At NHK Group, quality and safety are not just goals; they are the foundation of everything we do. As a leading global manufacturer of hygienic machinery parts, we ensure that our products comply with the most stringent international standards for safety and design.

Below you will find our declarations of conformity and certifications. This page also provides insight into why these certifications are critically important for advanced food processing systems.

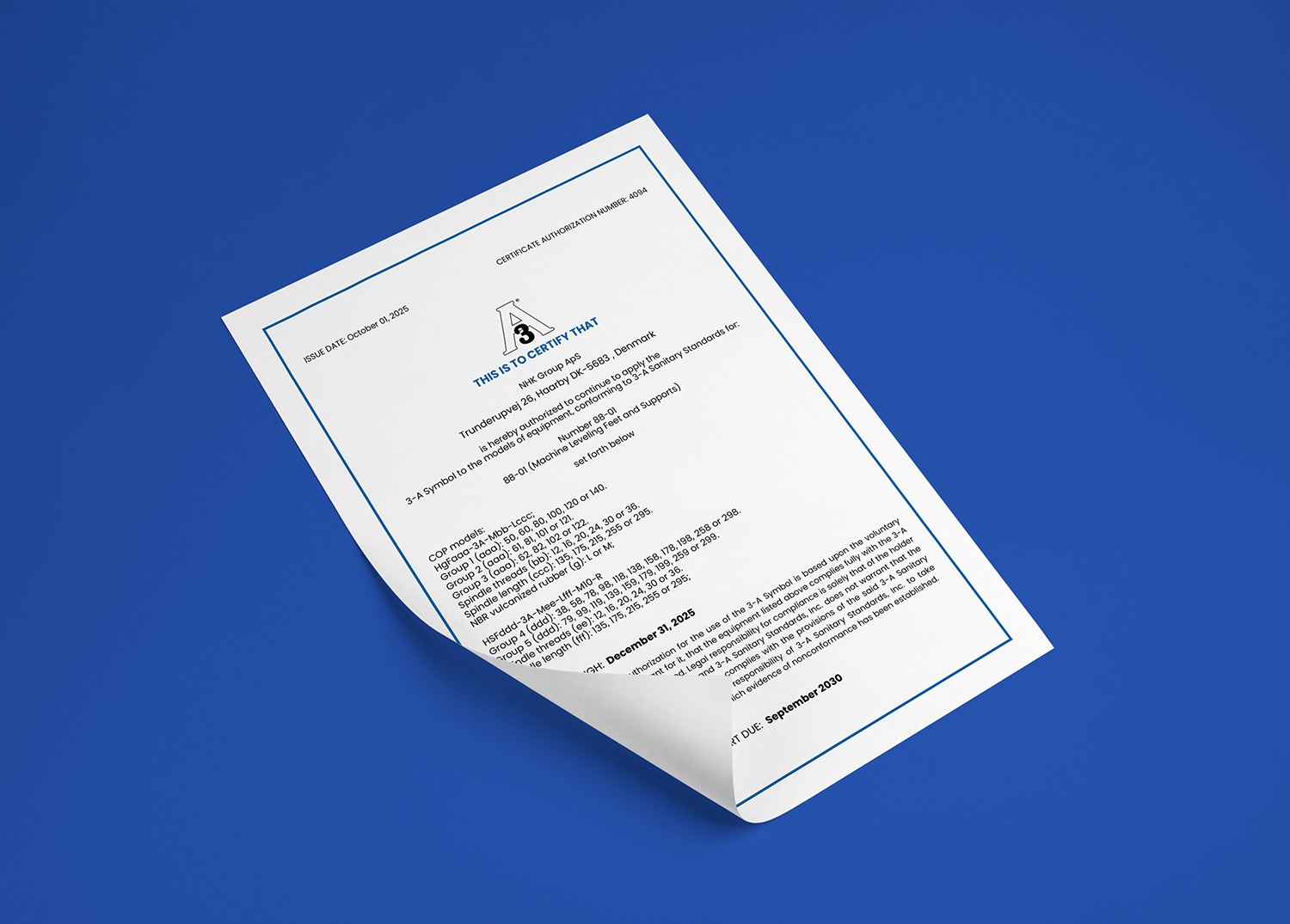

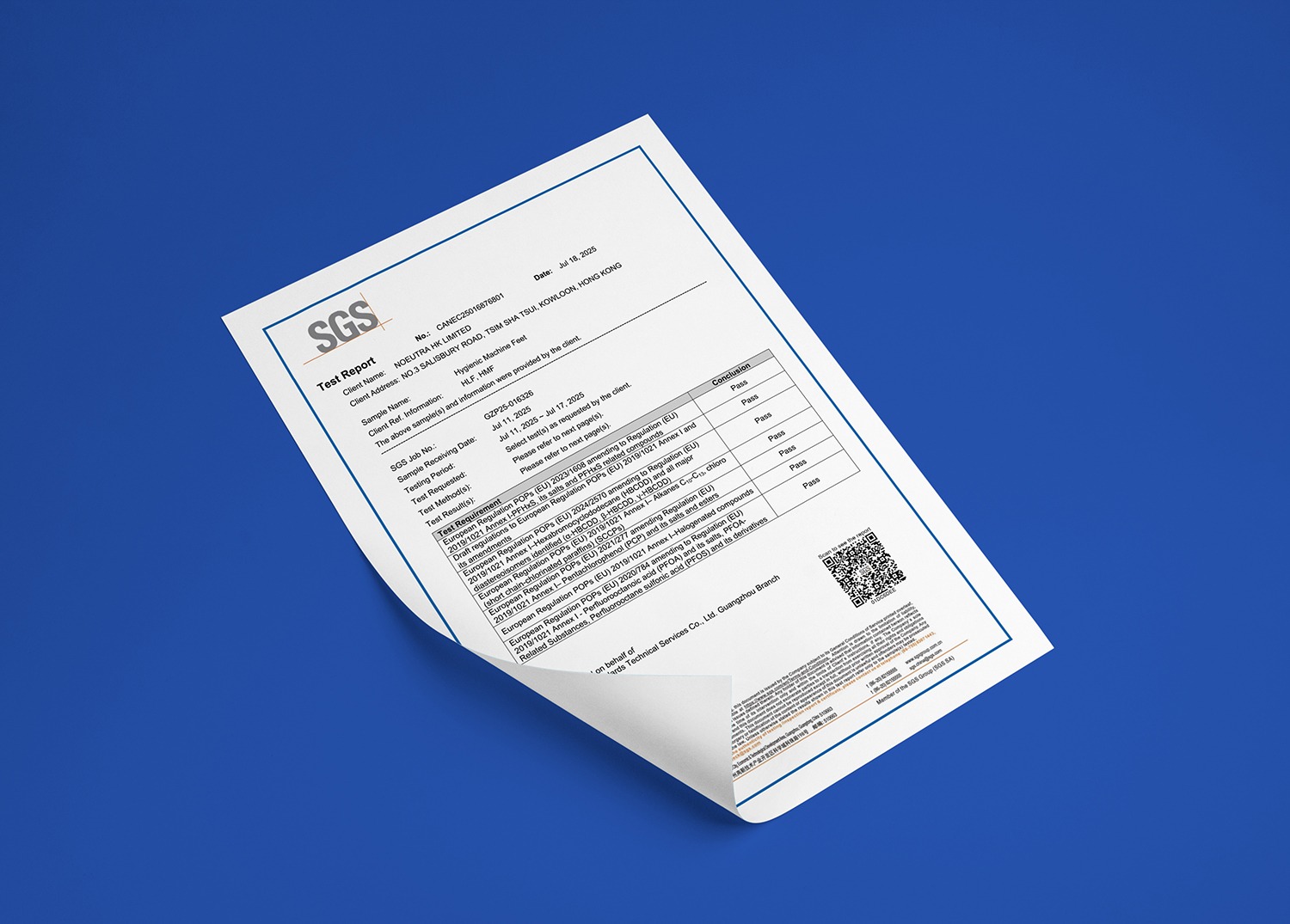

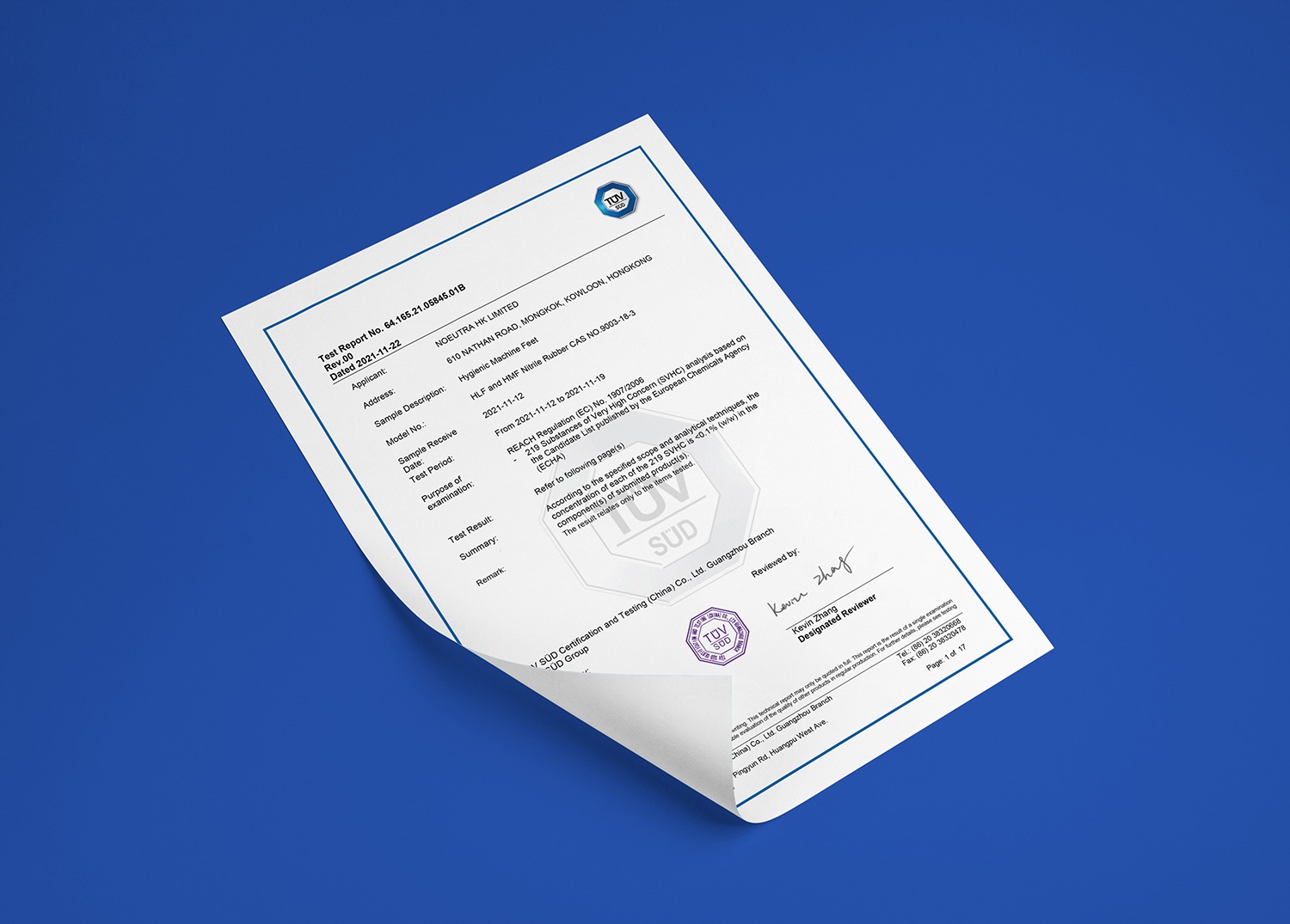

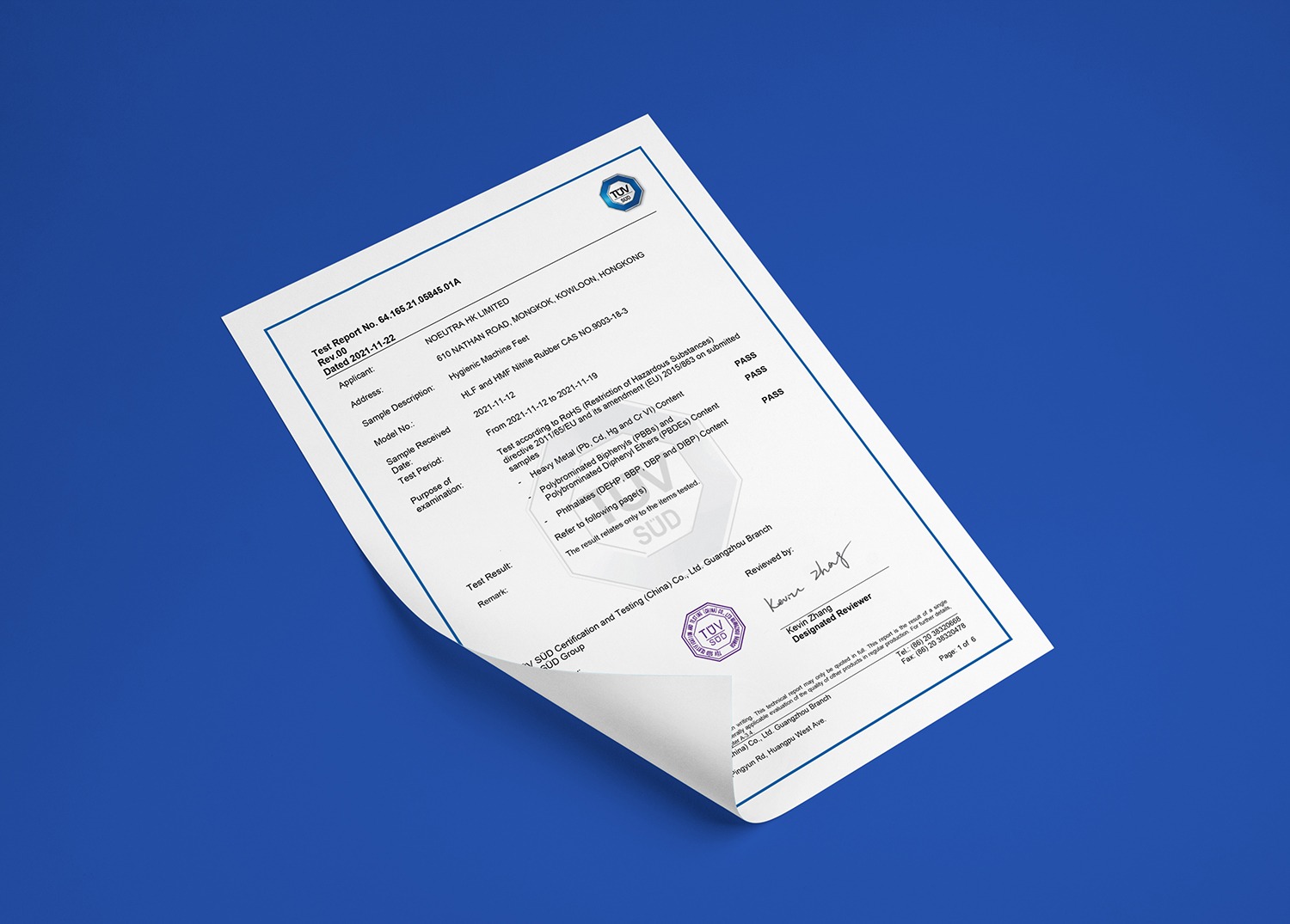

Our EHEDG certified products represent the gold standard for hygienic design in Europe and globally. This certification is awarded only after rigorous, performance-based testing proves that a component is verifiably easy to clean and poses no contamination risk. The design principles focus on eliminating dead zones and crevices, ensuring