Contáctenos

necesitas más información? Ponerse en contacto hoy. Le ayudaremos a encontrar el tipo de máquina y pie nivelador adecuados para sus necesidades.

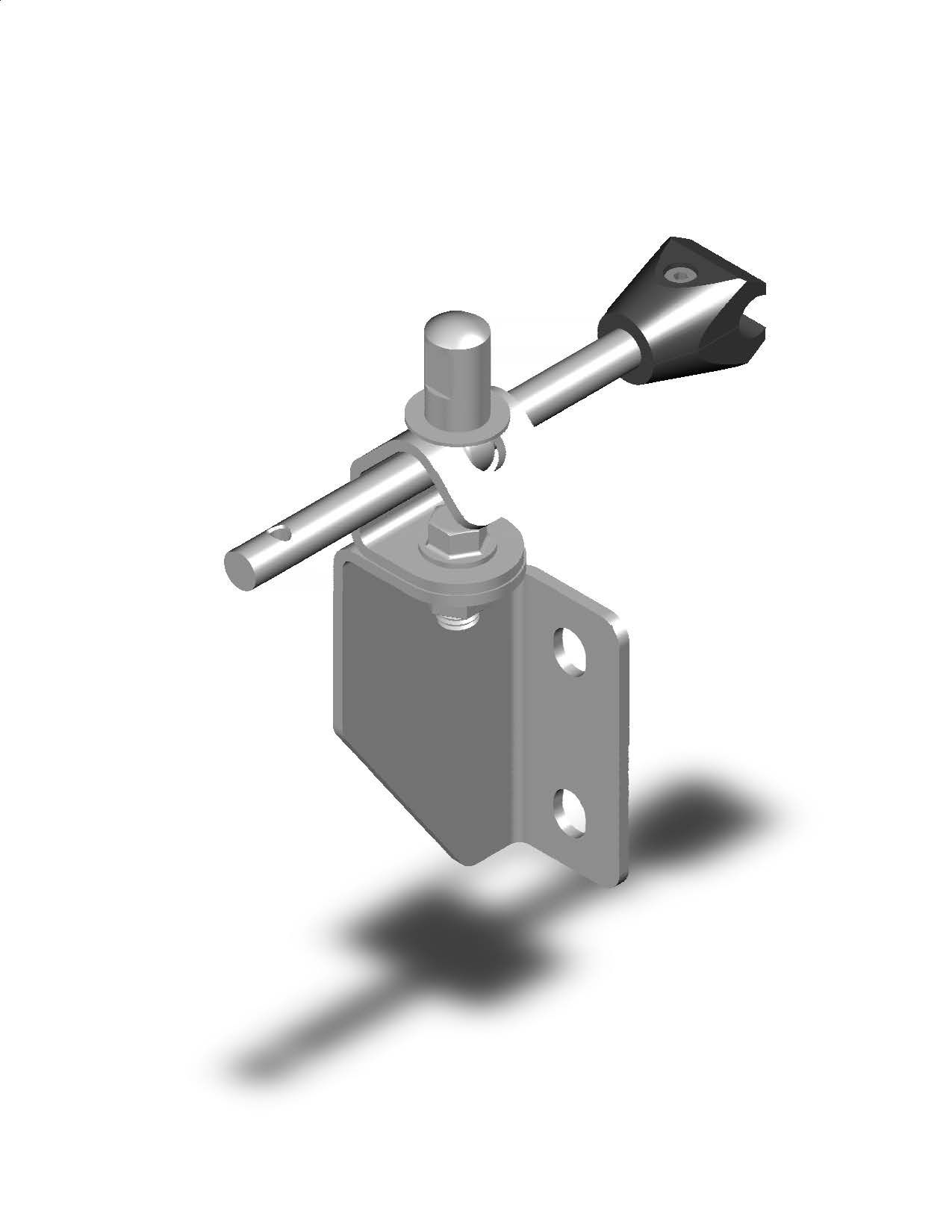

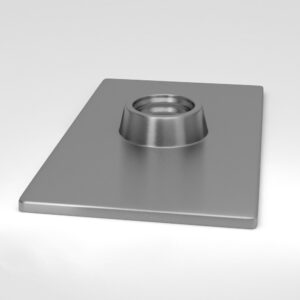

Swivel side guide brackets stainless steel Hygienic conveyor components

Swivel Side Guide Brackets in Stainless Steel

When conveyors run in hygienic environments, product guiding must be stable, adjustable, and easy to clean—every single day. Soportes de guía laterales giratorios de acero inoxidable. are an essential hygienic conveyor component that keeps guide rails aligned while supporting quick format changes and reliable washdown performance.

Hygienic Conveyor Components for Washdown, Food & Pharma Lines

Unlike fixed brackets, swivel side guide brackets allow controlled angular adjustment. This makes them ideal for curves, transfers, infeed/outfeed zones, and applications where product shapes vary slightly. Combined with hygienic design principles and stainless steel durability, swivel brackets help reduce contamination risks, improve line efficiency, and support compliance-driven production.

