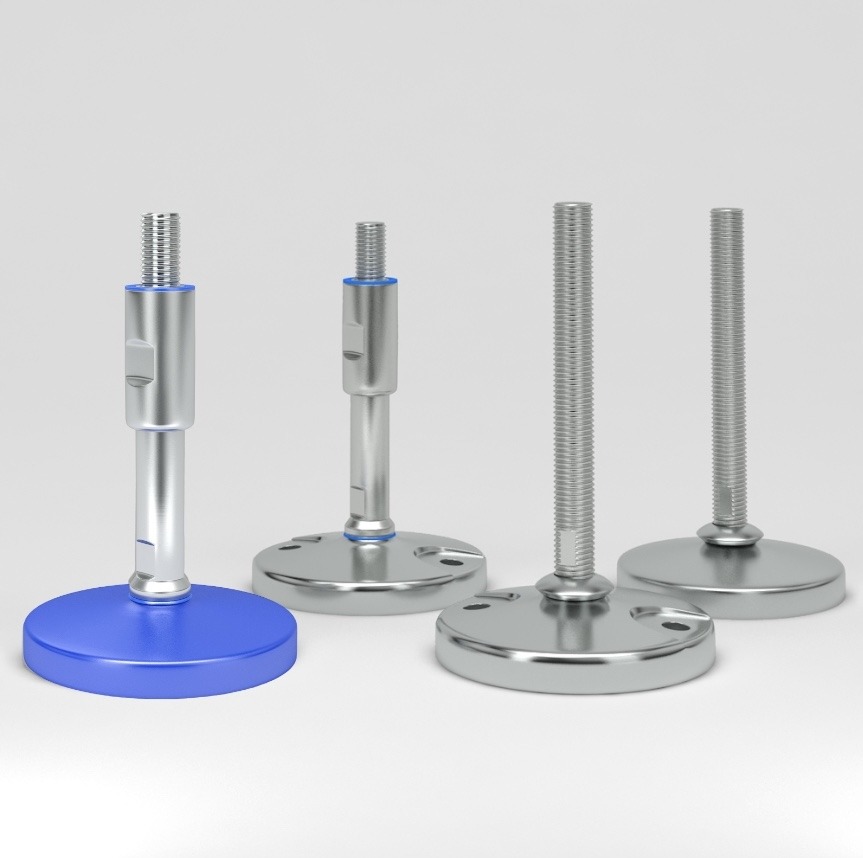

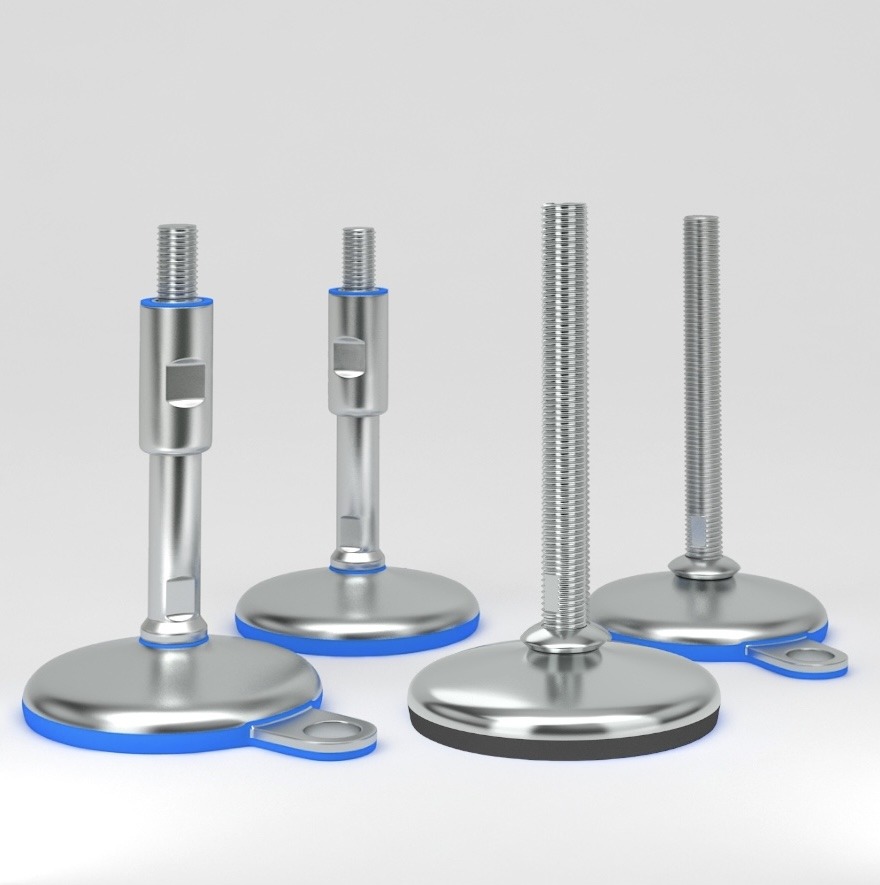

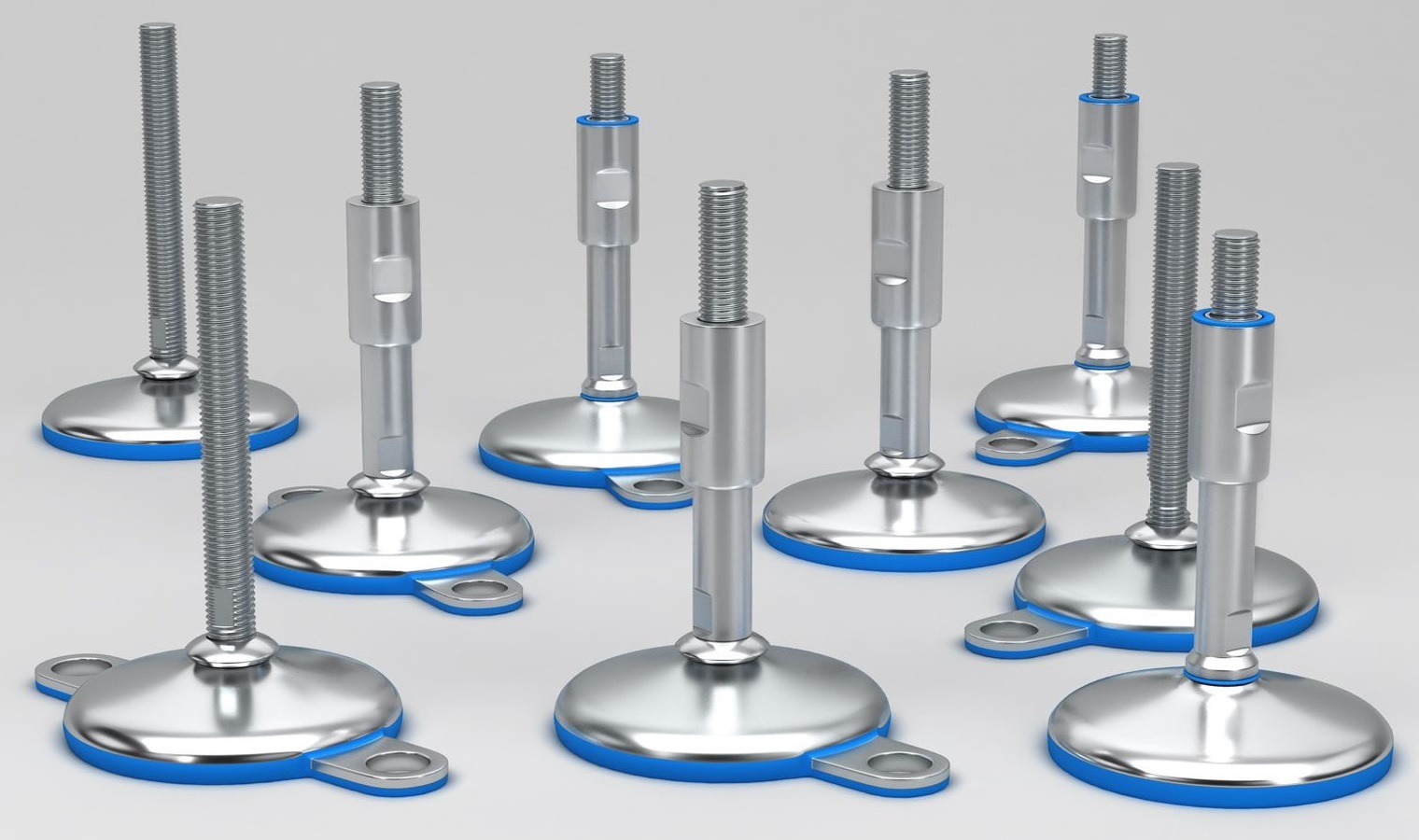

Adjustable Feet in Stainless Steel across various Industries

In packaging and processing industries, precision and stability are paramount to ensure quality production, efficient operations, and hygiene compliance. Stainless steel adjustable feet offer an essential foundation, ensuring machinery remains level and securely in place, even in demanding environments. With their high resistance to corrosion and adjustable design, these feet are ideal for various packaging and processing applications, from food and pharmaceuticals to chemical processing. As organizations in these industries grow and optimize, adjustable feet in stainless steel play a pivotal role in strategic planning and development, providing a strong base to achieve operational excellence. Adjustable feet crafted from stainless steel contribute to the stability and safety of heavy and complex machinery. Packaging and processing industries rely on smooth, steady operations to prevent accidents, minimize downtime, and reduce waste. By securing machinery, stainless steel adjustable feet enable precise leveling, keeping equipment aligned even on uneven surfaces. This leveling helps reduce the risk of mechanical failure, thereby enhancing overall safety and ensuring optimal working conditions. Strategic planning in any industry emphasizes long-term operational efficiency. Stainless steel adjustable feet, resistant to corrosion, wear, and chemical exposure, are designed to withstand harsh industrial environments. This durability translates to reduced maintenance costs and longer-lasting machinery foundations, contributing to cost savings. By investing in robust stainless steel leveling feet, organizations can allocate resources more effectively, cutting down on frequent replacements and repairs, which is a significant advantage in high-demand environments. For food processing and packaging, cleanliness and adherence to sanitation standards are critical. Stainless steel adjustable feet are specifically designed to meet hygienic requirements, as stainless steel is easy to clean and highly resistant to bacterial buildup. In food processing environments where sanitation regulations are rigorous, the use of stainless steel adjustable feet supports compliance, maintaining a clean workspace, and reducing contamination risks. Food processing machinery often generates considerable noise and vibration, which can lead to wear on equipment and discomfort for workers. Stainless steel adjustable feet mitigate these effects, reducing the impact of vibrations and noise by stabilizing machines. This benefit extends to packaged products as well, helping