ミニステンレススチールデザインの楕円フランジベアリング

精度が最も重要な製造および加工の分野では、 NHK機械部品 卓越性の光として現れます。当社は、食品および医薬品の細心の注意を払った製造および加工向けに設計されたコンポーネントや部品の製造を専門としています。私たちの旅は、持続可能な開発と成長、細部への揺るぎない取り組み、持続可能で責任ある生産慣行の構築への献身によって定義されます。 で NHK機械部品, sustainability is more than a message—it’s a design principle. We believe the most effective way to reduce environmental impact is to produce long-lasting 機械部品 that perform reliably in harsh industrial environments. That’s why our focus begins with: Durability in demanding conditions (cleaning chemicals, moisture, temperature changes, frequent washdown) Long service life, reducing replacement frequency and waste 100% recyclable material choices, supporting circular manufacturing When a component lasts longer, you buy less, replace less, and dispose of less. That is sustainability in practice. As a global supplier of 衛生的な機械部品, NHK Machinery Parts delivers a broad portfolio for manufacturers operating in regulated or high-performance environments—especially food processing, packaging, pharmaceutical, and biotech. Our range includes: フランジベアリングユニット for stable shaft support and smooth rotation In this article, we highlight the engineering value of flange bearings—often overlooked, yet critical to reliable motion and long-term uptime. フランジベアリング are essential mounted bearing solutions that support rotating shafts while providing stable, accurate alignment on a machine frame or side plate. They are widely used in applications where consistent motion and dependable load handling are non-negotiable. Conveyors and side-mounted shafts Packaging machinery and automation systems Food processing equipment in wet or washdown zones Manufacturing lines requiring stable rotation and low downtime In short: flange bearings keep production moving smoothly—quietly, efficiently, and consistently. In hygienic and industrial environments, bearing performance is only as good as the materials, sealing, and manufacturing behind it. NHK Machinery Parts designs flange bearing solutions to meet high expectations for both 精度 そして reliability. Our quality approach includes: Carefully selected materials suitable for harsh environments Manufacturing consistency for repeatable performance Options tailored for corrosion resistance and long service life Product choices that support hygiene-focused production standards The result: dependable bearing performance that helps protect equipment uptime and product safety. No two machines are identical—so flange bearings shouldn’t be “one-size-fits-all.” NHK Machinery Parts offers multiple configurations and sizes to match your load, shaft size, mounting layout, and environmental conditions. Whether you need: Stainless steel flange bearings for corrosion-prone areas Compact units for space-limited installations Heavy-duty options for industrial load demands …we help you select the right flange bearing unit for stable rotation and long-term performance. Sustainability is engineered into our flange bearings the same way it is into our full product range: by prioritizing longevity, reliability, and recyclability. Longer lifetime reduces replacement cycles Fewer replacements mean less waste and fewer deliveries Durable performance protects equipment efficiency over time Choosing an NHK Machinery Parts flange bearing is not just a technical decision—it’s a step toward more responsible manufacturing. For compact machinery and space-constrained designs, mini two-bolt flange bearing units in stainless steel offer a smart combination of: Compact footprint Stable mounting Cleanable stainless construction Reliable support for smaller shafts and precise movement These units are ideal for applications where hygienic design and tight installation space must work together. NHK Machinery Parts supplies a complete portfolio of hygienic stainless steel machinery components built for demanding 産業: Designed for stability and cleanability. EHEDG コンプライアンス supports hygienic design requirements in regulated industries. Engineered for smooth transfer and easier cleaning in food and pharmaceutical conveyor systems. Mobility-focused castors made for hygienic environments where cleaning access and corrosion resistance matter. Reliable protection for bearing assemblies in wet areas—supporting long service life and reduced downtime. Precision-mounted bearing solutions for stable rotation and dependable performance. Suitable for applications requiring dust and splash protection across many industrial environments. Compact, efficient bearing solutions for space-saving machine design. Supports controlled product flow while maintaining cleanability on conveyor systems. Built to meet strict hygiene expectations for safe and efficient product movement. Reliable power transmission designed for demanding conditions and hygiene-focused production. A compact, hygienic flange bearing option for applications needing small footprint, stable mounting, and corrosion resistance. 業界では precision engineering, 衛生的なデザイン、 そして 耐久性 are mission-critical, NHK Machinery Parts is your trusted partner. From stainless steel flange bearings に EHEDG 水平調整脚 そして IP67 ベアリングユニット, our components are engineered to help you build cleaner, more reliable, and more sustainable production equipment. Explore our product range and contact NHK Machinery Parts to find the right solution—where precision engineering meets long-lasting performance.精密加工と耐久性の融合 NHKマシナリーパーツのフランジベアリングの世界

