Contáctenos

necesitas más información? Ponerse en contacto hoy. Le ayudaremos a encontrar el tipo de máquina y pie nivelador adecuados para sus necesidades.

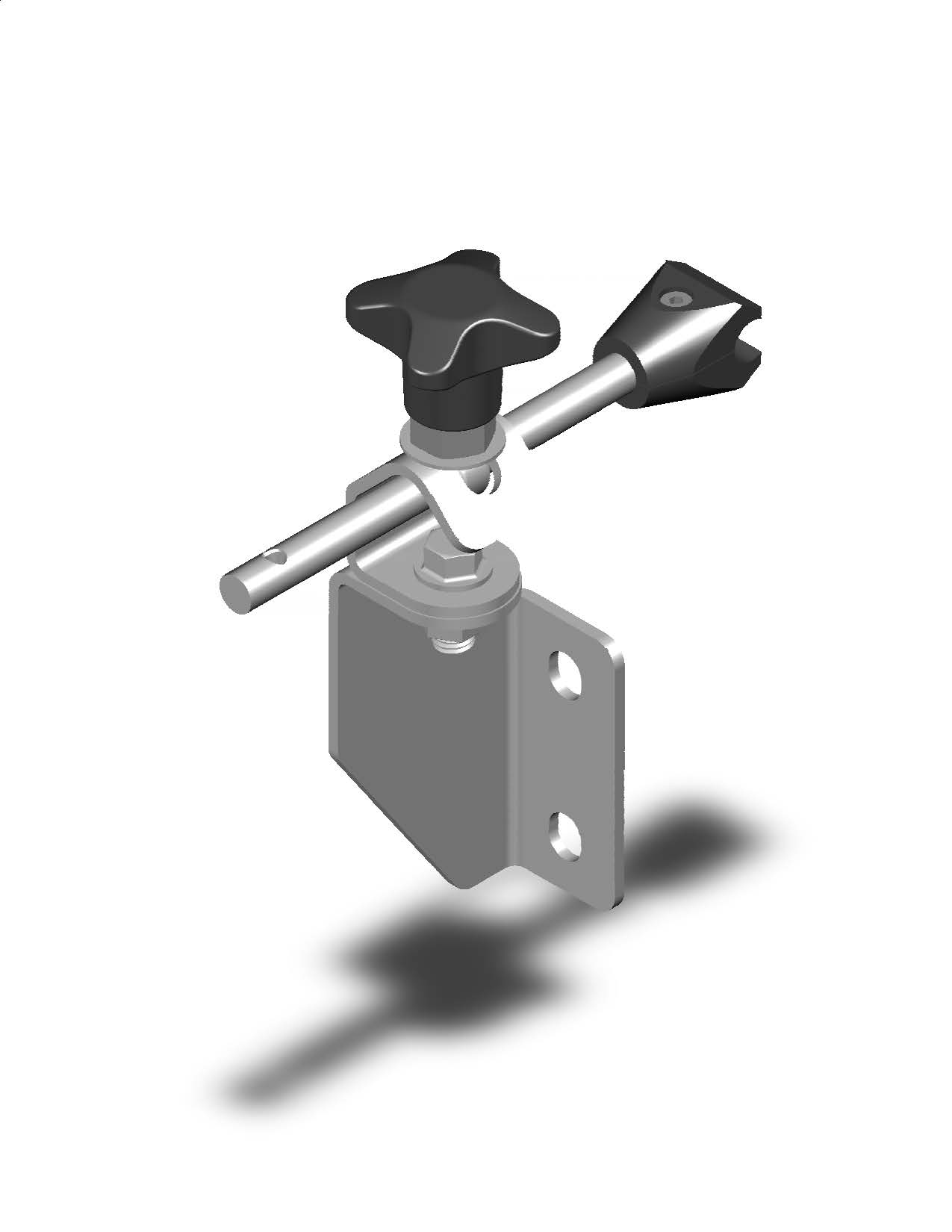

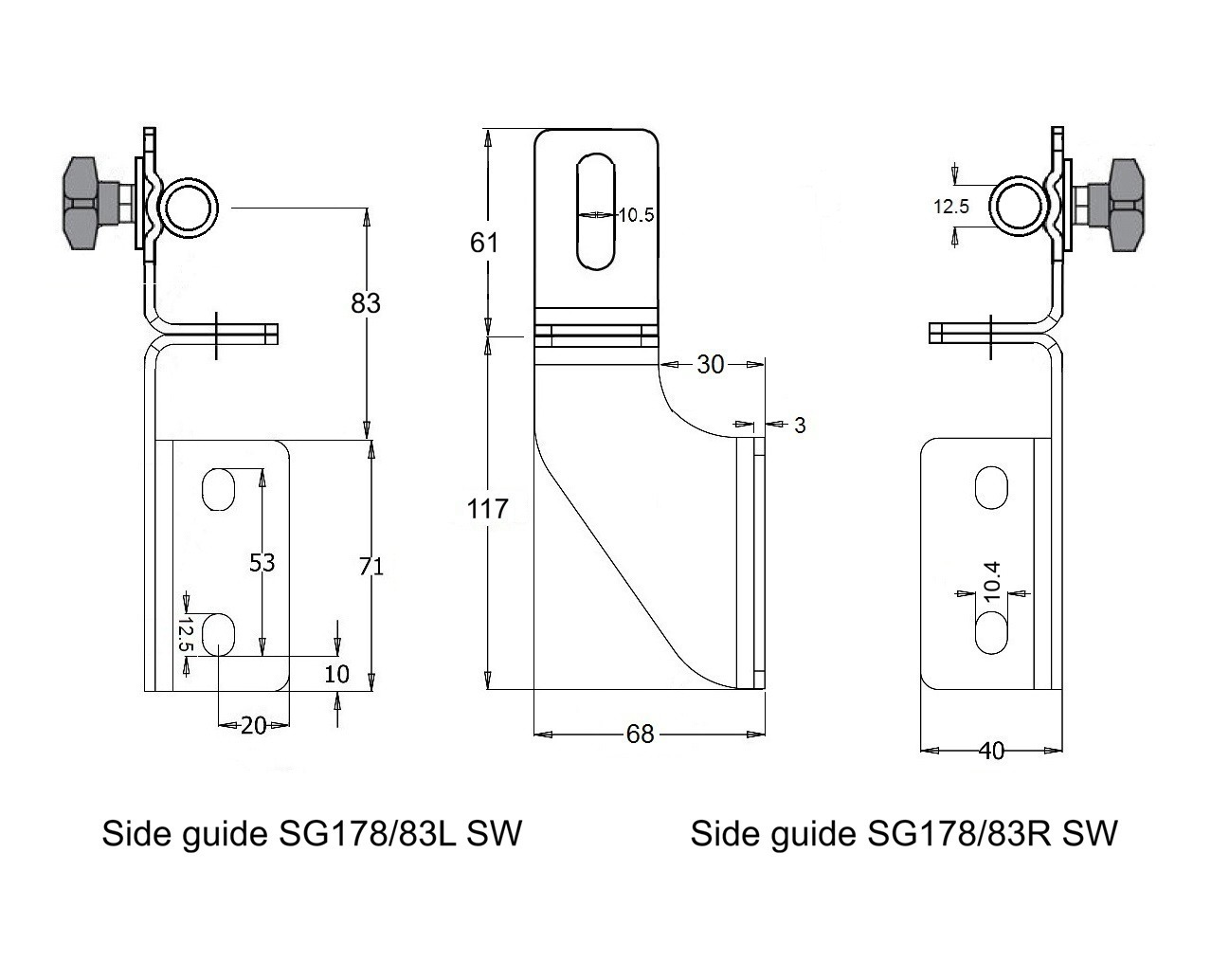

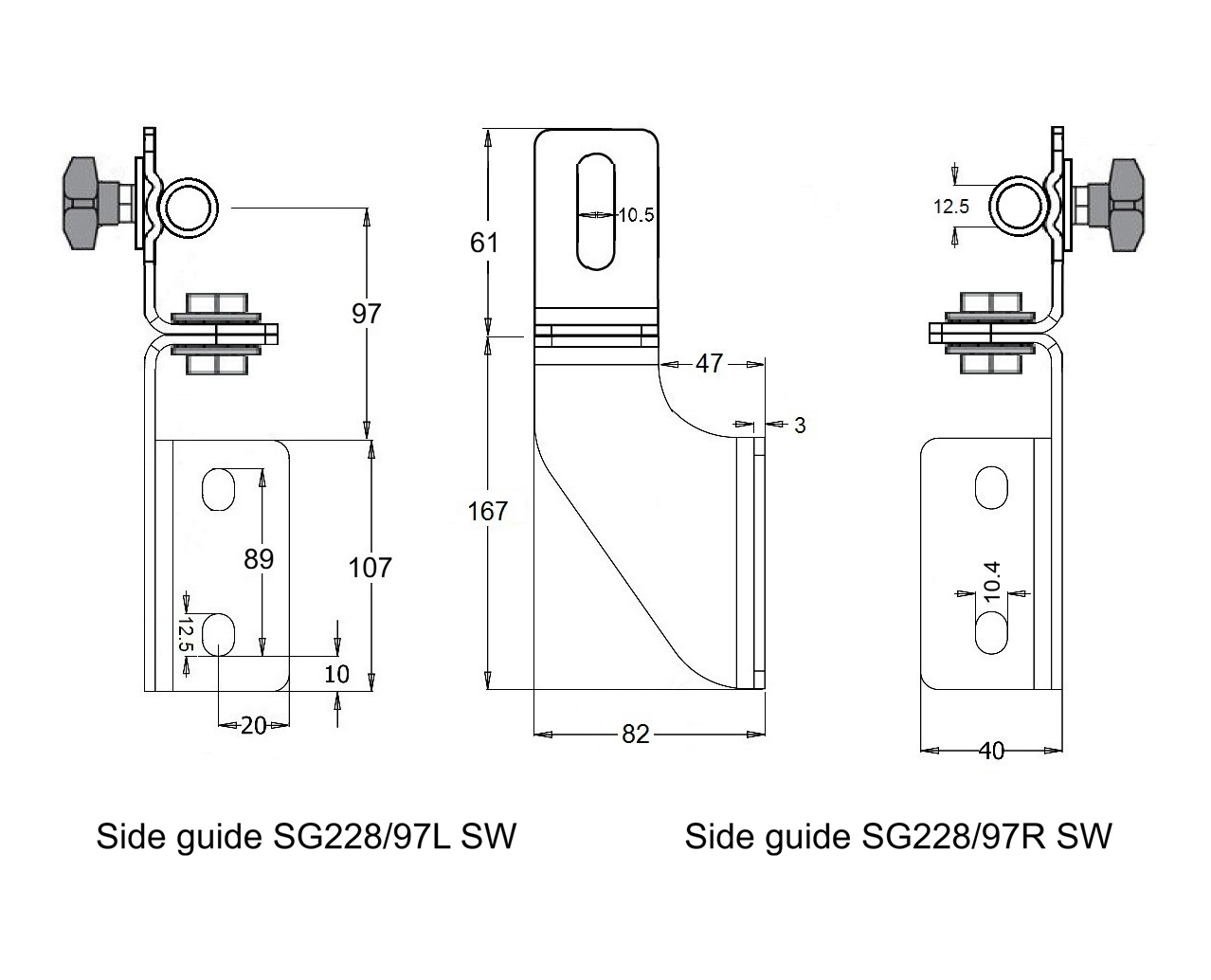

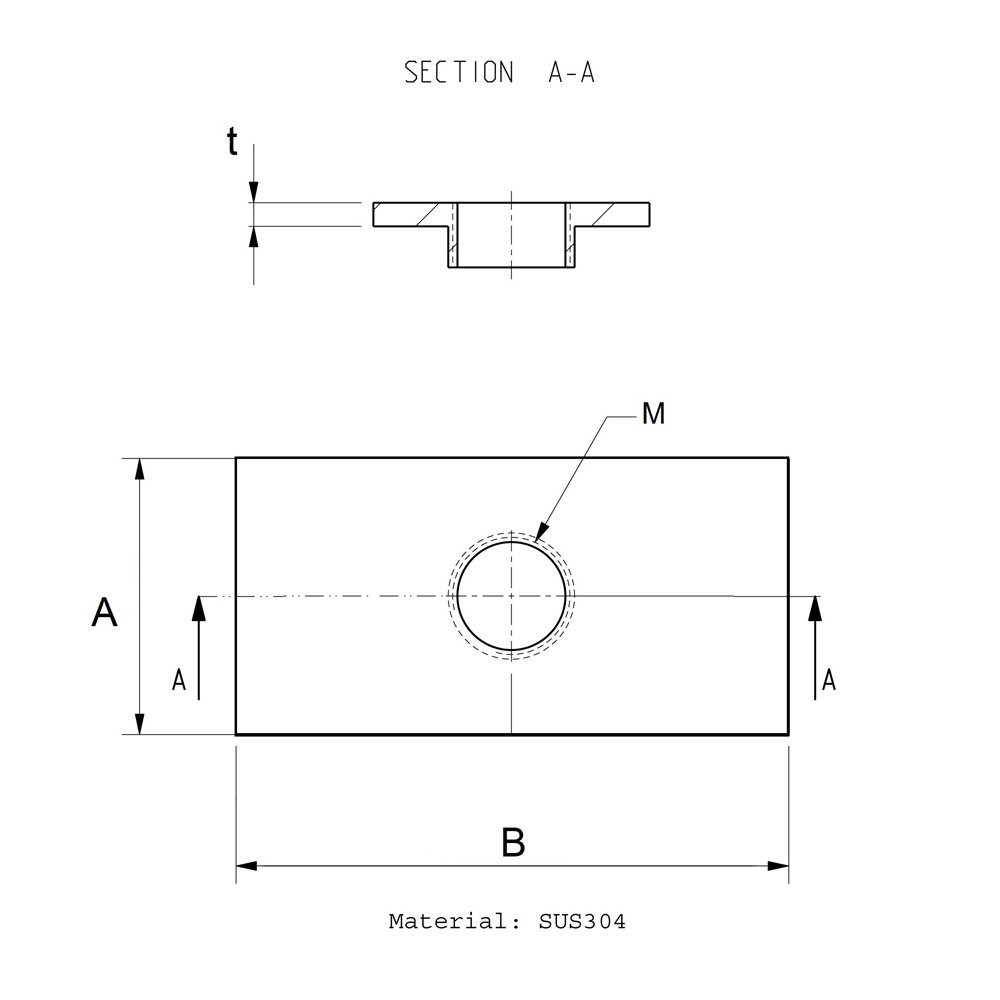

Swivel side guide brackets stainless steel Sanitary conveyor components

Stainless Steel Swivel Side Guide Brackets

In sanitary production, guiding components must do two things extremely well: keep product flow stable and support rapid, repeatable cleaning. Soportes de guía laterales giratorios de acero inoxidable. are a key sanitary conveyor component used to mount and adjust side guide rails—helping operators align products accurately while maintaining a clean, easy-to-wash conveyor setup.

Sanitary Conveyor Components for Washdown Reliability and Fast Changeovers

Because swivel brackets allow controlled angular positioning, they’re ideal for conveyor curves, transfer zones, and production lines with frequent SKU changes. When designed for sanitary use, they reduce dirt traps, simplify washdowns, and support consistent hygiene standards across food, beverage, and pharmaceutical environments.

