Side Guides in Focus: Bolstering Hygiene and Efficiency in Food and Pharmaceutical Sectors

In the intricate world of food processing and pharmaceutical manufacturing, the emphasis on hygiene and precision is unparalleled. Every component, no matter how minor it appears, plays a pivotal role in ensuring that the highest standards of cleanliness and efficiency are maintained. Amidst these components, side guides, particularly those crafted from stainless steel, have emerged as integral elements. They stand as the bastions of hygiene and functionality, contributing immensely to the uncompromising standards of these industries.

Unravelling the Efficacy of Stainless Steel Side Guides

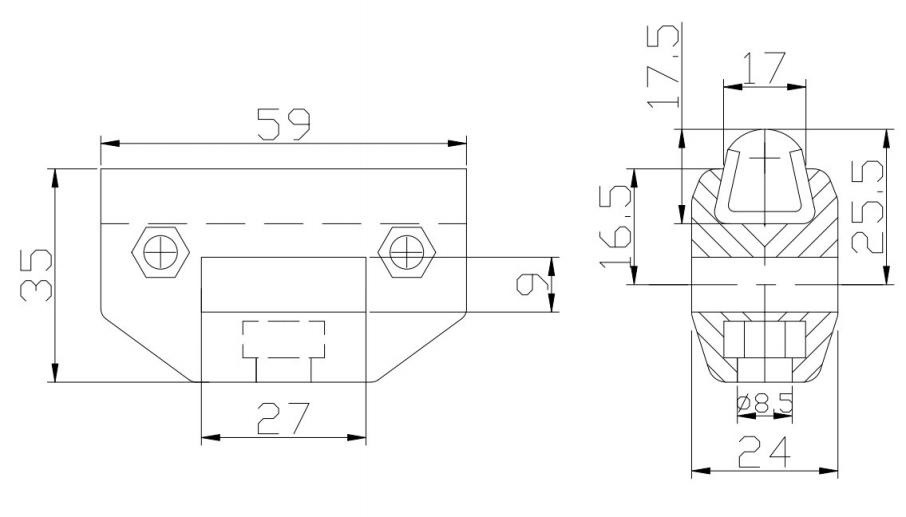

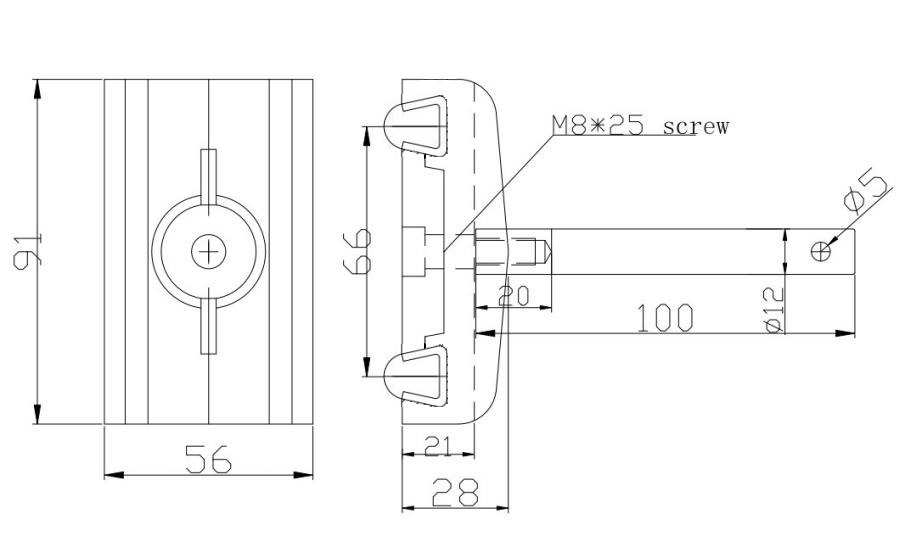

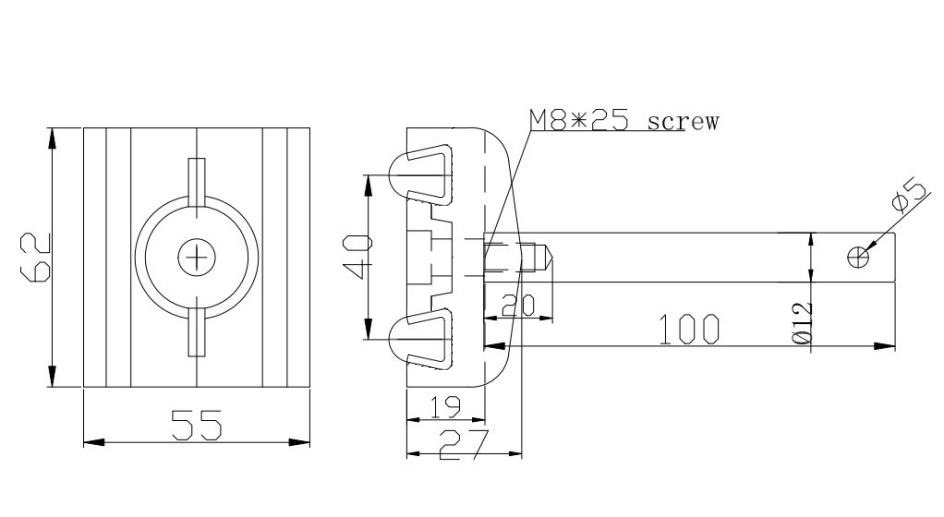

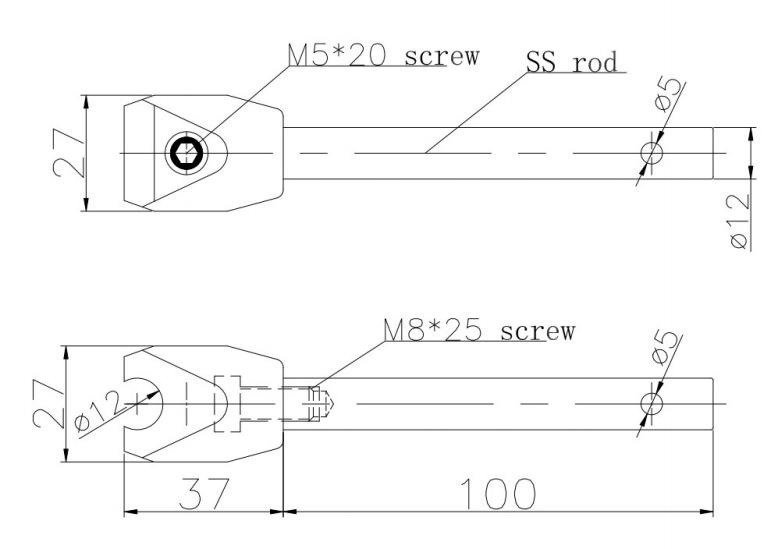

Stainless steel side guides are precision-engineered to cater to the rigorous demands of environments where cleanliness is as crucial as efficiency. Their design and material inherently resist corrosion, endure extreme temperatures and withstand aggressive cleaning protocols, making them a staple in settings that are unforgiving to compromise.

Hygienic Design

Crafted with smooth surfaces and minimal crevices, stainless steel side guides are designed to prevent bacterial build-up. They support easy cleaning and sanitization, ensuring that both food processing and pharmaceutical manufacturing environments remain contaminant-free.

Durability

Constructed from stainless steel, these side guides exhibit unparalleled durability. They resist wear and tear, corrosion, and the impacts of harsh cleaning agents, ensuring long-lasting performance and minimal maintenance.

Precision

In industries where the margin for error is minimal, the role of stainless steel side guides in ensuring that processes are carried out with utmost precision cannot be overstated. They facilitate the seamless movement and handling of products, ensuring quality and consistency.

The Interplay with Food Processing

In the food processing sector, the stainless steel side guides are instrumental in ensuring that products are handled, processed, and packaged with impeccable hygiene. Their design facilitates easy cleaning, ensuring that every stage of processing upholds the highest standards of food safety.

Integration in Pharmaceutical Manufacturing

In the pharmaceutical realm, precision and hygiene are non-negotiable. Stainless steel side guides ensure that products are handled with accuracy, and the risk of contamination is nullified. Their durability ensures that they remain a constant, reliable component amidst the dynamic, demanding environment of pharmaceutical manufacturing.