Hygienic Components & Machinery Parts | NHK Group

Sustainability That Starts With Product Lifetime

Precision Redefined: Hygienic Components for Modern Industry

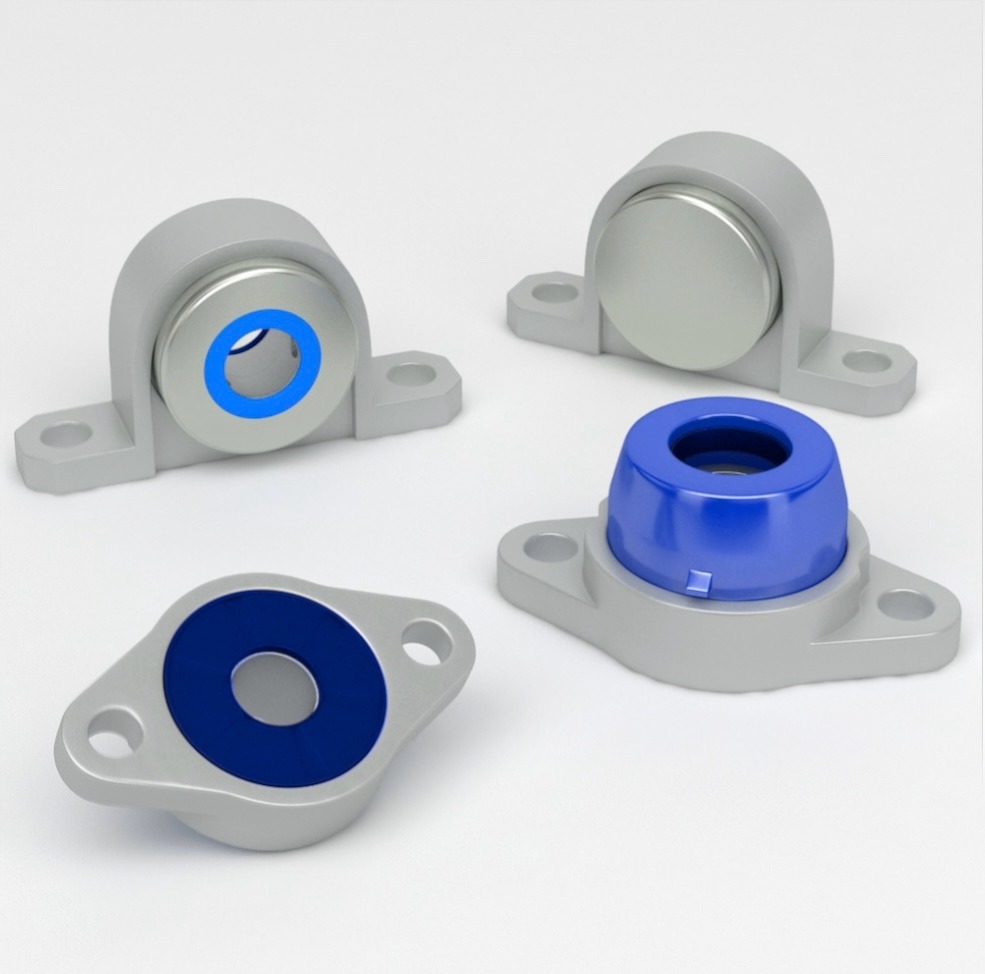

Flange Bearings: The Epitome of Precision and Stability

Where flange bearing units are used

期待を超える品質

Customized Flange Bearing Solutions for Your Application

Sustainability at the Core of Every Bearing Unit

How durable flange bearings support sustainability

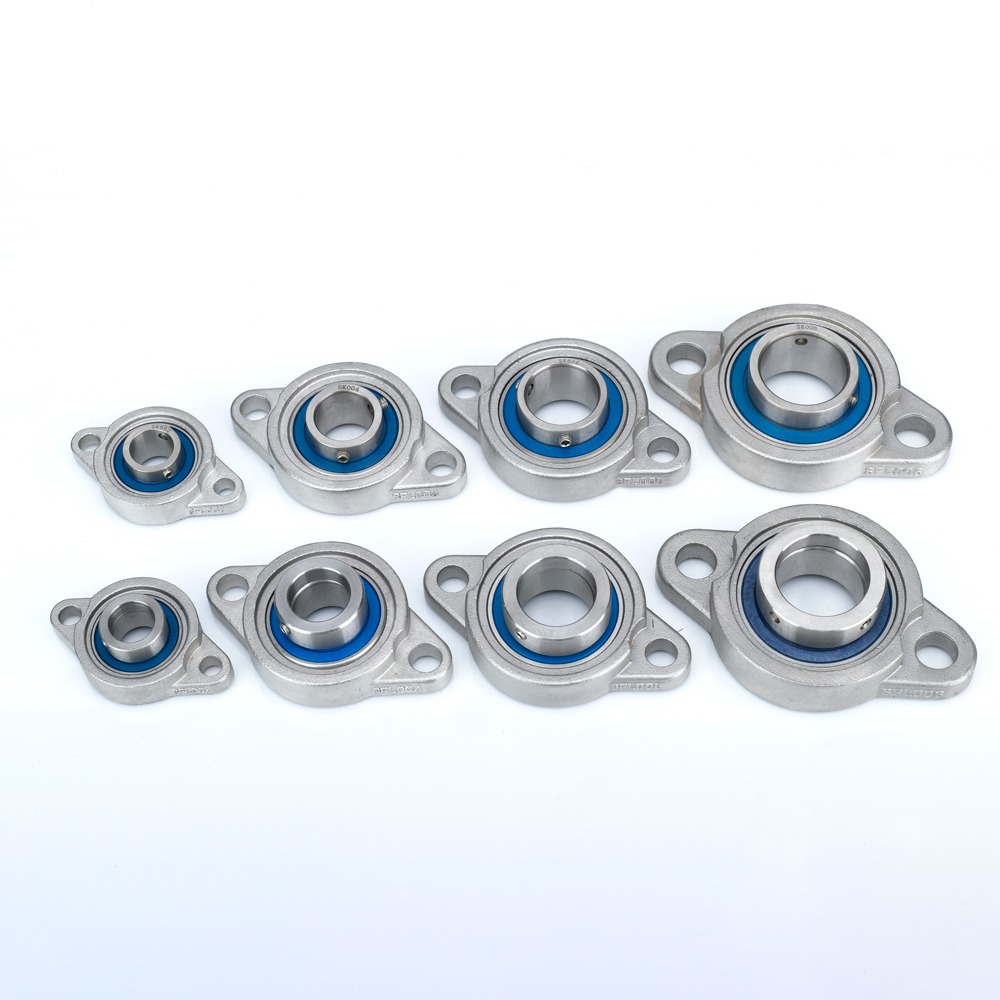

Mini Two-Bolt Flange Units in Stainless Steel

Explore Our Comprehensive Hygienic Product Range

EHEDG Stainless Steel Machine Levelling Feet

Hygienic 3-A Conveyor Parts in Stainless Steel

衛生的なデザインの工業用キャスター

Waterproof IP67 Bearing House Units

Ball Bearing Units in Stainless Steel