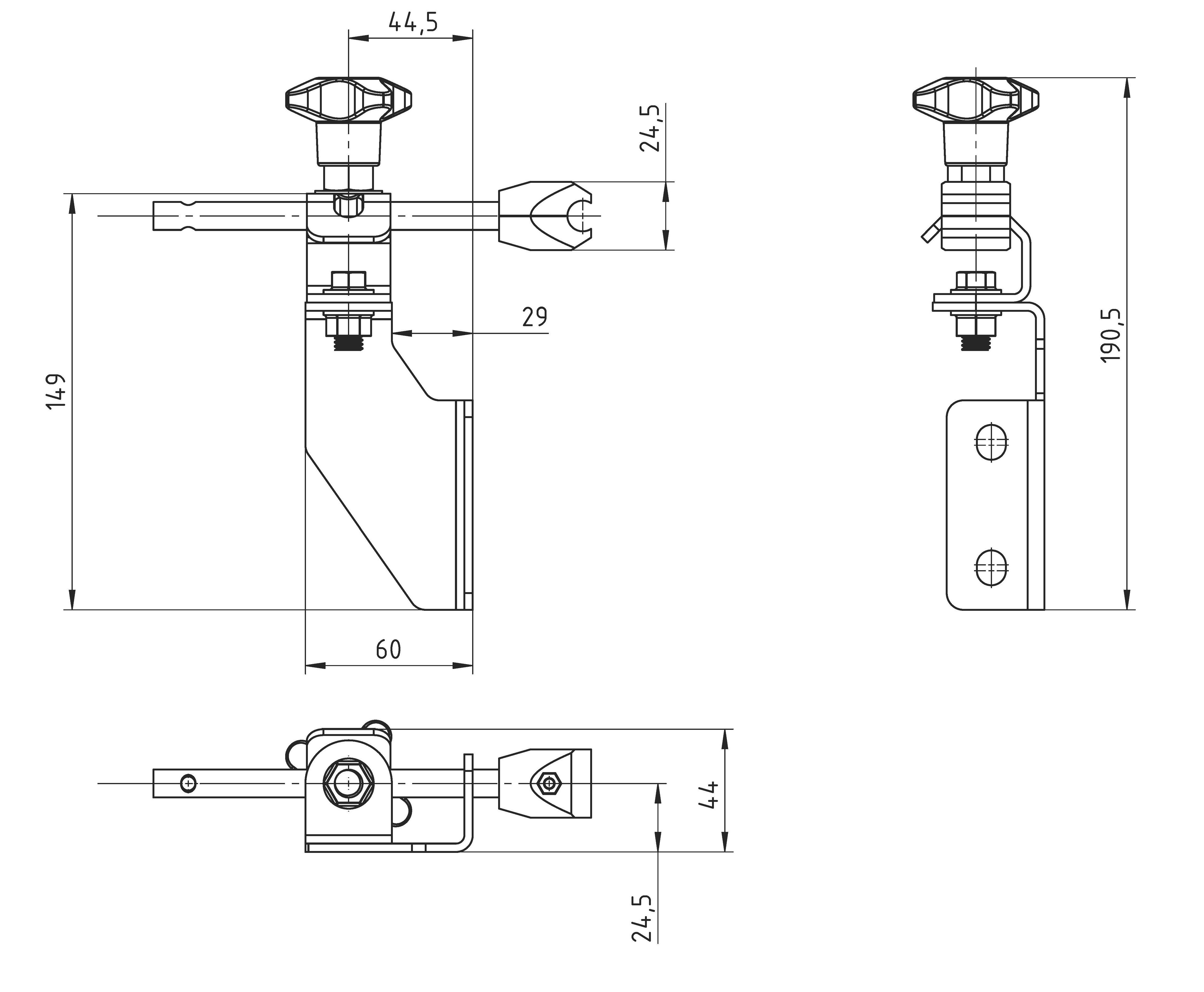

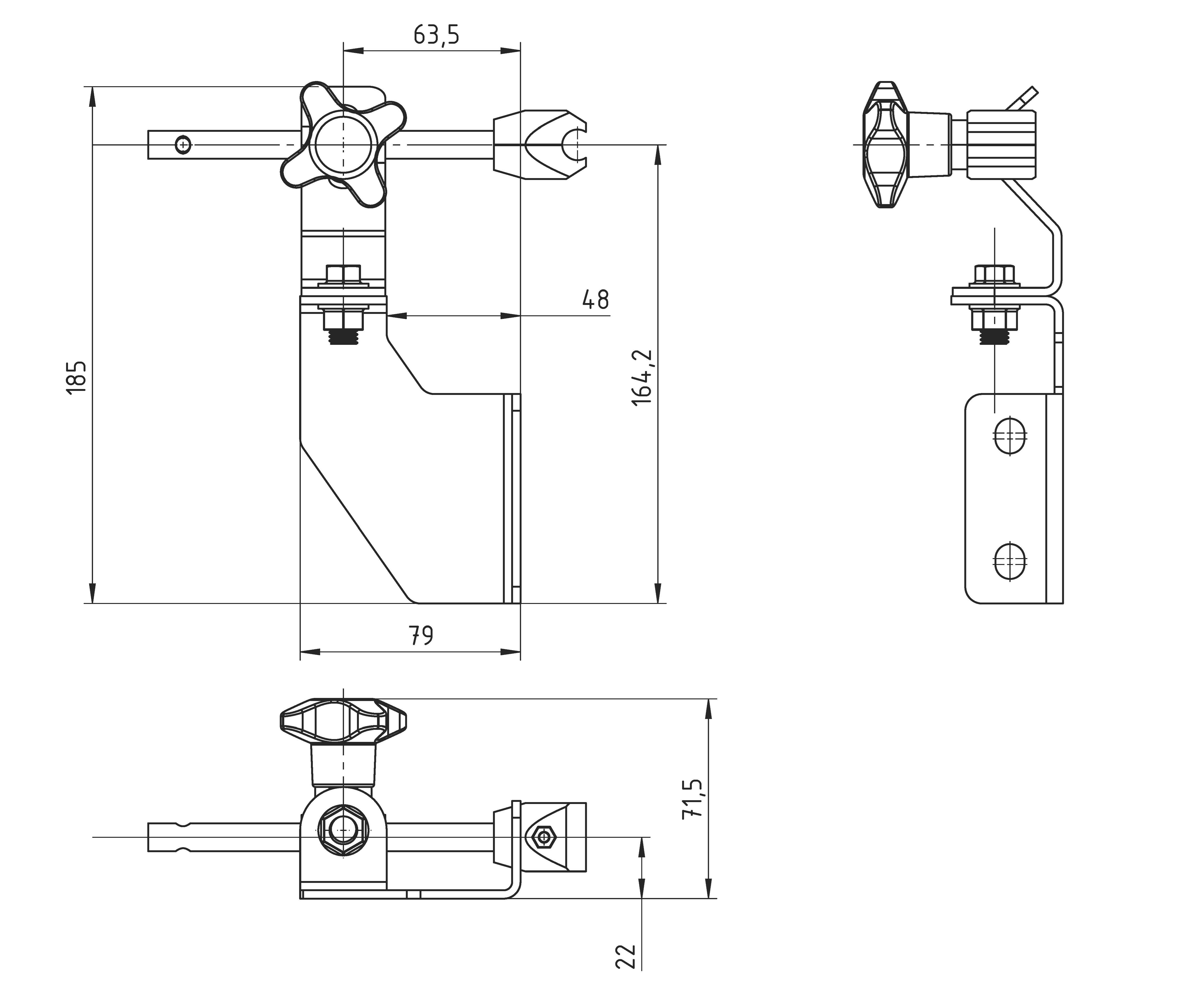

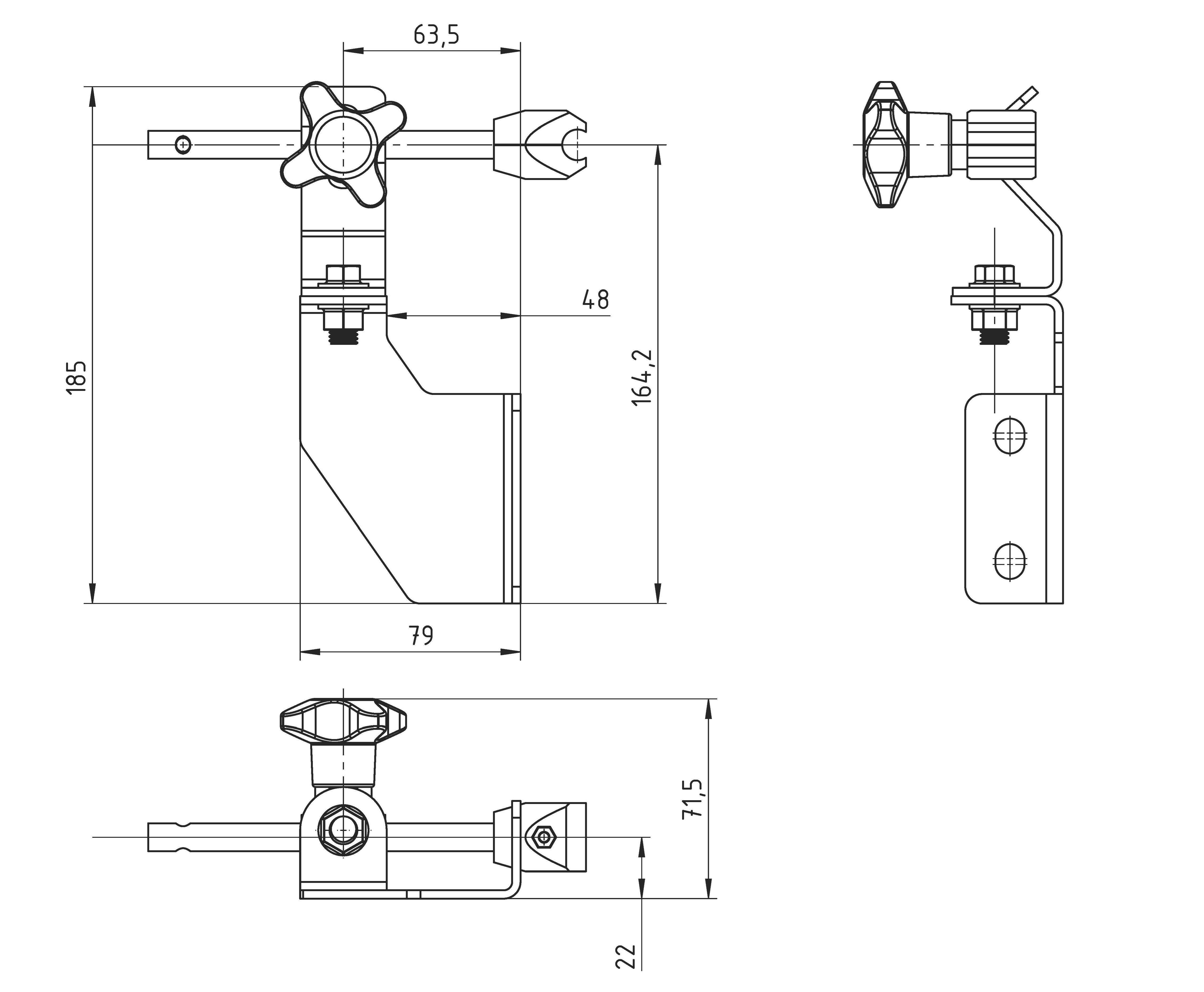

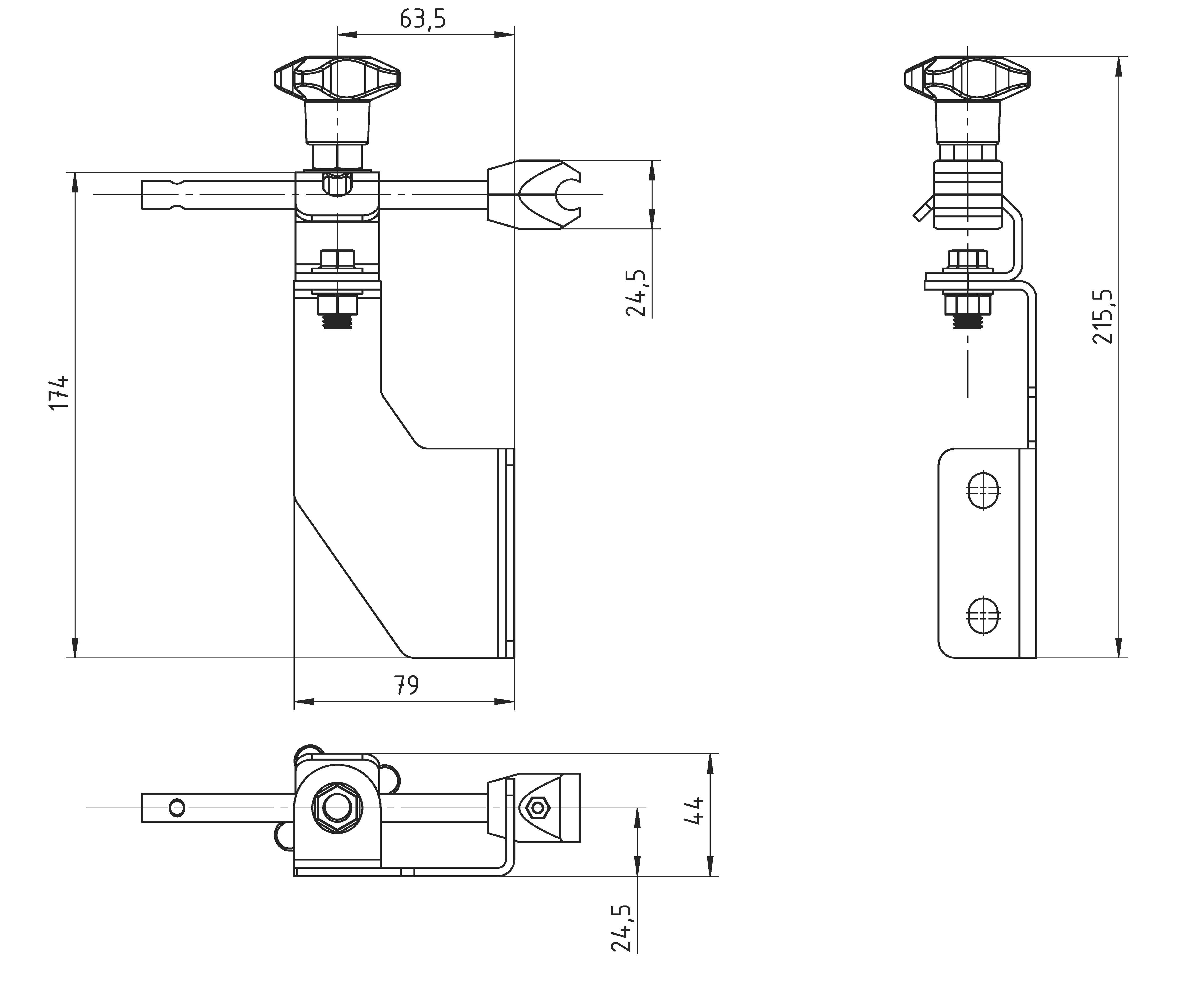

SG 110 29/29 Sanitary swivel side guide brackets stainless steel

SG 110 29/54 Sanitary swivel side guide brackets stainless steel

SG 110 48/29 Sanitary swivel side guide brackets stainless steel

SG 110 48/54 Sanitary swivel side guide brackets stainless steel