Integration of stainless steel side guides

The integration of stainless steel side guides transcends functional necessity; it is an embodiment of the commitment to quality, safety, and efficiency in the food processing and pharmaceutical manufacturing sectors. As these industries continue to evolve, and standards become even more stringent, the role of these side guides is set to be more pronounced. They are not just components but critical allies in the unyielding quest for excellence, safety, and efficiency.

Keywords:

- Stainless steel side guides

- Food processing

- Pharmaceutical manufacturing

- Hygienic design

- Durability

- Precision handling

- Easy cleaning

- Contaminant-free

Do you want to become a customer?

Do you have any questions about our products? You are always welcome to contact us for questions about performance and solutions for your machine or anything else. You can read more about how to contact us here. You can find us in Denmark, the UK, Germany and Hong Kong.

See other essential hygienic designed components for the food processing and pharmaceutical industries.

Certified hygienic components

Stainless steel solid base machine levelling feet in hygienic design

Machine levelling feet in a hygienic design

Industrial castors in hygienic design

Waterproof IP67 bearing house

Sealed Stainless Bearing Units

Bearing units in IP54 thermo plastic housing

Mounted ball bearing units in stainless steel

Mini Bearing Units in Stainless Steel

Hygienic conveyor parts in stainless steel

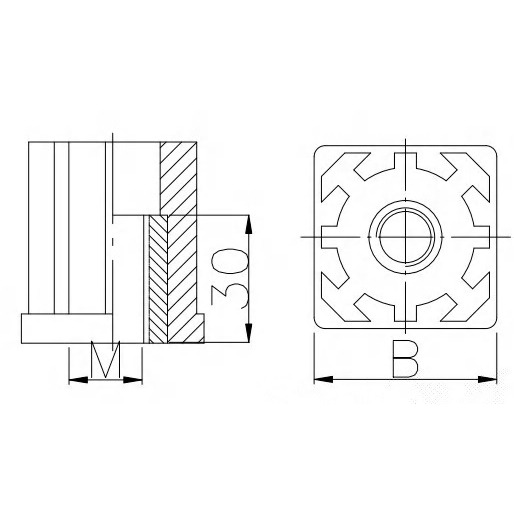

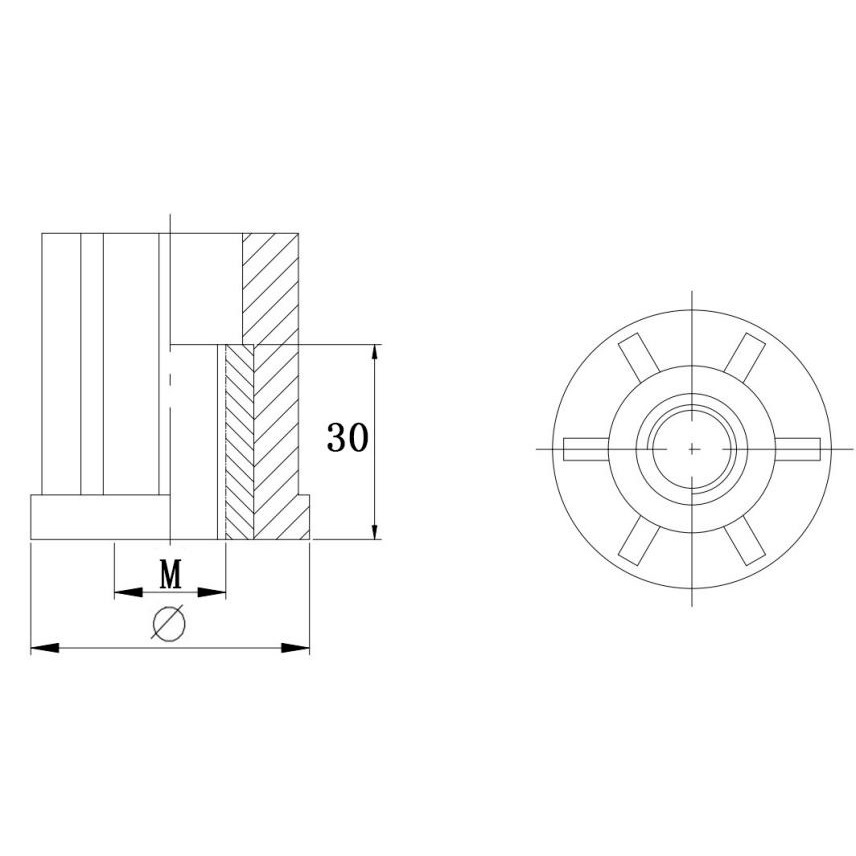

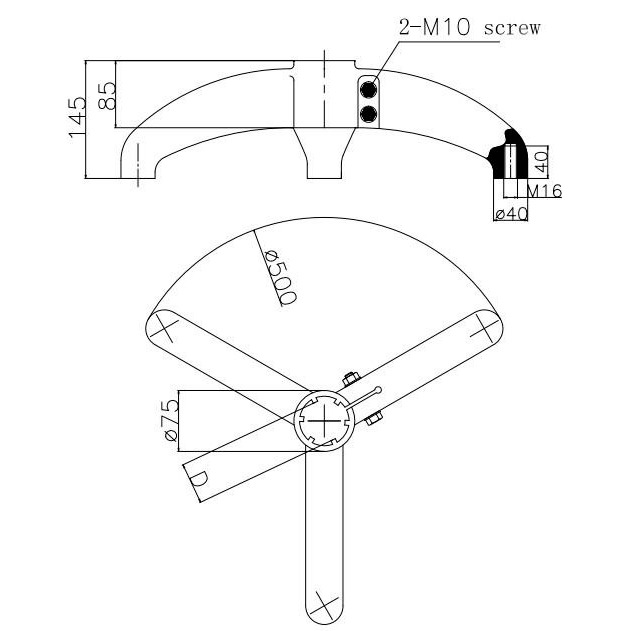

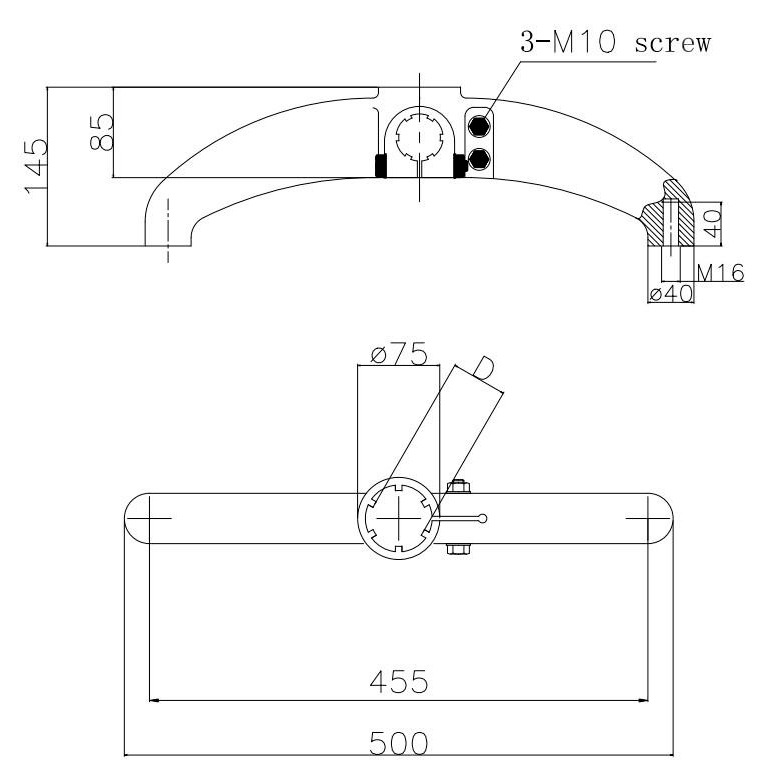

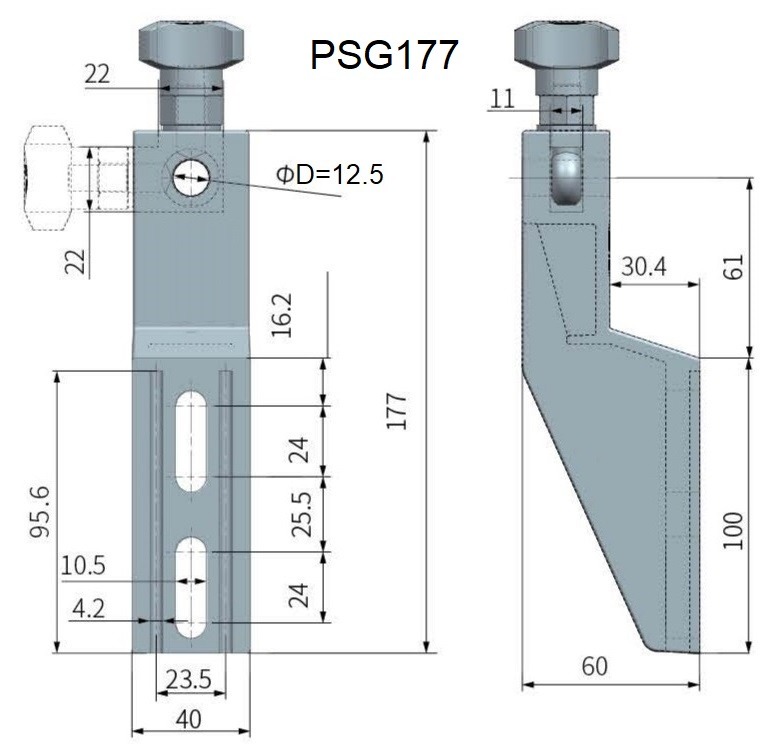

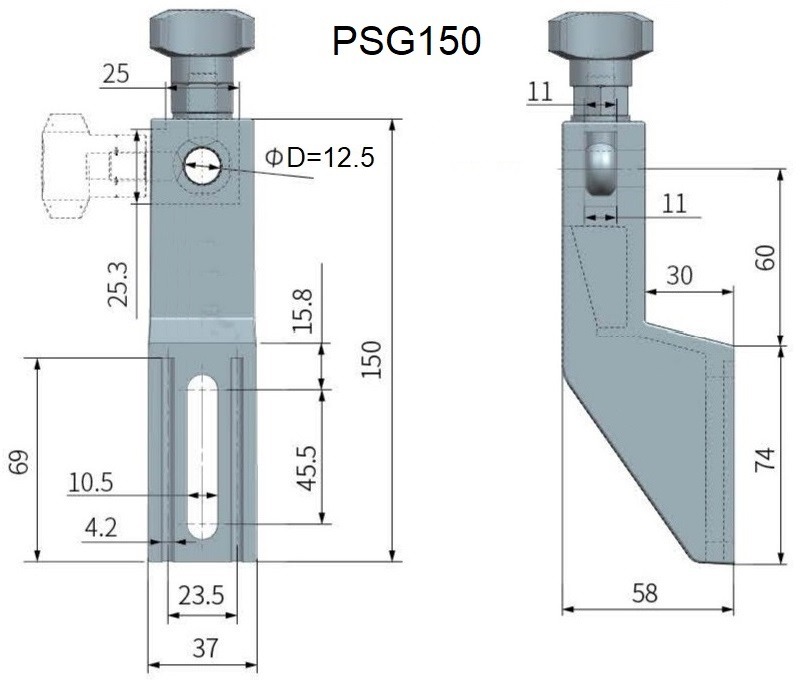

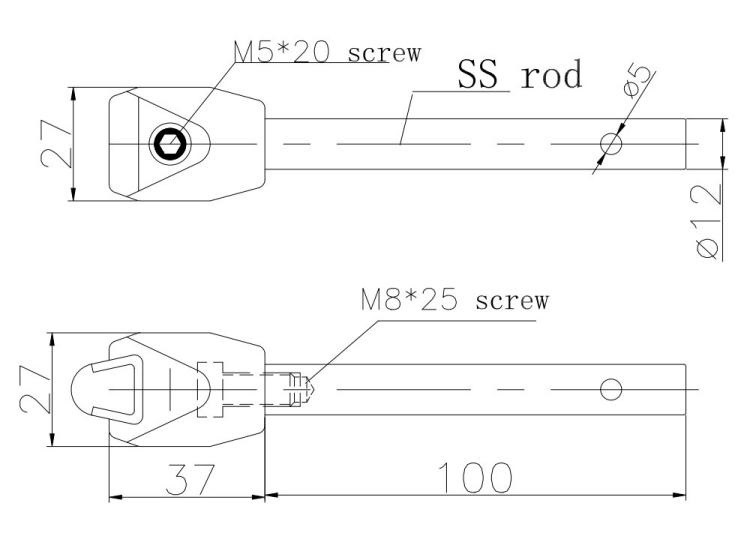

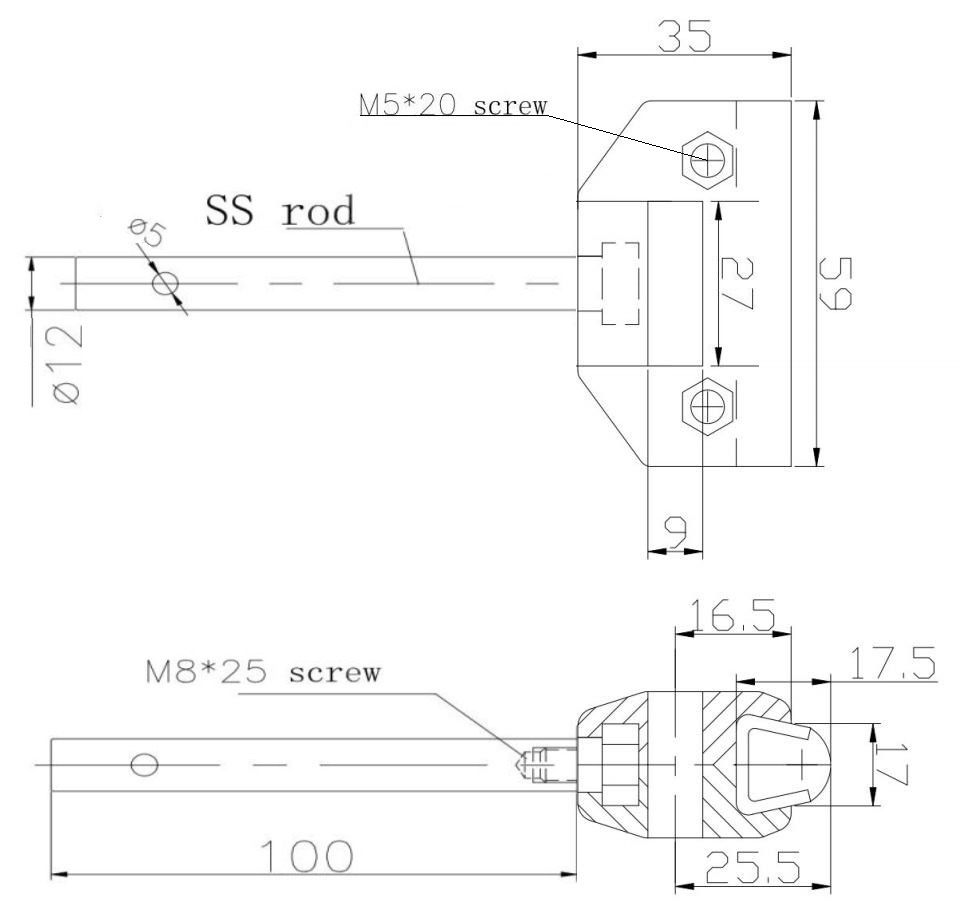