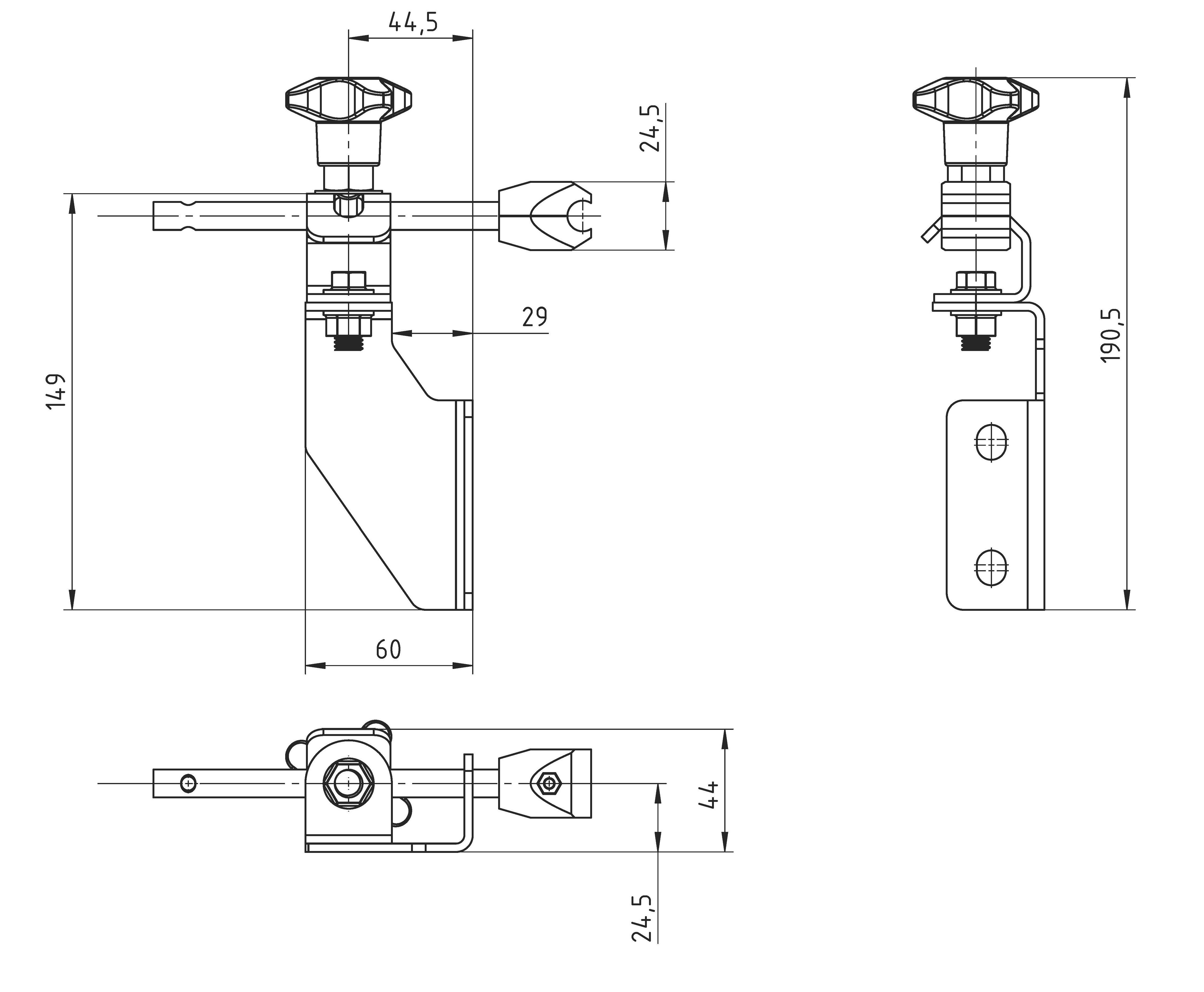

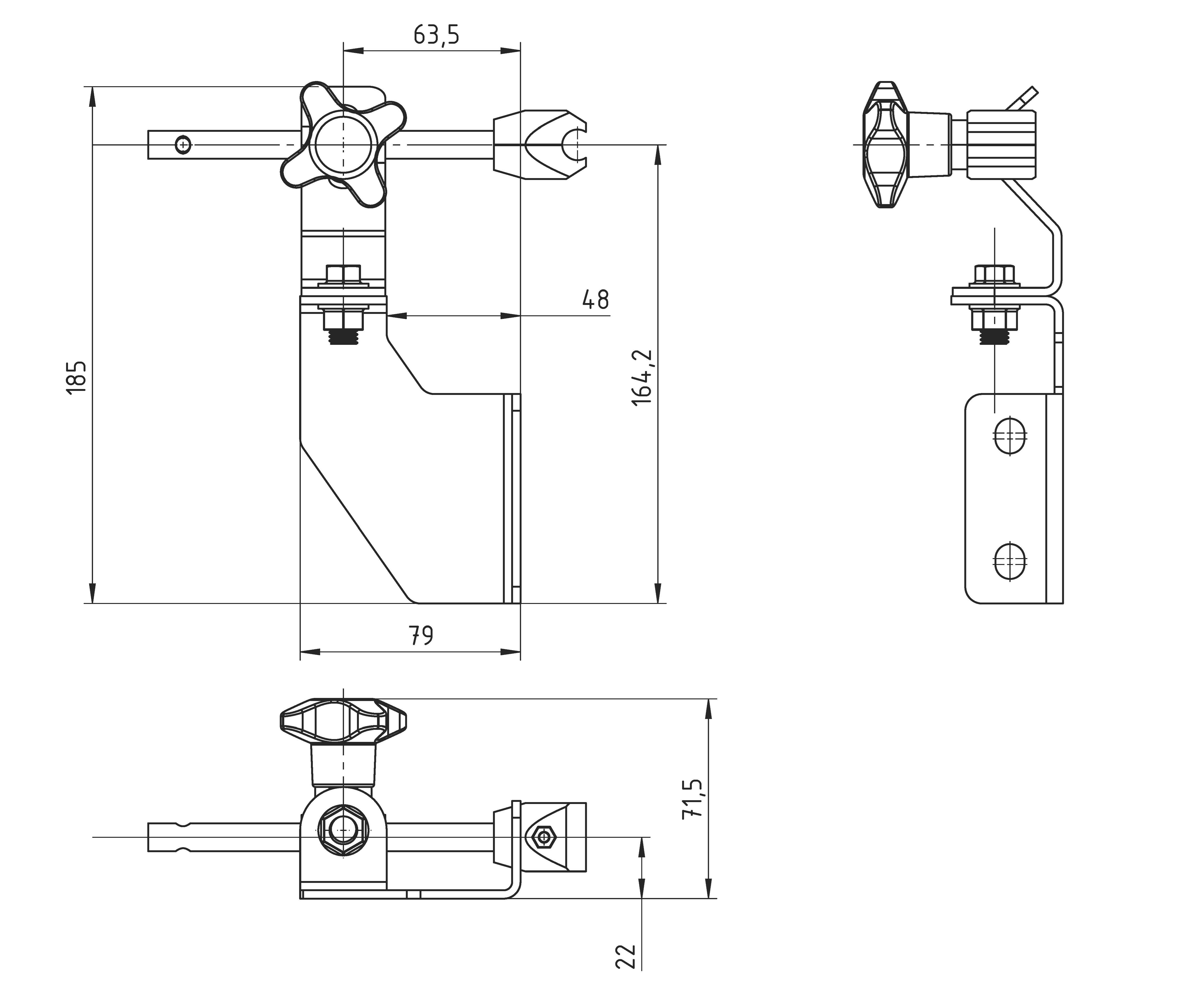

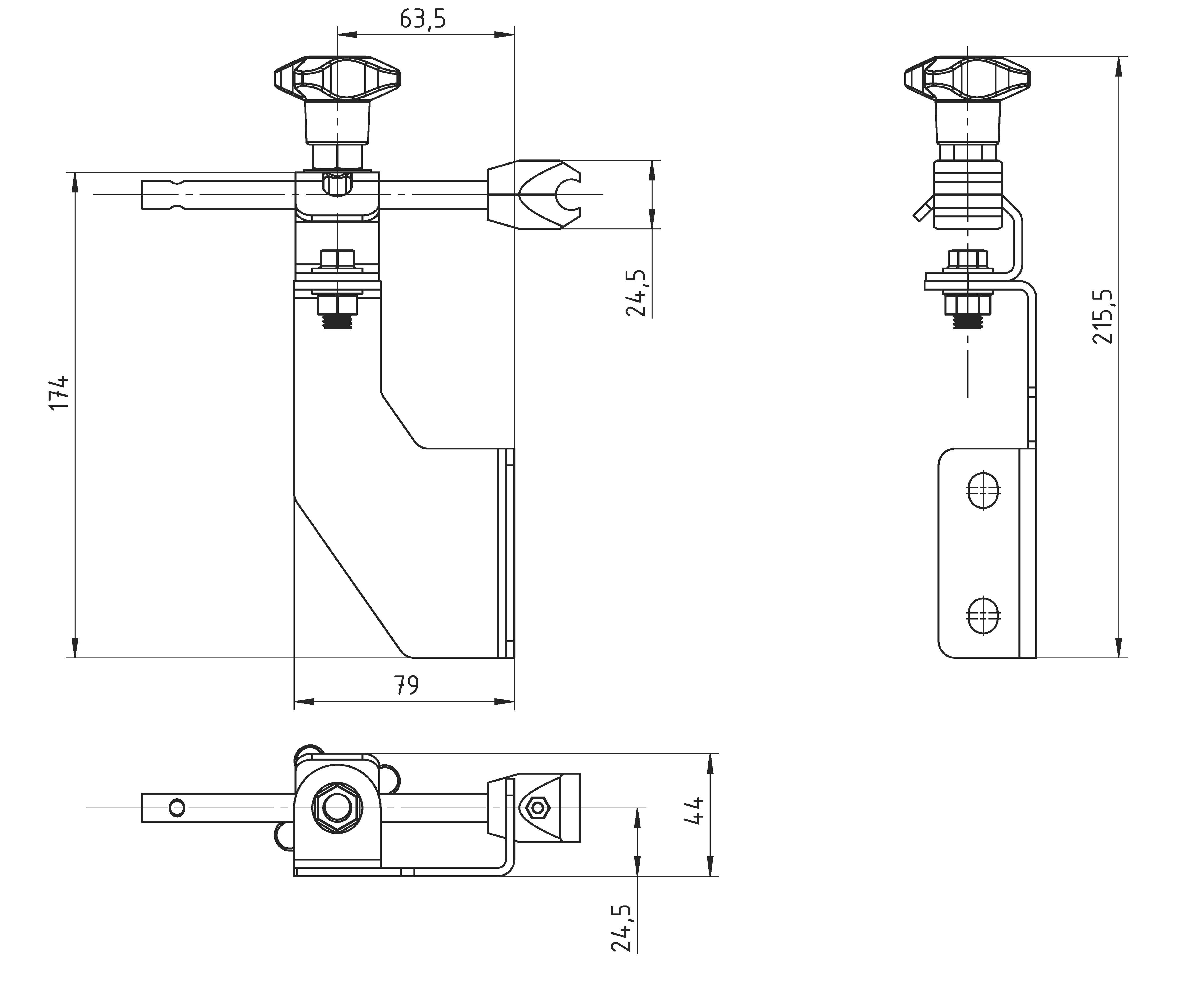

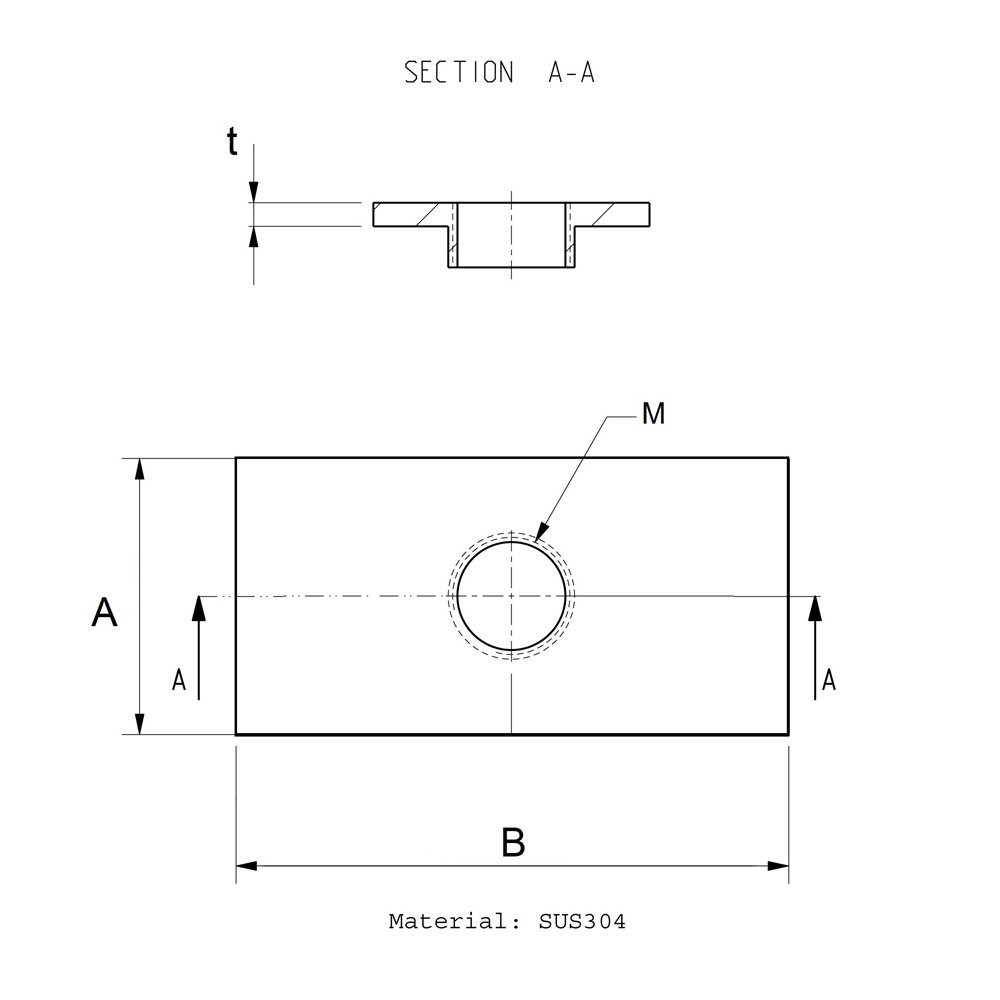

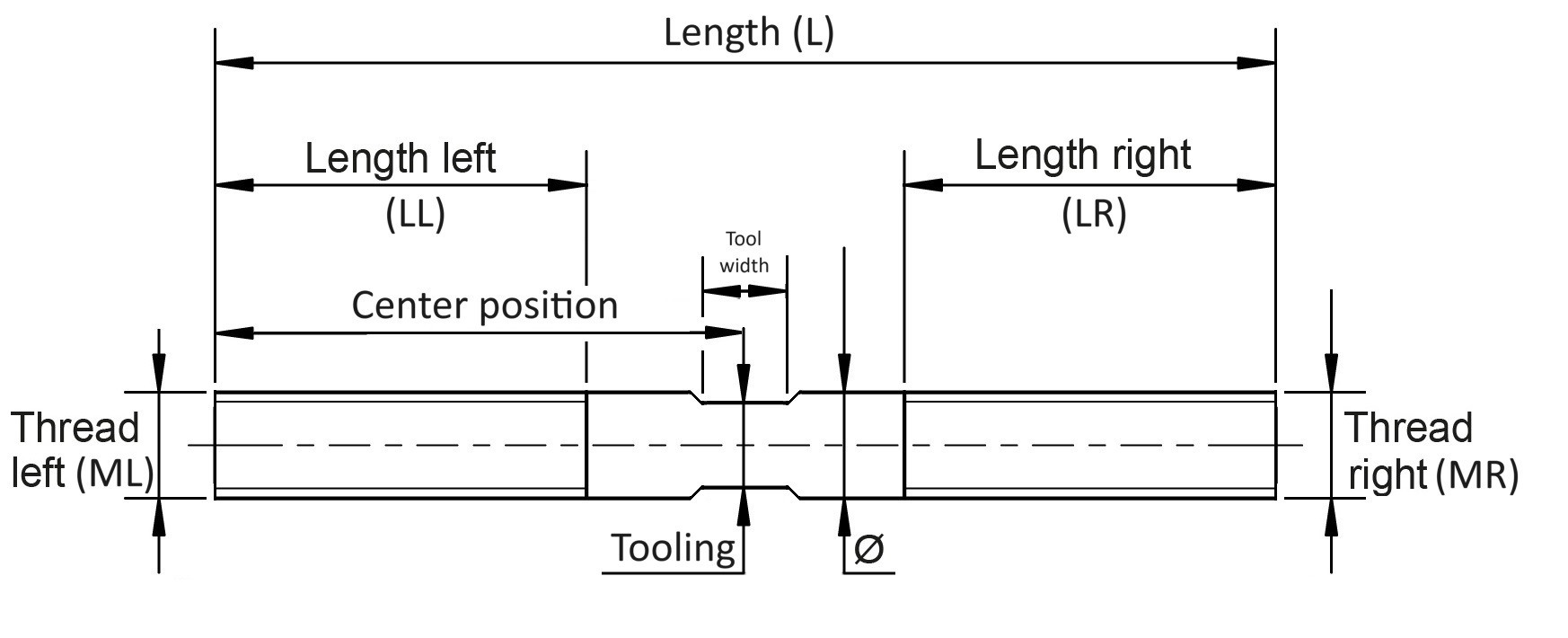

HSG 110 29/29 Hygienic swivel side guide brackets stainless steel

HSG 110 29/54 Hygienic swivel side guide brackets stainless steel

HSG 110 48/29 Hygienic swivel side guide brackets stainless steel

HSG 110 48/54 Hygienic swivel side guide brackets stainless steel

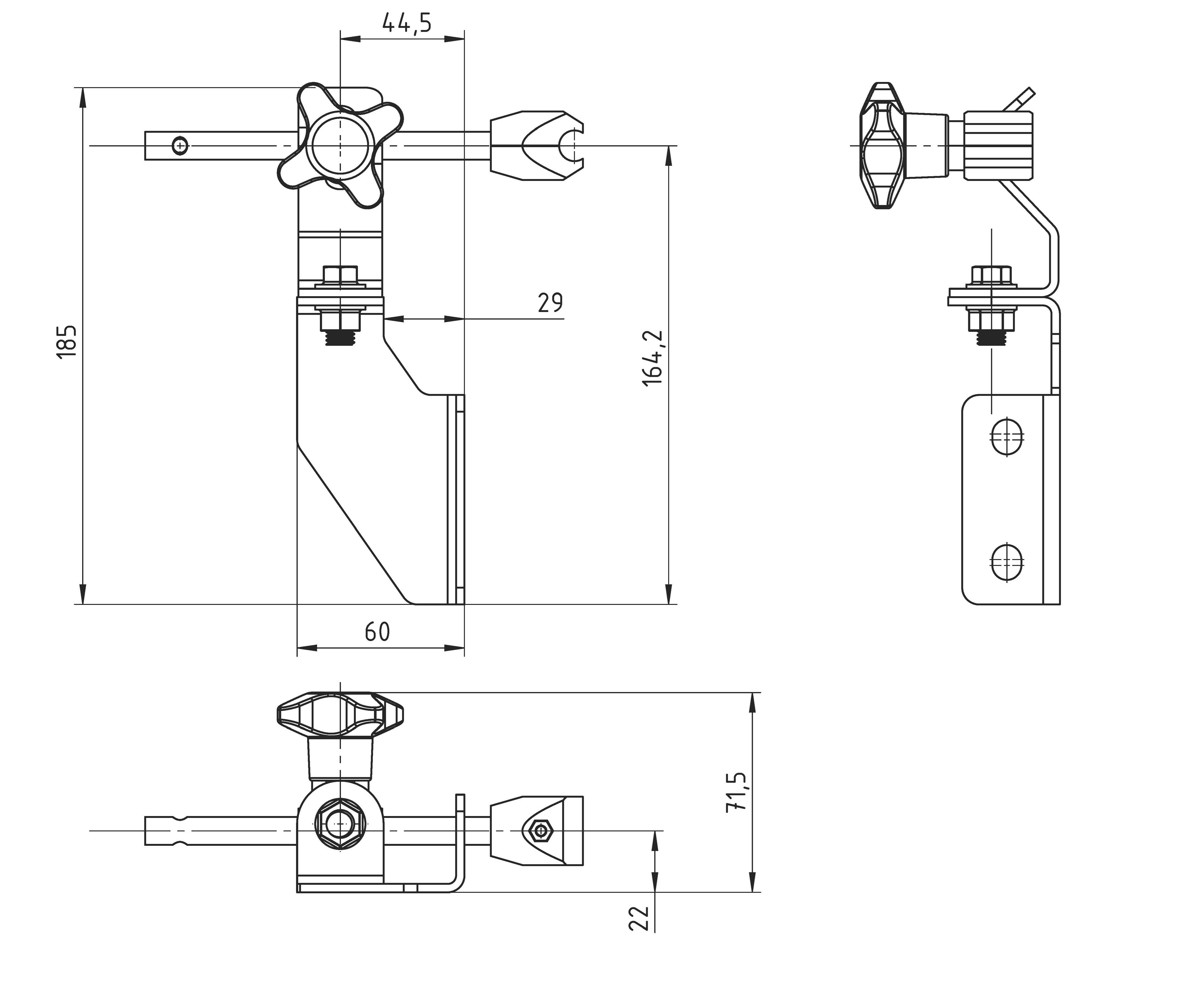

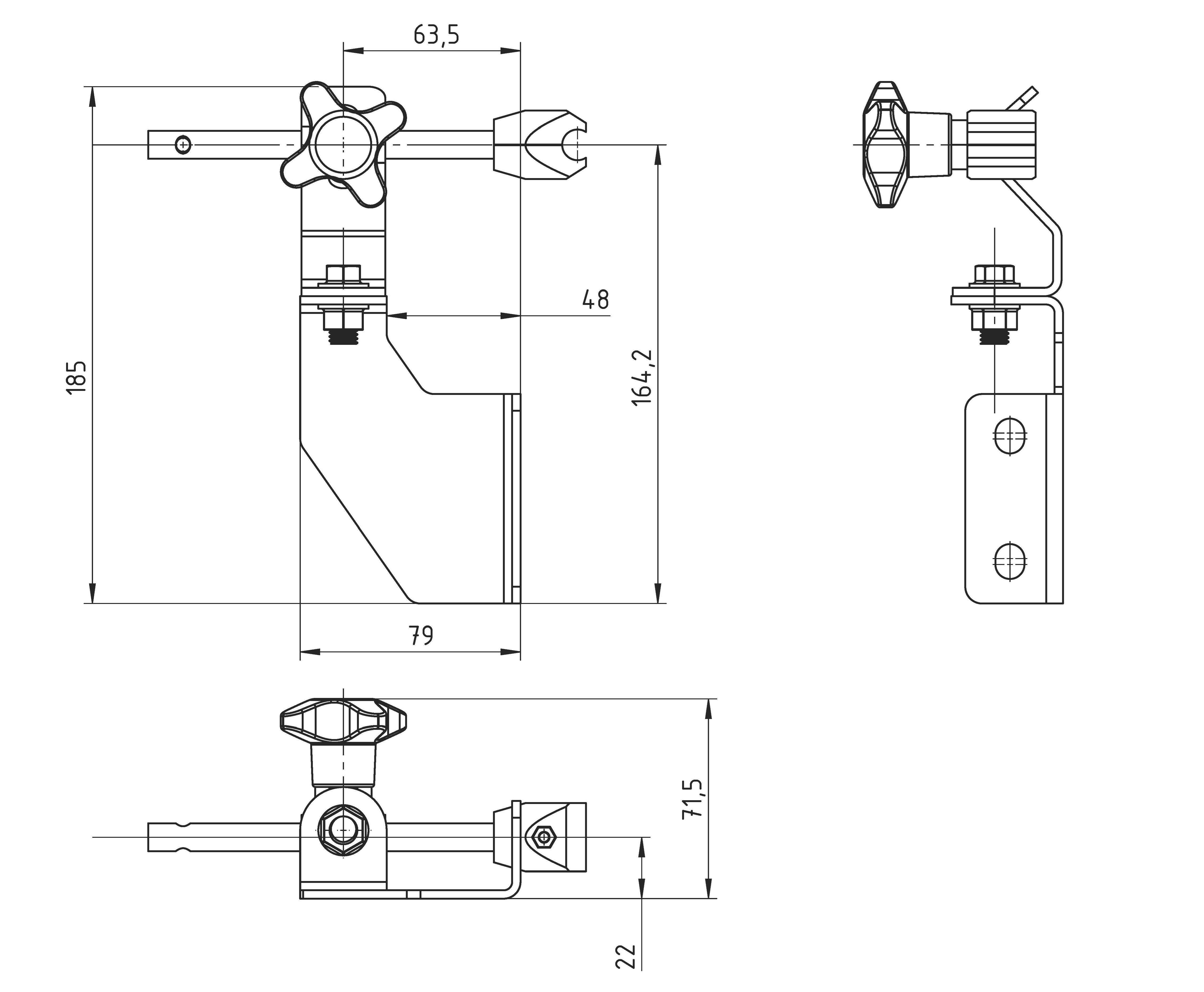

HSG 135 29/29 Hygienic swivel side guide brackets stainless steel

HSG 135 29/54 Hygienic swivel side guide brackets stainless steel

HSG 135 48/29 Hygienic swivel side guide brackets stainless steel

HSG 135 48/54 Hygienic swivel side guide brackets stainless steel

Why swivel side guide brackets matter on hygienic conveyors

Side guides do more than “hold a rail.” They protect throughput and product quality by:

preventing product tipping and jams

reducing scuffing, deformation, and packaging damage

