Certified EHEDG Hygienic Feet vs. Certified Sanitary Feet

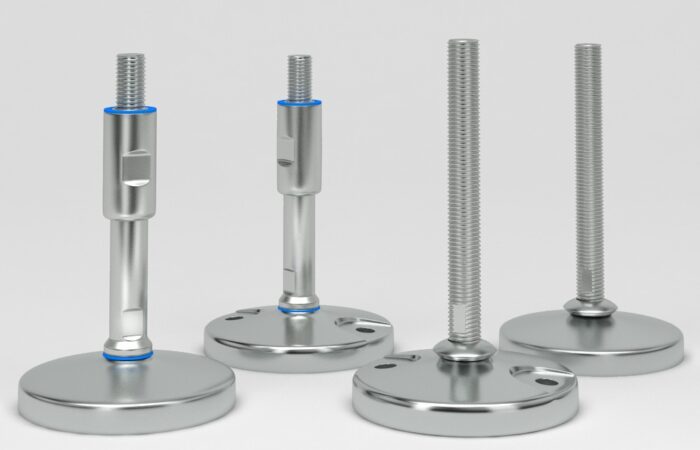

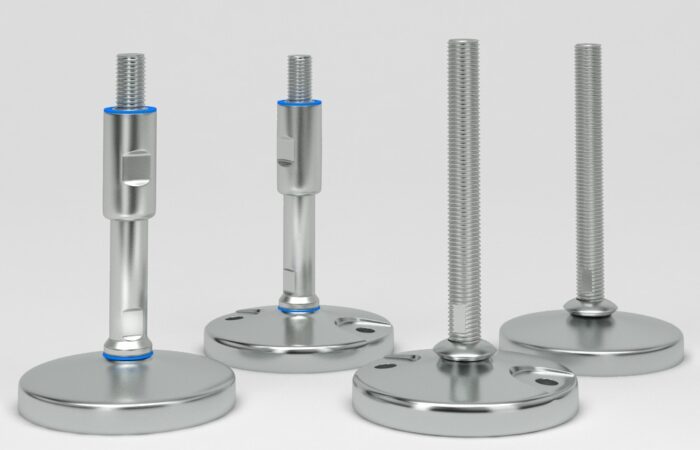

In industries where hygiene is paramount—such as food processing, pharmaceuticals, and biotechnology—choosing the right certified leveling feet for machinery is crucial. Two of the most recognized certifications for hygienic and sanitary equipment are: Both certifications ensure compliance with strict industry regulations, but they differ in design philosophy, cleanability, and intended applications. This article compares Certified EHEDG Hygienic Feet with Certified Sanitary Standards Feet, covering usage, industries, materials, leading manufacturers, certifications, case studies, and customer testimonials to help businesses make an informed decision. EHEDG-certified hygienic feet and certified sanitary feet are essential for industries requiring strict hygiene compliance, such as food processing, pharmaceuticals, and cleanrooms. While EHEDG feet offer crevice-free, fully-sealed designs optimized for European and global standards, sanitary standard feet are tailored for North American dairy and food industry regulations. The right choice depends on cleanability, compliance needs, and industry applications. Investing in the correct certified feet ensures regulatory approval, improved sanitation efficiency, and long-term cost savings. Which certification best fits your operational needs? Let’s explore the differences to help you decide. EHEDG hygienic feet are optimized for cleanrooms and high-sterility environments, while certified sanitary feet are best suited for dairy, food, and beverage processing in North America. Key Takeaway: EHEDG certification ensures compliance with global food & pharma safety standards, while certified sanitary standard is focused on North American dairy and food processing regulations. A dairy plant in Germany needed EHEDG-compliant hygienic feet to meet strict EU food safety laws. Meanwhile, a U.S. dairy required certified sanitary feet for FDA and USDA approval. Results: A meat packaging facility switched from standard sanitary feet to EHEDG-certified hygienic feet, reducing: A pharmaceutical company using EHEDG hygienic feet achieved full compliance with FDA and EU pharma hygiene regulations, reducing contamination risks. A beer producer upgraded from standard feet to EHEDG feet to meet EU hygiene laws, allowing exports to European markets. ✔ “EHEDG-certified feet helped us meet global hygiene standards and expand to new markets.” – Quality Manager, Beverage Company ✔ “Switching to EHEDG feet reduced cleaning time by 50% in our biotech facility!” – Operations Director, Pharmaceutical Company ✔ “Sanitary standard feet ensured our dairy plant met all FDA & USDA requirements.” – Dairy Production Engineer For pharmaceutical, biotech, and high-sterility food processing, EHEDG-certified hygienic feet are superior. For dairy, food, and beverage processing in North America, sanitary standard feet are ideal. In industries where hygiene is non-negotiable, the choice between EHEDG-certified hygienic feet and certified sanitary standard feet can significantly impact compliance, efficiency, and safety. Understanding their key differences in design, materials, and regulatory standards will help you select the optimal solution for food processing, pharmaceuticals, and cleanroom applications.

