Durable IP67 Waterproof Bearing House Units: The Key to Reducing Water and Cleaning Detergent Usage

In today’s industries, sustainability and efficiency go hand in hand. Companies constantly seek ways to improve operations while reducing their environmental impact, especially in industries like food processing, pharmaceuticals, and packaging, where sanitation is paramount. One effective solution is the adoption of durable IP67 waterproof bearing house units. Known for their resistance to harsh environments, these bearings are a game-changer, enabling significant reductions in water and detergent usage during cleaning processes, without compromising hygiene and performance standards.

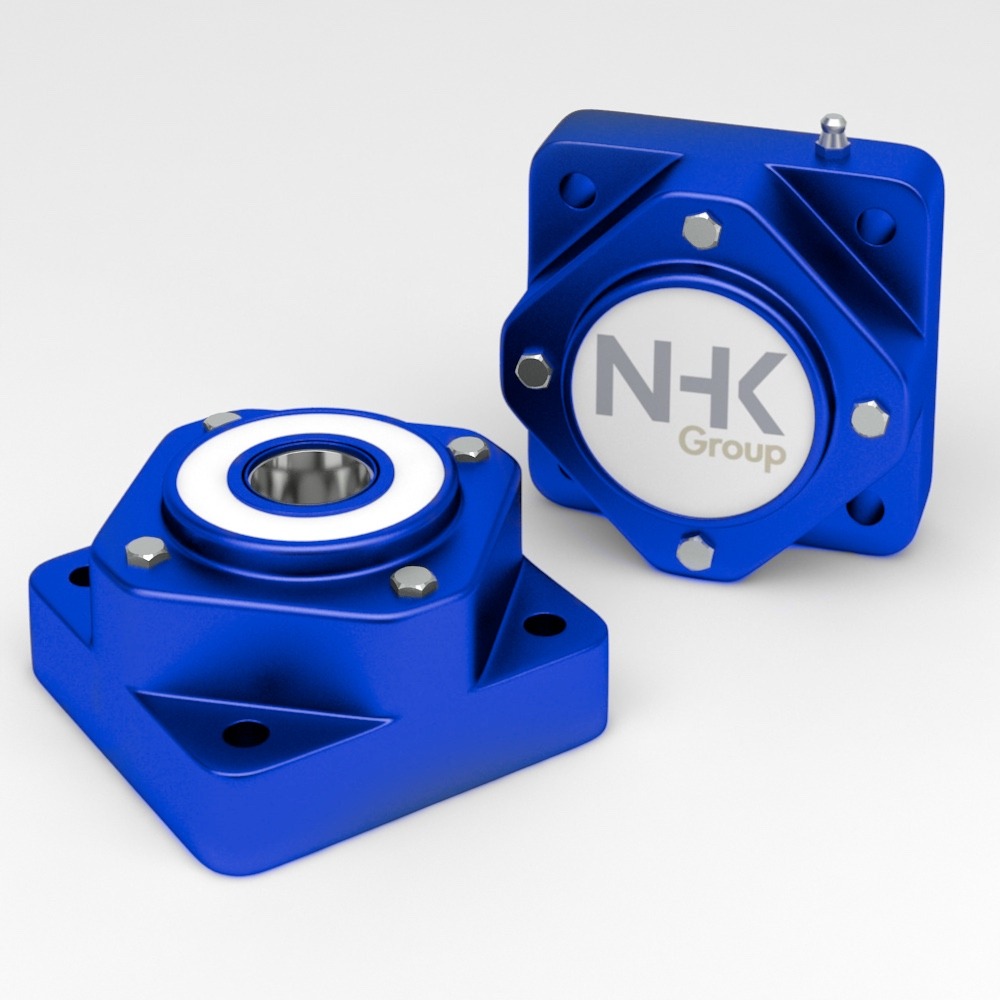

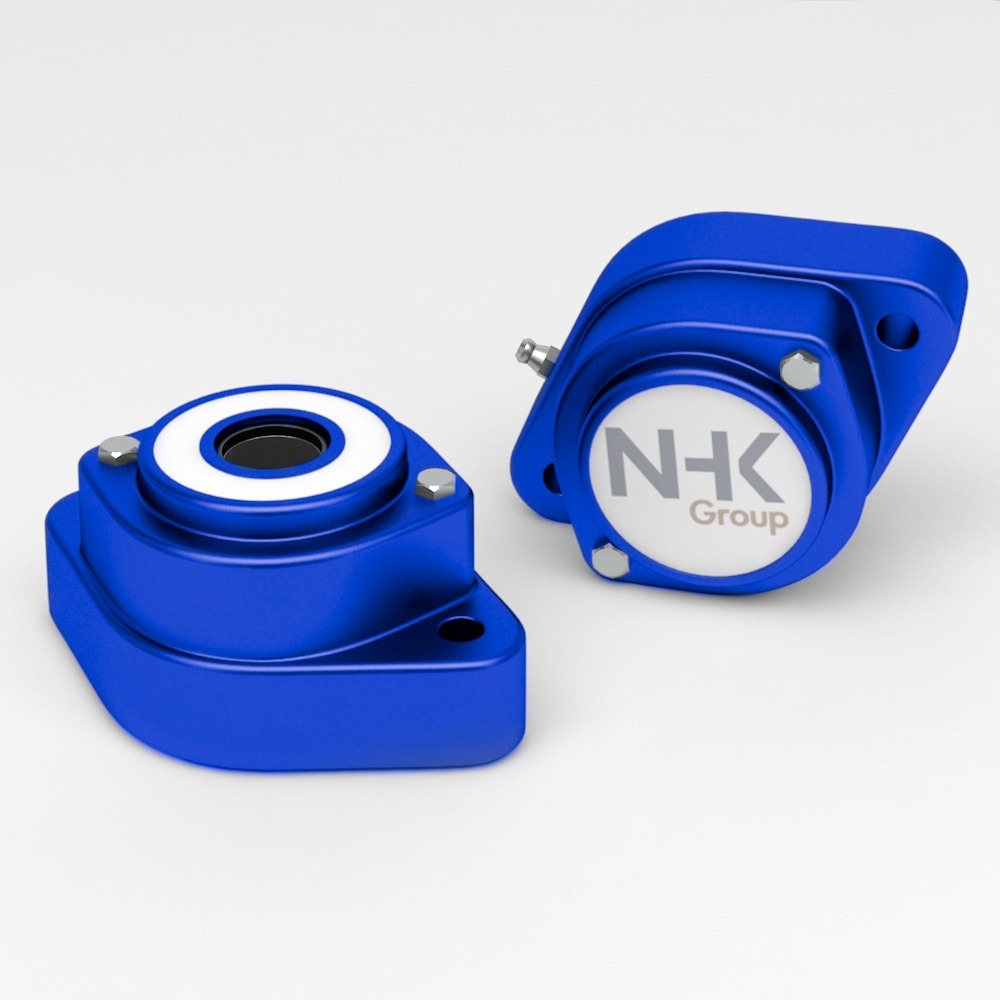

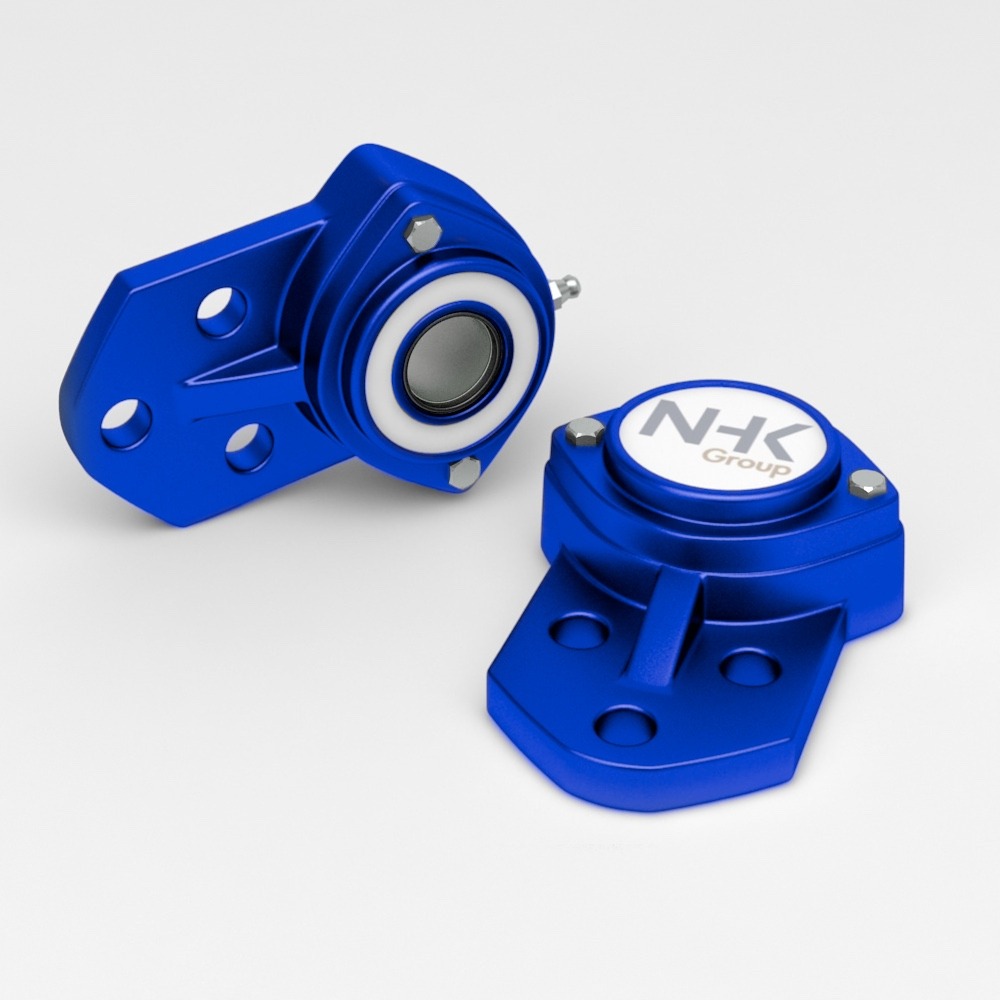

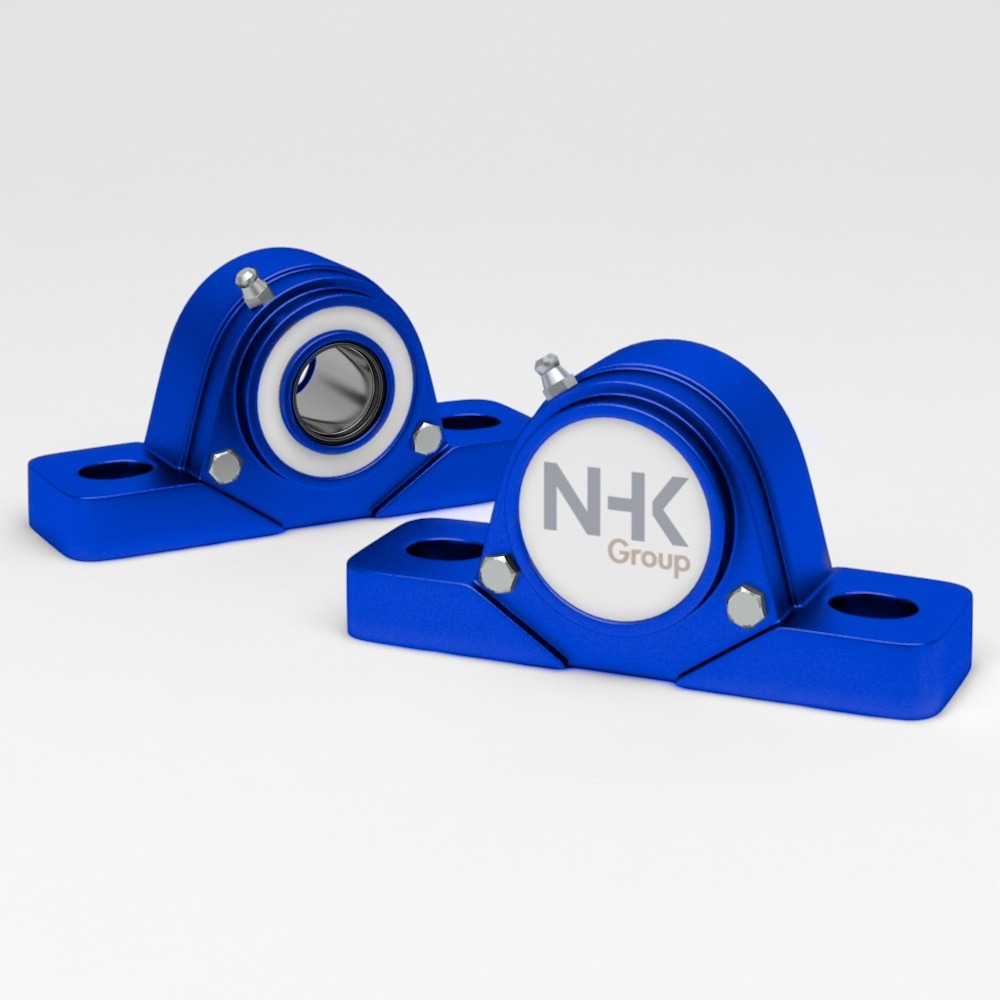

What Are IP67 Waterproof Bearing House Units?