keeping products centered for inspection, labeling, and packing steps

stabilizing flow through curves, merges, and transfer points

In washdown and high-care areas, the bracket itself must also support sanitation. Poorly designed brackets can create dirt traps, slow cleaning, and become a hidden hygiene risk.

Hygienic design features that support easier cleaning

A hygienic swivel bracket is defined as much by geometry as by material. The best designs focus on cleanability and contamination control:

Smooth surfaces: fewer places for residue, moisture, or biofilm to cling

Crevice-minimized construction: reduced gaps, pockets, and recesses

Open, accessible shape: easier rinsing, foaming, and visual inspection

Washdown-friendly hardware: fewer “dirt trap” fasteners and hard-to-reach interfaces

In practice, this means shorter cleaning cycles, better sanitation results, and less re-cleaning—especially important in regulated food and pharmaceutical environments.

Stainless steel options: AISI 304 vs AISI 316

Most hygienic conveyor components are offered in stainless steel grades suited to different environments:

AISI 304 (1.4301)

A strong all-round choice for many food, packaging, and general washdown applications. Good corrosion resistance and widely used across hygienic machinery components.

AISI 316 (1.4401 / 1.4404)

Preferred where the environment is more aggressive—salt exposure, brine, acidic products, or harsh detergents. If your cleaning chemistry is tough or your products contain chlorides (common in meat/seafood), 316 typically provides longer service life and better corrosion resistance.

Quick rule:

Elegir 304 for standard hygienic zones

Elegir 316 for harsher washdown, salt, or aggressive chemicals

Key benefits of stainless steel swivel side guide brackets

1) Faster, more reliable changeovers

Swivel adjustment supports quick repositioning of guide rails when switching product widths, formats, or packaging types—reducing downtime and setup variability.

2) Better guiding on curves and transitions