Ensuring Hygiene and Compliance in Sanitary Industries

Choosing Between EHEDG Hygienic Feet and Sanitary Standard Feet

EHEDG Hygienic Feet vs. Sanitary Standard Feet: Key Differences

Feature

EHEDG Hygienic Feet

Sanitary Feet

Design

Self-draining, sealed threads, smooth crevice-free surface

Designed for dairy & food safety, but may have minor crevices

Intended Use

Ideal for Europe-focused compliance (pharma, biotech, food processing)

Best for North American dairy & food industry

Surface Finish

Polished to Ra ≤ 0.8 µm for ultra-cleanability

Typically Ra ≤ 1.2 µm, ensuring food safety but allowing light surface texture

Materials

AISI 316L stainless steel, FDA-approved EPDM, NBR

AISI 304 or 316 stainless steel, may include plastic parts

Cleanability

CIP (Clean-in-Place) & SIP (Sterilization-in-Place) ready

Requires manual wash-downs in some cases

Certification Body

European Hygienic Engineering & Design Group (EHEDG)

Sanitary Standards

Industries

Food, dairy, beverage, pharma, cleanroom, cosmetics

Primarily dairy, plus food & beverage processing

Regulatory Compliance

Aligns with EU regulations (ISO 14159, EN 1672-2)

Complies with FDA, USDA, PMO (Pasteurized Milk Ordinance)

Durability

Designed for aggressive washdowns & harsh chemicals

Built for frequent manual cleaning with dairy-safe cleaners

Cost

Higher initial cost but long-term savings in cleaning & compliance

Moderate cost but may require more frequent replacements

Industries and Applications

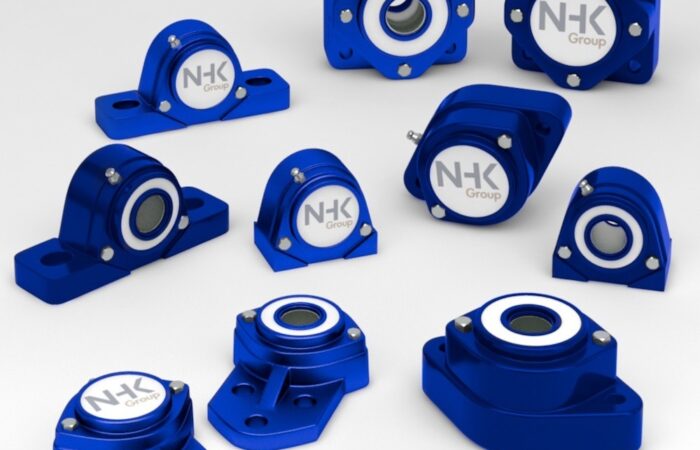

Industries Using EHEDG Hygienic Feet

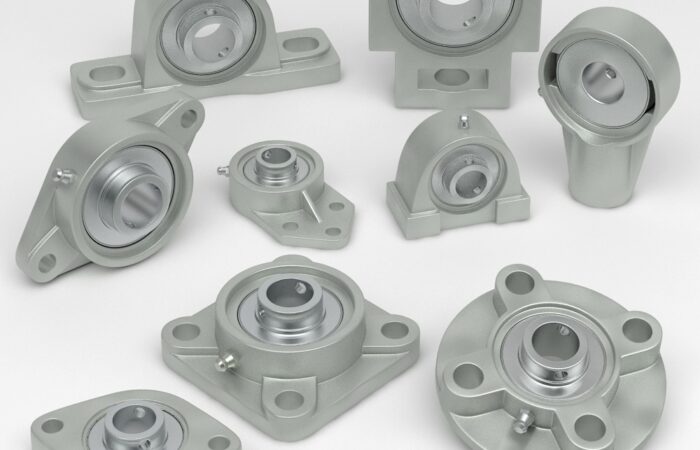

Industries Using Sanitary Feet

Key Takeaway:

Material Composition

EHEDG Hygienic Feet

Certified Sanitary Feet

Certifications & Compliance

EHEDG Hygienic Feet Must Comply With:

Sanitary Feet Must Comply With:

Real-World Applications

1. Dairy Processing Facility (EU vs. US Compliance)

✅ EHEDG feet improved cleanability, reducing bacterial contamination by 40%

✅ Certified sanitary feet ensured compliance with US dairy safety laws2. Meat Processing Facility (Hygiene & Cost Savings)

✅ Cleaning time by 35%

✅ Water and detergent costs by 28%3. Pharmaceutical Production (SIP Compatibility)

4. Brewery Equipment (Global Market Expansion)

Trust & Reliability

EHEDG vs. Sanitary Standard – Which is Best?

Contact

Articles