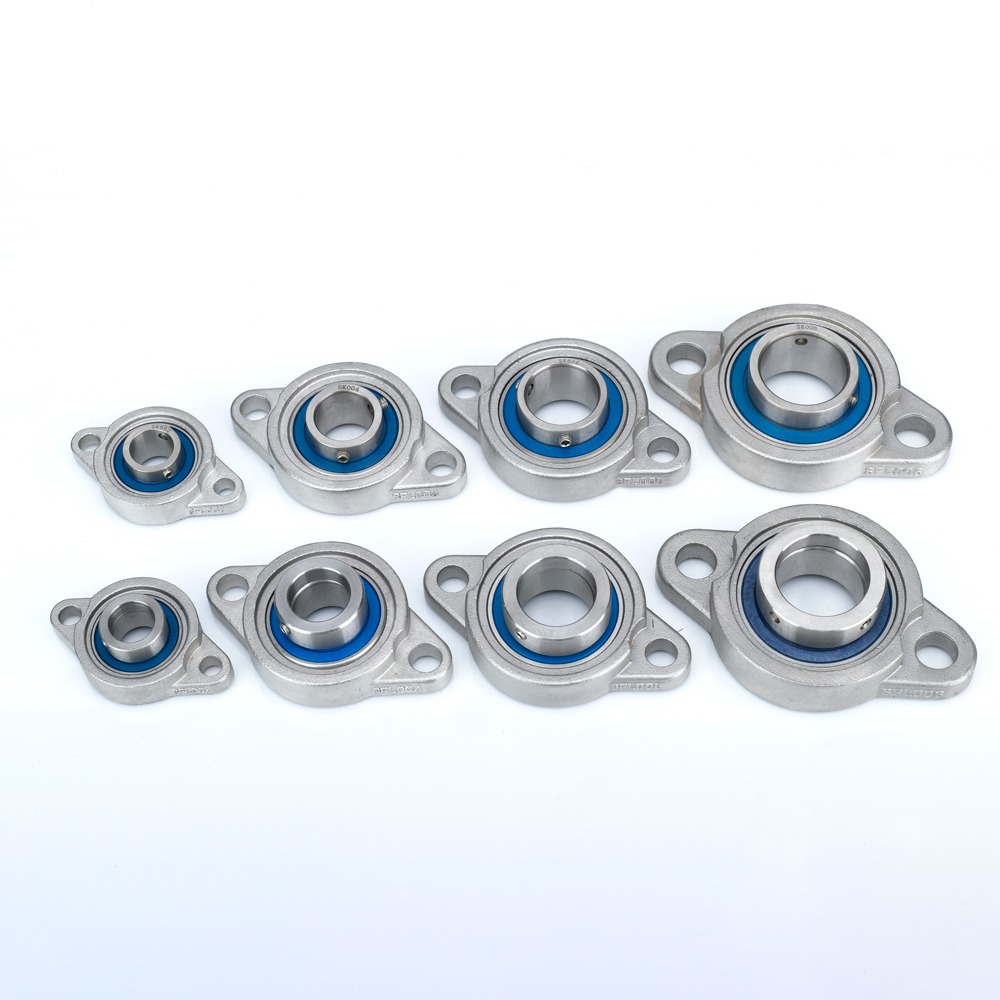

Ovaal flenslager in mini-roestvaststalen uitvoering

Op het gebied van productie en verwerking, waar precisie voorop staat, NHK-machineonderdelen ontpopt zich als een baken van uitmuntendheid. Wij zijn gespecialiseerd in het vervaardigen van componenten en onderdelen die zijn ontworpen voor de nauwgezette productie en verwerking van voedingsmiddelen en farmaceutische producten. Onze reis wordt bepaald door duurzame ontwikkeling en groei, een niet-aflatende toewijding aan details en een toewijding aan het creëren van duurzame en verantwoorde productiepraktijken. Bij NHK-machineonderdelen, sustainability is more than a message—it’s a design principle. We believe the most effective way to reduce environmental impact is to produce long-lasting machineonderdelen that perform reliably in harsh industrial environments. That’s why our focus begins with: Durability in demanding conditions (cleaning chemicals, moisture, temperature changes, frequent washdown) Long service life, reducing replacement frequency and waste 100% recyclable material choices, supporting circular manufacturing When a component lasts longer, you buy less, replace less, and dispose of less. That is sustainability in practice. As a global supplier of hygiënische machineonderdelen, NHK Machinery Parts delivers a broad portfolio for manufacturers operating in regulated or high-performance environments—especially food processing, packaging, pharmaceutical, and biotech. Our range includes: Flenslagereenheden for stable shaft support and smooth rotation In this article, we highlight the engineering value of flange bearings—often overlooked, yet critical to reliable motion and long-term uptime. Flange bearings are essential mounted bearing solutions that support rotating shafts while providing stable, accurate alignment on a machine frame or side plate. They are widely used in applications where consistent motion and dependable load handling are non-negotiable. Conveyors and side-mounted shafts Packaging machinery and automation systems Food processing equipment in wet or washdown zones Manufacturing lines requiring stable rotation and low downtime In short: flange bearings keep production moving smoothly—quietly, efficiently, and consistently. In hygienic and industrial environments, bearing performance is only as good as the materials, sealing, and manufacturing behind it. NHK Machinery Parts designs flange bearing solutions to meet high expectations for both precisie En reliability. Our quality approach includes: Carefully selected materials suitable for harsh environments Manufacturing consistency for repeatable performance Options tailored for corrosion resistance and long service life Product choices that support hygiene-focused production standards The result: dependable bearing performance that helps protect equipment uptime and product safety. No two machines are identical—so flange bearings shouldn’t be “one-size-fits-all.” NHK Machinery