Development in Machine Design with IP67 Waterproof Bearing

In the ever-evolving fields of food processing, packaging, and machine design, the importance of resilience and adaptability in components cannot be overstated. Industries that depend on precise and reliable conveyor systems and handling equipment, like food processing conveyors and food packaging conveyors, demand components that withstand both the test of time and the environmental challenges they’re exposed to. One such essential element in modern machinery is the IP67 waterproof bearing house unit, an advanced, future-proof component with significant benefits. Strategic planning and development that incorporate IP67 waterproof bearing house units ensure durability, cleanliness, and efficiency for a wide range of applications, from modular conveyors to box filling systems. The food and packaging industries rely heavily on hygiene and longevity in their conveyor and packaging systems. Machines used in these sectors face continuous exposure to moisture, harsh cleaning processes, and various environmental stresses. IP67 waterproof bearing house units provide the robust resistance required to thrive in these settings, allowing for greater durability and fewer maintenance disruptions. IP67-rated units are designed to prevent the ingress of dust and water, offering the highest protection level available. This quality is invaluable in food processing environments where stringent hygiene standards are paramount. Modular conveyors equipped with IP67 waterproof bearings can be cleaned efficiently without risking corrosion or contamination, helping maintain product integrity and meeting regulatory standards. In the context of strategic planning, the goal is to develop equipment that not only meets current demands but also anticipates future needs. Equipment such as parts conveyors and food packaging conveyors serves as the backbone of many production and packaging lines, handling various items from raw materials to finished goods. Bearing units in these conveyors play a crucial role in maintaining smooth operations and minimizing downtime. Integrating IP67 waterproof bearing house units into parts and food packaging conveyors enhances their resilience. These bearing units are specifically crafted to handle both dry and wet conditions, making them ideal for food processing conveyors that require frequent washing. They also reduce the likelihood of breakdowns, an advantage that supports strategic, uninterrupted productivity. Businesses incorporating these bearings benefit from extended equipment life, reduced maintenance costs, and compliance with hygiene regulations, all of which contribute to a solid foundation for future-proof machine design. Modular conveyors are prized for their flexibility and ease of reconfiguration, which allow production lines to adapt to changing needs. By incorporating IP67 waterproof bearing house units, modular conveyors gain additional durability, helping them perform optimally in both wet and dry environments. These bearing units are built to resist water, dust, and contaminants, ensuring long-lasting efficiency and reducing the risk of mechanical failure. The use of IP67 waterproof bearings is particularly beneficial for companies looking to maximize their return on investment in modular conveyors. With components that withstand frequent cleaning cycles, these conveyors deliver consistent, high-quality performance over the long term, even under harsh conditions. The ability to withstand rigorous cleaning processes and environmental exposure makes IP67 waterproof bearing units a strategic choice for food and beverage facilities where sanitation is key. For companies looking to streamline their packaging and sorting processes, packaging conveyors and parts separators are essential assets. However, traditional bearing units in these systems may suffer from reduced performance when exposed to moisture, dust, or other contaminants. Incorporating IP67 waterproof bearing house units into these systems enhances their durability and hygiene, providing additional security for continuous operation. Parts separators often handle a variety of products and components, each with unique requirements for cleanliness and precision. IP67 bearing units ensure these machines operate smoothly, resisting environmental stressors while keeping contaminants at bay. The reliability of these bearings supports seamless separation and sorting, helping to avoid contamination and cross-contact, particularly crucial in sensitive industries like food processing. In high-volume production settings, box filling systems are critical for efficiently packaging goods, from perishable foods to non-perishable items. These systems benefit greatly from IP67-rated bearings, as they prevent contamination and withstand rigorous cleaning processes. Bearing failure in a box filling system can result in costly downtime and delays, which is why IP67 waterproof bearing house units are a forward-thinking investment. With IP67 waterproof bearing units in place, box filling systems achieve superior performance and reduced maintenance needs. This design choice supports a seamless workflow, helping facilities maintain production rates and minimize disruptions. In the context of strategic planning, these bearings represent an investment in stability, supporting future growth and adaptation as production demands evolve. For companies involved in the design and development of machinery, adopting IP67 waterproof bearing house units in conveyor and handling systems delivers significant long-term benefits. The resilience of these units minimizes wear and tear, reducing the frequency and cost of repairs. This durability is particularly important for food processing conveyors and other machinery that faces frequent washdowns and sanitation processes. By prioritizing future-proof components like IP67 waterproof bearing units, companies position themselves to meet both current and future standards in hygiene, productivity, and operational efficiency. These bearings provide an added layer of reliability, allowing businesses to maintain higher performance and comply with health and safety regulations in the food and packaging industries. As companies strategize for growth, the importance of selecting robust and resilient components becomes clear. IP67 waterproof bearing house units offer a compelling solution for organizations aiming to future-proof their operations. From modular conveyors to food processing conveyors, parts conveyors, parts separators, and box filling systems, these bearing units enhance the durability and efficiency of critical equipment, ensuring operational success and compliance with hygiene regulations. Incorporating IP67 waterproof bearing units not only meets today’s stringent standards but also sets the stage for sustainable and adaptable machine design. The strategic planning behind this investment aligns with a future-proof vision, where resilient, reliable, and easy-to-maintain machinery contributes to a facility’s long-term productivity and profitability. As industries evolve, these waterproof bearing units will continue to play a pivotal role, making them an essential component in modern machine construction and development. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Plummer Blocks and Flange Bearings is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440C Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.Strategic Planning and Future-Proof Development in Machine Design with IP67 Waterproof Bearing House Units