Swivel brackets are ideal where guides must follow conveyor geometry. They help maintain smooth product contact and reduce snagging at critical points.

3) Improved hygiene performance

Easy-to-clean design reduces residue build-up and supports consistent sanitation outcomes—especially in high-care food areas.

4) Washdown durability

Stainless steel construction withstands repeated cleaning cycles, moisture, and temperature swings—helping minimize maintenance and replacement frequency.

5) Increased line stability and product quality

A well-aligned guide system reduces jams, rework, and product damage—protecting throughput and OEE.

Typical industries and applications

Stainless steel swivel side guide brackets for hygienic conveyors are commonly used in:

Food processing & packaging: meat & poultry, dairy, seafood, bakery, ready meals, produce

Beverage and bottling lines: guiding through inspection, labeling, case packing

Pharmaceutical & biotech: hygienic transfer, secondary packaging, clean production zones

Medical/healthcare products: sanitary conveying and packing processes

They’re especially valuable where frequent washdown and tight hygiene standards are part of daily operations.

How to choose the right swivel side guide bracket

To select the best hygienic swivel bracket, match the component to your conveyor design and sanitation requirements:

Environment checklist

Is the bracket used in dry, wet, o full washdown zones?

Are you exposed to chlorides/salts or aggressive detergents?

Do you need 304 o 316 stainless steel?

Functional checklist

Do you need swivel adjustment for curves, angles, o variable product shapes?

Is tool-free adjustment required for operators (e.g., quick changeover routines)?

What level of rigidity is needed (high speed, vibration, heavy products)?

Interface checklist

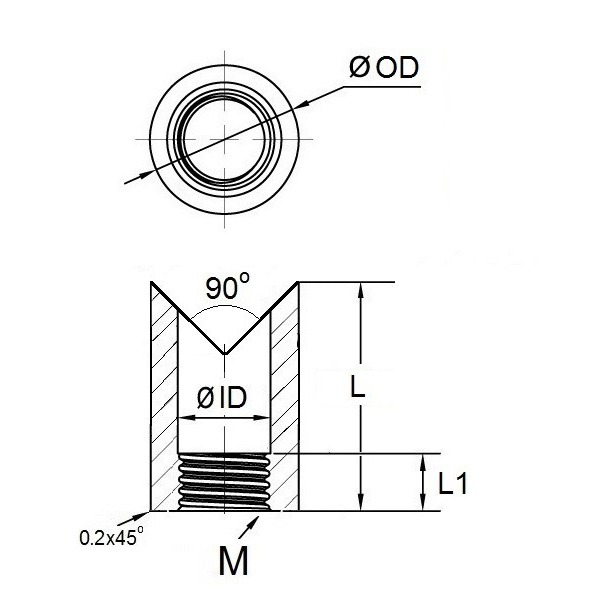

Guide rail size and mounting type (tube, profile, frame)

Fastener type and locking method

Space constraints around the conveyor (cleaning access, guarding)

Tip: In hygienic lines, “easy to clean” often matters as much as load rating. A bracket that saves minutes per cleaning cycle can pay back quickly.