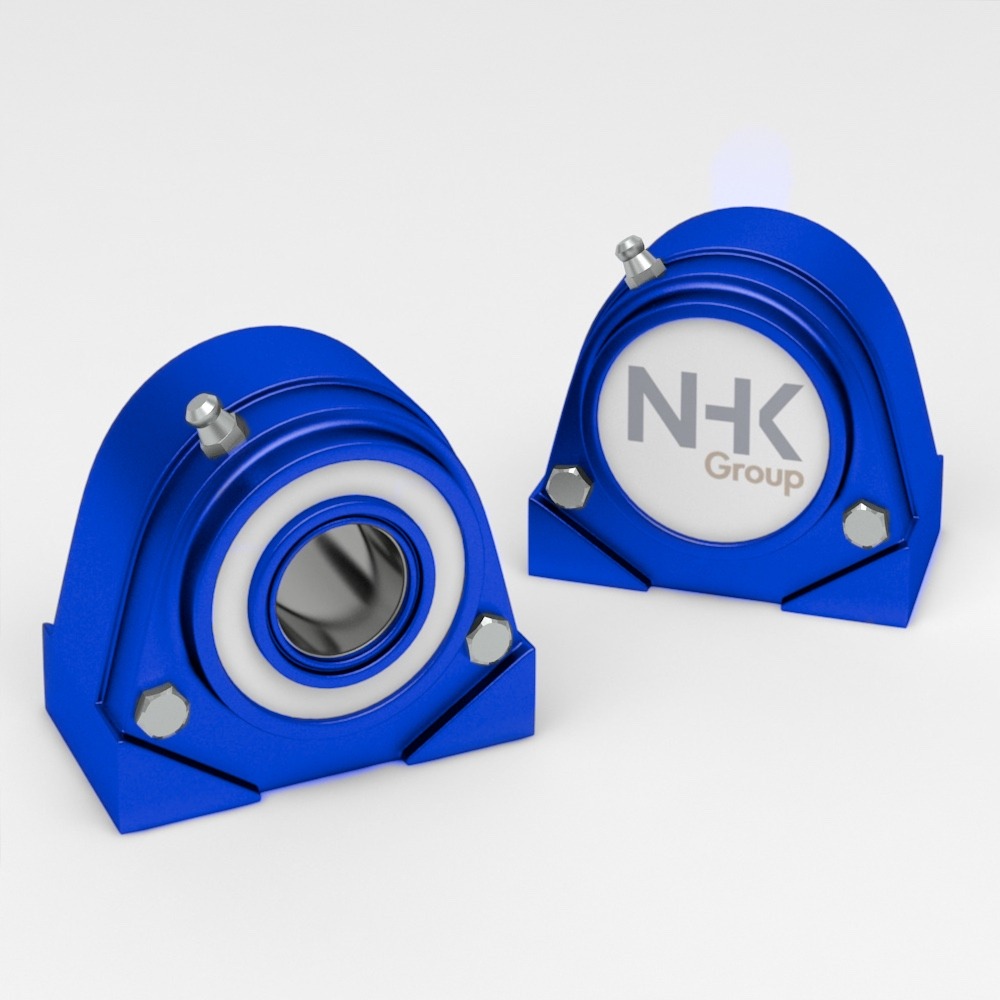

IP67 waterproof bearing house units are specialized bearing assemblies designed to withstand extreme conditions, including full immersion in water and exposure to dust. The IP (Ingress Protection) rating of 67 signifies the highest level of protection against solids and a high resistance to water, making these bearings ideal for industries that require thorough cleaning to maintain sanitary standards.

Advantages of IP67 Waterproof Bearing Units

Using IP67 waterproof bearing units brings several advantages:

- Enhanced Durability: Resistant to wear from moisture and dust, these bearings have a longer lifespan, reducing the frequency of replacements and lowering maintenance costs.

- Hygiene Assurance: High ingress protection prevents contamination in sensitive environments, ensuring product quality and safety, especially in the food and pharmaceutical sectors.

- Reduced Water and Detergent Consumption: Due to their robust sealing, these bearings require less intensive cleaning, helping companies conserve water and detergents while maintaining cleanliness.

The Impact of Cleaning Practices in Industrial Settings

Industries like food processing and pharmaceuticals often undergo multiple rounds of cleaning daily to maintain strict hygiene standards. Traditional bearing units can accumulate debris, moisture, and chemicals, leading to accelerated wear and a higher risk of contamination. Consequently, cleaning processes for such units can demand large amounts of water, energy, and cleaning agents.

IP67 waterproof bearings eliminate these issues. By preventing water and contaminants from entering the bearing housing, they reduce the need for excessive cleaning. This not only saves resources but also reduces downtime, optimizing productivity.

How IP67 Waterproof Bearings Help Reduce Water and Detergent Usage

- Enhanced Sealing for Contaminant Resistance: The superior sealing on IP67 waterproof bearing units repels contaminants, reducing the accumulation of residue. As a result, cleaning is quicker and less resource-intensive.

- Lower Frequency of Intensive Cleaning: Traditional bearings require deep cleaning to clear out built-up residue. IP67 waterproof bearings, however, minimize residue accumulation, meaning intensive cleaning can be scheduled less frequently.

- Streamlined Cleaning Processes: With IP67 bearings, cleaning crews can use lower-pressure water sprays and milder detergents, as there’s no need to break down stubborn grime and residue. This translates to reduced water consumption and fewer chemicals, contributing to a more sustainable cleaning routine.

Key Industries Benefiting from IP67 Waterproof Bearing Units

The versatility of IP67 waterproof bearings makes them essential across various sectors:

- Food and Beverage Processing: Food production requires equipment that can withstand constant exposure to water, cleaning agents, and organic matter. IP67 waterproof bearings ensure contaminants do not penetrate the housing, which is crucial in maintaining food safety standards.

