Roulement à bride à deux boulons

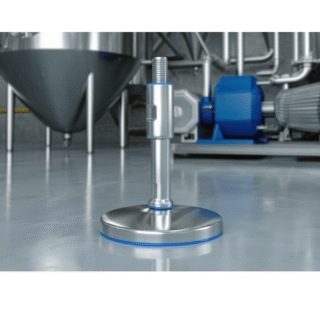

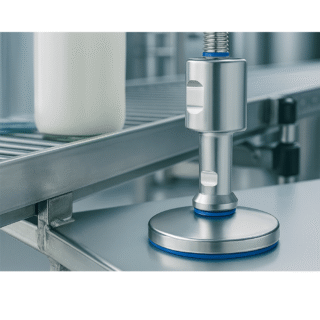

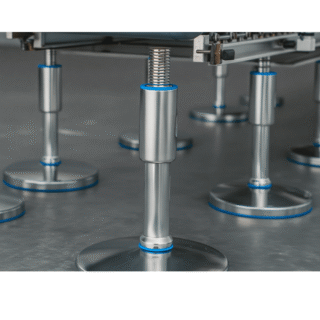

Discover what a two-bolt flange bearing is, where it’s used, how to choose the right unit, and best practices for installation, sealing, and maintenance. Palier à bride ovale à 2 trous étanche IP67 | Palier à roulement hygiénique certifié UN two-bolt flange bearing (often called a 2-bolt flange bearing unit ou 2-bolt flanged bearing) is a mounted bearing assembly designed to support a rotating shaft while being bolted to a flat surface. The “two-bolt flange” refers to the mounting flange with two bolt holes, allowing quick, secure alignment on machine frames, side plates, conveyor structures, guards, and panels. Most two-bolt flange bearing units consist of: UN housing (flange body) with two mounting holes UN bearing insert (typically a ball bearing) UN locking method to fix the insert to the shaft (set screw, eccentric collar, or clamp style) Optional seals and covers to protect against contamination and washdown This design is popular because it offers a strong, compact mounting method while simplifying maintenance and replacement. Bride ovale à 2 trous SFL en acier inoxydable avec couvercle | Pièces de machines NHK Two-bolt flange units are widely chosen because they combine mechanical stability avec simple mounting: The two-bolt pattern makes installation straightforward on flat plates and machine sidewalls. It’s also easy to reposition during line modifications. Two-bolt flange units handle typical radial loads seen in conveyors, packaging machines, processing equipment, and rotating assemblies. When maintenance is required, many units allow the insert to be changed without redesigning the machine. From light dust protection to aggressive washdown, sealing levels can be matched to the environment. Roulement à billes FLPL à bride ovale à 2 boulons | Précision et durabilité | Pièces de machines NHK Two-bolt flange bearings are used wherever a shaft needs stable support on a vertical or angled surface, including: Convoyeurs (belt, modular, roller, and hygienic conveyors) Machines d'emballage (cartoners, case packers, flow wrappers) Équipement de transformation des aliments (washdown zones, wet areas, splashing zones) Beverage lines (filling, rinsing, capping, labeling systems) Pharmaceutical and biotech equipment (cleanable assemblies, controlled environments) Material handling and automation (guides, rollers, actuators, transfer systems) Palier à bride ovale à 2 trous SFL en acier inoxydable | Pièces de machines NHK Choosing the right housing material is critical for reliability and compliance. Ideal for hygienic and corrosion-prone environments: Washdown and chemical exposure Food, beverage, dairy, meat, seafood, ready-meals Pharmaceutical and biotech production Common in general industrial environments: Dry areas, moderate loads Lower cost, strong mechanical stiffness Often used where corrosion resistance and weight reduction matter: Wet environments Good chemical resistance (depends on polymer) Useful in many washdown applications, especially when paired with sealed inserts The insert is the heart of the unit. Best where corrosion resistance is required. Common in hygienic processing and outdoor systems. Used in dry, controlled environments. Typically lower cost, widely available. Contact seals help block water spray and fine contamination Non-contact seals reduce friction and heat but offer less protection Multi-lip seal systems provide stronger protection in wet/washdown zones If your equipment is exposed to frequent cleaning or splashing, prioritize high-quality sealing and a housing designed to reduce crevices. Two-bolt flange bearing inserts typically lock to the shaft in one of these ways: Simple and widely used Best for moderate loads and standard speeds Shaft surface quality matters for holding strength Stronger locking for vibration and reversing loads Common in conveyors and general machinery Even clamping around the shaft Good concentricity and often better for higher speeds and precision applications Popular where vibration, alignment accuracy, or hygienic cleaning routines demand reliability Use this selection checklist: Dry production area vs splash zone vs full washdown Chemicals used (alkaline/acid foams, sanitizers) Temperature range and thermal cycling Radial load (common) and any axial load present Shock loads from starts/stops or product impacts Shaft speed and duty cycle Correct bore diameter Shaft tolerance and surface finish Keyway presence (if used) If your goal is high resistance to water and contamination, choose: Robust seal system Housing design that avoids “dirt shelves” and crevices Corrosion-resistant materials Greaseable vs maintenance-free (sealed-for-life) Re-lubrication intervals and access points Replace insert only vs replace complete unit Correct installation prevents premature wear and failures. Misalignment is a top cause of bearing problems. Ensure the flange sits flat and the shaft rotates freely before final tightening. Over-tightening can distort housings or mounting plates. Under-tightening can cause movement and vibration. Follow manufacturer torque guidance for mounting bolts and locking mechanism. Set screw and collar systems must be correctly positioned. Clamp styles should be evenly tightened to specification. Keep the insert and sealing surfaces clean. In hygienic environments, use clean tools and prevent residue build-up around the housing. Increased noise or vibration Rising operating temperature Shaft play or visible misalignment Grease leakage or water ingress signs Corrosion staining on housing or insert Inspect seals and covers regularly Confirm mounting bolts remain secure Use the correct grease type (if greaseable) and avoid over-greasing Review washdown direction and spray pressure—direct high-pressure spray at seals can shorten life even on sealed units In hygiene-critical production, selection is not just about load—it’s about cleanability and risk reduction. Look for designs that support: Smooth surfaces and minimal crevices Crevice-minimized seal geometry Corrosion-resistant materials suitable for your cleaning regime Optional protective end caps (where appropriate) Documented material suitability and traceability when required A two-bolt flange unit that survives washdown but traps residue is not truly hygienic—aim for both durability and cleanability. Mini unités à bride à deux boulons en acier inoxydable SUFL | Pièces détachées pour machines NHK Mini unités à bride à deux boulons en acier inoxydable SKFL | Pièces détachées pour machines NHK UN two-bolt flange is usually more compact and easier to mount on narrow frames. A four-bolt flange can offer more mounting stability for heavier loads or larger shafts. Yes—if you select appropriate materials (often stainless or composite) and robust sealing designed for wet environments. Many bearing inserts allow a degree of self-alignment within the housing. This helps compensate for minor mounting inaccuracies, but it’s not a substitute for good installation and alignment.Two-Bolt Flange Bearing Units

