Mini Paslanmaz Çelik Tasarımlı Oval Flanş Rulmanı

Hassasiyetin çok önemli olduğu üretim ve işleme alanında, NHK Makine Parçaları bir mükemmellik işareti olarak ortaya çıkıyor. Gıda ve farmasötik ürünlerin titizlikle üretimi ve işlenmesi için tasarlanmış bileşen ve parçaların imalatında uzmanız. Yolculuğumuz, sürdürülebilir kalkınma ve büyüme, detaylara olan sarsılmaz bağlılık ve sürdürülebilir ve sorumlu üretim uygulamaları yaratmaya olan bağlılığımız ile tanımlanıyor. Şu tarihte: NHK Makine Parçaları, sustainability is more than a message—it’s a design principle. We believe the most effective way to reduce environmental impact is to produce long-lasting makine bileşenleri that perform reliably in harsh industrial environments. That’s why our focus begins with: Durability in demanding conditions (cleaning chemicals, moisture, temperature changes, frequent washdown) Long service life, reducing replacement frequency and waste 100% recyclable material choices, supporting circular manufacturing When a component lasts longer, you buy less, replace less, and dispose of less. That is sustainability in practice. As a global supplier of hijyenik makine parçaları, NHK Machinery Parts delivers a broad portfolio for manufacturers operating in regulated or high-performance environments—especially food processing, packaging, pharmaceutical, and biotech. Our range includes: Flanşlı yatak üniteleri for stable shaft support and smooth rotation In this article, we highlight the engineering value of flange bearings—often overlooked, yet critical to reliable motion and long-term uptime. Flanş yatakları are essential mounted bearing solutions that support rotating shafts while providing stable, accurate alignment on a machine frame or side plate. They are widely used in applications where consistent motion and dependable load handling are non-negotiable. Conveyors and side-mounted shafts Packaging machinery and automation systems Food processing equipment in wet or washdown zones Manufacturing lines requiring stable rotation and low downtime In short: flange bearings keep production moving smoothly—quietly, efficiently, and consistently. In hygienic and industrial environments, bearing performance is only as good as the materials, sealing, and manufacturing behind it. NHK Machinery Parts designs flange bearing solutions to meet high expectations for both kesinlik Ve reliability. Our quality approach includes: Carefully selected materials suitable for harsh environments Manufacturing consistency for repeatable performance Options tailored for corrosion resistance and long service life Product choices that support hygiene-focused production standards The result: dependable bearing performance that helps protect equipment uptime and product safety. No two machines are identical—so flange bearings shouldn’t be “one-size-fits-all.” NHK Machinery Parts offers multiple configurations and sizes to match your load, shaft size, mounting layout, and environmental conditions. Whether you need: Stainless steel flange bearings for corrosion-prone areas Compact units for space-limited installations Heavy-duty options for industrial load demands …we help you select the right flange bearing unit for stable rotation and long-term performance. Sustainability is engineered into our flange bearings the same way it is into our full product range: by prioritizing longevity, reliability, and recyclability. Longer lifetime reduces replacement cycles Fewer replacements mean less waste and fewer deliveries Durable performance protects equipment efficiency over time Choosing an NHK Machinery Parts flange bearing is not just a technical decision—it’s a step toward more responsible manufacturing. For compact machinery and space-constrained designs, mini two-bolt flange bearing units in stainless steel offer a smart combination of: Compact footprint Stable mounting Cleanable stainless construction Reliable support for smaller shafts and precise movement These units are ideal for applications where hygienic design and tight installation space must work together. NHK Machinery Parts supplies a complete portfolio of hygienic stainless steel machinery components built for demanding endüstriler: Designed for stability and cleanability. EHEDG uyum supports hygienic design requirements in regulated industries. Engineered for smooth transfer and easier cleaning in food and pharmaceutical conveyor systems. Mobility-focused castors made for hygienic environments where cleaning access and corrosion resistance matter. Reliable protection for bearing assemblies in wet areas—supporting long service life and reduced downtime. Precision-mounted bearing solutions for stable rotation and dependable performance. Suitable for applications requiring dust and splash protection across many industrial environments. Compact, efficient bearing solutions for space-saving machine design. Supports controlled product flow while maintaining cleanability on conveyor systems. Built to meet strict hygiene expectations for safe and efficient product movement. Reliable power transmission designed for demanding conditions and hygiene-focused production. A compact, hygienic flange bearing option for applications needing small footprint, stable mounting, and corrosion resistance. Endüstrilerde precision engineering, hijyenik tasarım, Ve dayanıklılık are mission-critical, NHK Machinery Parts is your trusted partner. From stainless steel flange bearings ile EHEDG tesviye ayakları Ve IP67 rulman üniteleri, our components are engineered to help you build cleaner, more reliable, and more sustainable production equipment. Explore our product range and contact NHK Machinery Parts to find the right solution—where precision engineering meets long-lasting performance.Hassas Mühendislik Dayanıklılıkla Buluşuyor: NHK Machinery Parts'tan Flanşlı Rulmanlar Dünyası

