Side guide brackets stainless steel Hygienic conveyor components

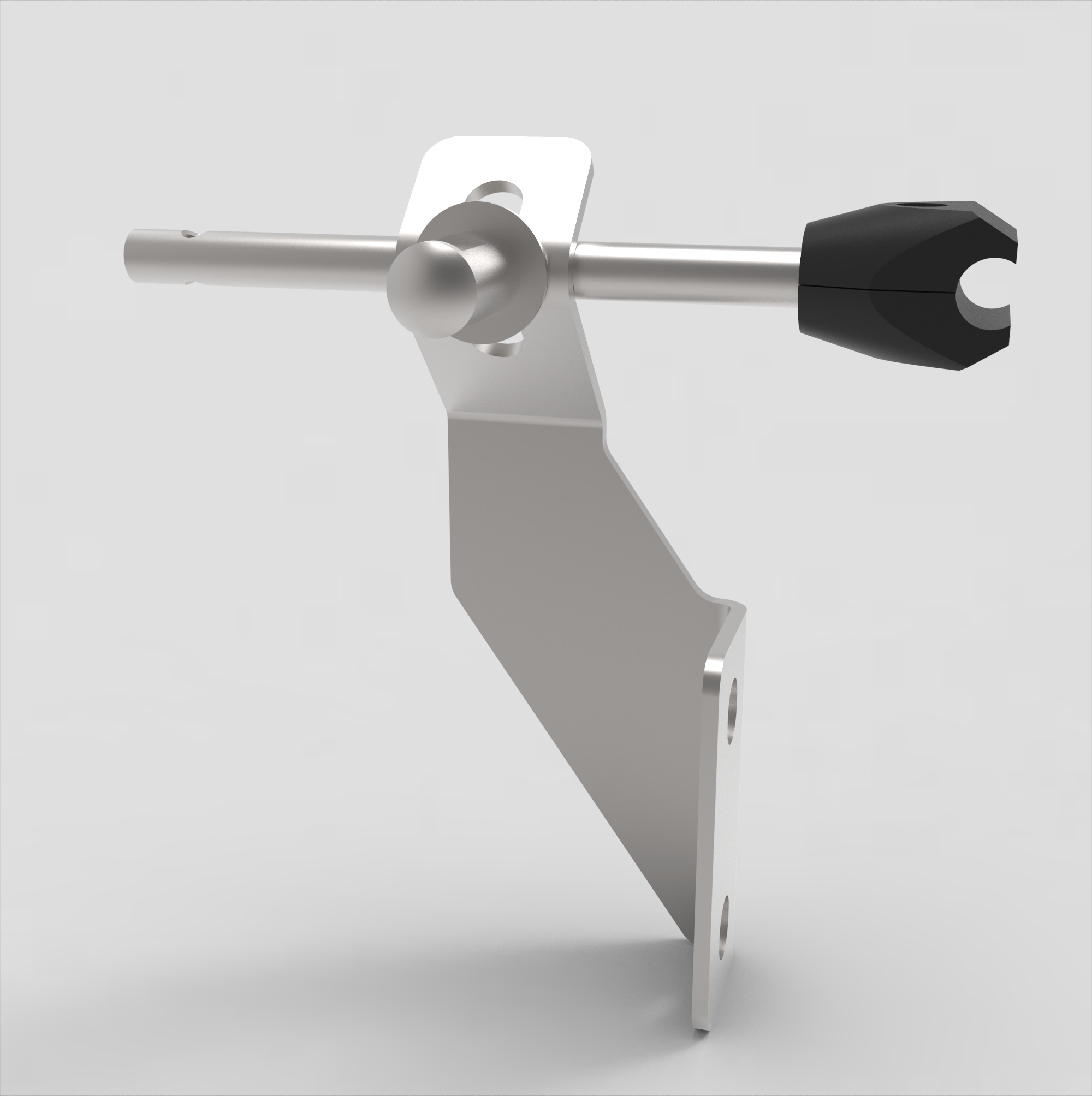

Side Guide Brackets in Stainless Steel

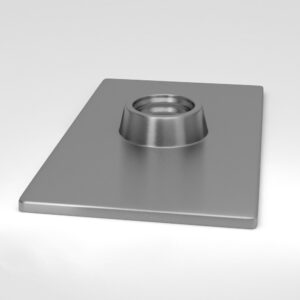

In hygienic production, even “small” conveyor parts can decide whether a line is easy to clean—or a constant source of contamination risk and downtime. ステンレス製サイドガイドブラケット are a critical component in conveyor guiding systems, keeping products aligned while supporting fast format changes and reliable operation in wet, washdown, and high-hygiene environments.

Hygienic Conveyor Components for Washdown Production Lines

Designed for food processing, pharmaceutical, and packaging applications, hygienic side guide brackets combine corrosion-resistant materials with smooth, easy-to-clean geometry—helping you reduce cleaning time, improve line efficiency, and support compliance with hygienic design principles.

