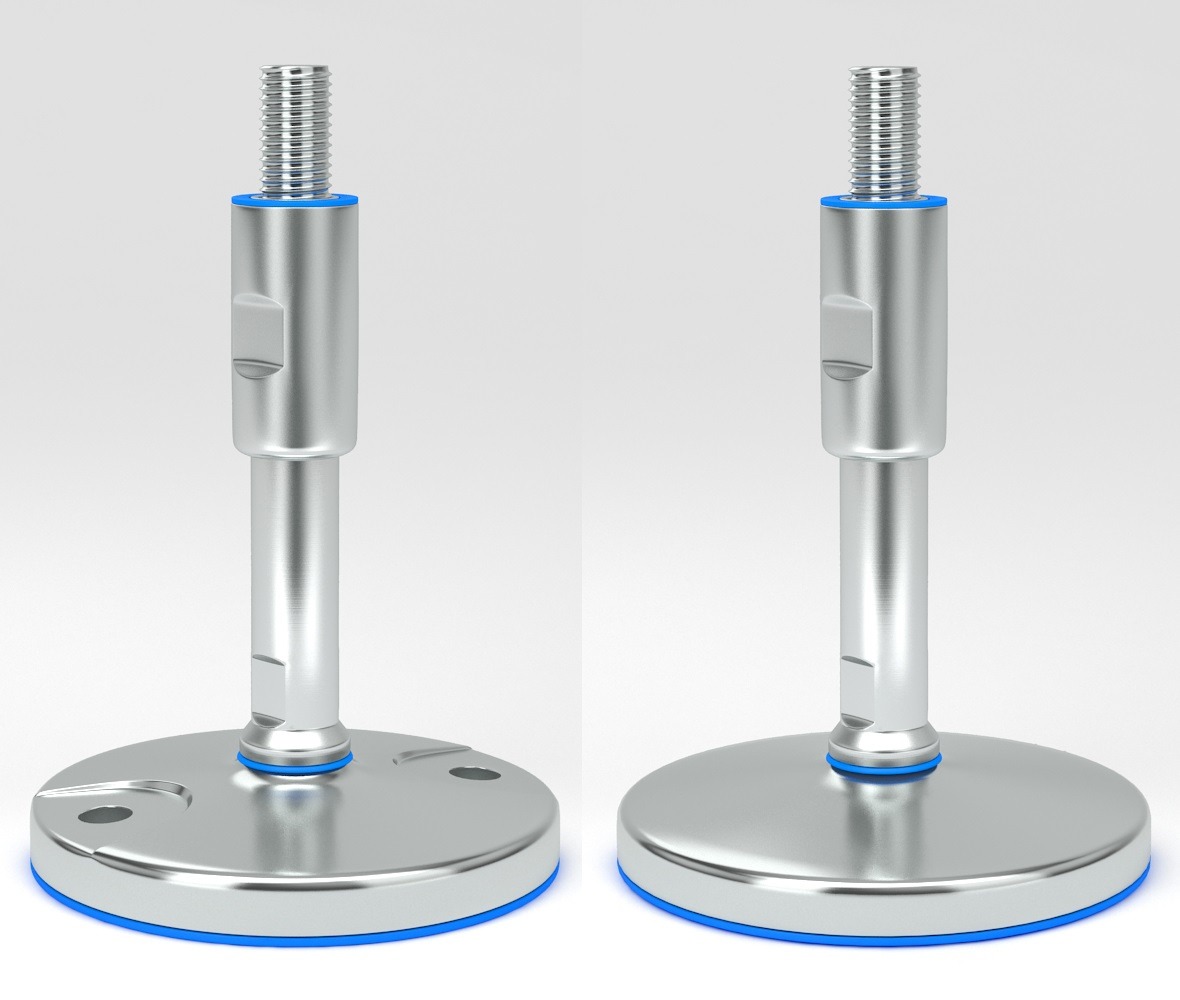

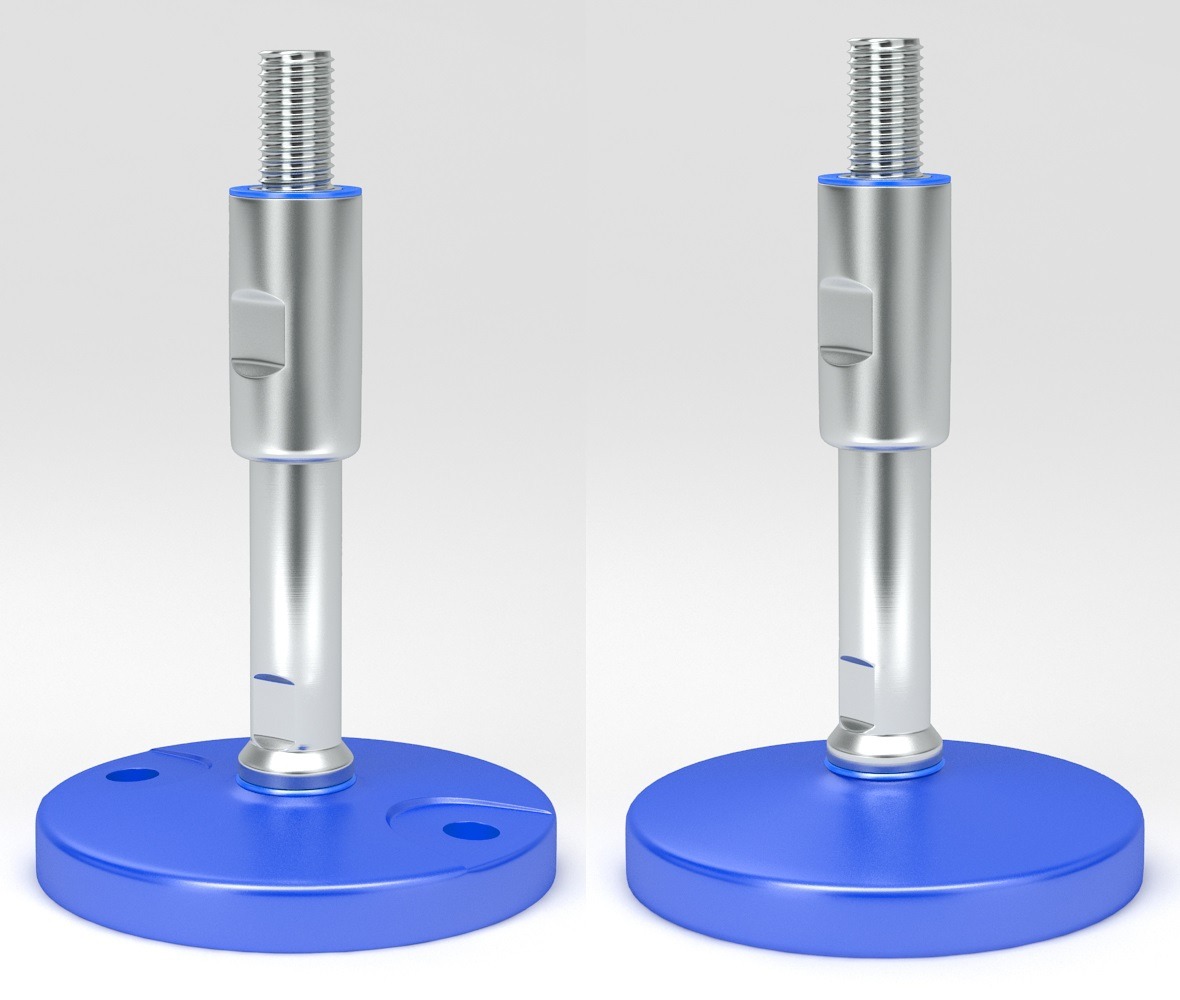

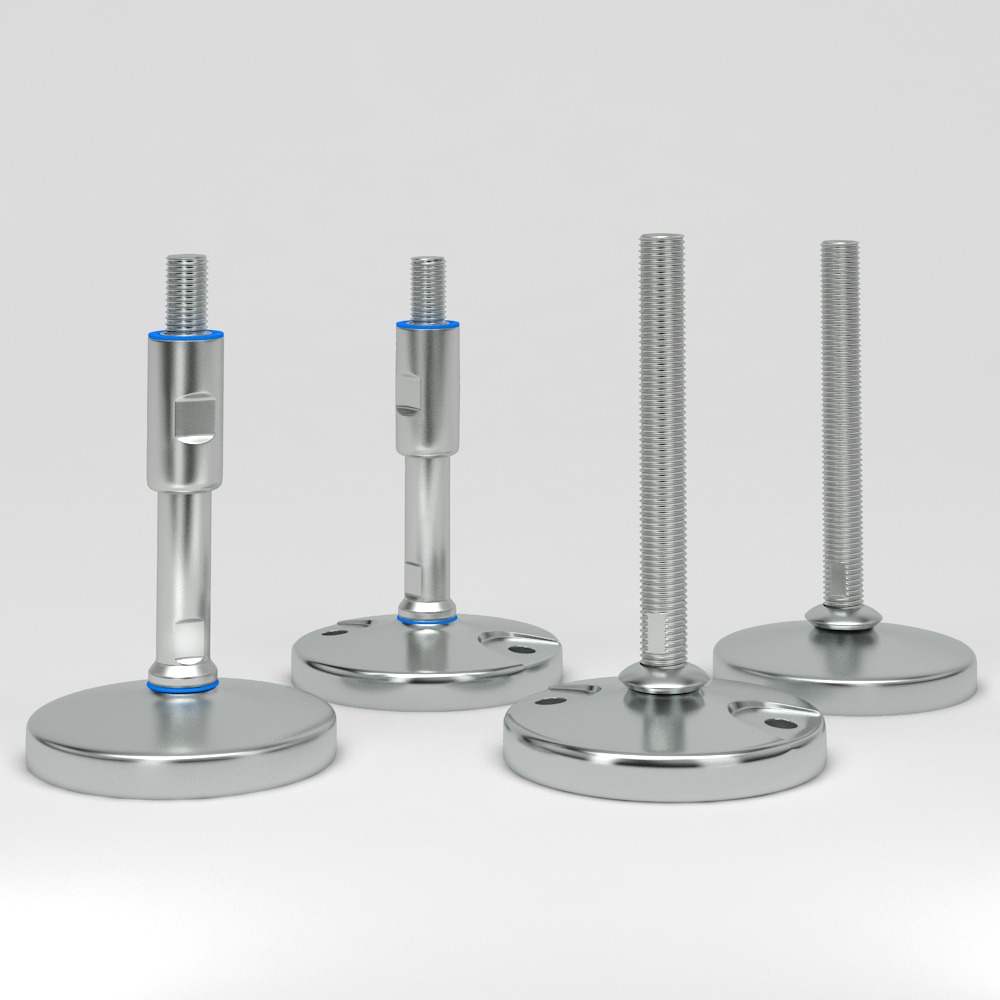

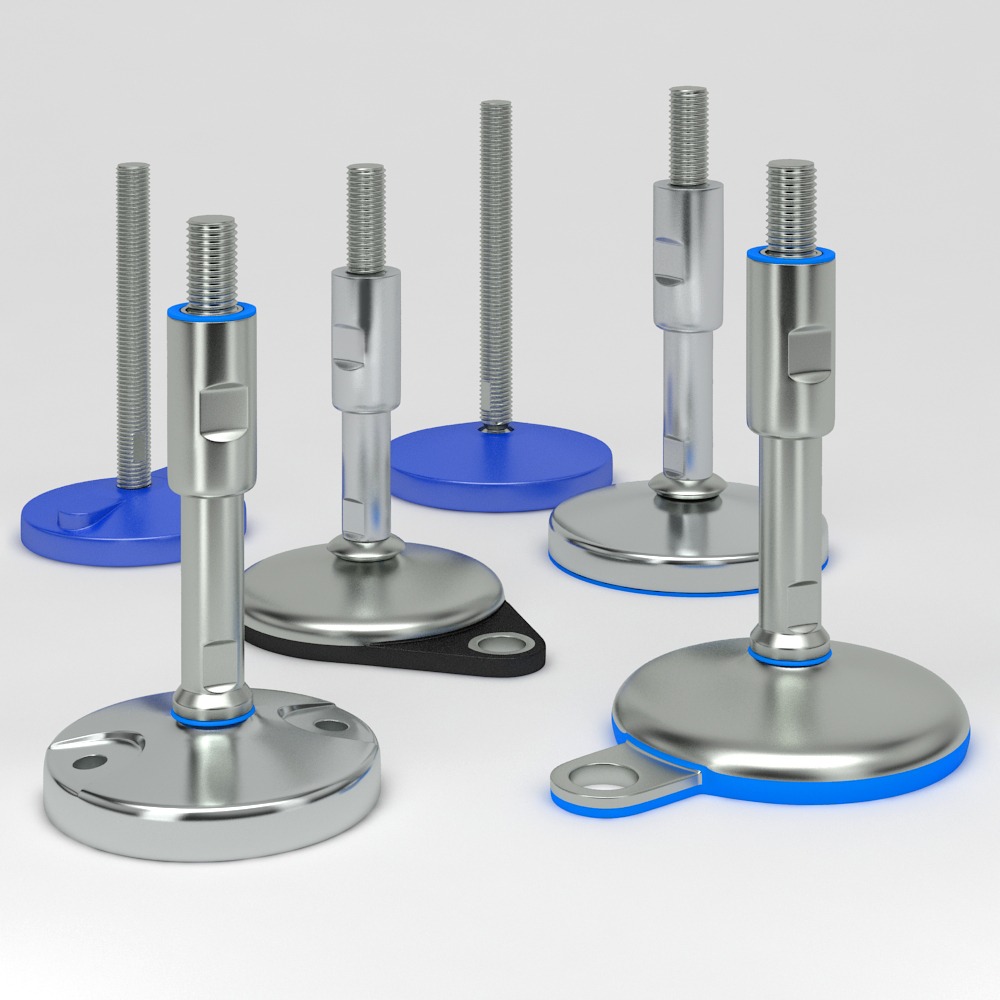

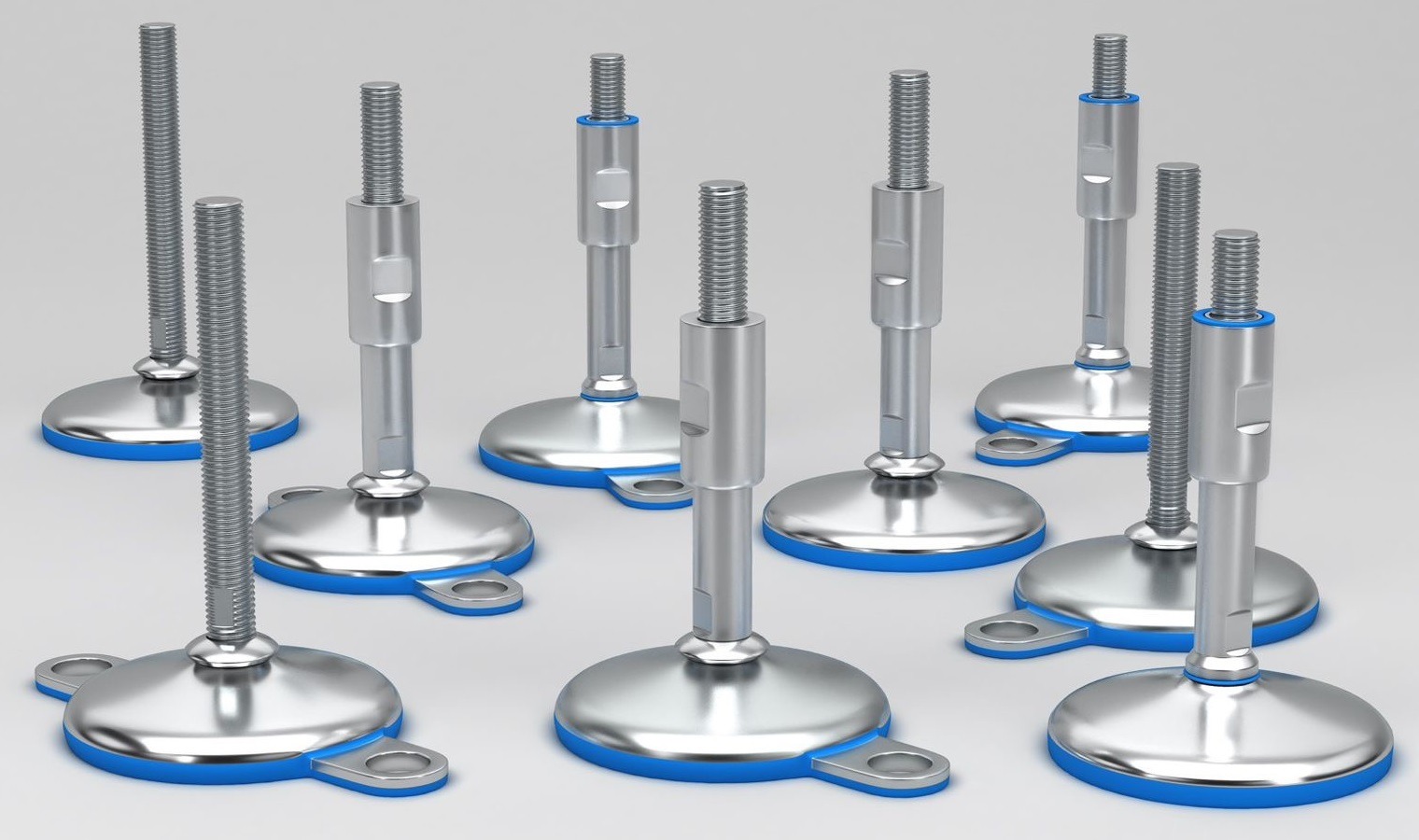

Certified stainless steel machine feet

In industrial environments, the smallest details often have the most significant impact. Machine feet are no exception. These components, although seemingly minor, play a pivotal role in ensuring operational stability, safety, and efficiency across various sectors, from food processing and pharmaceuticals to packaging and biotechnology. This article explores why certified stainless steel machine feet are essential, highlighting their unique advantages and the value of certifications for industries with stringent hygiene and durability standards. Machine feet are designed to provide stability to machinery by keeping it level, reducing vibrations, and ensuring a balanced load. They are crucial for safeguarding the structural integrity of machines, maintaining smooth operation, and extending equipment lifespan. With the increasing demands of high-volume production, machine feet also contribute significantly to preventing wear and tear, minimizing downtime, and enhancing worker safety. In industries where precision, hygiene, and reliability are paramount, opting for machine feet made from certified stainless steel offers unparalleled advantages. Not only do they offer robustness and corrosion resistance, but they also meet rigorous