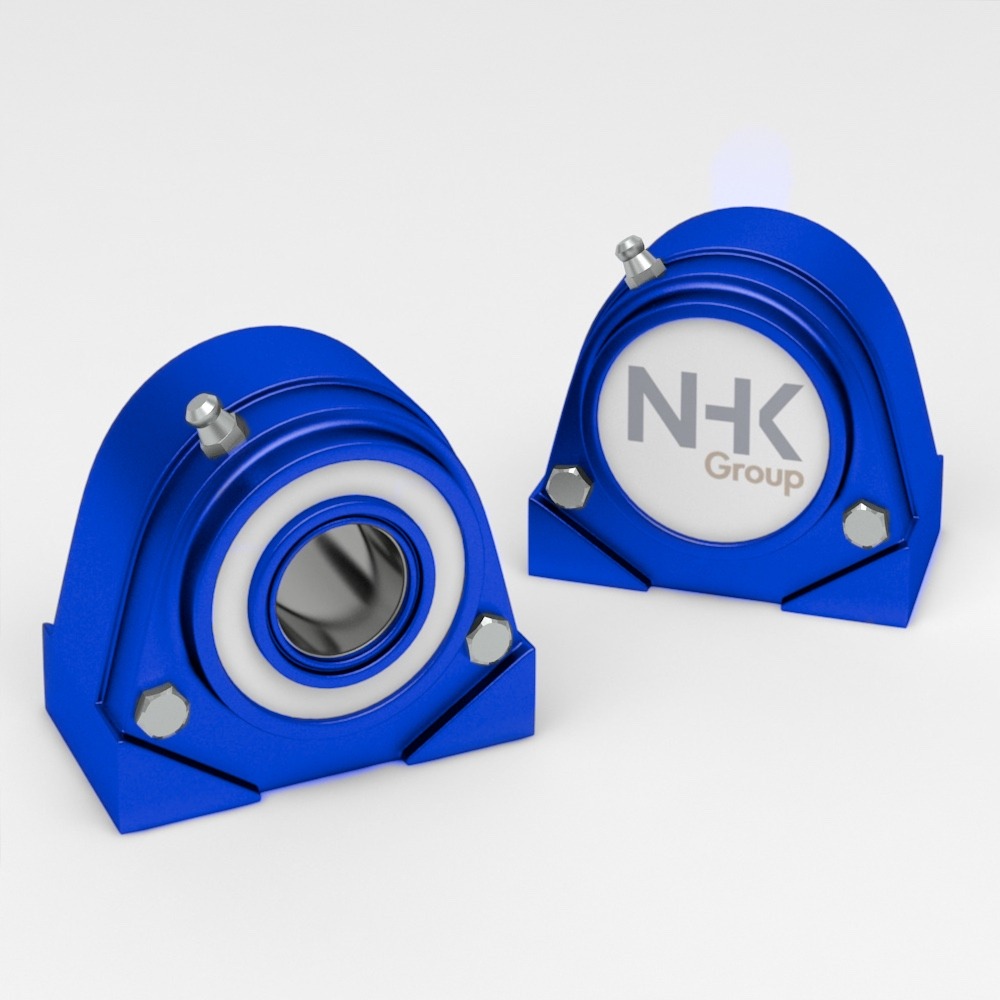

Easy to clean Waterproof bearing house units

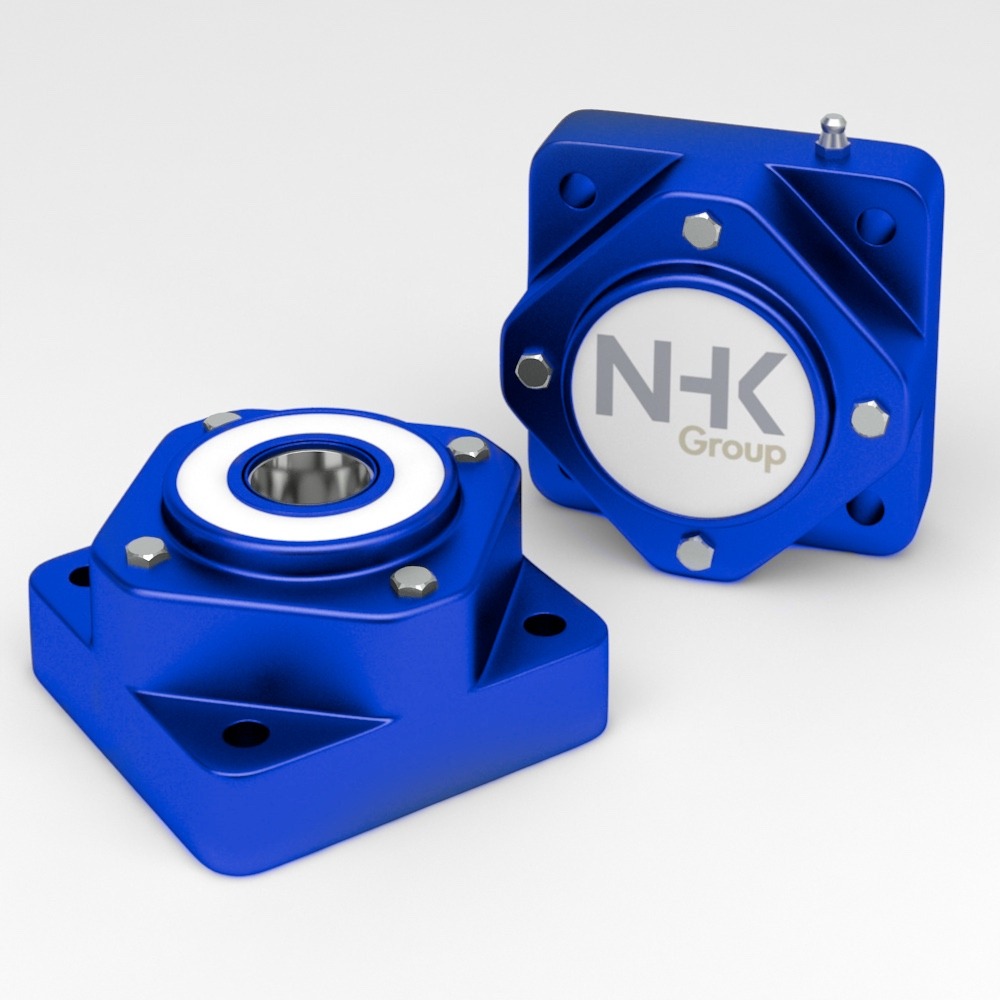

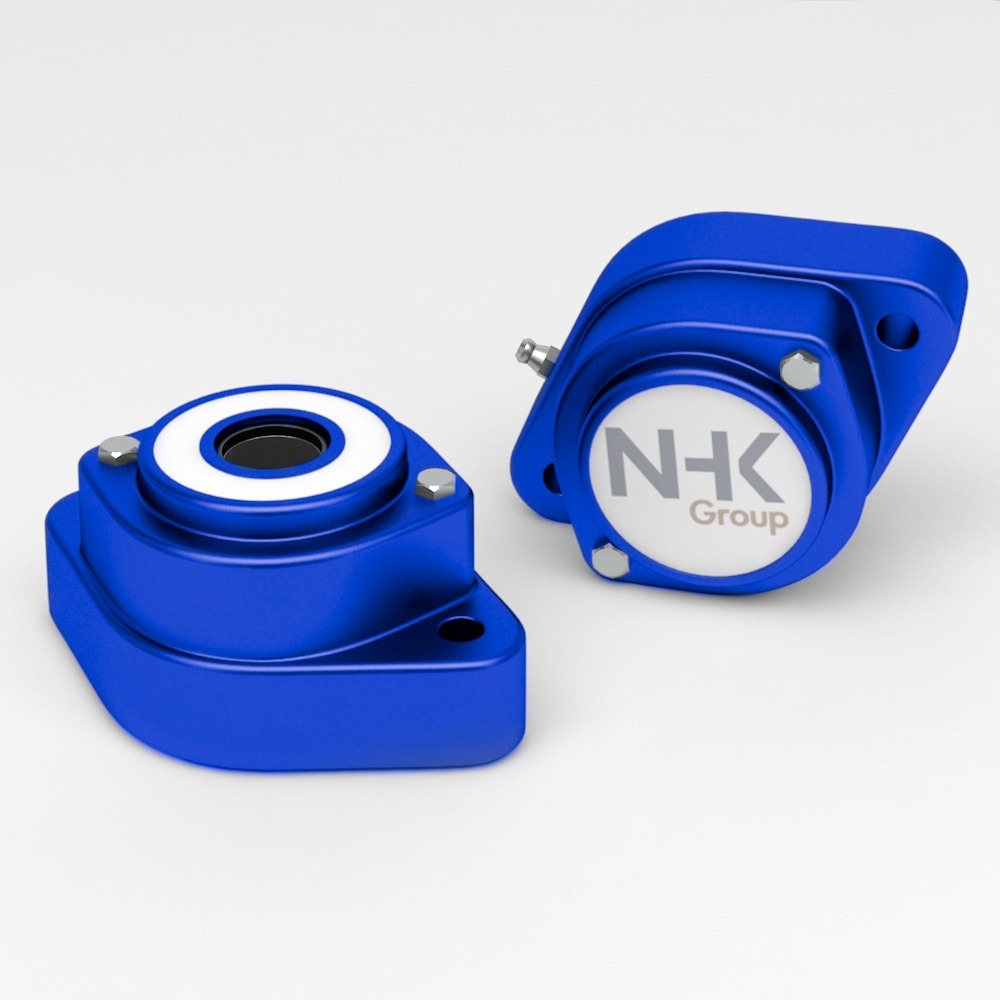

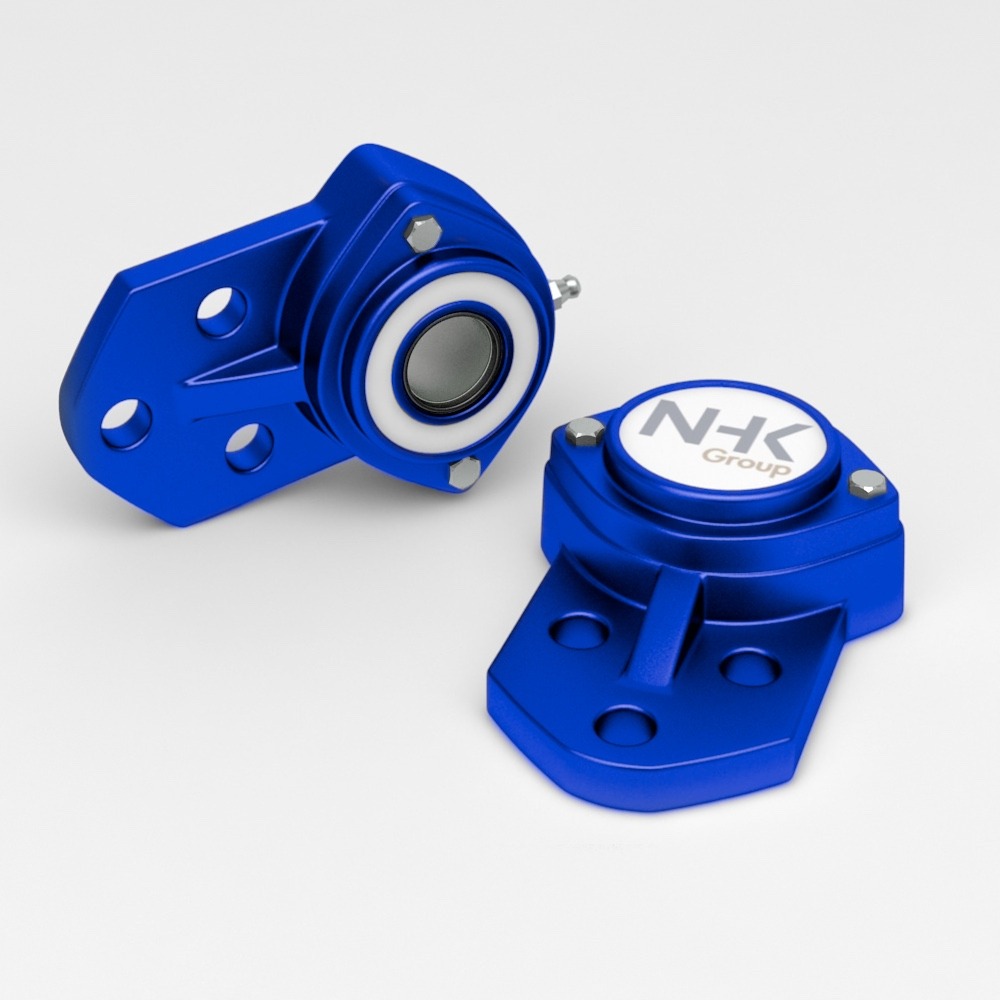

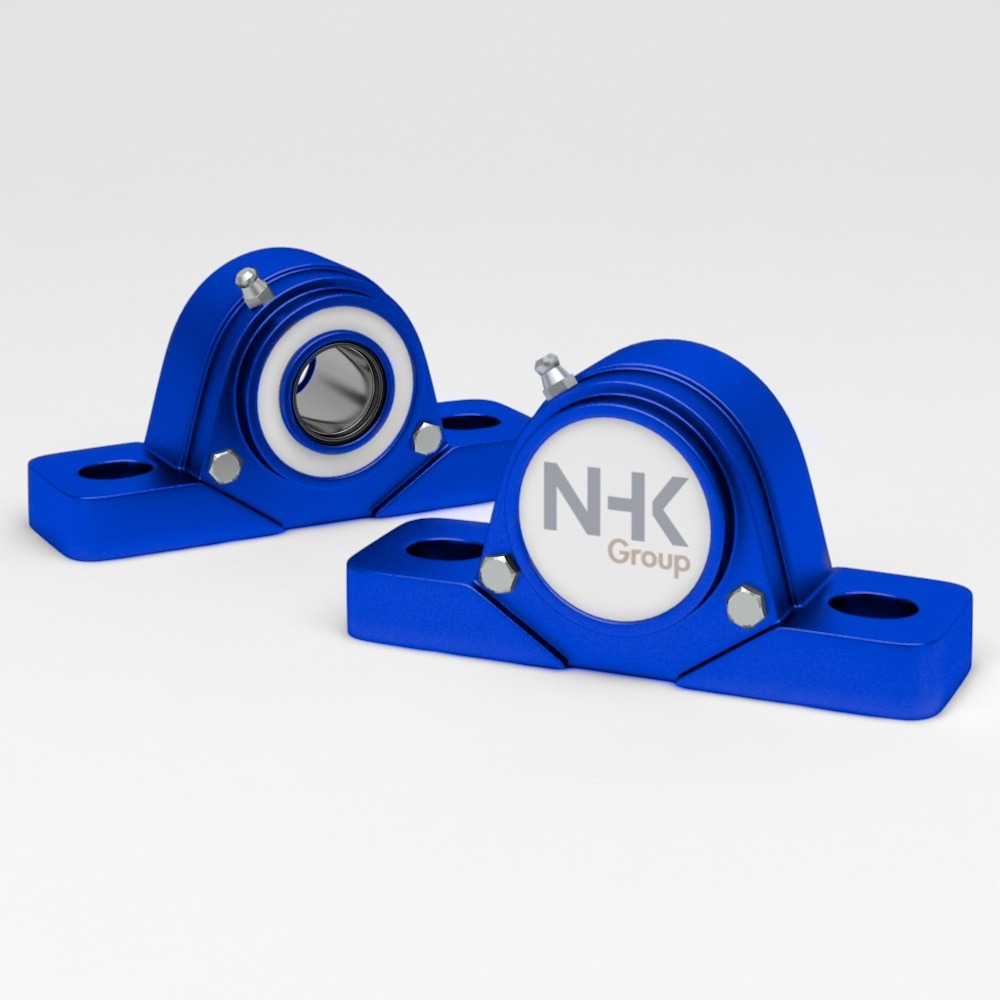

In industries where machinery operates under extreme and sometimes hazardous conditions, maintenance and downtime are inevitable. Whether it’s the food processing, pharmaceutical, or heavy manufacturing sector, machinery components must withstand rigorous cleaning, exposure to water, and even harsh chemicals. Bearing house units, in particular, are critical components as they support rotating shafts and endure substantial wear and tear. Traditionally, standard bearing units have posed challenges, often requiring frequent maintenance and replacement. However, the advent of easy-to-clean waterproof bearing house units has transformed maintenance protocols, offering significant reductions in downtime and maintenance costs. This article explores the benefits of these innovative bearing house units and their role in boosting operational efficiency. Waterproof bearing house units are designed to resist water, chemicals, and other contaminants. Traditional bearings are susceptible to damage from moisture and other corrosive elements, which compromises their functionality over time. By contrast, waterproof units are engineered with high-grade stainless steel or other corrosion-resistant materials and designed with seals that keep moisture and contaminants out. This characteristic is