microbiological safety throughout your entire processing line. By integrating our EHEDG compliant parts, you ensure seamless access to the EU market and demonstrate an unwavering commitment to food safety. Compliance with 3-A Sanitary Standards signifies our commitment to the highest level of hygienic engineering. Every 3-A certified component we manufacture is meticulously designed to be easily disassembled, cleaned-in-place (CIP), and inspected. The non-porous, smooth surfaces prevent bacteria from harboring, ensuring the utmost safety in food, dairy, and pharmaceutical processing. Choosing our 3-A certified parts guarantees that your equipment will meet stringent U.S. regulatory requirements and operate with maximum efficiency and cleanability. We guarantee that all materials in our components intended for food contact are fully compliant with FDA regulations. This means that polymers, elastomers, and other materials have been rigorously tested and are certified as food-grade, ensuring they will not leach harmful chemicals into your products. FDA compliance is a fundamental requirement for equipment used in the U.S. market. With NHK Group parts, you build a foundation of safety and consumer trust into your processing systems. We guarantee that all materials in our components are free from PFAS (Per- and Polyfluoroalkyl Substances). This means that polymers, elastomers, and coatings have been carefully selected and verified to contain no fluorinated chemicals, ensuring environmental safety and clean material composition. PFAS-free compliance supports sustainable production and meets the latest EU environmental directives. With NHK Group parts, you build a safer, future-proof foundation for your hygienic processing systems. Our adherence to the EU’s REACH regulation underscores our commitment to human health and environmental protection. We proactively manage and document the chemical