industry standards, guaranteeing optimal performance under the most challenging conditions. Stainless steel is renowned for its corrosion resistance, particularly in wet, humid, or chemically exposed environments. Machine feet made from certified stainless steel resist rust and corrosion, which is crucial in industries like food processing and pharmaceuticals, where cleanliness and sterility are non-negotiable. Certified stainless steel feet prevent contamination risks and eliminate the need for frequent replacements, resulting in substantial long-term savings. Certified stainless steel machine feet also offer impressive durability, withstanding heavy loads, frequent cleaning, and high-impact forces. This makes them an ideal choice for industries with demanding production schedules, as they can endure continuous use without compromising structural integrity. For food processing, pharmaceutical, and biotechnology sectors, adherence to hygiene standards is essential. Certified stainless steel machine feet meet strict hygiene requirements, often mandated by certifications from organizations such as the NSF (National Sanitation Foundation) or the EHEDG (European Hygienic Engineering & Design Group). These certifications ensure that machine feet are designed for easy cleaning and are resistant to bacteria and mold growth, protecting products from contamination. These certified feet are often polished to a high-grade finish, reducing the risk of particle buildup, making it easier to sanitize surfaces, and facilitating efficient cleaning processes. Such features align with industry standards for food safety, which mandate that machinery must prevent any risk of contamination. In any industrial setting, stability is critical. Certified stainless steel machine feet are designed to ensure maximum stability and prevent tipping, slipping, or shaking during operation. This stability is essential in high-speed production lines, where machines generate considerable vibrations. These vibrations, if not managed, can lead to structural damage, inaccurate measurements, and even complete equipment breakdowns. Certified feet are specifically tested to withstand these forces, providing a stable base that minimizes vibrations and protects the machinery from operational wear. As a result, industries that use certified stainless steel machine feet can expect a decrease in maintenance costs, fewer instances of machine failure, and an overall safer work environment for operators. The regulatory landscape in industries such as pharmaceuticals and food processing is becoming increasingly stringent. Certified stainless steel machine feet comply with ISO (International Organization for Standardization) and other relevant certifications, confirming that these components meet rigorous quality standards. This compliance guarantees that businesses avoid penalties related to non-compliance and assures clients that their production processes meet global standards. ISO-certified