Installation and maintenance tips for hygienic performance

Set alignment under real production conditions (belt speed + product flow) before final tightening

Standardize tightening practice so guides don’t drift over time

Inspect swivel joints and contact points during planned maintenance (look for wear or looseness)

Include brackets in sanitation verification (visual inspection and swab points where relevant)

Replace worn adjustment hardware early to maintain secure locking and consistent guide positioning

Clean, repeatable adjustment is a major advantage of swivel brackets—keep them maintained so they stay reliable.

FAQ: Swivel side guide brackets

What’s the advantage of a swivel side guide bracket vs a fixed bracket?

Swivel brackets allow controlled angular alignment, which improves guiding through curves and transitions and supports quicker setup for changing product formats.

Are stainless steel swivel brackets suitable for washdown conveyors?

Yes—when designed for hygienic use. Look for smooth surfaces, minimal crevices, and stainless grades appropriate for your cleaning chemistry (often 304 or 316).

Should I choose AISI 304 or AISI 316?

304 is common for general hygienic use. 316 is recommended for harsher washdown, salt/brine exposure, and aggressive detergents where corrosion risk is higher.

Call to action

Upgrade your guide system with stainless steel swivel side guide brackets engineered for hygienic conveyors—for cleaner changeovers, better product flow, and washdown-ready durability. Choose a smooth, easy-to-clean design and the right stainless grade to match your hygiene zone.

Get your catalogue here

Contáctenos

necesitas más información? Ponerse en contacto hoy. Le ayudaremos a encontrar el tipo de máquina y pie nivelador adecuados para sus necesidades.

Swivel Side Guide Brackets in Stainless Steel

When conveyors run in hygienic environments, product guiding must be stable, adjustable, and easy to clean—every single day. Soportes de guía laterales giratorios de acero inoxidable. are an essential hygienic conveyor component that keeps guide rails aligned while supporting quick format changes and reliable washdown performance.

Hygienic Conveyor Components for Washdown, Food & Pharma Lines

Unlike fixed brackets, swivel side guide brackets allow controlled angular adjustment. This makes them ideal for curves, transfers, infeed/outfeed zones, and applications where product shapes vary slightly. Combined with hygienic design principles and stainless steel durability, swivel brackets help reduce contamination risks, improve line efficiency, and support compliance-driven production.