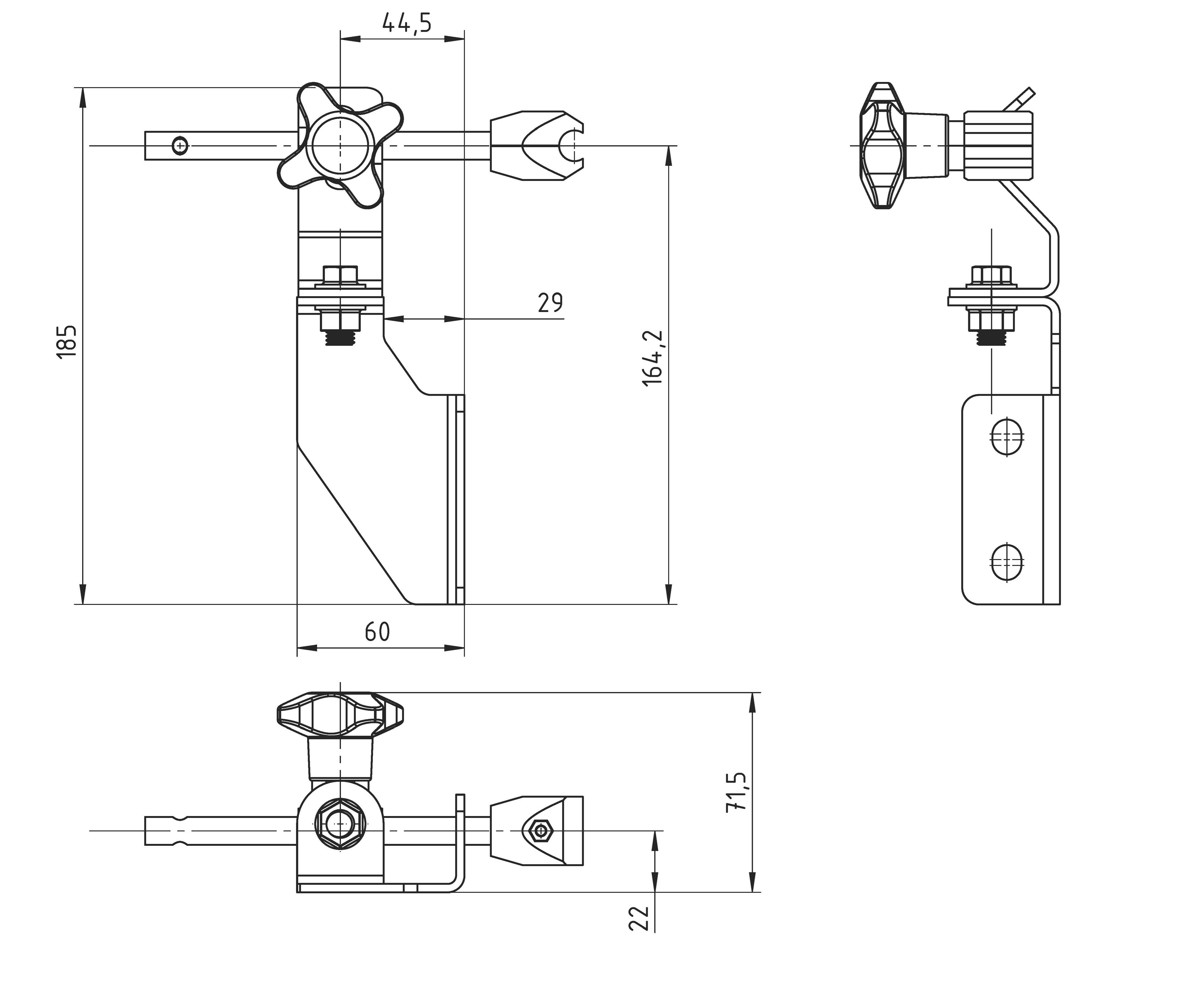

SG 135 29/29 Sanitary swivel side guide brackets stainless steel

SG 135 29/54 Sanitary swivel side guide brackets stainless steel

SG 135 48/29 Sanitary swivel side guide brackets stainless steel

SG 135 48/54 Sanitary swivel side guide brackets stainless steel

What swivel side guide brackets do on a conveyor

Side guide systems keep products centered and controlled as they move through the line. Swivel side guide brackets add flexibility by allowing the guide rail to pivot slightly, which helps:

guide products smoothly through curves and transitions

reduce snagging at infeed/outfeed points

maintain stable contact for inspection, labeling, and packing

adapt guiding to different formats without complex rework

In short: swivel adjustment improves both product handling and line efficiency—especially when your conveyor layout isn’t perfectly straight.