Parts offers multiple configurations and sizes to match your load, shaft size, mounting layout, and environmental conditions. Whether you need: Stainless steel flange bearings for corrosion-prone areas Compact units for space-limited installations Heavy-duty options for industrial load demands …we help you select the right flange bearing unit for stable rotation and long-term performance. Sustainability is engineered into our flange bearings the same way it is into our full product range: by prioritizing longevity, reliability, and recyclability. Longer lifetime reduces replacement cycles Fewer replacements mean less waste and fewer deliveries Durable performance protects equipment efficiency over time Choosing an NHK Machinery Parts flange bearing is not just a technical decision—it’s a step toward more responsible manufacturing. For compact machinery and space-constrained designs, mini two-bolt flange bearing units in stainless steel offer a smart combination of: Compact footprint Stable mounting Cleanable stainless construction Reliable support for smaller shafts and precise movement These units are ideal for applications where hygienic design and tight installation space must work together. NHK Machinery Parts supplies a complete portfolio of hygienic stainless steel machinery components built for demanding industrieën: Designed for stability and cleanability. EHEDG naleving supports hygienic design requirements in regulated industries. Engineered for smooth transfer and easier cleaning in food and pharmaceutical conveyor systems. Mobility-focused castors made for hygienic environments where cleaning access and corrosion resistance matter. Reliable protection for bearing assemblies in wet areas—supporting long service life and reduced downtime. Precision-mounted bearing solutions for stable rotation and dependable performance. Suitable for applications requiring dust and splash protection across many industrial environments. Compact, efficient bearing solutions for space-saving machine design. Supports controlled product flow while maintaining cleanability on conveyor systems. Built to meet strict hygiene expectations for safe and efficient product movement. Reliable power transmission designed for demanding conditions and hygiene-focused production. A compact, hygienic flange bearing option for applications needing small footprint, stable mounting, and corrosion resistance. In industrieën waar precision engineering, hygiënisch ontwerp, En duurzaamheid are mission-critical, NHK Machinery Parts is your trusted partner. From stainless steel flange bearings naar EHEDG stelvoeten En IP67 lagereenheden, our components are engineered to help you build cleaner, more reliable, and more sustainable production equipment. Explore our product range and contact NHK Machinery Parts to find the right solution—where precision engineering meets long-lasting performance.Precisietechniek ontmoet duurzaamheid: de wereld van flenslagers van NHK Machinery Parts