A Comprehensive SEO Guide to Selection, Installation, and Hygienic Performance

What Is a Two-Bolt Flange Bearing?

Why Two-Bolt Flange Bearings Are Used So Often

Fast mounting and repeatable alignment

Good radial load support

Service-friendly design

Flexible sealing options

Common Applications for Two-Bolt Flanged Bearing Units

Two-Bolt Flange Housing Materials and Why They Matter

Stainless steel housings

Cast iron housings

Not recommended for harsh washdown unless properly protected and compatible with cleaning chemicals.Composite (polymer) housings

Bearing Insert Options: Stainless vs Standard, Sealed vs Open

Stainless steel bearing inserts

Standard steel inserts

Sealing levels

Locking Methods: Set Screw, Eccentric Collar, or Clamp

Set screw locking

Eccentric collar locking

Clamp (concentric) locking

How to Choose the Right Two-Bolt Flange Bearing Unit

1) Environment and cleaning method

2) Load and speed requirements

3) Shaft size and fit

4) Sealing and ingress protection expectations

5) Maintenance strategy

Installation Best Practices for Long Bearing Life

Align before tightening

Use correct bolt torque

Confirm shaft locking method is properly engaged

Avoid contamination during assembly

Maintenance and Troubleshooting Tips

Signs your two-bolt flange bearing needs attention

Good routine practices

Hygienic Design Considerations (Food, Beverage, Pharma)

FAQ: Two-Bolt Flange Bearings

What’s the difference between a two-bolt and four-bolt flange bearing?

Can two-bolt flange bearings be used in washdown areas?

Are two-bolt flange bearings self-aligning?

Questions et contact

Consultez nos autres articles :

Contact

Des articles

Le véritable coût des temps d’arrêt : les composants de votre machine d’emballage sont-ils une bombe à retardement ?

Équipements de traitement des liquides : sources de contamination cachées dans les composants des machines

La menace corrosive invisible dans la conservation des aliments : les composants de votre machine tombent-ils en panne silencieusement ?

Le risque caché de contamination dans votre boulangerie : les composants de votre machine sabotent-ils vos normes d’hygiène ?

La menace invisible dans votre laiterie : les composants de votre machine compromettent-ils la sécurité alimentaire ?

Le tueur silencieux de l’efficacité des convoyeurs : vos composants créent-ils des goulots d’étranglement ?

Le risque invisible dans la transformation de la viande : les composants de votre machine sont-ils un maillon faible ?

Le goulot d’étranglement invisible dans votre chaîne d’embouteillage : vos composants vous freinent-ils ?

Composants de Machines Industrielles et Normes de Protection

Les équipements de transformation alimentaire et les machines d'emballage exigent des composants précis qui répondent aux normes internationales de protection et de sécurité strictes. La compréhension des indices de protection IP est fondamentale pour les ingénieurs sélectionnant des pièces pour des environnements humides ou corrosifs exigeants. L'indice IP67 offre une protection complète contre la poussière et l'immersion temporaire dans l'eau, tandis que la IP69K Standard représente le plus haut niveau de protection disponible, conçu spécifiquement pour les environnements de nettoyage haute pression intensifs. L'acier inoxydable joue un rôle critique et fondamental dans la fabrication de machines hygiéniques modernes. Les compositions d'alliage comme le 420 et le 440 inoxydable ont des propriétés distinctes admirablement adaptées à différentes applications industrielles. Le 420 inoxydable offre une meilleure résistance à la corrosion et convient particulièrement aux équipements de transformation alimentaire. Le 440 inoxydable fournit une dureté supérieure et une rétention de tranchant exceptionnelle pour les outils de coupe. Les roulements de précision sont essentiels et absolument indispensables pour assurer la performance optimale des machines complexes. La sélection appropriée des matériaux garantit une durée de vie prolongée et une maintenance réduite significativement. Les standards internationaux continuent d'évoluer progressivement pour répondre aux exigences croissantes des industries modernes. Les innovations technologiques permettent de mieux comprendre et optimiser les performances des composants. La fiabilité des équipements dépend entièrement de la qualité des composants utilisés. Les fabricants leaders investissent massivement dans la recherche et le développement de nouveaux matériaux et techniques avancées.