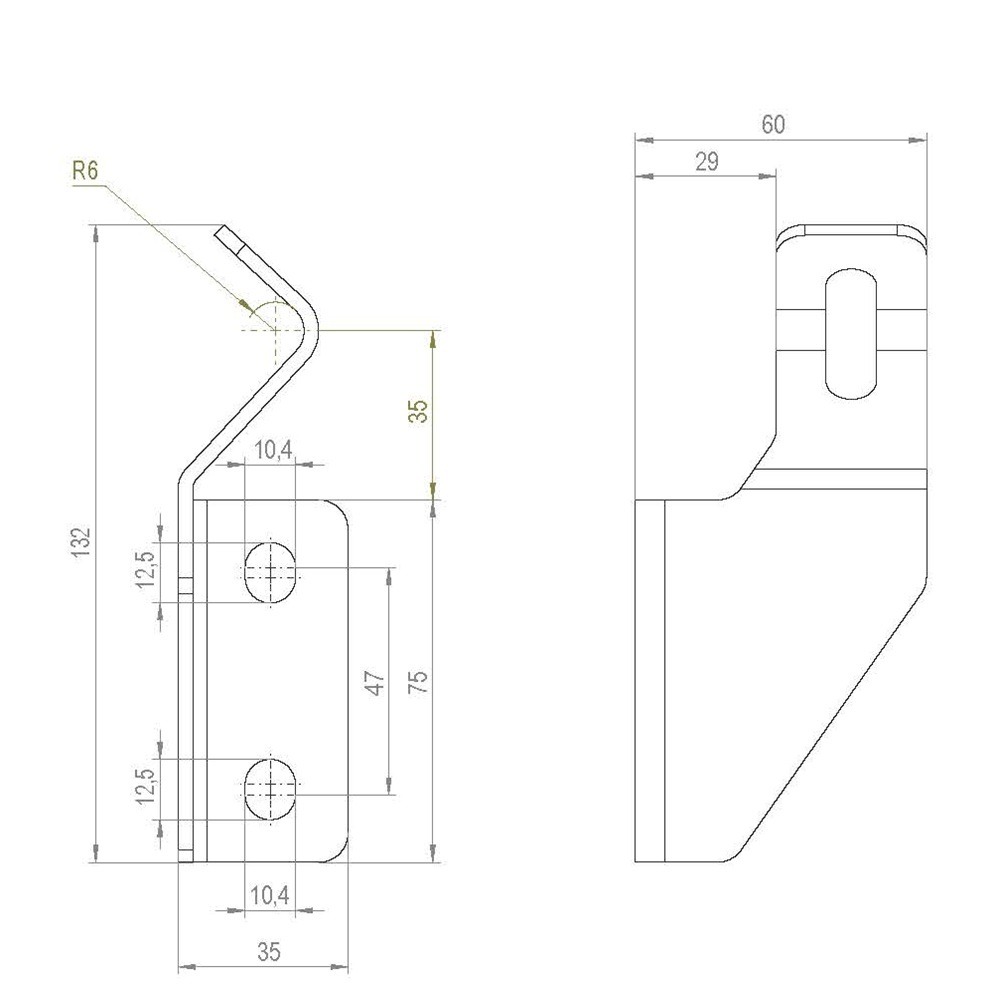

HSG 132 29 Hygienic side guide brackets stainless steel

HSG 132 48 Hygienic side guide brackets stainless steel

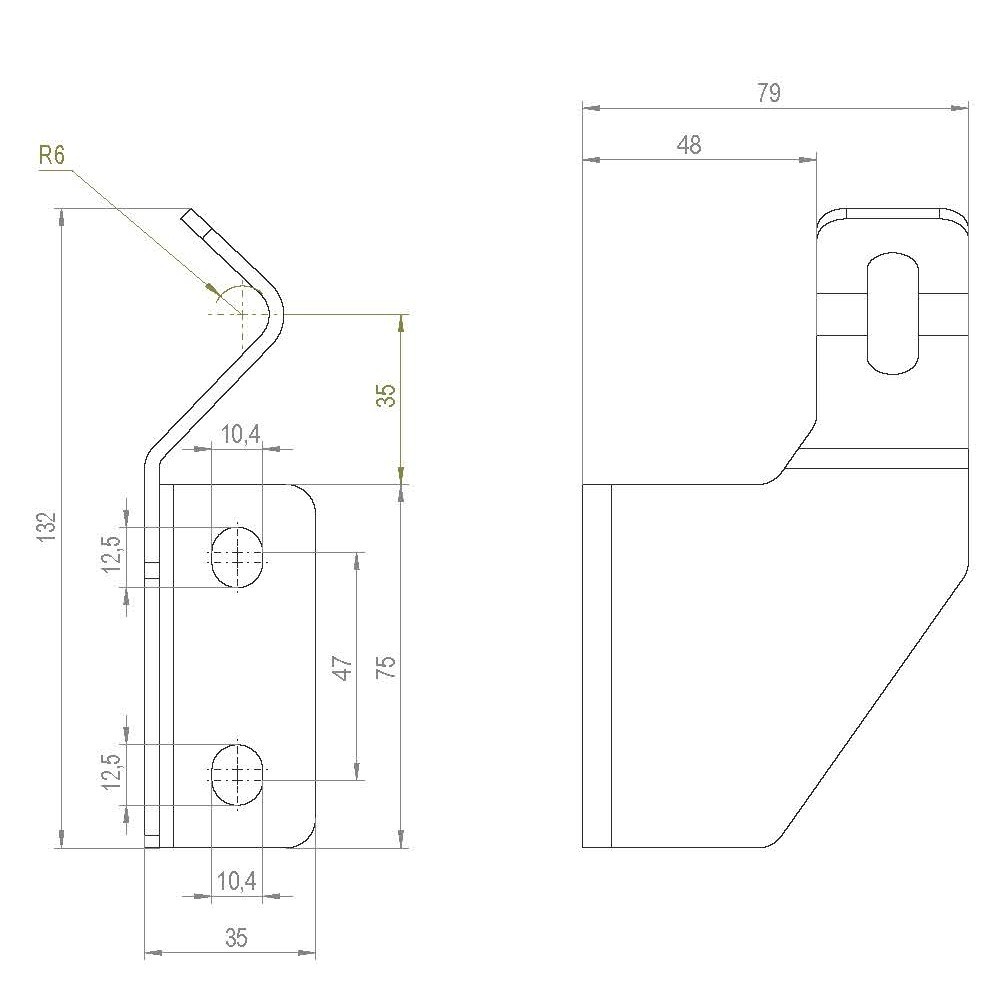

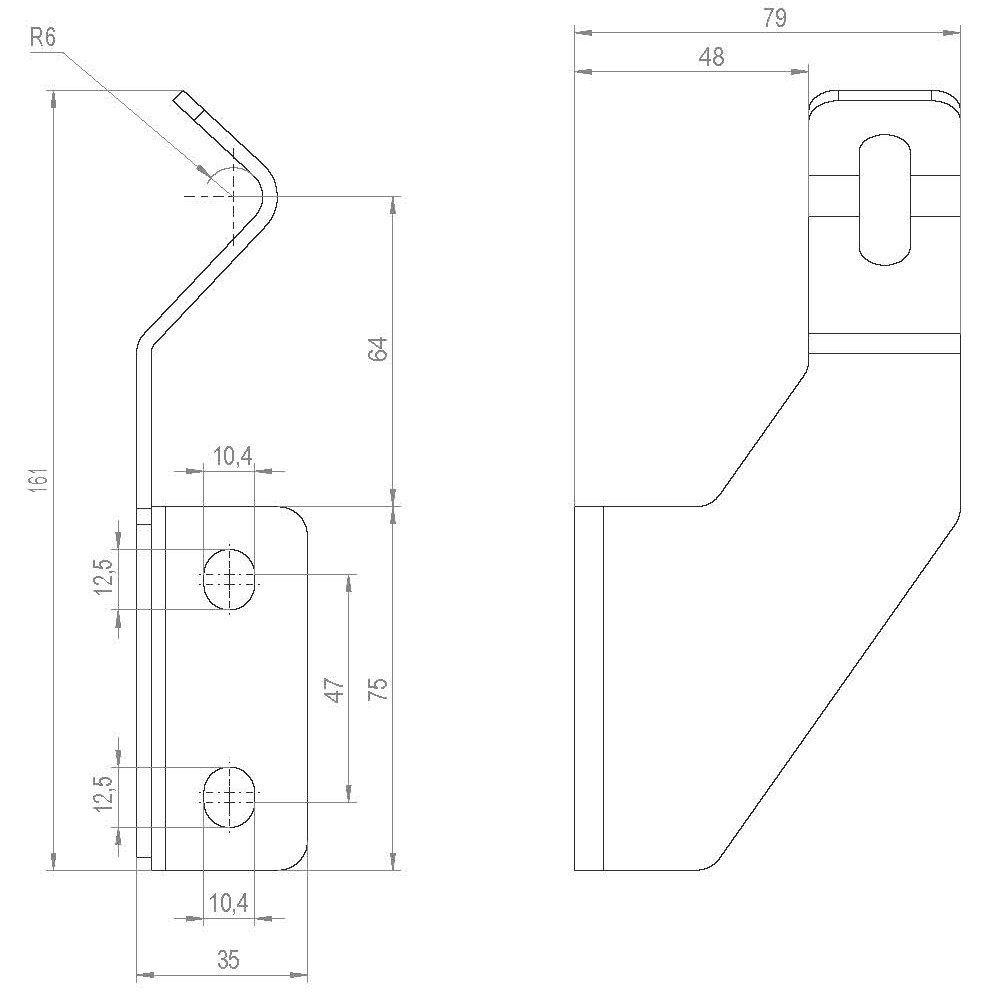

HSG 161 29 Hygienic side guide brackets stainless steel

HSG 161 48 Hygienic side guide brackets stainless steel

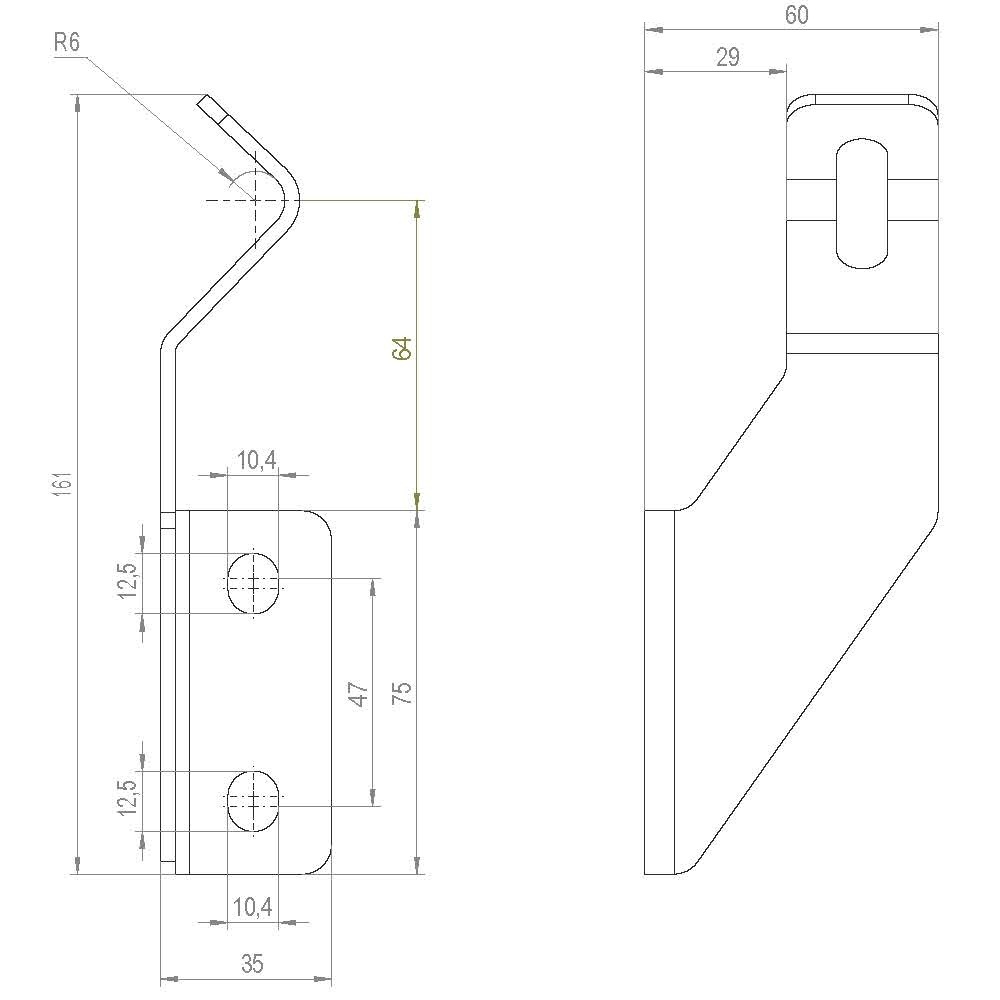

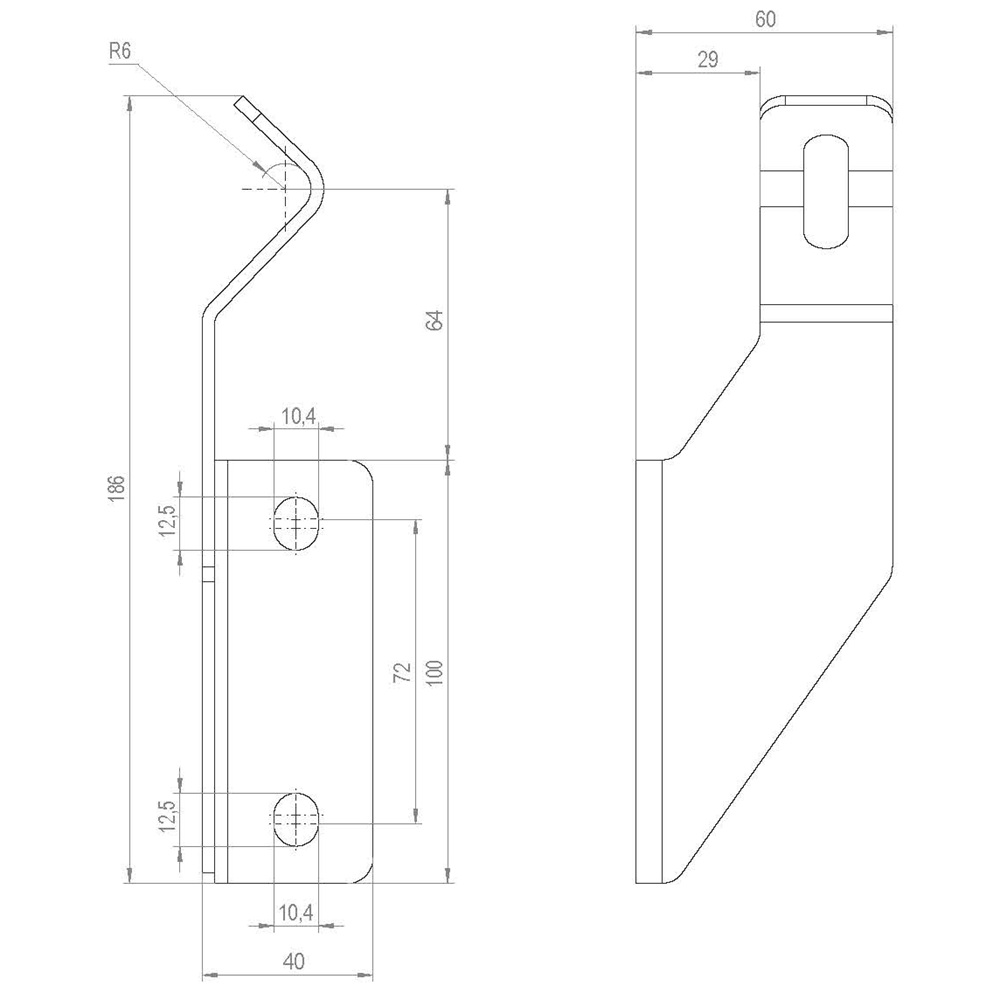

HSG 186 29 Hygienic side guide brackets stainless steel

HSG 186 48 Hygienic side guide brackets stainless steel

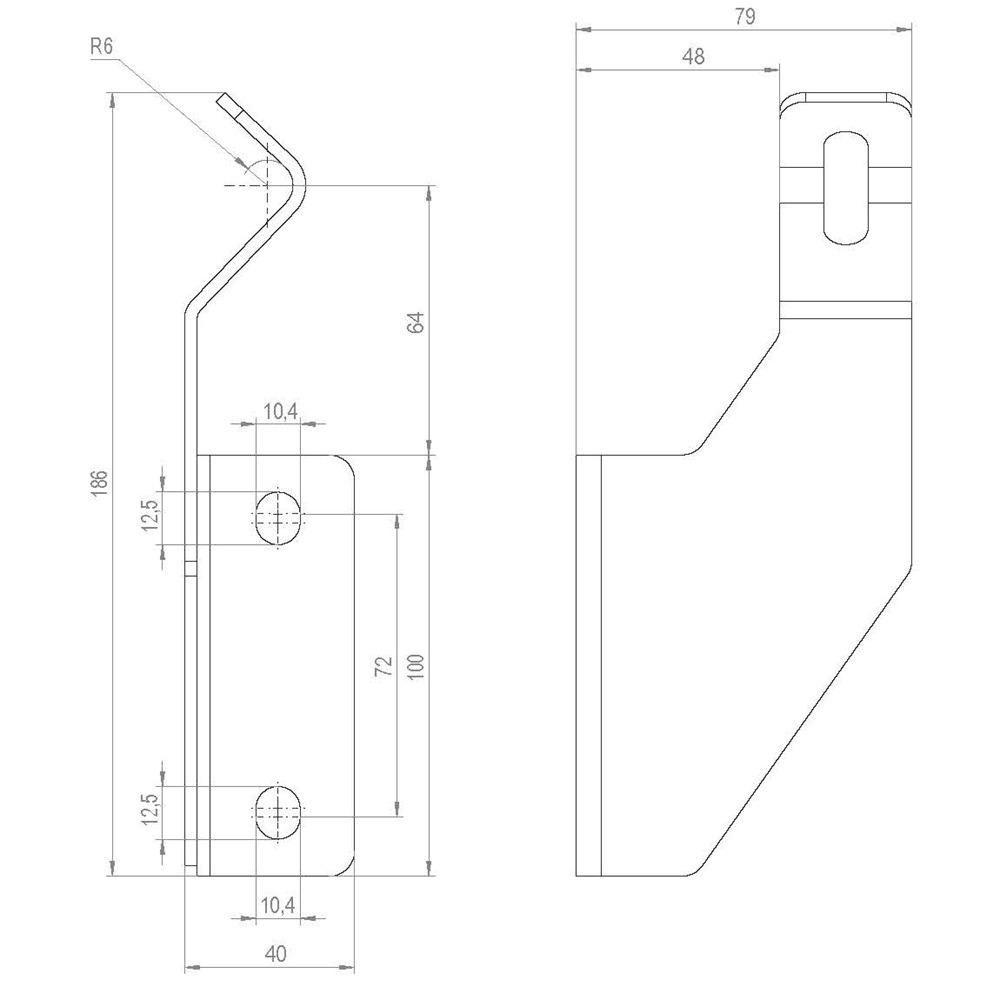

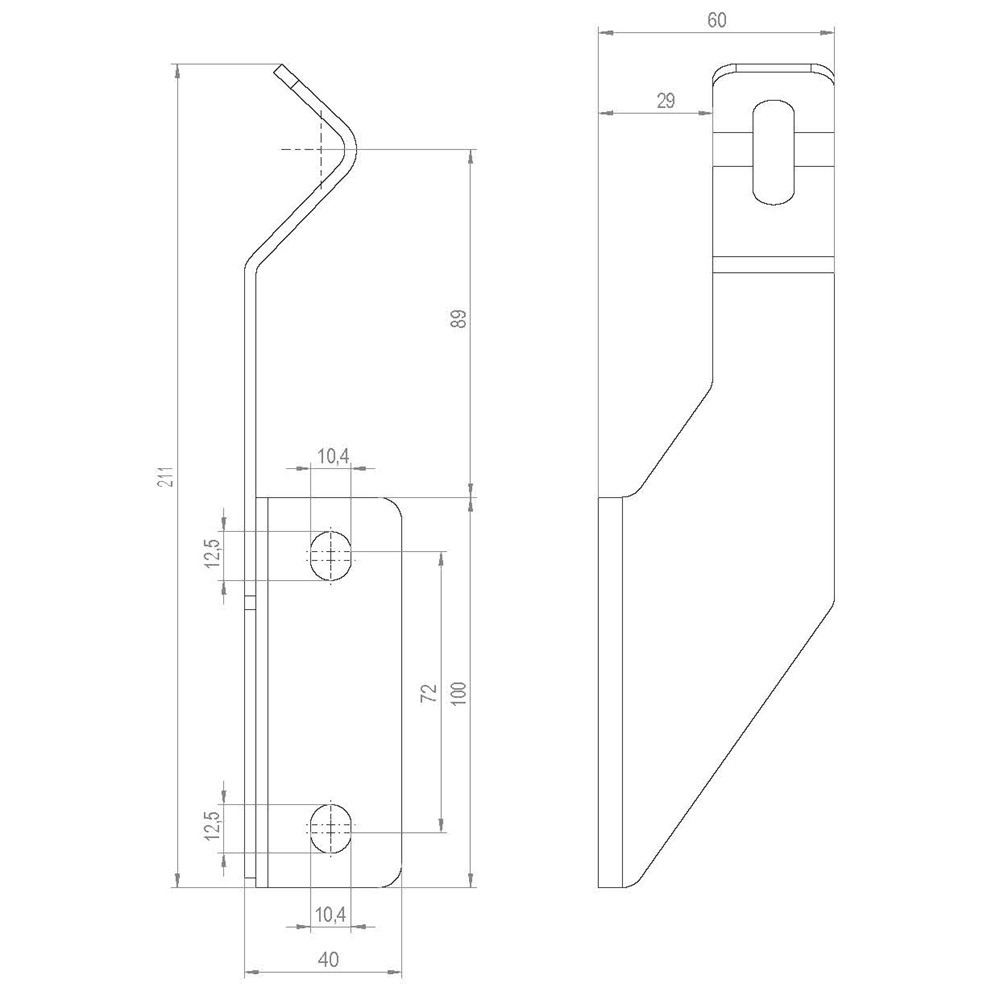

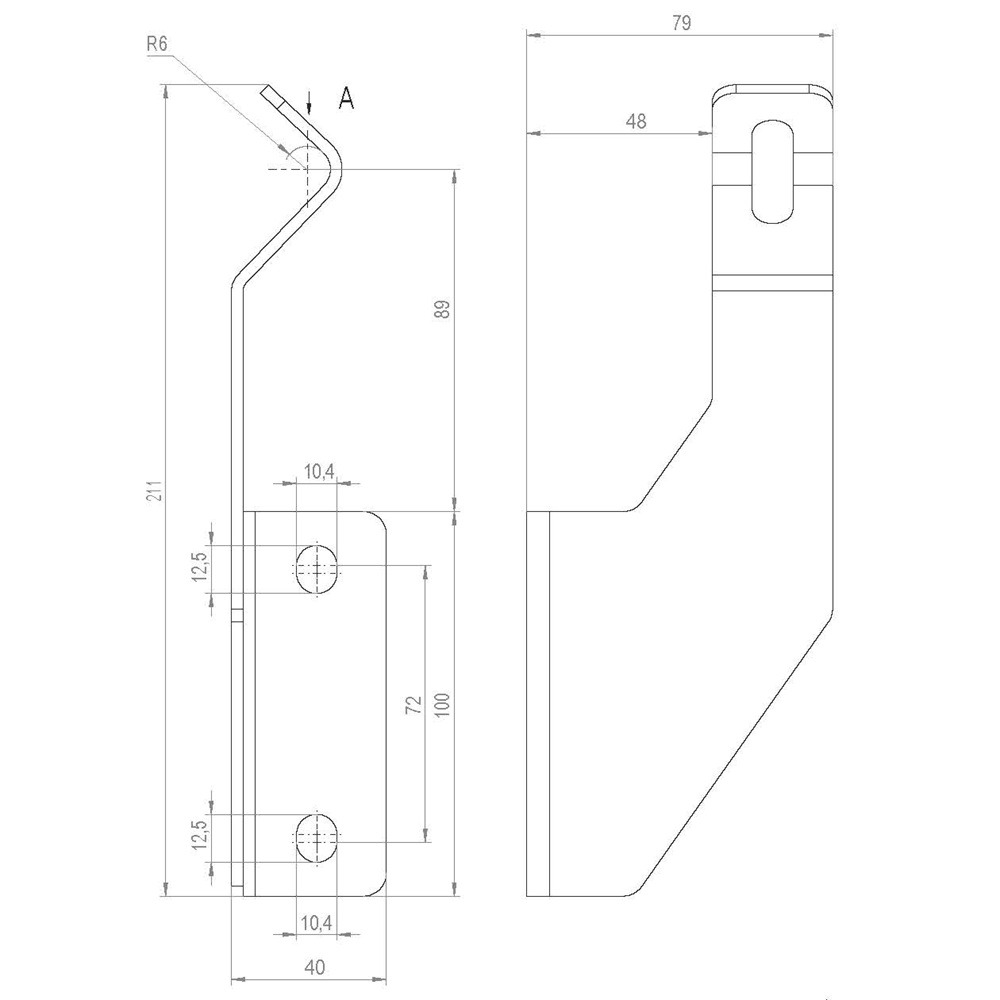