Why stainless steel is the sanitary choice

Sanitary conveyors operate under moisture, chemicals, and frequent cleaning cycles. Stainless steel is preferred because it offers:

Alta resistencia a la corrosión in wet and washdown conditions

durabilidad under aggressive detergents and disinfectants

Resistencia mecánica for stable guiding at higher speeds

long service life, minimizing maintenance and replacements

AISI 304 vs AISI 316 for sanitary environments

AISI 304 (1.4301): a strong standard choice for many sanitary conveyor applications

AISI 316 (1.4401 / 1.4404): better for salt exposure, brine, and harsher chemical cleaning (common in meat, seafood, and high-care washdown areas)

If your cleaning chemistry is aggressive or your process includes chlorides, 316 often delivers better long-term protection against corrosion.

Sanitary design features that support faster cleaning

“Stainless” is not automatically “sanitary.” A sanitary swivel bracket should be designed to minimize contamination traps and speed up cleaning.

Look for brackets with:

smooth, easy-to-wipe surfaces

minimal recesses, pockets, and sharp transitions

open geometry for visual inspection and complete rinse-down

reduced dirt traps around joints and fastening points

These details make a real difference in daily sanitation routines—helping reduce water use, detergent use, and downtime between production runs.

Key benefits of sanitary swivel side guide brackets

1) Cleaner operation and easier washdown

Sanitary-friendly geometry reduces residue build-up and helps teams achieve more consistent hygiene outcomes.

2) Faster format changes

Swivel adjustment supports quick guide rail repositioning for new product widths and packaging formats—ideal for high-mix production.

3) Better product control through curves

Swivel brackets help maintain smooth guiding through bends and transitions, reducing scuffs, jams, and product tipping.

4) Improved uptime and lower maintenance

Stainless steel durability reduces corrosion-related failures and extends replacement intervals—especially in wet zones.

5) More consistent line performance

Stable, repeatable guiding reduces waste and improves overall equipment effectiveness (OEE).

Where sanitary swivel side guide brackets are used

Estos stainless steel swivel side guide brackets for sanitary conveyors are common in:

Food processing & packaging: dairy, bakery, produce, ready meals, meat & poultry, seafood

Beverage lines: bottles, cans, cartons, inspection and case packing conveyors

Pharmaceutical & biotech: clean production transport and secondary packaging

Medical/healthcare products: sanitary conveying and packing areas

They are especially valuable wherever washdowns are frequent and downtime must be minimized.

How to choose the right swivel side guide bracket

A practical selection checklist:

Sanitary environment

dry vs wet vs full washdown zone

cleaning chemistry (mild vs aggressive)

304 vs 316 stainless steel requirement

Conveyor function

straight run vs curves/transfers

product stability needs (tall packs, lightweight items, fragile packaging)

line speed and vibration levels

Mounting and adjustment

mounting interface (tube, profile, frame bracket)

required adjustment range and rigidity

tool-free vs tool-based tightening preference

Tip: If a bracket is hard to access for cleaning, it will eventually cost you time. Prioritize cleanability and accessibility, not just strength.

Installation and maintenance tips (sanitary best practice)

Align guides under real running conditions before final tightening

Standardize tightening procedure to prevent guide drift

Inspect pivot points and fasteners during preventive maintenance

Include brackets in sanitation checks (visual + verification points)

Replace worn locking hardware early to keep changeovers reliable

FAQ: Sanitary swivel side guide brackets

Are swivel side guide brackets suitable for washdown conveyors?

Yes, when built in stainless steel and designed with sanitary geometry to minimize dirt traps and support full rinse-down.

Do swivel brackets reduce conveyor jams?

They can—especially in curves and transfer zones, where small alignment improvements can reduce snagging, tipping, and scuffing.

Which stainless steel grade should I select?

304 is common for many sanitary lines. 316 is recommended for harsher washdown, salt/brine exposure, and aggressive detergents.

Call to action

Improve guiding, reduce downtime, and keep sanitation efficient with stainless steel swivel side guide brackets—a high-impact upgrade to any sanitary conveyor system. Choose an easy-to-clean design and the right stainless grade to match your washdown conditions.

Get your catalogue here

Contáctenos

necesitas más información? Ponerse en contacto hoy. Le ayudaremos a encontrar el tipo de máquina y pie nivelador adecuados para sus necesidades.

Stainless Steel Swivel Side Guide Brackets

In sanitary production, guiding components must do two things extremely well: keep product flow stable and support rapid, repeatable cleaning. Soportes de guía laterales giratorios de acero inoxidable. are a key sanitary conveyor component used to mount and adjust side guide rails—helping operators align products accurately while maintaining a clean, easy-to-wash conveyor setup.

Sanitary Conveyor Components for Washdown Reliability and Fast Changeovers

Because swivel brackets allow controlled angular positioning, they’re ideal for conveyor curves, transfer zones, and production lines with frequent SKU changes. When designed for sanitary use, they reduce dirt traps, simplify washdowns, and support consistent hygiene standards across food, beverage, and pharmaceutical environments.