- Pharmaceutical Manufacturing: Hygiene is paramount in pharmaceuticals. IP67 waterproof bearings help maintain sterile environments, enabling manufacturers to avoid frequent deep cleans while ensuring a high hygiene standard.

- Packaging Industry: In packaging facilities, particularly those handling food and pharmaceutical products, cleaning is essential to avoid cross-contamination. IP67 bearings allow companies to maintain clean environments with less frequent cleaning cycles, enhancing efficiency and sustainability.

Cost Savings with IP67 Waterproof Bearings

- Reduced Water Bills: As cleaning needs decrease, so does water consumption. Over time, this reduction can yield significant cost savings, especially in water-intensive industries like food processing.

- Lower Detergent and Chemical Expenses: IP67 waterproof bearings can cut detergent usage, which benefits both the environment and the company’s budget. Fewer chemicals mean less residue left behind, reducing the potential for corrosion on equipment.

- Extended Equipment Lifespan: By preventing water and chemical ingress, IP67 waterproof bearings protect the machinery around them. This not only reduces the frequency of bearing replacements but also helps preserve the surrounding components, extending the overall equipment lifespan.

Environmental Benefits of Using IP67 Waterproof Bearings

The environmental advantages of IP67 waterproof bearings are substantial. Reduced water consumption means less strain on natural resources, a growing concern as water scarcity becomes more prevalent globally. Decreased reliance on detergents and chemicals leads to lower pollution levels, helping companies align with eco-friendly goals and comply with increasingly stringent environmental regulations.

Additionally, the extended lifespan of IP67 bearings reduces the frequency of replacements, meaning fewer parts end up as industrial waste. This aligns with circular economy principles, where products are used longer and waste is minimized, further reducing the environmental footprint of industrial operations.

Selecting the Right IP67 Waterproof Bearing Unit

When choosing IP67 waterproof bearing units, it’s essential to consider factors such as the operating environment, load capacity, and speed requirements. Different bearings are tailored for specific applications, so it’s important to consult with experts or manufacturers to select the right unit that meets both operational needs and sanitation standards.

Best Practices for Maintenance and Maximizing Benefits

While IP67 waterproof bearings reduce cleaning needs, regular inspections ensure peak performance and further longevity. Here are some best practices for maintaining these bearings:

- Regular Visual Inspections: Check for signs of wear or damage. Early detection allows for proactive maintenance, extending the bearing’s lifespan.

- Lubrication: Although IP67 waterproof bearings are low-maintenance, proper lubrication is crucial. Using food-grade lubricants for bearings in food and beverage environments enhances safety and performance.

- Avoiding Over-Pressurization: While the bearings are waterproof, using excessively high-pressure sprays for cleaning can eventually wear down seals. A balanced approach to cleaning optimizes both hygiene and the lifespan of the bearing.

Future of IP67 Waterproof Bearings in Industrial Applications

As industries continue to prioritize sustainable practices, the adoption of IP67 waterproof bearings is expected to rise. Innovations in bearing materials and designs will likely enhance durability and further reduce maintenance requirements. In the future, more companies will adopt IP67-rated bearings as standard, reaping the rewards of reduced water and chemical usage while meeting hygiene standards.

Durable IP67 waterproof bearing house units: Reduce water and cleaning detergent usage

IP67 waterproof bearing house units represent a smart investment for industries that value sustainability, efficiency, and hygiene. By reducing the need for intensive cleaning, these bearings save water, cut down on detergent use, and lower operational costs—all while maintaining stringent sanitation standards. As companies face increasing pressure to improve environmental practices, IP67 waterproof bearings offer a practical solution to achieving cleaner operations with a lighter environmental footprint.

Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Blocks and Direct Mount Bearings is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440 Stainless Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.