HSG 211 29 Hygienic side guide brackets stainless steel

HSG 211 48 Hygienic side guide brackets stainless steel

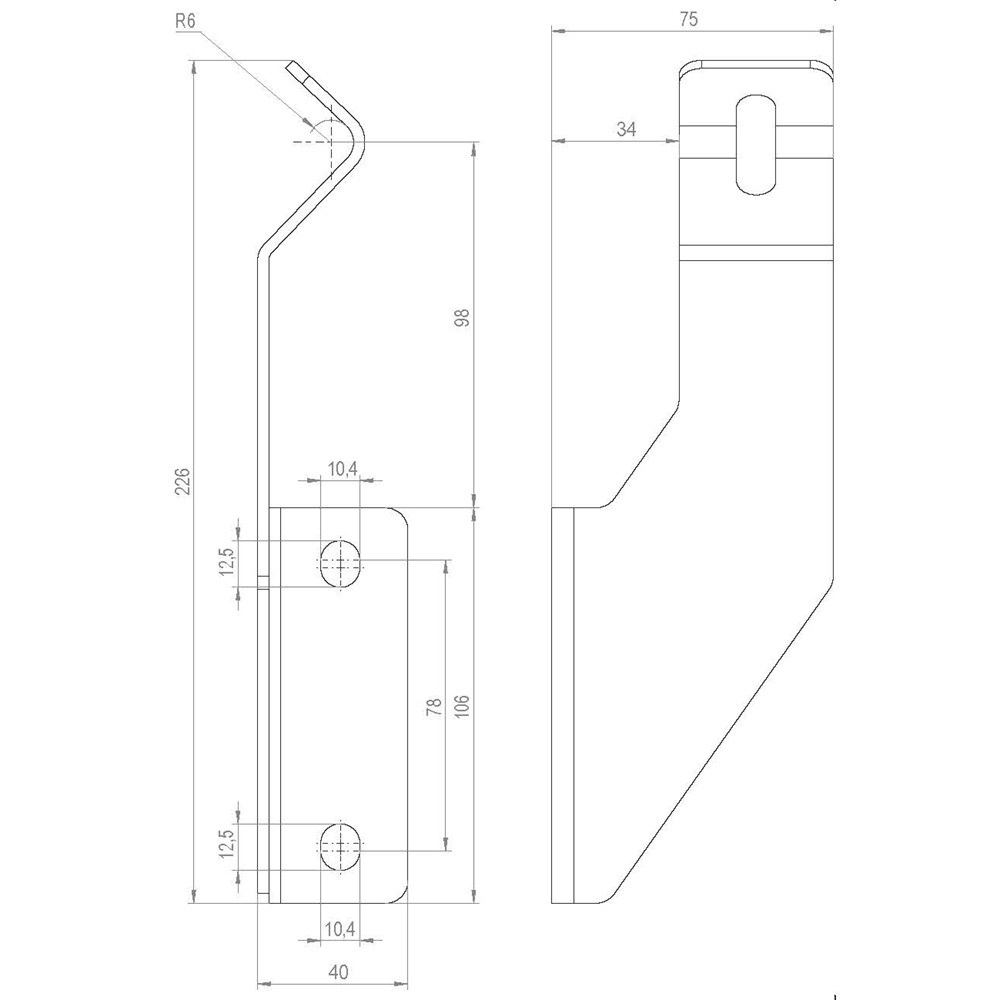

HSG 226 34 Hygienic side guide brackets stainless steel

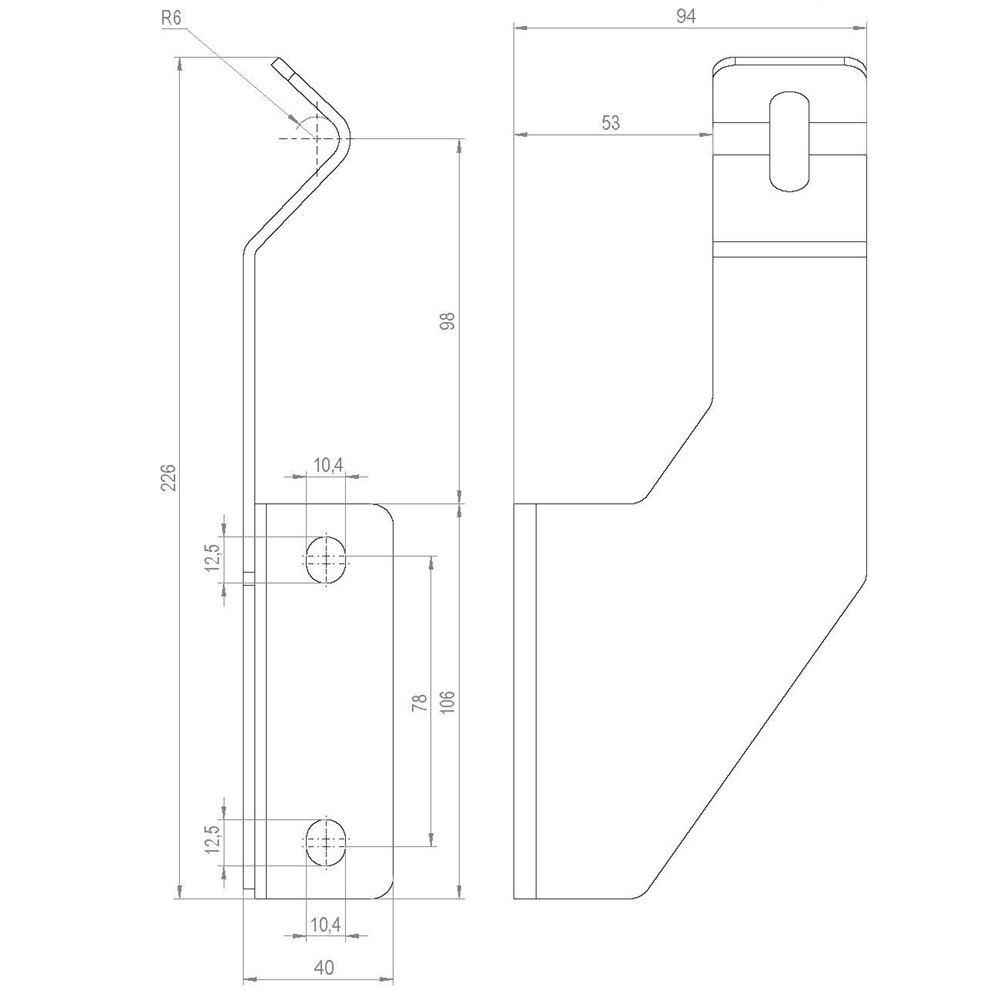

HSG 226 53 Hygienic side guide brackets stainless steel

Why stainless steel side guide brackets matter in hygienic conveyors

Side guides protect product flow, prevent tipping, and keep items centered through conveyors, transfers, and curves. In washdown zones, standard brackets with sharp edges, recesses, or hard-to-clean joints can trap residue and moisture.