substances used in our manufacturing processes to ensure they are safe. Specifically, we guarantee our products do not contain Substances of Very High Concern (SVHCs) beyond the permitted threshold. This compliance not only ensures market access within the European Union but also reflects our global dedication to responsible and sustainable manufacturing. NHK Group is fully compliant with the RoHS directive, restricting the use of specific hazardous materials found in electrical and electronic products. This is crucial as modern machinery parts increasingly integrate sensors and electronic controls. Our RoHS compliance ensures these components are free from lead, mercury, cadmium, and other harmful substances. This commitment protects the environment from hazardous waste and ensures the safety of personnel who handle our equipment throughout its lifecycle. Our products are fully compliant with the EU Regulation (EU) 2019/1021 on Persistent Organic Pollutants (POPs). Choosing the right certified components doesn’t need to be complicated. Our friendly specialists are here to listen, understand your process, and recommend the best hygienic parts for your equipment. Let us help you boost safety, stay compliant, and keep your production running smoothly. Certifications

3 - A Certificate

EHEDG

FDA

PFAS

REACH

RoHS

POP

Quality & Industry Standards

Our Certifications

EHEDG (European Hygienic Engineering & Design Group)

3-A Sanitary Standards

FDA (U.S. Food and Drug Administration)

PFAS-Free (Per- and Polyfluoroalkyl Substances)

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals)

RoHS (Restriction of Hazardous Substances)

This certificate confirms that all materials used in our components — including stainless steel, elastomers, plastics, and surface treatments — do not contain any restricted POP substances above the regulatory thresholds. POP Compliance Certificate

Request a Consultation