Hygienic Components & Machinery Parts | NHK Group

Sustainability That Starts With Product Lifetime

Precision Redefined: Hygienic Components for Modern Industry

Flange Bearings: The Epitome of Precision and Stability

Where flange bearing units are used

Beklentileri Aşan Kalite

Customized Flange Bearing Solutions for Your Application

Sustainability at the Core of Every Bearing Unit

How durable flange bearings support sustainability

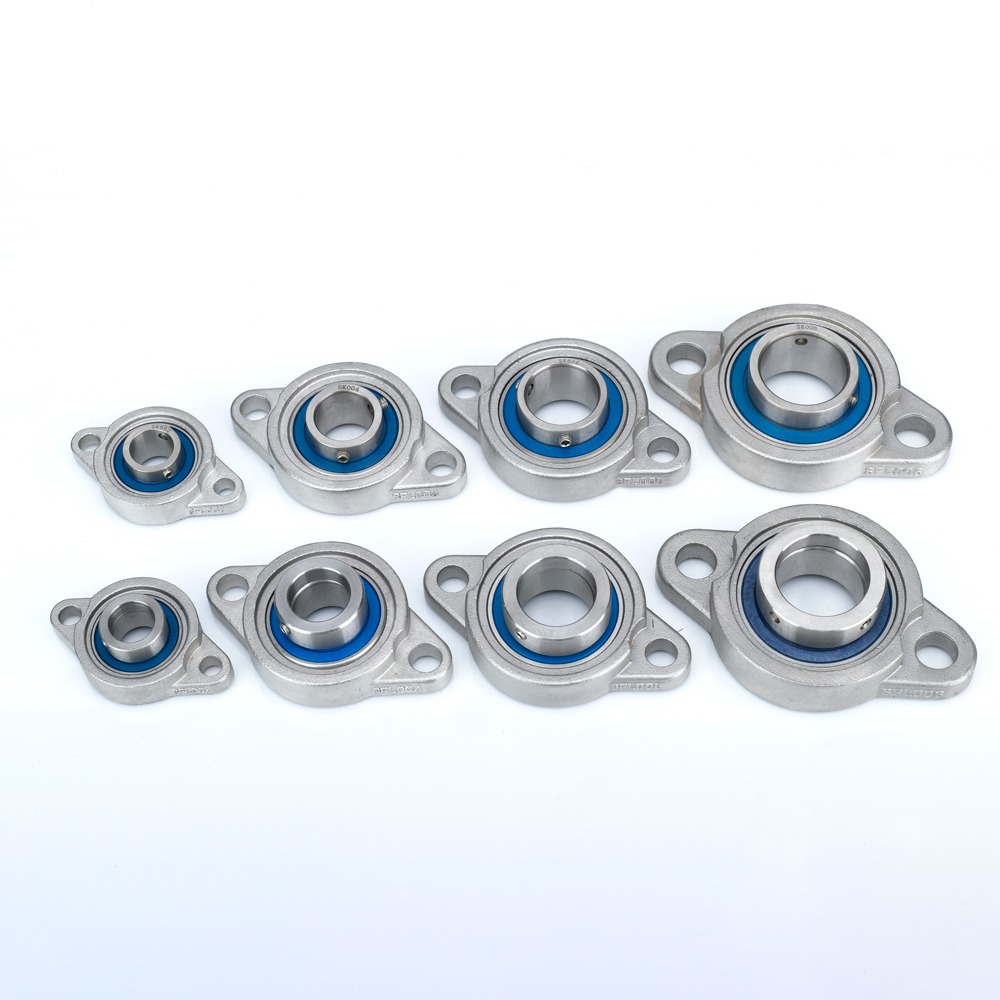

Mini Two-Bolt Flange Units in Stainless Steel

Explore Our Comprehensive Hygienic Product Range

EHEDG Stainless Steel Machine Levelling Feet

Hygienic 3-A Conveyor Parts in Stainless Steel

Hijyenik Tasarımlı Endüstriyel Tekerlekler

Waterproof IP67 Bearing House Units

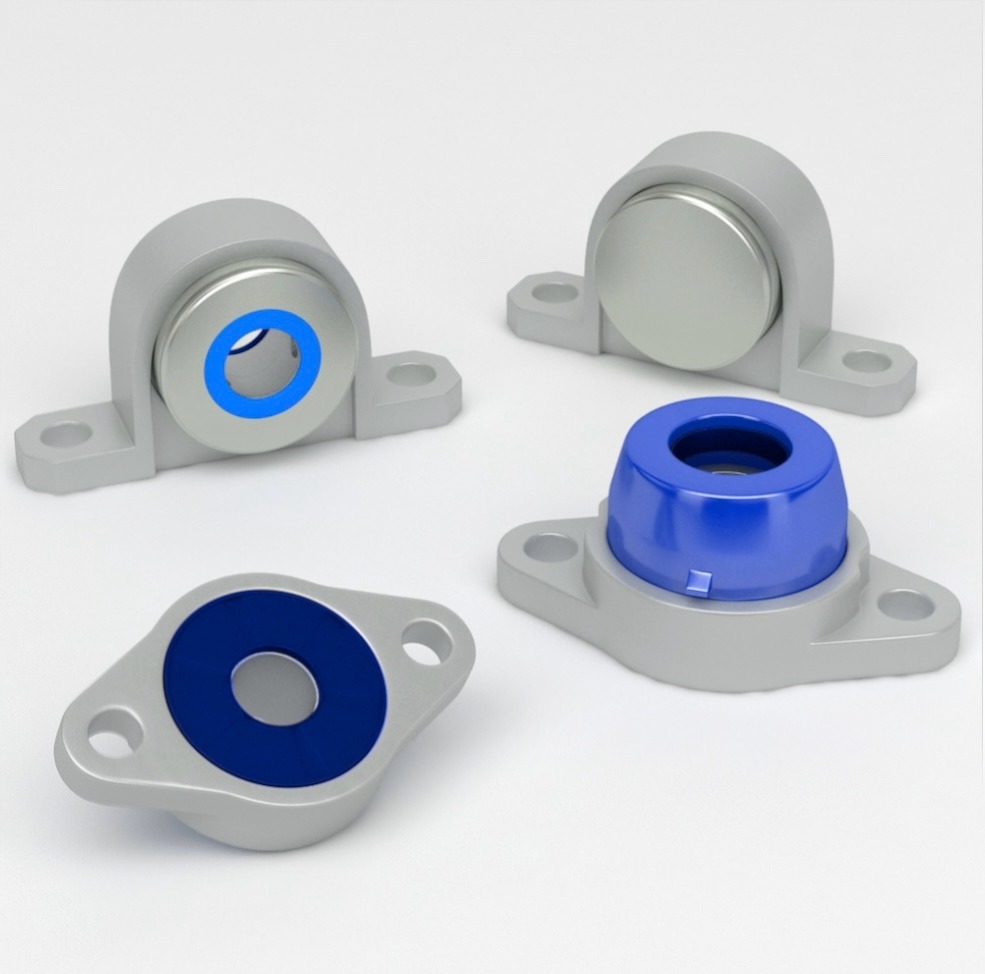

Ball Bearing Units in Stainless Steel

Bearing Units in IP54 Thermoplastic Housing

Paslanmaz Çelik Mini Rulman Üniteleri

Side Guides in Hygienic Stainless Steel Design

Paslanmaz Çelikten Hijyenik Konveyör Parçaları

Gear and Drum Motors in Hygienic Stainless Steel Design

Mini Paslanmaz Çelik Tasarımlı İki Cıvatalı Oval Flanş Rulman

NHK Machinery Parts: Precision, Durability, and Sustainable Performance

Endüstriyel Makine Parçaları ve Koruma Standartları

