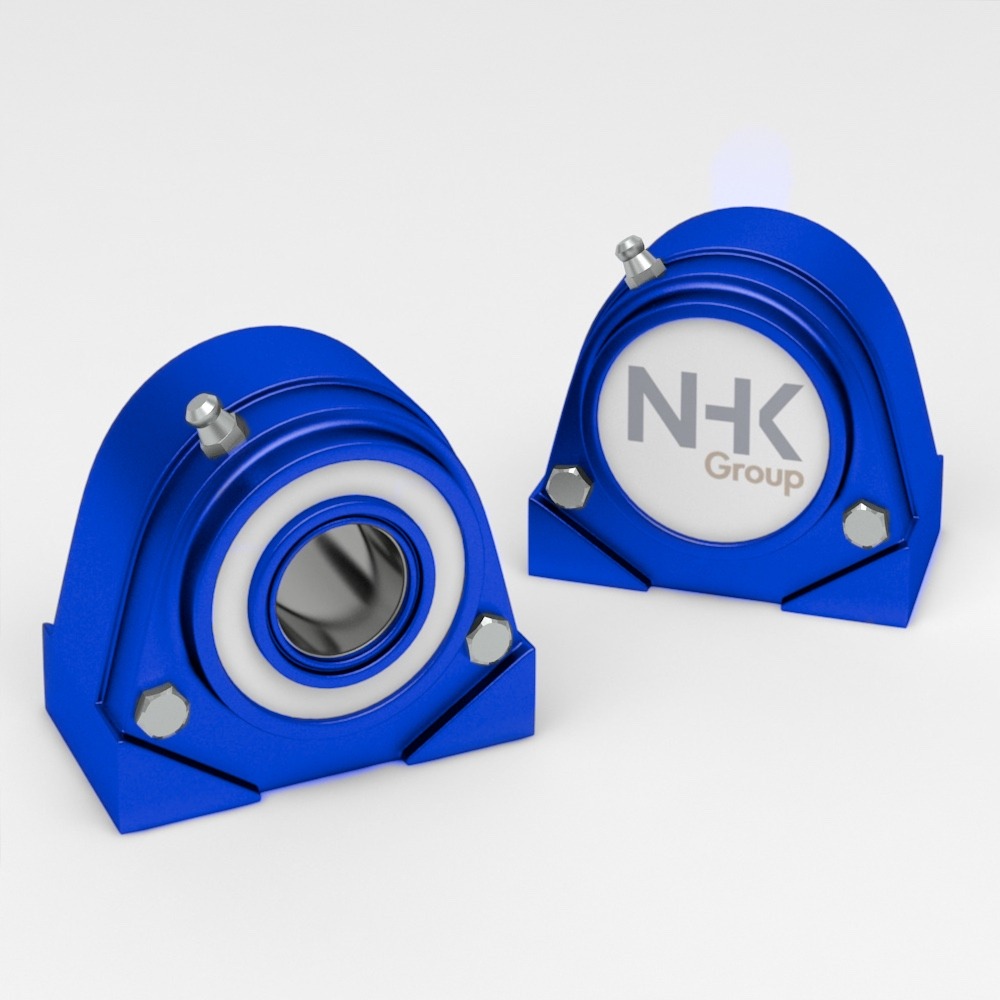

EHEDG Certified bearing house units

In industries like food processing, pharmaceuticals, and biotechnology, stringent hygiene standards are non-negotiable. Each component in the manufacturing line plays a critical role in maintaining sanitary conditions, but few are as fundamental as bearing house units. Certified by the European Hygienic Engineering and Design Group (EHEDG), EHEDG bearing house units are engineered to ensure the highest levels of cleanliness, helping manufacturers avoid the risks of contamination and costly product recalls. This article explores how EHEDG-certified bearing units contribute to safe, contamination-free production environments and why they are indispensable in industries where hygiene is paramount. The EHEDG is an international consortium dedicated to ensuring the hygienic design of food production equipment and facilities. EHEDG-certified components, like bearing house units, are designed to eliminate areas where bacteria or contaminants could accumulate. The certification process is rigorous, ensuring that each component meets exacting standards for cleanability and contamination prevention. In a market where hygiene concerns can directly impact brand reputation, investing in EHEDG-certified equipment helps companies adhere to stringent safety protocols and regulatory requirements. Bearing house units support and protect rotating shafts in machinery, maintaining smooth operation and reducing wear and tear. However, conventional bearing units often have design flaws that can lead to contamination risks. Small crevices, grooves, or complex shapes on standard units create opportunities for contaminants to settle and multiply. In industries where even minor contamination can lead to severe health risks and product recalls, EHEDG-certified bearing house units are engineered with hygienic design principles, minimizing these risks by prioritizing cleanability and resilience. EHEDG-certified bearing house units are designed to limit contamination risks through advanced material selection, surface finishes, and shape optimization. Here’s how: Using EHEDG-certified bearing house units in hygiene-sensitive environments offers significant benefits, both in terms of operational efficiency and product safety. Product recalls are costly and detrimental to a company’s reputation. In many cases, contamination that leads to recalls is preventable, often traceable to inadequate hygienic practices. By incorporating EHEDG-certified bearing units, companies can take proactive steps toward reducing contamination risks at every stage of the production process. With these components, manufacturers create a robust line of defense against contaminants, thus reducing the chances of costly recalls that could disrupt production, impact brand loyalty, and erode consumer confidence. EHEDG-certified bearing units are invaluable in applications that demand consistent hygiene, such as: Investing in EHEDG-certified bearing units can be a strategic move for companies aiming to improve hygiene standards. When selecting bearing units, consider factors such as material compatibility with your cleaning processes, ease of maintenance, and the specific hygiene requirements of your industry. Collaborating with trusted suppliers and verifying the EHEDG certification of each unit will further ensure quality and compliance with hygienic standards. In the food, pharmaceutical, and biotechnology industries, maintaining strict hygiene standards is essential for consumer safety and regulatory compliance. EHEDG-certified bearing house units offer a practical solution to contamination challenges, reducing the risk of product recalls and ensuring a sanitary production environment. By investing in these hygienically designed units, companies can safeguard their reputation, optimize production, and demonstrate their commitment to consumer health. In an era where cleanliness and safety are paramount, EHEDG-certified bearing units are more than just components—they are essential elements of a contamination-free manufacturing line. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Bearing Housings and Flanged Bearings is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. Stainless Steel 440 and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.EHEDG Certified Bearing House Units: Avoiding Contamination and Product Recalls

