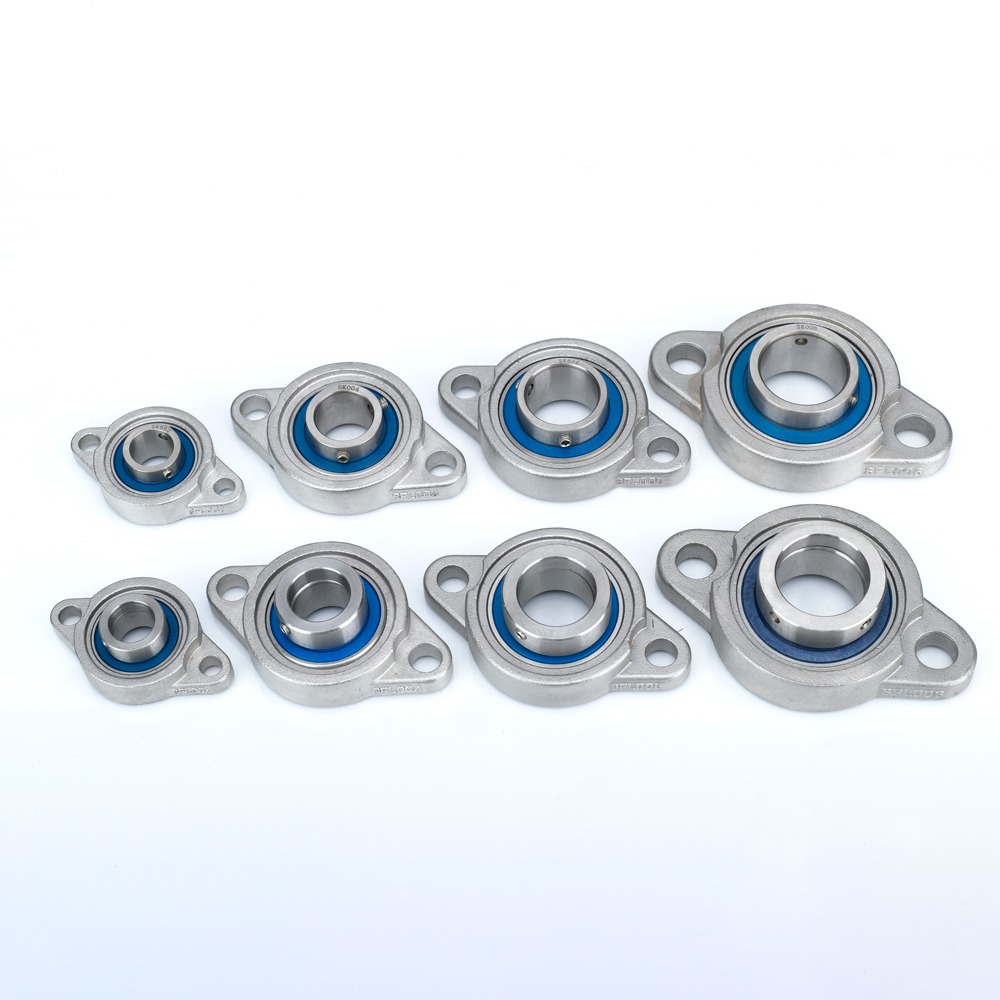

Cuscinetto a flangia ovale in design mini in acciaio inossidabile

Nel campo della produzione e della lavorazione, dove la precisione è fondamentale, Parti di macchinari NHK emerge come un faro di eccellenza. Siamo specializzati nella realizzazione di componenti e parti progettati per la meticolosa produzione e lavorazione di prodotti alimentari e farmaceutici. Il nostro viaggio è definito dallo sviluppo e dalla crescita sostenibili, da un impegno costante per i dettagli e da una dedizione alla creazione di pratiche di produzione sostenibili e responsabili. A Parti di macchinari NHK, sustainability is more than a message—it’s a design principle. We believe the most effective way to reduce environmental impact is to produce long-lasting componenti di macchinari that perform reliably in harsh industrial environments. That’s why our focus begins with: Durability in demanding conditions (cleaning chemicals, moisture, temperature changes, frequent washdown) Long service life, reducing replacement frequency and waste 100% recyclable material choices, supporting circular manufacturing When a component lasts longer, you buy less, replace less, and dispose of less. That is sustainability in practice. As a global supplier of parti di macchine igieniche, NHK Machinery Parts delivers a broad portfolio for manufacturers operating in regulated or high-performance environments—especially food processing, packaging, pharmaceutical, and biotech. Our range includes: Unità cuscinetto flangiate for stable shaft support and smooth rotation In this article, we highlight the engineering value of flange bearings—often overlooked, yet critical to reliable motion and long-term uptime. Cuscinetti flangiati are essential mounted bearing solutions that support rotating shafts while providing stable, accurate alignment on a machine frame or side plate. They are widely used in applications where consistent motion and dependable load handling are non-negotiable. Conveyors and side-mounted shafts Packaging machinery and automation systems Food processing equipment in wet or washdown zones Manufacturing lines requiring stable rotation and low downtime In short: flange bearings keep production moving smoothly—quietly, efficiently, and consistently. In hygienic and industrial environments, bearing performance is only as good as the materials, sealing, and manufacturing behind it. NHK Machinery Parts designs flange bearing solutions to meet high expectations for both precisione E reliability. Our quality approach includes: Carefully selected materials suitable for harsh environments Manufacturing consistency for repeatable performance Options tailored for corrosion resistance and long service life Product choices that support hygiene-focused production standards The result: dependable bearing performance that helps protect equipment uptime and product safety. No two machines are identical—so flange bearings shouldn’t be “one-size-fits-all.” NHK Machinery