prevent packaging mishaps due to movement or instability during filling or sealing processes. Pharmaceutical and biotechnology industries demand exacting standards in both precision and hygiene. Adjustable feet in stainless steel are vital for supporting delicate equipment in sterile environments. Stainless steel’s corrosion resistance and hygienic properties meet the stringent regulations required in these industries. With adjustable feet, machinery remains stable and precise, allowing for accurate measurements, formulations, and processing without any environmental interference. In cleanroom environments where pharmaceutical production and biotechnology research occur, every component must contribute to an uncontaminated environment. Stainless steel adjustable feet, easy to clean and sanitize, are designed to integrate seamlessly with cleanroom standards. Adjustable feet maintain equipment at optimal levels while supporting high standards of cleanliness, providing operational stability without compromising the sterility of the environment. In the chemical and cosmetic industries, production processes often involve exposure to harsh substances and frequent washdowns. Stainless steel adjustable feet provide the corrosion resistance needed in these environments, standing up to aggressive chemicals without degrading. This longevity reduces the frequency of replacement and ensures machinery remains stable, even during intensive processes. By maintaining machine alignment and positioning, adjustable feet minimize the risk of leakage or contamination in chemical and cosmetic formulations. The adjustable nature of these feet is particularly beneficial for industries where machinery configurations may change frequently. Whether accommodating new processes, scaling production, or adapting to evolving regulations, stainless steel adjustable feet allow for rapid reconfiguration without the need for extensive modifications. This adaptability supports strategic planning initiatives, helping businesses to pivot quickly and efficiently. Stainless steel is known for its robustness and resistance to rust, making it a top choice for adjustable feet in industries requiring high hygiene standards. This material extends the lifespan of machinery, supports operational efficiency, and upholds cleanliness. By reducing the likelihood of corrosion, stainless steel adjustable feet provide a stable foundation that contributes to the overall productivity of processing environments. The adjustable aspect of these feet allows for precise height and angle modifications, accommodating machinery on uneven floors. Precision in leveling is crucial in industries that require exacting standards, as any tilt or imbalance could lead to operational