feet are subjected to extensive testing, ensuring they maintain consistent quality and performance over time. This certification also assures businesses that machine feet are constructed from high-grade materials, offering exceptional resistance to corrosion, fatigue, and other forms of wear. By using certified feet, companies can enhance their quality control measures, minimizing risks and building a reputation for reliability and excellence. In industrial environments, machinery downtime can lead to significant losses. Certified stainless steel machine feet contribute to operational efficiency by supporting smooth and uninterrupted machine operation. These machine feet absorb vibrations and withstand impact, enabling machines to perform at optimal speed and precision without causing undue wear on components. The low-maintenance nature of certified stainless steel feet also helps reduce operational costs. Since these components are less prone to damage and degradation, they require fewer replacements and repairs. This translates into less frequent downtime, allowing industries to maintain a steady production flow and improve overall productivity. While the initial cost of certified stainless steel machine feet may be higher than standard alternatives, the long-term savings are substantial. These feet provide exceptional durability, meaning businesses avoid the recurring expenses associated with replacements, repairs, and machine maintenance. Additionally, the reduced risk of contamination, especially in hygiene-sensitive industries, minimizes the need for costly recalls or waste disposal, saving businesses both time and resources. Certified stainless steel feet are an investment in quality and reliability, providing peace of mind for business owners who can trust that their equipment will perform consistently, even in harsh environments. Sustainability is a growing concern across industries, with businesses looking for ways to reduce waste and lower their environmental footprint. Certified stainless steel machine feet contribute to sustainability by offering a longer lifespan and requiring fewer replacements. This reduces the volume of waste generated and lessens the demand for additional raw materials, promoting a more sustainable production cycle. Furthermore, many certified stainless steel components are recyclable, meaning they can be repurposed at the end of their life cycle rather than adding to landfill waste. For industries striving to align with eco-friendly practices, certified machine feet are an environmentally responsible choice that reflects their commitment to sustainability. Certified stainless steel machine feet are a vital yet often overlooked component in many industries. By offering unparalleled durability, hygiene compliance, and stability, they provide a reliable foundation for machinery and equipment. These certified components support industries with high standards, ensuring both product integrity and worker safety while maximizing operational efficiency. Investing in certified stainless steel machine feet enhances a company’s reputation, maintains compliance with stringent industry standards, and leads to long-term cost savings. By choosing certified options, industries can safeguard their production processes, improve operational resilience, and ultimately deliver products that meet the highest quality standards. For businesses in food processing, pharmaceuticals, packaging, and biotechnology, certified stainless steel machine feet are more than just components—they are essential elements of a well-optimized and sustainable production system. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Block Units and Flange Bearings is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440 Stainless Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.Why Use Certified Stainless Steel Machine Feet: A Key Component in Industrial Optimization

Download our catalogue here

The Role of Machine Feet in Industrial Operations

1. Superior Corrosion Resistance and Durability

2. Compliance with Hygiene Standards

3. Enhanced Safety and Stability

4. Compliance with Regulatory Standards and Quality Assurance

5. Increased Efficiency and Reduced Downtime

6. Cost-Effectiveness and Long-Term Savings

7. Environmental Impact and Sustainability

Certified stainless machine feet

Check out our wide range of certified standard components

Contact

Understanding Machinery Components & Protection Standards