Download our catalogue here

What is EHEDG Certification?

The Role of Bearing House Units in Hygiene-Critical Industries

How EHEDG-Certified Bearing House Units Prevent Contamination

EHEDG-certified bearing units often feature smooth surfaces with rounded edges, which reduce the risk of residue buildup. By eliminating areas where particles might cling, the units facilitate thorough cleaning, minimizing the risk of contamination even in hard-to-reach areas.

EHEDG-certified bearings are usually made of high-grade stainless steel, which is corrosion-resistant and non-porous. This material not only withstands rigorous cleaning agents but also prevents bacterial growth. Stainless steel’s durability also extends the unit’s lifespan, contributing to cost savings over time.

EHEDG-certified bearing units incorporate advanced sealing technologies that prevent contaminants from entering the bearing system. These seals are often designed to resist aggressive cleaning agents, ensuring long-lasting protection against microbial infiltration. The seals also reduce maintenance needs, which helps maintain consistent hygiene standards without frequent intervention.

Many EHEDG-certified bearing units feature a self-draining design, which allows cleaning fluids to flow out freely without pooling. This feature is crucial, as standing water can serve as a breeding ground for bacteria. By facilitating a quick, efficient cleaning process, the self-draining design further minimizes the risk of contamination.Key Benefits of EHEDG-Certified Bearing House Units

EHEDG-certified bearings are designed for easy cleaning, often without requiring disassembly. This efficient design reduces downtime during sanitation, which helps manufacturers maintain higher production rates while adhering to hygiene standards. With faster cleaning, production schedules are minimally impacted, leading to enhanced productivity.

Contamination in food and pharmaceutical production can result in severe health risks and costly recalls. EHEDG-certified bearing units, by design, reduce the likelihood of bacterial growth, protecting companies from the financial and reputational damages associated with contaminated products. For instance, a food recall could not only lead to substantial financial losses but also impact consumer trust, which takes time to rebuild.

Industries like food, pharmaceuticals, and biotechnology operate under strict regulations to ensure consumer safety. EHEDG-certified bearing units simplify compliance with these regulations by adhering to globally recognized hygienic standards. This certification also demonstrates a company’s commitment to hygiene, which can strengthen its standing with regulatory bodies and customers alike.

The durable materials and superior construction of EHEDG-certified bearings result in a longer operational life, even under harsh conditions. These bearing units withstand regular exposure to cleaning agents and high temperatures, which typically degrade conventional units. By investing in EHEDG-certified equipment, companies save on replacement and maintenance costs over time.Why EHEDG-Certified Bearing Units Matter in Preventing Product Recalls

Examples of EHEDG-Certified Bearing Unit Applications

From dairy production to meat processing, EHEDG-certified bearing units ensure that production lines are free from contamination risks. These bearings are especially useful in areas where machinery is exposed to frequent cleaning cycles and stringent sanitation protocols.

In pharmaceutical manufacturing, any contamination could compromise product integrity, leading to serious health risks. EHEDG-certified bearing units minimize such risks by maintaining a hygienic environment throughout production, reducing contamination risks for sensitive drugs and formulations.

Biotechnology processes often involve sensitive biological materials, making contamination control crucial. EHEDG-certified bearings support clean, contamination-free environments, crucial for producing safe, effective products in biotechnology applications.Choosing EHEDG-Certified Bearing House Units

EHEDG Certified bearing house units: Avoiding contamination and product recall

Check out our wide range of certified standard components

Contact

Understanding Machinery Components & Protection Standards