disruptions, inaccurate measurements, or contamination risks. With stainless steel adjustable feet, adjustments are easy to make, supporting efficient workflow and maintaining quality standards. Adjustable stainless steel feet facilitate scalability. As businesses expand, production floors often require reconfiguration to accommodate additional or updated machinery. The flexibility and durability of stainless steel adjustable feet mean that as machinery is added or repositioned, adjustments can be made quickly without sacrificing stability. This scalability is crucial for industries with rapid growth trajectories or evolving product lines. Sustainability is becoming a strategic priority across industries. Stainless steel adjustable feet align with this goal by providing a durable solution that minimizes waste. Stainless steel is recyclable, contributing to an organization’s sustainability efforts, while its durability means fewer replacements and lower environmental impact over time. In conclusion, stainless steel adjustable feet are more than just a support component—they are integral to the strategic development of packaging and processing industries. Their durability, resistance to harsh environments, and hygienic properties make them invaluable to food, pharmaceutical, chemical, and cosmetic applications. As businesses prioritize operational efficiency, stability, and sustainability, stainless steel adjustable feet provide a robust solution that supports growth and adaptability. By investing in these essential components, companies can lay a stable foundation for future expansion, optimize resources, and adhere to industry standards. Industrial machinery requires precision-engineered components that meet exacting standards for durability, safety, and performance. This comprehensive guide explores the essential machinery parts that drive modern manufacturing across food processing, packaging, and chemical industries. Understanding the difference between Plummer Blocks and Flange Bearing Units is crucial for engineers and procurement professionals seeking to optimize equipment longevity. Pillow block bearings, also known as plummer blocks, are self-aligning bearing units that simplify installation and significantly reduce maintenance costs. These versatile components mount on machine frames and support rotating shafts with exceptional precision, ensuring smooth operation in demanding industrial environments. Flange bearing units offer a more compact alternative, featuring integrated flanges that enable direct mounting to flat surfaces without additional hardware. Both designs come in various materials, including stainless steel grades optimized for corrosive environments and food-grade applications where hygiene is paramount. The importance of material selection cannot be overstated in machinery design. 