particularly valuable in industries with stringent hygiene requirements, such as food processing and pharmaceuticals, where machinery must endure frequent washdowns. Downtime is one of the most significant operational costs across industries. Every minute a machine is offline due to maintenance or unexpected failures can result in thousands of dollars in lost production. The costs of labor, parts, and missed production quickly accumulate, impacting profitability. Traditional bearing units often require extensive maintenance schedules to prevent moisture infiltration, which means more time spent on maintenance tasks rather than production. Easy-to-clean waterproof bearing house units, on the other hand, reduce maintenance requirements and extend intervals between inspections. With these units, companies can save both time and resources. Waterproof bearing house units are crafted to withstand extreme conditions. Made from stainless steel or high-performance polymers, they resist corrosion, temperature fluctuations, and abrasive contaminants. Their longer lifespan translates to fewer replacements, directly cutting down on part costs. Hygiene is paramount in sectors like food and pharmaceuticals. These units are engineered with smooth surfaces and sealed designs that prevent bacterial buildup, making them easy to sanitize. Reduced contamination risk means these units contribute to safer operations, enhancing the product’s quality and safety standards. Waterproof bearing units are often designed for quick disassembly and reassembly, which significantly cuts down the time required for cleaning and inspections. Their ease of maintenance enables faster and less labor-intensive cleaning processes, allowing production teams to focus on maximizing uptime. In conventional bearing units, lubrication is essential to maintain smooth rotation, and frequent lubrication is needed, especially in wet environments where oil or grease can wash away. Many waterproof units are designed to require less lubrication or even operate in a self-lubricating capacity, which helps minimize downtime associated with regular maintenance. A waterproof bearing housing unit’s advanced sealing mechanism allows for smoother operations with less friction. This increased efficiency reduces the amount of energy needed to operate the machinery, contributing to overall lower operational costs. Less friction also means less heat, prolonging the bearing’s life. In the food and beverage industry, strict hygiene standards demand regular washdowns with high-pressure water and cleaning agents. Waterproof bearing house units prevent water and contaminants from entering, safeguarding the machinery’s internal components. Easy-to-clean features reduce contamination risks, making these bearings ideal for operations handling dairy, meat, and beverage processing. These industries also have stringent cleanliness requirements, with machines often exposed to chemicals, sterilization agents, and water. Waterproof bearing units in pharmaceutical applications prevent bacterial buildup and make it easier to maintain