Parts offers multiple configurations and sizes to match your load, shaft size, mounting layout, and environmental conditions. Whether you need: Stainless steel flange bearings for corrosion-prone areas Compact units for space-limited installations Heavy-duty options for industrial load demands …we help you select the right flange bearing unit for stable rotation and long-term performance. Sustainability is engineered into our flange bearings the same way it is into our full product range: by prioritizing longevity, reliability, and recyclability. Longer lifetime reduces replacement cycles Fewer replacements mean less waste and fewer deliveries Durable performance protects equipment efficiency over time Choosing an NHK Machinery Parts flange bearing is not just a technical decision—it’s a step toward more responsible manufacturing. For compact machinery and space-constrained designs, mini two-bolt flange bearing units in stainless steel offer a smart combination of: Compact footprint Stable mounting Cleanable stainless construction Reliable support for smaller shafts and precise movement These units are ideal for applications where hygienic design and tight installation space must work together. NHK Machinery Parts supplies a complete portfolio of hygienic stainless steel machinery components built for demanding industrie: Designed for stability and cleanability. EHEDG conformità supports hygienic design requirements in regulated industries. Engineered for smooth transfer and easier cleaning in food and pharmaceutical conveyor systems. Mobility-focused castors made for hygienic environments where cleaning access and corrosion resistance matter. Reliable protection for bearing assemblies in wet areas—supporting long service life and reduced downtime. Precision-mounted bearing solutions for stable rotation and dependable performance. Suitable for applications requiring dust and splash protection across many industrial environments. Compact, efficient bearing solutions for space-saving machine design. Supports controlled product flow while maintaining cleanability on conveyor systems. Built to meet strict hygiene expectations for safe and efficient product movement. Reliable power transmission designed for demanding conditions and hygiene-focused production. A compact, hygienic flange bearing option for applications needing small footprint, stable mounting, and corrosion resistance. Nei settori in cui precision engineering, progettazione igienica, E durata are mission-critical, NHK Machinery Parts is your trusted partner. From stainless steel flange bearings A EHEDG piedini livellatori E IP67 unità cuscinetto, our components are engineered to help you build cleaner, more reliable, and more sustainable production equipment. Explore our product range and contact NHK Machinery Parts to find the right solution—where precision engineering meets long-lasting performance.L'ingegneria di precisione incontra la durata: il mondo dei cuscinetti flangiati di NHK Machinery Parts