440C Steel and 420 grades offer distinctly different properties suited to specific applications and environmental conditions. The 440 stainless steel variant provides superior hardness and exceptional edge retention, making it ideal for cutting tools and high-wear applications requiring maximum durability. Meanwhile, 420 stainless steel offers better corrosion resistance and is preferred in food processing equipment where chemical exposure is common. Hygienic stainless steel components have become essential in food machinery, meeting EHEDG standards and facilitating rapid equipment cleaning required in modern food production facilities. Understanding ingress protection ratings is equally critical for machinery durability and operational reliability. IP67 rating ensures protection against dust and temporary water immersion, while IP68 rating provides complete dust protection and sustained water immersion capabilities for submerged operations. The IP69K standard represents the highest protection level, specifically designed for high-pressure wash-down environments found in industrial food processing facilities. These ratings define how effectively machinery components withstand environmental challenges and maintain performance. Modern industrial facilities increasingly demand equipment that combines high performance with ease of maintenance and sanitation. The choice between different bearing types depends on operational requirements, environmental conditions, and budget constraints. Proper component selection ensures extended equipment lifespan, reduced downtime, and improved operational efficiency.Strategic Planning and Development with Stainless Steel Adjustable Feet in Packaging and Processing Industries

The Strategic Benefits of Using Stainless Steel Adjustable Feet

Enhancing Stability and Safety

Supporting Long-Term Cost Efficiency

Stainless Steel Adjustable Feet in Food Packaging and Processing

Hygiene and Sanitation Standards

Reducing Vibrations and Noise

Pharmaceutical and Biotechnology Applications of Stainless Steel Adjustable Feet

Precision and Stability for Sensitive Equipment

Facilitating Cleanroom Compatibility

Chemical and Cosmetic Processing Applications

Stability in Harsh and Corrosive Environments

Flexibility in Machinery Configuration

Key Features of Stainless Steel Adjustable Feet

Corrosion Resistance and Durability

Precision in Adjustment

Strategic Planning with Stainless Steel Adjustable Feet

Supporting Scalable Operations

Promoting Sustainability

The Role of Stainless Steel Adjustable Feet in Industrial Development

Contact

Understanding Machinery Components & Protection Standards