Hygienic Components & Machinery Parts | NHK Group

Sustainability That Starts With Product Lifetime

Precision Redefined: Hygienic Components for Modern Industry

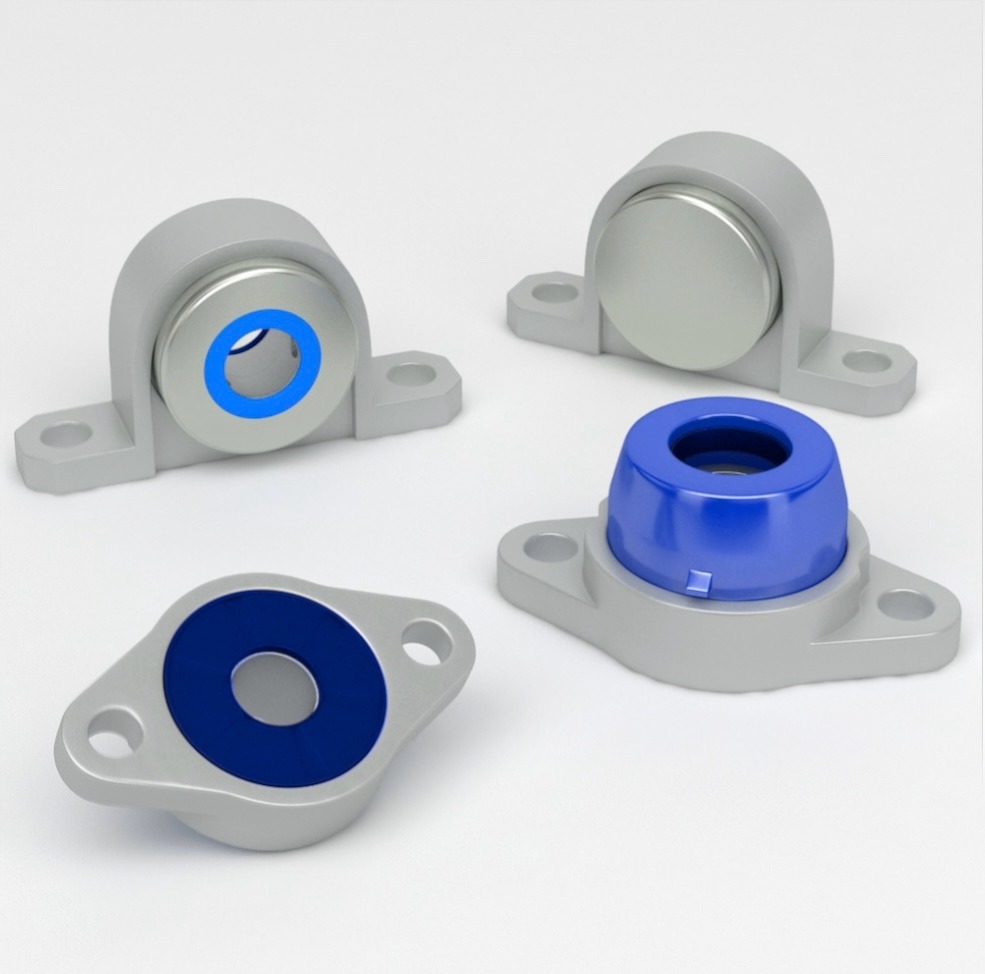

Flange Bearings: The Epitome of Precision and Stability

Where flange bearing units are used

Kwaliteit die de verwachtingen overtreft

Customized Flange Bearing Solutions for Your Application

Sustainability at the Core of Every Bearing Unit

How durable flange bearings support sustainability

Mini Two-Bolt Flange Units in Stainless Steel

Explore Our Comprehensive Hygienic Product Range

EHEDG Stainless Steel Machine Levelling Feet

Hygienic 3-A Conveyor Parts in Stainless Steel

Industriële wielen in hygiënisch ontwerp

Waterproof IP67 Bearing House Units

Ball Bearing Units in Stainless Steel

Bearing Units in IP54 Thermoplastic Housing

Mini-lagereenheden van roestvrij staal

Side Guides in Hygienic Stainless Steel Design

Hygiënische transportbandonderdelen van roestvrij staal

Gear and Drum Motors in Hygienic Stainless Steel Design

Ovaal flenslager met twee bouten in mini-roestvaststalen ontwerp

NHK Machinery Parts: Precision, Durability, and Sustainable Performance

Industriemachinedelen en Beschermingsnormen

De voedselindustrie en verpakkingsmachines vereisen nauwkeurig gemaakte componenten die volledig voldoen aan internationale beschermings-, duurzaamheids- en hygiëne-standaarden strenge. De IP-classificatie is absoluut fundamenteel voor het bepalen van geschiktheid van componenten in vochtige, corrosieve of hogedruk-wasomgevingen veeleisend. IP67 biedt volledige bescherming tegen stof en tijdelijke onderdompeling in water, terwijl IP69K het hoogste beschermingsniveau vertegenwoordigt, speciaal ontworpen voor intensieve industriële reinigingsomgevingen en processen. De keuze van roestvrijstalen materialen is cruciaal en essentieel voor de fabricage van hygiënische machines modern. Roestvrijstaal 440 en 420 vertonen verschillende eigenschappen uitstekend aangepast aan specifieke toepassingen diverse. Roestvrijstaal 440 biedt superieure hardheid uitzonderlijke en uitzonderlijke snijkantbehoud, ideaal voor snijgereedschap en onderdelen met hoge slijtage. Roestvrijstaal 420 levert betere corrosieweerstand en wordt voorkeur gegeven in voedselverwerkingsapparatuur. Precieze Kogellagers zijn essentieel en onmisbaar voor optimale machineprestaties uitstekend. De internationale standaarden blijven zich voortdurend ontwikkelen om aan de groeiende eisen van de moderne industrie te voldoen volledig. Innovatie en technologie zijn sleutelwoorden voor succes industrieel. De betrouwbaarheid van apparatuur hangt af van kwaliteitscomponenten altijd. Bedrijven profiteren aanzienlijk van investeringen in superieure onderdelen.