Hygienic stainless steel side guide brackets are engineered to solve that by focusing on:

洗浄性: smooth surfaces, minimal crevices, easy access for rinse-down

耐久性: resistance to corrosion, chemicals, and repeated wash cycles

調整機能: quick alignment and secure locking for reliable guiding

Consistency: repeatable set-up reduces waste and line stops

Hygienic design features that improve cleanability

A truly hygienic bracket isn’t just “stainless”—it’s designed to reduce contamination traps.

Look for these bracket design characteristics:

Smooth, crevice-minimized surfaces to limit residue build-up

Open, accessible geometry that supports fast inspection and cleaning

No unnecessary ribs, recesses, or hidden pockets where bacteria can grow

Washdown-friendly construction suited for wet production and aggressive detergents

This is especially important in meat & poultry, dairy, ready meals, seafood, and other applications where hygiene audits and sanitation routines are frequent and strict.

Material choice: AISI 304 vs AISI 316

Most hygienic conveyor side guide brackets are offered in:

AISI 304 (1.4301): excellent general corrosion resistance; widely used in food and packaging

AISI 316 (1.4401 / 1.4404): improved resistance to salts, chlorides, and aggressive cleaning chemicals; preferred in harsh washdown zones

If your line handles brines, salt-heavy products, or strong chemicals, 316 is often the safer long-term choice.

Key benefits for food, pharma, and packaging lines

Faster cleaning and reduced water usage

Hygienic geometry makes it easier to rinse and foam-clean effectively—helping reduce cleaning time, water consumption, and detergent use.

Reliable guiding with less product damage

Stable brackets keep guide rails aligned, minimizing jams, scuffs, and toppled products—especially at higher speeds.

Quicker changeovers

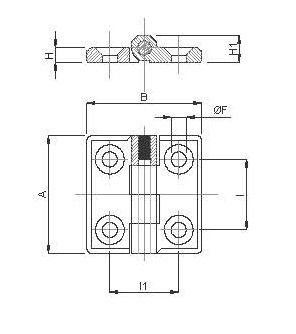

Adjustable systems with ergonomic locking (e.g., star knobs) make it simple to reposition guides for different SKUs, pack sizes, or tray formats.