SG 110 29/29 Sanitary swivel side guide brackets stainless steel

SG 110 29/54 Sanitary swivel side guide brackets stainless steel

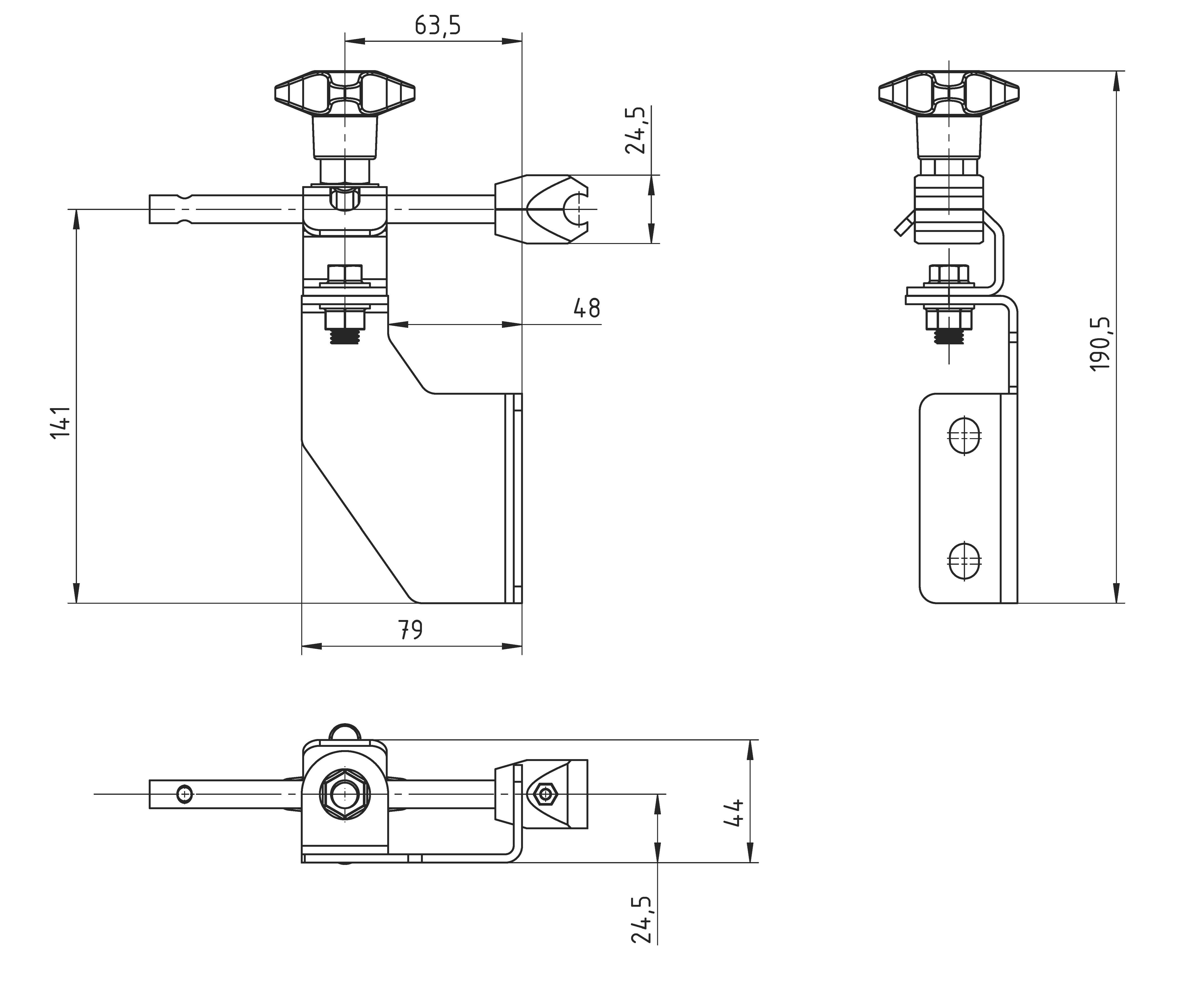

SG 110 48/29 Sanitary swivel side guide brackets stainless steel

SG 110 48/54 Sanitary swivel side guide brackets stainless steel

SG 135 29/29 Sanitary swivel side guide brackets stainless steel

SG 135 29/54 Sanitary swivel side guide brackets stainless steel

SG 135 48/29 Sanitary swivel side guide brackets stainless steel

SG 135 48/54 Sanitary swivel side guide brackets stainless steel

What swivel side guide brackets do on a conveyor

Side guide systems keep products centered and controlled as they move through the line. Swivel side guide brackets add flexibility by allowing the guide rail to pivot slightly, which helps:

guide products smoothly through curves and transitions

reduce snagging at infeed/outfeed points

maintain stable contact for inspection, labeling, and packing

adapt guiding to different formats without complex rework

In short: swivel adjustment improves both product handling and line efficiency—especially when your conveyor layout isn’t perfectly straight.

Why stainless steel is the sanitary choice

Sanitary conveyors operate under moisture, chemicals, and frequent cleaning cycles. Stainless steel is preferred because it offers:

Alta resistencia a la corrosión in wet and washdown conditions

durabilidad under aggressive detergents and disinfectants

Resistencia mecánica for stable guiding at higher speeds

long service life, minimizing maintenance and replacements

AISI 304 vs AISI 316 for sanitary environments

AISI 304 (1.4301): a strong standard choice for many sanitary conveyor applications

AISI 316 (1.4401 / 1.4404): better for salt exposure, brine, and harsher chemical cleaning (common in meat, seafood, and high-care washdown areas)

If your cleaning chemistry is aggressive or your process includes chlorides, 316 often delivers better long-term protection against corrosion.

Sanitary design features that support faster cleaning

“Stainless” is not automatically “sanitary.” A sanitary swivel bracket should be designed to minimize contamination traps and speed up cleaning.

Look for brackets with:

smooth, easy-to-wipe surfaces

minimal recesses, pockets, and sharp transitions

open geometry for visual inspection and complete rinse-down

reduced dirt traps around joints and fastening points

These details make a real difference in daily sanitation routines—helping reduce water use, detergent use, and downtime between production runs.

Key benefits of sanitary swivel side guide brackets

1) Cleaner operation and easier washdown

Sanitary-friendly geometry reduces residue build-up and helps teams achieve more consistent hygiene outcomes.

2) Faster format changes

Swivel adjustment supports quick guide rail repositioning for new product widths and packaging formats—ideal for high-mix production.

3) Better product control through curves

Swivel brackets help maintain smooth guiding through bends and transitions, reducing scuffs, jams, and product tipping.

4) Improved uptime and lower maintenance

Stainless steel durability reduces corrosion-related failures and extends replacement intervals—especially in wet zones.

5) More consistent line performance

Stable, repeatable guiding reduces waste and improves overall equipment effectiveness (OEE).

Where sanitary swivel side guide brackets are used

Estos stainless steel swivel side guide brackets for sanitary conveyors are common in:

Food processing & packaging: dairy, bakery, produce, ready meals, meat & poultry, seafood

Beverage lines: bottles, cans, cartons, inspection and case packing conveyors

Pharmaceutical & biotech: clean production transport and secondary packaging

Medical/healthcare products: sanitary conveying and packing areas

They are especially valuable wherever washdowns are frequent and downtime must be minimized.

How to choose the right swivel side guide bracket

A practical selection checklist:

Sanitary environment

dry vs wet vs full washdown zone

cleaning chemistry (mild vs aggressive)

304 vs 316 stainless steel requirement

Conveyor function

straight run vs curves/transfers

product stability needs (tall packs, lightweight items, fragile packaging)

line speed and vibration levels

Mounting and adjustment

mounting interface (tube, profile, frame bracket)

required adjustment range and rigidity

tool-free vs tool-based tightening preference

Tip: If a bracket is hard to access for cleaning, it will eventually cost you time. Prioritize cleanability and accessibility, not just strength.