sterile environments, reducing both maintenance costs and contamination risks. In packaging, waterproof bearing units play a crucial role by withstanding the cleaning protocols necessary in environments where frequent product changes and washdowns occur. Their durability supports high-speed operations without frequent interruptions, ensuring packaging lines remain operational for longer periods. Marine environments pose unique challenges, including exposure to saltwater and varying weather conditions. Waterproof bearing units are resistant to corrosion and harsh environments, making them indispensable for marine machinery, offshore oil rigs, and other outdoor applications. When selecting a waterproof bearing house unit, it’s essential to look for the following features to ensure they will offer the most benefit: Investing in easy-to-clean waterproof bearing house units is a strategic decision that offers long-term savings. Their ability to withstand extreme conditions and rigorous cleaning requirements makes them invaluable assets in industries where hygiene, efficiency, and uptime are paramount. By reducing downtime, these bearing units lower maintenance costs and enhance productivity, directly contributing to a company’s bottom line. Furthermore, they support cleaner, safer production environments, which is a growing priority for regulatory compliance and customer trust. For industries seeking to optimize operations, easy-to-clean waterproof bearing units represent a vital step forward. They embody the essential qualities of durability, efficiency, and hygiene, which are critical for maintaining seamless production. Embracing these units allows companies to meet today’s operational challenges while positioning themselves for future success. Whether you’re in food processing, pharmaceuticals, or manufacturing, upgrading to these bearing units is an investment in both performance and profitability. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Block Units and Flange Mounted Units is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. Type 440 Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.Easy-to-Clean Waterproof Bearing House Units: Reducing Downtime and Maintenance Costs in Industrial Operations

Download our catalogue here

Why Waterproof Bearing House Units Matter

The Cost of Downtime and Maintenance in Industrial Operations

Benefits of Easy-to-Clean Waterproof Bearing House Units

1. Enhanced Durability and Longevity

2. Minimized Contamination Risk

3. Simplified Maintenance Procedures

4. Reduced Need for Lubrication

5. Improved Energy Efficiency

Applications Across Industries

Food and Beverage Industry

Pharmaceutical and Biotechnology Sectors

Packaging and Automation

Marine and Outdoor Applications

Key Features to Look For in Easy-to-Clean Waterproof Bearing Units

A Sound Investment in Long-Term Efficiency

Easy to clean Waterproof bearing house units: Reduce downtime and maintenance costs

Check out our wide range of certified standard components

Contact

Understanding Machinery Components & Protection Standards