Longer component lifetime

Stainless steel resists corrosion and wear, which reduces maintenance costs and unplanned replacements.

Common applications for stainless steel side guide brackets

Hygienic conveyor side guide brackets 以下の分野で広く使用されています:

Food processing & packaging: bakery, dairy, meat, poultry, seafood, produce, ready meals

Pharma & biotech: cleanroom-adjacent transport, secondary packaging, inspection lines

Medical & healthcare products: hygienic handling and packing processes

General packaging machinery: case packing, labeling, checkweighing, metal detection lines

How to choose the right side guide bracket

選択する場合 stainless steel side guide brackets for hygienic conveyors, evaluate:

環境: dry, wet, washdown, chemical exposure

材料: AISI 304 vs AISI 316

Adjustment type: fixed vs swivel; manual knob vs tool-based tightening

Mounting interface: tube, profile, conveyor frame, or bracket system

Load and vibration: product weight, conveyor speed, impact points

Cleanability requirements: risk level, sanitation frequency, audit standards

A good rule: choose the bracket that stays rigid in operation but is simple to loosen, clean, and reset during changeover.

Installation and maintenance tips

Align guides under real running conditions (speed + product flow) before final tightening

Use consistent torque/tightening practice to avoid movement over time

Inspect contact points regularly for wear or misalignment

Include brackets in sanitation verification (visual + swab plans where relevant)

Replace worn knobs/seals early to keep locking performance consistent

FAQ: Hygienic side guide brackets

Are stainless steel side guide brackets food-grade?

They are commonly used in food environments, but “food-grade” depends on the full design (cleanability) and material selection (304/316), plus your plant’s hygiene requirements.

Do I need 316 stainless steel?

If your line is exposed to salts, chlorides, or strong chemicals, 316 typically offers better long-term corrosion resistance.

What’s the advantage of swivel side guide brackets?

Swivel brackets help accommodate angles, curves, or variable product shapes while maintaining stable guiding and easier setup.

Call to action

If you’re upgrading your conveyor for washdown reliability, stainless steel hygienic side guide brackets are a simple change that delivers big results: faster cleaning, safer production, and smoother product flow. Choose easy-to-clean designs, select the right stainless grade, and standardize your guide system to reduce downtime and improve hygiene performance.

Get your catalogue here

Side Guide Brackets in Stainless Steel

In hygienic production, even “small” conveyor parts can decide whether a line is easy to clean—or a constant source of contamination risk and downtime. ステンレス製サイドガイドブラケット are a critical component in conveyor guiding systems, keeping products aligned while supporting fast format changes and reliable operation in wet, washdown, and high-hygiene environments.

Hygienic Conveyor Components for Washdown Production Lines

Designed for food processing, pharmaceutical, and packaging applications, hygienic side guide brackets combine corrosion-resistant materials with smooth, easy-to-clean geometry—helping you reduce cleaning time, improve line efficiency, and support compliance with hygienic design principles.

HSG 132 29 Hygienic side guide brackets stainless steel

HSG 132 48 Hygienic side guide brackets stainless steel

HSG 161 29 Hygienic side guide brackets stainless steel

HSG 161 48 Hygienic side guide brackets stainless steel

HSG 186 29 Hygienic side guide brackets stainless steel

HSG 186 48 Hygienic side guide brackets stainless steel

HSG 211 29 Hygienic side guide brackets stainless steel

HSG 211 48 Hygienic side guide brackets stainless steel

HSG 226 34 Hygienic side guide brackets stainless steel

HSG 226 53 Hygienic side guide brackets stainless steel

Why stainless steel side guide brackets matter in hygienic conveyors

Side guides protect product flow, prevent tipping, and keep items centered through conveyors, transfers, and curves. In washdown zones, standard brackets with sharp edges, recesses, or hard-to-clean joints can trap residue and moisture.

Hygienic stainless steel side guide brackets are engineered to solve that by focusing on:

洗浄性: smooth surfaces, minimal crevices, easy access for rinse-down

耐久性: resistance to corrosion, chemicals, and repeated wash cycles

調整機能: quick alignment and secure locking for reliable guiding

Consistency: repeatable set-up reduces waste and line stops

Hygienic design features that improve cleanability

A truly hygienic bracket isn’t just “stainless”—it’s designed to reduce contamination traps.

Look for these bracket design characteristics:

Smooth, crevice-minimized surfaces to limit residue build-up

Open, accessible geometry that supports fast inspection and cleaning

No unnecessary ribs, recesses, or hidden pockets where bacteria can grow

Washdown-friendly construction suited for wet production and aggressive detergents

This is especially important in meat & poultry, dairy, ready meals, seafood, and other applications where hygiene audits and sanitation routines are frequent and strict.

Material choice: AISI 304 vs AISI 316

Most hygienic conveyor side guide brackets are offered in:

AISI 304 (1.4301): excellent general corrosion resistance; widely used in food and packaging

AISI 316 (1.4401 / 1.4404): improved resistance to salts, chlorides, and aggressive cleaning chemicals; preferred in harsh washdown zones

If your line handles brines, salt-heavy products, or strong chemicals, 316 is often the safer long-term choice.

Key benefits for food, pharma, and packaging lines

Faster cleaning and reduced water usage

Hygienic geometry makes it easier to rinse and foam-clean effectively—helping reduce cleaning time, water consumption, and detergent use.

Reliable guiding with less product damage

Stable brackets keep guide rails aligned, minimizing jams, scuffs, and toppled products—especially at higher speeds.

Quicker changeovers

Adjustable systems with ergonomic locking (e.g., star knobs) make it simple to reposition guides for different SKUs, pack sizes, or tray formats.

Longer component lifetime

Stainless steel resists corrosion and wear, which reduces maintenance costs and unplanned replacements.

Common applications for stainless steel side guide brackets

Hygienic conveyor side guide brackets 以下の分野で広く使用されています:

Food processing & packaging: bakery, dairy, meat, poultry, seafood, produce, ready meals

Pharma & biotech: cleanroom-adjacent transport, secondary packaging, inspection lines

Medical & healthcare products: hygienic handling and packing processes

General packaging machinery: case packing, labeling, checkweighing, metal detection lines

How to choose the right side guide bracket

選択する場合 stainless steel side guide brackets for hygienic conveyors, evaluate:

環境: dry, wet, washdown, chemical exposure

材料: AISI 304 vs AISI 316

Adjustment type: fixed vs swivel; manual knob vs tool-based tightening

Mounting interface: tube, profile, conveyor frame, or bracket system

Load and vibration: product weight, conveyor speed, impact points

Cleanability requirements: risk level, sanitation frequency, audit standards

A good rule: choose the bracket that stays rigid in operation but is simple to loosen, clean, and reset during changeover.