Gıda işleme endüstrisi ve ambalaj makineleri, uluslararası koruma, dayanıklılık ve hijyen standartlarını karşılayan hassas imal edilmiş bileşenleri gerektirir. IP sınıflandırması, nemli, korozif veya yüksek basınçlı yıkama ortamlarında bileşenlerin uygunluğunu belirlemek için temeldir mutlak. IP67, toza karşı tam koruma ve geçici su daldırmasına karşı koruma sağlarken, IP69K endüstriyel temizleme ortamları için özel olarak tasarlanmış en yüksek koruma seviyesini temsil eder. Paslanmaz çelik malzeme seçimi, hijyenik makinelerin üretimi için kritiktir ve önemlidir. Paslanmaz çelik 440 ve 420, belirli uygulamalara uyarlanmış farklı özellikler gösterir açıkça. 440 paslanmaz çelik, kesme araçları ve yüksek aşınmaya maruz kalan parçalar için ideal olan üstün sertlik sağlar. 420 paslanmaz çelik daha iyi korozyon direnci sunar ve tercih edilir. Rulman Hassasiyeti makine performansı için gereklidir ve vasıtasız. Yüksek kaliteli bileşenlere yapılan yatırım daha uzun ömür sağlar. Uluslararası standartlar modern endüstrinin artan taleplerini karşılamak için gelişmeye devam ediyor. Teknoloji ilerlemesi sektördeki yenilikleri destekler. Güvenilirlik endüstriyel başarısı belirler. Şirketler kalite bileşenlerine yatırımdan yararlanır.