Bearing Units in IP54 Thermoplastic Housing

ステンレス製ミニベアリングユニット

Side Guides in Hygienic Stainless Steel Design

ステンレススチール製の衛生的なコンベア部品

Gear and Drum Motors in Hygienic Stainless Steel Design

ミニステンレススチール設計の2ボルト楕円フランジベアリング

NHK Machinery Parts: Precision, Durability, and Sustainable Performance

産業機械部品と保護基準

食品加工産業と包装機械は、国際的な保護、耐久性、衛生基準を満たす精密に製造された部品を必要とします。IP分類は、湿気、腐食、または高圧洗浄環境での部品の適性を決定するための基礎です絶対。IP67は粉塵に対する完全な保護と水への一時的な浸漬に対する保護を提供し、IP68とIP69Kは、特に産業洗浄環境用に設計されたさらに高い保護レベルを提供します。ステンレス鋼材料の選択は、衛生的な機械の製造に重要です極めて。ステンレス鋼440および420は、特定の用途に適応した異なる特性を示します明らかに。ステンレス鋼440は優れた硬度を提供し、切削工具に理想的です完全に。ステンレス鋼420はより良い耐食性を提供します優位に。精密ベアリングは機械のパフォーマンスに不可欠です絶対。高品質な部品への投資は長期的な効率を確保します着実に。国際標準は現代産業の増加する要件に対応するために進化し続けています継続的に。技術革新は業界の改善を推進します。信頼性は産業的成功の鍵です。企業は高品質部品への投資から恩恵を受けます。