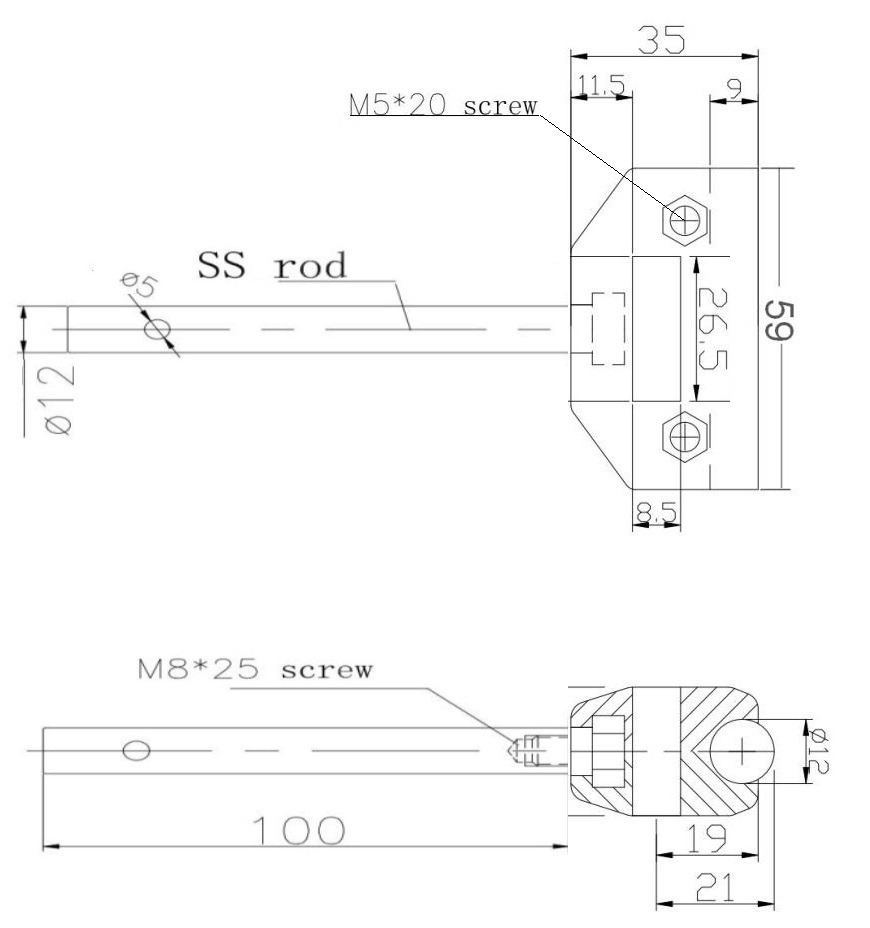

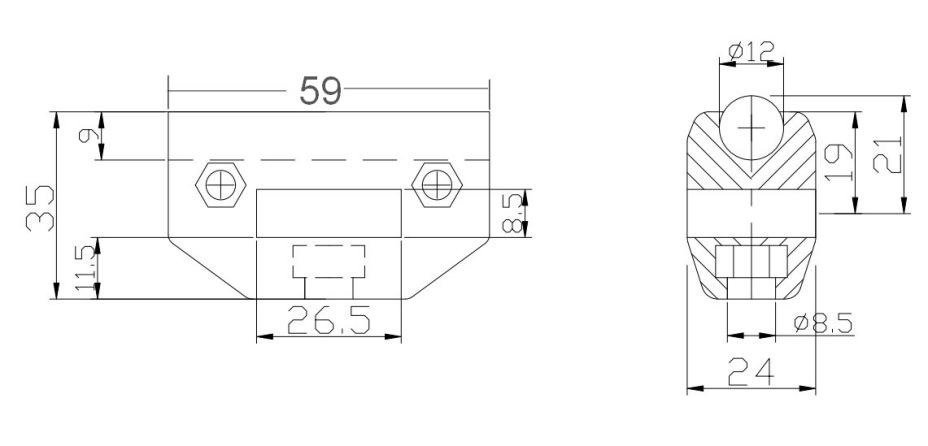

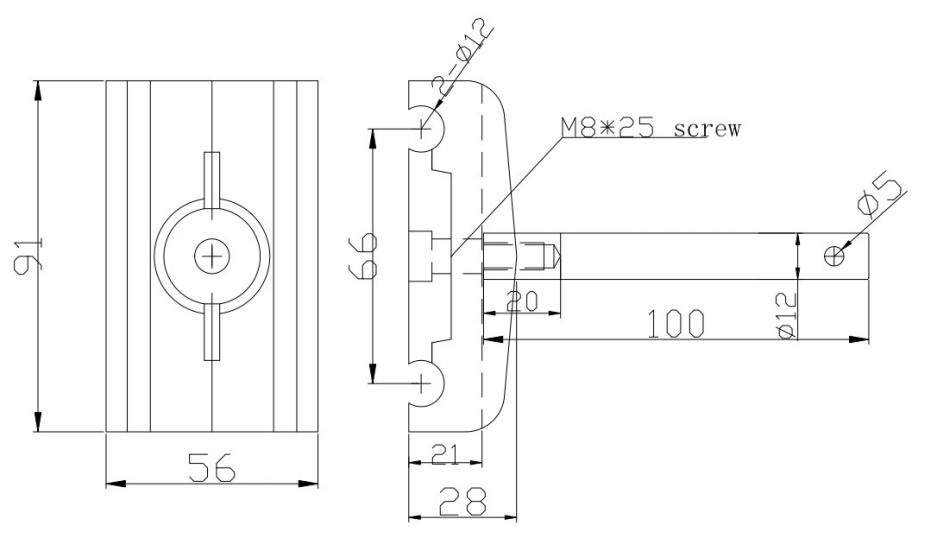

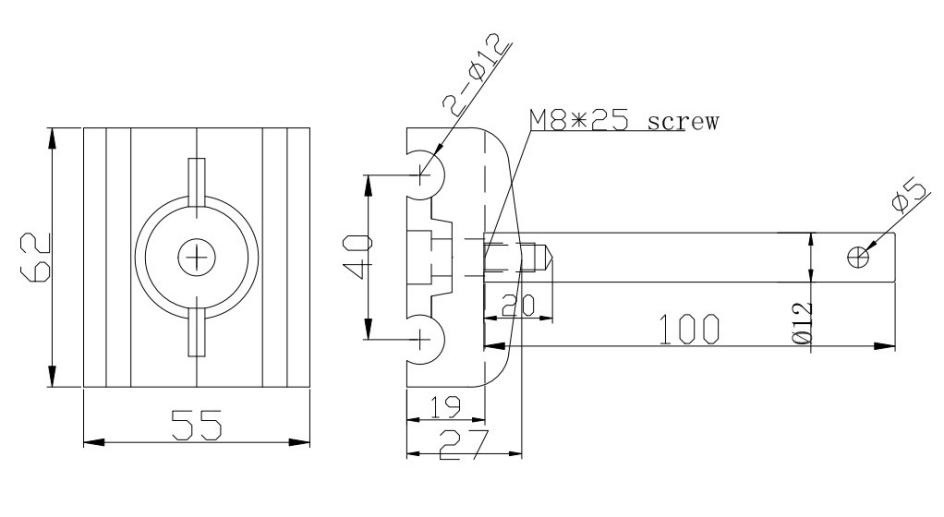

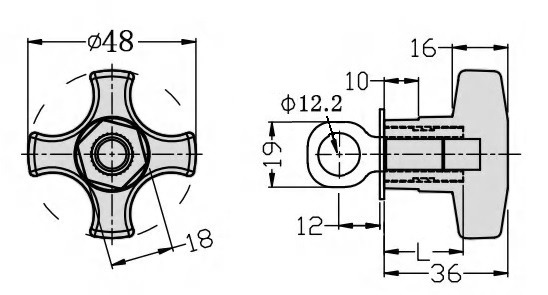

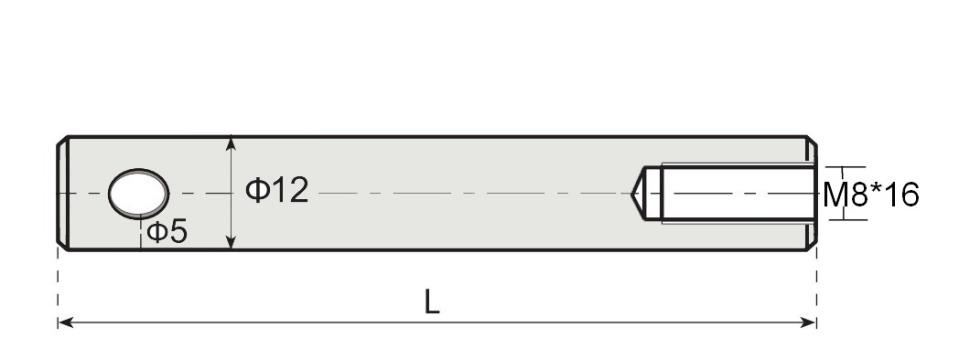

Side guide in hygienic stainless steel design

Gear and drum motor in hygienic stainless steel design