Hygienic Components & Machinery Parts | NHK Group

Sustainability That Starts With Product Lifetime

Precision Redefined: Hygienic Components for Modern Industry

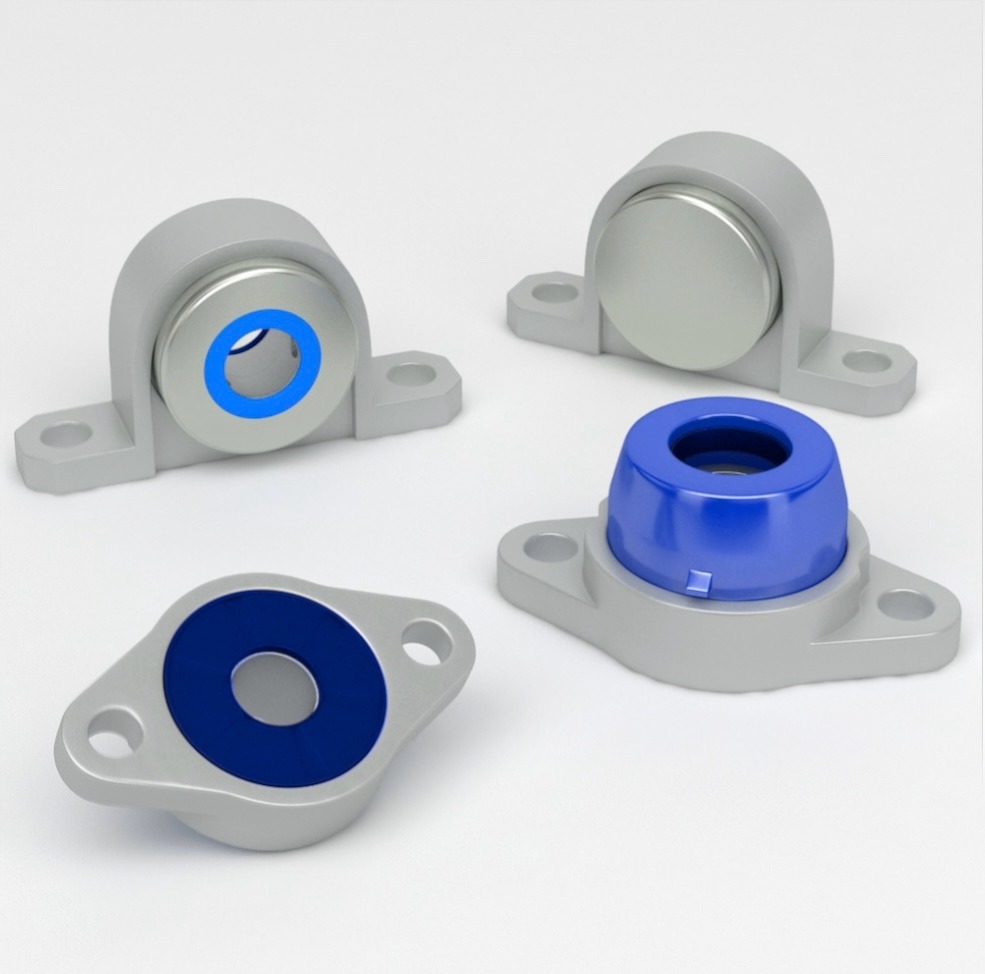

Flange Bearings: The Epitome of Precision and Stability

Where flange bearing units are used

Qualità che supera le aspettative

Customized Flange Bearing Solutions for Your Application

Sustainability at the Core of Every Bearing Unit

How durable flange bearings support sustainability

Mini Two-Bolt Flange Units in Stainless Steel

Explore Our Comprehensive Hygienic Product Range

EHEDG Stainless Steel Machine Levelling Feet

Hygienic 3-A Conveyor Parts in Stainless Steel

Ruote industriali dal design igienico

Waterproof IP67 Bearing House Units

Ball Bearing Units in Stainless Steel

Bearing Units in IP54 Thermoplastic Housing

Mini Unità Cuscinetti in Acciaio Inox

Side Guides in Hygienic Stainless Steel Design

Parti igieniche del trasportatore in acciaio inossidabile

Gear and Drum Motors in Hygienic Stainless Steel Design

Cuscinetto a flangia ovale a due bulloni in design mini in acciaio inossidabile

NHK Machinery Parts: Precision, Durability, and Sustainable Performance

Componenti Industriali e Standard di Protezione

L'industria della trasformazione alimentare e le macchine per l'imballaggio richiedono componenti precisi che soddisfino rigorosamente gli standard internazionali di protezione, durabilità e igiene completa. La classificazione IP è assolutamente fondamentale per determinare l'idoneità dei componenti in ambienti umidi, corrosivi o con lavaggio ad alta pressione intenso. Lo standard IP67 fornisce protezione completa contro polvere e immersione temporanea in acqua, mentre IP68 e IP69K offrono livelli di protezione ancora superiori, specificamente progettati per ambienti di pulizia industriale intensiva e continua. La scelta dei materiali in acciaio inossidabile è critica e vitale per la fabbricazione di macchinari igienici moderni. Gli acciai inossidabili 440 e 420 presentano proprietà distintamente distinte perfettamente adattate ad applicazioni specifiche diverse. L'acciaio 440 offre durezza superiore eccezionale e ritenzione del filo straordinaria, ideale per utensili da taglio e strumenti sottoposti a elevata usura continua. L'acciaio 420 fornisce migliore resistenza alla corrosione e preferito nelle attrezzature di trasformazione alimentare. I cuscinetti di precisione sono fondamentali e assolutamente indispensabili per il funzionamento ottimale dei macchinari industriali. I standard internazionali continuano a evolversi continuamente per soddisfare le crescenti esigenze dell'industria moderna. L'innovazione tecnologica permette il miglioramento costante dei processi di produzione e delle metodologie. La qualità è un fattore determinante nel successo competitivo delle aziende moderne. L'investimento in componenti di qualità superiore garantisce risultati eccellenti nel tempo.