Installation and maintenance tips (sanitary best practice)

Align guides under real running conditions before final tightening

Standardize tightening procedure to prevent guide drift

Inspect pivot points and fasteners during preventive maintenance

Include brackets in sanitation checks (visual + verification points)

Replace worn locking hardware early to keep changeovers reliable

FAQ: Sanitary swivel side guide brackets

Are swivel side guide brackets suitable for washdown conveyors?

Yes, when built in stainless steel and designed with sanitary geometry to minimize dirt traps and support full rinse-down.

Do swivel brackets reduce conveyor jams?

They can—especially in curves and transfer zones, where small alignment improvements can reduce snagging, tipping, and scuffing.

Which stainless steel grade should I select?

304 is common for many sanitary lines. 316 is recommended for harsher washdown, salt/brine exposure, and aggressive detergents.

Call to action

Improve guiding, reduce downtime, and keep sanitation efficient with stainless steel swivel side guide brackets—a high-impact upgrade to any sanitary conveyor system. Choose an easy-to-clean design and the right stainless grade to match your washdown conditions.

Get your catalogue here

Stainless Steel Swivel Side Guide Brackets

In sanitary production, guiding components must do two things extremely well: keep product flow stable and support rapid, repeatable cleaning. Soportes de guía laterales giratorios de acero inoxidable. are a key sanitary conveyor component used to mount and adjust side guide rails—helping operators align products accurately while maintaining a clean, easy-to-wash conveyor setup.

Sanitary Conveyor Components for Washdown Reliability and Fast Changeovers

Because swivel brackets allow controlled angular positioning, they’re ideal for conveyor curves, transfer zones, and production lines with frequent SKU changes. When designed for sanitary use, they reduce dirt traps, simplify washdowns, and support consistent hygiene standards across food, beverage, and pharmaceutical environments.

SG 110 29/29 Sanitary swivel side guide brackets stainless steel

SG 110 29/54 Sanitary swivel side guide brackets stainless steel

SG 110 48/29 Sanitary swivel side guide brackets stainless steel

SG 110 48/54 Sanitary swivel side guide brackets stainless steel

SG 135 29/29 Sanitary swivel side guide brackets stainless steel

SG 135 29/54 Sanitary swivel side guide brackets stainless steel

SG 135 48/29 Sanitary swivel side guide brackets stainless steel

SG 135 48/54 Sanitary swivel side guide brackets stainless steel

What swivel side guide brackets do on a conveyor

Side guide systems keep products centered and controlled as they move through the line. Swivel side guide brackets add flexibility by allowing the guide rail to pivot slightly, which helps:

guide products smoothly through curves and transitions

reduce snagging at infeed/outfeed points

maintain stable contact for inspection, labeling, and packing

adapt guiding to different formats without complex rework

In short: swivel adjustment improves both product handling and line efficiency—especially when your conveyor layout isn’t perfectly straight.

Why stainless steel is the sanitary choice

Sanitary conveyors operate under moisture, chemicals, and frequent cleaning cycles. Stainless steel is preferred because it offers:

Alta resistencia a la corrosión in wet and washdown conditions

durabilidad under aggressive detergents and disinfectants

Resistencia mecánica for stable guiding at higher speeds

long service life, minimizing maintenance and replacements

AISI 304 vs AISI 316 for sanitary environments

AISI 304 (1.4301): a strong standard choice for many sanitary conveyor applications

AISI 316 (1.4401 / 1.4404): better for salt exposure, brine, and harsher chemical cleaning (common in meat, seafood, and high-care washdown areas)

If your cleaning chemistry is aggressive or your process includes chlorides, 316 often delivers better long-term protection against corrosion.

Sanitary design features that support faster cleaning

“Stainless” is not automatically “sanitary.” A sanitary swivel bracket should be designed to minimize contamination traps and speed up cleaning.

Look for brackets with:

smooth, easy-to-wipe surfaces

minimal recesses, pockets, and sharp transitions

open geometry for visual inspection and complete rinse-down

reduced dirt traps around joints and fastening points

These details make a real difference in daily sanitation routines—helping reduce water use, detergent use, and downtime between production runs.

Key benefits of sanitary swivel side guide brackets

1) Cleaner operation and easier washdown

Sanitary-friendly geometry reduces residue build-up and helps teams achieve more consistent hygiene outcomes.

2) Faster format changes

Swivel adjustment supports quick guide rail repositioning for new product widths and packaging formats—ideal for high-mix production.

3) Better product control through curves

Swivel brackets help maintain smooth guiding through bends and transitions, reducing scuffs, jams, and product tipping.

4) Improved uptime and lower maintenance

Stainless steel durability reduces corrosion-related failures and extends replacement intervals—especially in wet zones.

5) More consistent line performance

Stable, repeatable guiding reduces waste and improves overall equipment effectiveness (OEE).

Where sanitary swivel side guide brackets are used

Estos stainless steel swivel side guide brackets for sanitary conveyors are common in:

Food processing & packaging: dairy, bakery, produce, ready meals, meat & poultry, seafood

Beverage lines: bottles, cans, cartons, inspection and case packing conveyors

Pharmaceutical & biotech: clean production transport and secondary packaging

Medical/healthcare products: sanitary conveying and packing areas

They are especially valuable wherever washdowns are frequent and downtime must be minimized.

How to choose the right swivel side guide bracket

A practical selection checklist:

Sanitary environment

dry vs wet vs full washdown zone

cleaning chemistry (mild vs aggressive)

304 vs 316 stainless steel requirement

Conveyor function

straight run vs curves/transfers

product stability needs (tall packs, lightweight items, fragile packaging)

line speed and vibration levels

Mounting and adjustment

mounting interface (tube, profile, frame bracket)

required adjustment range and rigidity

tool-free vs tool-based tightening preference

Tip: If a bracket is hard to access for cleaning, it will eventually cost you time. Prioritize cleanability and accessibility, not just strength.

Installation and maintenance tips (sanitary best practice)

Align guides under real running conditions before final tightening

Standardize tightening procedure to prevent guide drift

Inspect pivot points and fasteners during preventive maintenance

Include brackets in sanitation checks (visual + verification points)

Replace worn locking hardware early to keep changeovers reliable

FAQ: Sanitary swivel side guide brackets

Are swivel side guide brackets suitable for washdown conveyors?

Yes, when built in stainless steel and designed with sanitary geometry to minimize dirt traps and support full rinse-down.

Do swivel brackets reduce conveyor jams?

They can—especially in curves and transfer zones, where small alignment improvements can reduce snagging, tipping, and scuffing.

Which stainless steel grade should I select?

304 is common for many sanitary lines. 316 is recommended for harsher washdown, salt/brine exposure, and aggressive detergents.

Call to action

Improve guiding, reduce downtime, and keep sanitation efficient with stainless steel swivel side guide brackets—a high-impact upgrade to any sanitary conveyor system. Choose an easy-to-clean design and the right stainless grade to match your washdown conditions.

Get your catalogue here

Contáctenos

necesitas más información? Ponerse en contacto hoy. Le ayudaremos a encontrar el tipo de máquina y pie nivelador adecuados para sus necesidades.