Understanding Stainless Steel

Stainless steel is a durable, corrosion-resistant metal alloy made primarily from iron, carbon, and at least 10.5% chromium. The chromium forms a thin oxide layer on the surface, protecting the metal from rust and corrosion. Additional elements like nickel and molybdenum can enhance its properties, such as strength and resistance to harsh environments. Stainless steel is widely used in industries like construction, food processing, healthcare, and automotive due to its strength, hygiene, and heat resistance. Common types include austenitic, ferritic, and martensitic, each suited for specific applications based on their unique properties.

Corrosion Resistance

- Stainless steel is highly resistant to corrosion, rust, and staining, especially when exposed to water and moisture. This is due to the chromium content (at least 10.5%) that forms a passive layer of chromium oxide on the surface, protecting the metal from oxidation.

- Different grades (e.g., 316 stainless steel) offer enhanced resistance to specific types of corrosion, such as pitting and crevice corrosion caused by exposure to chloride-rich environments (e.g., saltwater or chemical applications).

Durability and Strength

- Stainless steel offers excellent mechanical strength, making it ideal for applications requiring high strength and durability.

- It retains its toughness across a wide range of temperatures, including both high-temperature and cryogenic applications, making it versatile in extreme environments.

- Duplex stainless steels, in particular, provide higher strength than many other stainless steels and other metals.

Hygiene and Cleanliness

- Stainless steel has a non-porous surface, making it easy to clean and sanitize. This is especially important in industries such as food processing, pharmaceuticals, and healthcare where hygiene is critical.

- Its smooth surface prevents the growth of bacteria, making it the preferred material for medical tools, surgical equipment, and sterile environments.

Aesthetic Appeal

- Stainless steel has an attractive, modern, and polished appearance. Its natural luster makes it a popular choice for architectural and decorative applications.

- It is commonly used in high-end appliances, kitchen fixtures, and exterior cladding on buildings due to its sleek and shiny finish.

Heat Resistance

- Certain grades of stainless steel are resistant to both high temperatures and fire. For example, 310 and 316 stainless steel can withstand high-temperature applications without losing strength.

- Stainless steel is commonly used in applications such as furnace parts, heat exchangers, and boiler tubes where high-temperature resistance is crucial.

Low Maintenance and Long Life

- Stainless steel is low-maintenance due to its durability and resistance to corrosion. It requires minimal upkeep compared to other metals that may need regular coating or painting to protect against rust and wear.

- Its long life makes it a cost-effective material in the long term, even though it may have a higher initial cost compared to other materials.

Eco-Friendly and Recyclable

- Stainless steel is 100% recyclable. When it reaches the end of its useful life, it can be melted down and reused to create new stainless steel products, reducing the need for raw material extraction.

- Its longevity also contributes to sustainability, as it doesn’t need to be replaced as frequently as other materials.

Impact and Shock Resistance

- Stainless steel has excellent toughness and can withstand impact and shock loads without fracturing. This makes it ideal for applications that experience mechanical stress, such as tools, machinery, and transportation components.

Chemical Resistance

- Stainless steel exhibits strong resistance to a wide range of chemicals and acids, especially in higher grades like 316, which contains molybdenum to improve resistance to chemical corrosion.

- This makes stainless steel a suitable material for chemical processing plants, laboratories, and applications involving harsh chemicals.

Versatility and Formability

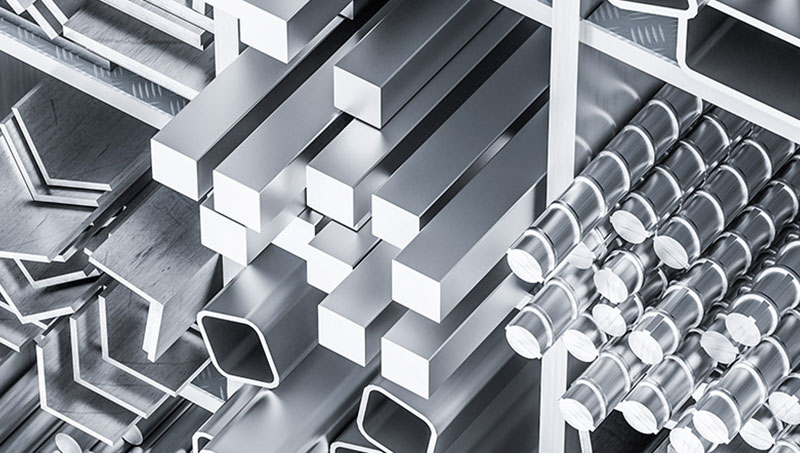

- Stainless steel can be fabricated into various shapes and forms through processes like welding, machining, and molding. It is highly versatile and can be used in a wide range of applications, from industrial equipment to consumer products.

- Its excellent workability and ability to be polished to a fine finish or left with a matte texture offer flexibility for different design requirements.

Temperature Resistance

- Stainless steel maintains its strength and toughness across a wide range of temperatures, making it suitable for both high-heat and low-temperature applications. High-grade stainless steels (such as 310 and 321) can withstand high temperatures and maintain structural integrity.

- At the same time, certain grades of stainless steel also have excellent performance in cryogenic or low-temperature environments, preventing brittleness and maintaining toughness.

Resistance to Scaling

- Stainless steel resists scaling and retains its strength at high temperatures. This makes it particularly useful in industries like power generation, chemical processing, and food production, where equipment is exposed to high heat or steam.

Non-Magnetic Grades

- Certain grades of stainless steel, such as 304 and 316, are non-magnetic, which is beneficial in applications where magnetic interference can be an issue, such as in medical devices or electronic equipment.

Improved Safety

- Stainless steel’s high strength and fire resistance enhance the safety of structures and equipment. Its non-reactive nature prevents dangerous chemical reactions, which is especially important in chemical and pharmaceutical industries.

These advantages make stainless steel a highly desirable material for a wide range of applications, offering both functional and aesthetic benefits.

Stainless steel’s exceptional combination of corrosion resistance, durability, hygiene, and versatility makes it a top choice across various industries, including food processing, pharmaceuticals, healthcare, construction, and manufacturing. Its long lifespan, low maintenance, and recyclability also contribute to its environmental sustainability, making it a material that delivers high performance while aligning with modern eco-conscious standards.

Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Pillow Blocks and Flange Mounted Units is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440C Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.