Download our catalogue here

Why IP67 Waterproof Bearing House Units Are Essential in Food Processing and Packaging

Building Resilience into Parts Conveyors and Food Packaging Conveyors

The Role of IP67 Bearings in Modular Conveyor Systems

Enhancing Packaging Conveyors and Parts Separators

IP67 Bearing Units in Box Filling Systems

Future-Proof Development and Long-Term ROI

IP67 waterproof bearing house units

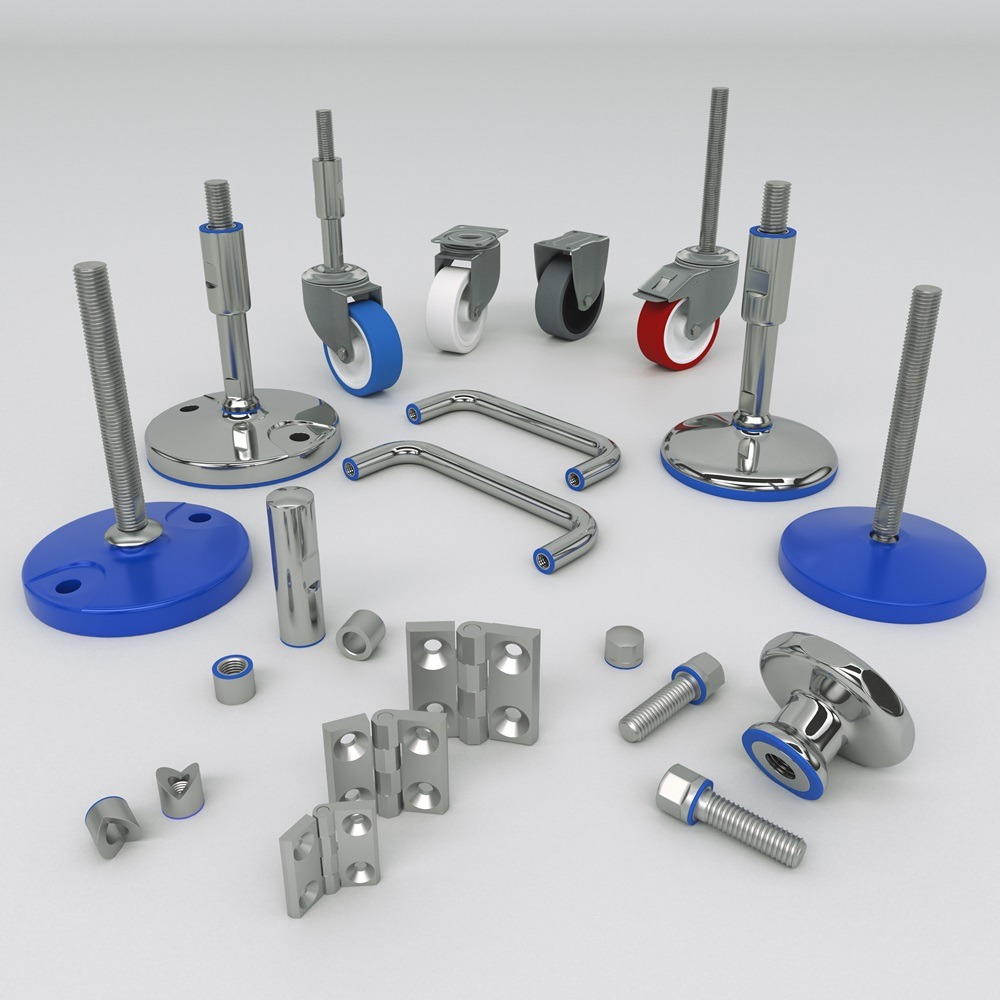

Check out our wide range of certified standard components

Contact

Understanding Machinery Components & Protection Standards