Installation and maintenance tips

Align guides under real running conditions (speed + product flow) before final tightening

Use consistent torque/tightening practice to avoid movement over time

Inspect contact points regularly for wear or misalignment

Include brackets in sanitation verification (visual + swab plans where relevant)

Replace worn knobs/seals early to keep locking performance consistent

FAQ: Hygienic side guide brackets

Are stainless steel side guide brackets food-grade?

They are commonly used in food environments, but “food-grade” depends on the full design (cleanability) and material selection (304/316), plus your plant’s hygiene requirements.

Do I need 316 stainless steel?

If your line is exposed to salts, chlorides, or strong chemicals, 316 typically offers better long-term corrosion resistance.

What’s the advantage of swivel side guide brackets?

Swivel brackets help accommodate angles, curves, or variable product shapes while maintaining stable guiding and easier setup.

Call to action

If you’re upgrading your conveyor for washdown reliability, stainless steel hygienic side guide brackets are a simple change that delivers big results: faster cleaning, safer production, and smoother product flow. Choose easy-to-clean designs, select the right stainless grade, and standardize your guide system to reduce downtime and improve hygiene performance.

Get your catalogue here

Side Guide Brackets in Stainless Steel

In hygienic production, even “small” conveyor parts can decide whether a line is easy to clean—or a constant source of contamination risk and downtime. ステンレス製サイドガイドブラケット are a critical component in conveyor guiding systems, keeping products aligned while supporting fast format changes and reliable operation in wet, washdown, and high-hygiene environments.

Hygienic Conveyor Components for Washdown Production Lines

Designed for food processing, pharmaceutical, and packaging applications, hygienic side guide brackets combine corrosion-resistant materials with smooth, easy-to-clean geometry—helping you reduce cleaning time, improve line efficiency, and support compliance with hygienic design principles.

HSG 132 29 Hygienic side guide brackets stainless steel

HSG 132 48 Hygienic side guide brackets stainless steel

HSG 161 29 Hygienic side guide brackets stainless steel

HSG 161 48 Hygienic side guide brackets stainless steel

HSG 186 29 Hygienic side guide brackets stainless steel

HSG 186 48 Hygienic side guide brackets stainless steel

HSG 211 29 Hygienic side guide brackets stainless steel

HSG 211 48 Hygienic side guide brackets stainless steel

HSG 226 34 Hygienic side guide brackets stainless steel

HSG 226 53 Hygienic side guide brackets stainless steel

Why stainless steel side guide brackets matter in hygienic conveyors

Side guides protect product flow, prevent tipping, and keep items centered through conveyors, transfers, and curves. In washdown zones, standard brackets with sharp edges, recesses, or hard-to-clean joints can trap residue and moisture.

Hygienic stainless steel side guide brackets are engineered to solve that by focusing on:

洗浄性: smooth surfaces, minimal crevices, easy access for rinse-down

耐久性: resistance to corrosion, chemicals, and repeated wash cycles

調整機能: quick alignment and secure locking for reliable guiding

Consistency: repeatable set-up reduces waste and line stops

Hygienic design features that improve cleanability

A truly hygienic bracket isn’t just “stainless”—it’s designed to reduce contamination traps.

Look for these bracket design characteristics:

Smooth, crevice-minimized surfaces to limit residue build-up

Open, accessible geometry that supports fast inspection and cleaning

No unnecessary ribs, recesses, or hidden pockets where bacteria can grow

Washdown-friendly construction suited for wet production and aggressive detergents

This is especially important in meat & poultry, dairy, ready meals, seafood, and other applications where hygiene audits and sanitation routines are frequent and strict.

Material choice: AISI 304 vs AISI 316

Most hygienic conveyor side guide brackets are offered in:

AISI 304 (1.4301): excellent general corrosion resistance; widely used in food and packaging

AISI 316 (1.4401 / 1.4404): improved resistance to salts, chlorides, and aggressive cleaning chemicals; preferred in harsh washdown zones

If your line handles brines, salt-heavy products, or strong chemicals, 316 is often the safer long-term choice.

Key benefits for food, pharma, and packaging lines

Faster cleaning and reduced water usage

Hygienic geometry makes it easier to rinse and foam-clean effectively—helping reduce cleaning time, water consumption, and detergent use.

Reliable guiding with less product damage

Stable brackets keep guide rails aligned, minimizing jams, scuffs, and toppled products—especially at higher speeds.

Quicker changeovers

Adjustable systems with ergonomic locking (e.g., star knobs) make it simple to reposition guides for different SKUs, pack sizes, or tray formats.

Longer component lifetime

Stainless steel resists corrosion and wear, which reduces maintenance costs and unplanned replacements.

Common applications for stainless steel side guide brackets

Hygienic conveyor side guide brackets 以下の分野で広く使用されています:

Food processing & packaging: bakery, dairy, meat, poultry, seafood, produce, ready meals

Pharma & biotech: cleanroom-adjacent transport, secondary packaging, inspection lines

Medical & healthcare products: hygienic handling and packing processes

General packaging machinery: case packing, labeling, checkweighing, metal detection lines

How to choose the right side guide bracket

選択する場合 stainless steel side guide brackets for hygienic conveyors, evaluate:

環境: dry, wet, washdown, chemical exposure

材料: AISI 304 vs AISI 316

Adjustment type: fixed vs swivel; manual knob vs tool-based tightening

Mounting interface: tube, profile, conveyor frame, or bracket system

Load and vibration: product weight, conveyor speed, impact points

Cleanability requirements: risk level, sanitation frequency, audit standards

A good rule: choose the bracket that stays rigid in operation but is simple to loosen, clean, and reset during changeover.

Installation and maintenance tips

Align guides under real running conditions (speed + product flow) before final tightening

Use consistent torque/tightening practice to avoid movement over time

Inspect contact points regularly for wear or misalignment

Include brackets in sanitation verification (visual + swab plans where relevant)

Replace worn knobs/seals early to keep locking performance consistent

FAQ: Hygienic side guide brackets

Are stainless steel side guide brackets food-grade?

They are commonly used in food environments, but “food-grade” depends on the full design (cleanability) and material selection (304/316), plus your plant’s hygiene requirements.

Do I need 316 stainless steel?

If your line is exposed to salts, chlorides, or strong chemicals, 316 typically offers better long-term corrosion resistance.

What’s the advantage of swivel side guide brackets?

Swivel brackets help accommodate angles, curves, or variable product shapes while maintaining stable guiding and easier setup.

Call to action

If you’re upgrading your conveyor for washdown reliability, stainless steel hygienic side guide brackets are a simple change that delivers big results: faster cleaning, safer production, and smoother product flow. Choose easy-to-clean designs, select the right stainless grade, and standardize your guide system to reduce downtime and improve hygiene performance.