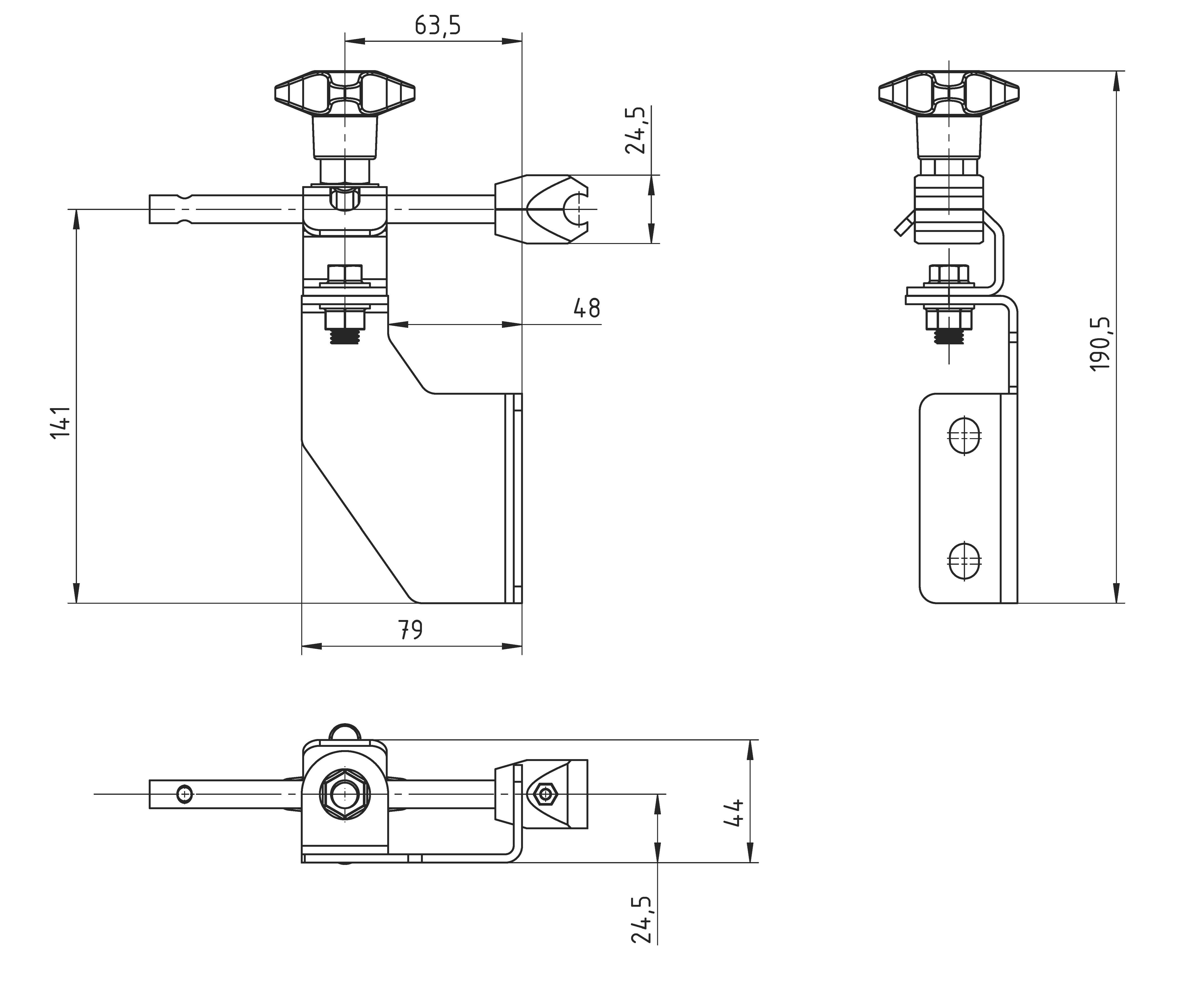

HSG 110 29/29 Hygienic swivel side guide brackets stainless steel

HSG 110 29/54 Hygienic swivel side guide brackets stainless steel

HSG 110 48/29 Hygienic swivel side guide brackets stainless steel

HSG 110 48/54 Hygienic swivel side guide brackets stainless steel

HSG 135 29/29 Hygienic swivel side guide brackets stainless steel

HSG 135 29/54 Hygienic swivel side guide brackets stainless steel

HSG 135 48/29 Hygienic swivel side guide brackets stainless steel

HSG 135 48/54 Hygienic swivel side guide brackets stainless steel

Why swivel side guide brackets matter on hygienic conveyors

Side guides do more than “hold a rail.” They protect throughput and product quality by:

preventing product tipping and jams

reducing scuffing, deformation, and packaging damage

keeping products centered for inspection, labeling, and packing steps

stabilizing flow through curves, merges, and transfer points

In washdown and high-care areas, the bracket itself must also support sanitation. Poorly designed brackets can create dirt traps, slow cleaning, and become a hidden hygiene risk.

Hygienic design features that support easier cleaning

A hygienic swivel bracket is defined as much by geometry as by material. The best designs focus on cleanability and contamination control:

Smooth surfaces: fewer places for residue, moisture, or biofilm to cling

Crevice-minimized construction: reduced gaps, pockets, and recesses

Open, accessible shape: easier rinsing, foaming, and visual inspection

Washdown-friendly hardware: fewer “dirt trap” fasteners and hard-to-reach interfaces

In practice, this means shorter cleaning cycles, better sanitation results, and less re-cleaning—especially important in regulated food and pharmaceutical environments.

Stainless steel options: AISI 304 vs AISI 316

Most hygienic conveyor components are offered in stainless steel grades suited to different environments:

AISI 304 (1.4301)

A strong all-round choice for many food, packaging, and general washdown applications. Good corrosion resistance and widely used across hygienic machinery components.

AISI 316 (1.4401 / 1.4404)

Preferred where the environment is more aggressive—salt exposure, brine, acidic products, or harsh detergents. If your cleaning chemistry is tough or your products contain chlorides (common in meat/seafood), 316 typically provides longer service life and better corrosion resistance.

Quick rule:

Elegir 304 for standard hygienic zones

Elegir 316 for harsher washdown, salt, or aggressive chemicals

Key benefits of stainless steel swivel side guide brackets

1) Faster, more reliable changeovers

Swivel adjustment supports quick repositioning of guide rails when switching product widths, formats, or packaging types—reducing downtime and setup variability.

2) Better guiding on curves and transitions

Swivel brackets are ideal where guides must follow conveyor geometry. They help maintain smooth product contact and reduce snagging at critical points.

3) Improved hygiene performance

Easy-to-clean design reduces residue build-up and supports consistent sanitation outcomes—especially in high-care food areas.

4) Washdown durability

Stainless steel construction withstands repeated cleaning cycles, moisture, and temperature swings—helping minimize maintenance and replacement frequency.

5) Increased line stability and product quality

A well-aligned guide system reduces jams, rework, and product damage—protecting throughput and OEE.

Typical industries and applications

Stainless steel swivel side guide brackets for hygienic conveyors are commonly used in:

Food processing & packaging: meat & poultry, dairy, seafood, bakery, ready meals, produce

Beverage and bottling lines: guiding through inspection, labeling, case packing

Pharmaceutical & biotech: hygienic transfer, secondary packaging, clean production zones

Medical/healthcare products: sanitary conveying and packing processes

They’re especially valuable where frequent washdown and tight hygiene standards are part of daily operations.

How to choose the right swivel side guide bracket

To select the best hygienic swivel bracket, match the component to your conveyor design and sanitation requirements:

Environment checklist

Is the bracket used in dry, wet, o full washdown zones?

Are you exposed to chlorides/salts or aggressive detergents?

Do you need 304 o 316 stainless steel?

Functional checklist

Do you need swivel adjustment for curves, angles, o variable product shapes?

Is tool-free adjustment required for operators (e.g., quick changeover routines)?

What level of rigidity is needed (high speed, vibration, heavy products)?

Interface checklist

Guide rail size and mounting type (tube, profile, frame)

Fastener type and locking method

Space constraints around the conveyor (cleaning access, guarding)

Tip: In hygienic lines, “easy to clean” often matters as much as load rating. A bracket that saves minutes per cleaning cycle can pay back quickly.

Installation and maintenance tips for hygienic performance

Set alignment under real production conditions (belt speed + product flow) before final tightening

Standardize tightening practice so guides don’t drift over time

Inspect swivel joints and contact points during planned maintenance (look for wear or looseness)

Include brackets in sanitation verification (visual inspection and swab points where relevant)

Replace worn adjustment hardware early to maintain secure locking and consistent guide positioning

Clean, repeatable adjustment is a major advantage of swivel brackets—keep them maintained so they stay reliable.

FAQ: Swivel side guide brackets

What’s the advantage of a swivel side guide bracket vs a fixed bracket?

Swivel brackets allow controlled angular alignment, which improves guiding through curves and transitions and supports quicker setup for changing product formats.

Are stainless steel swivel brackets suitable for washdown conveyors?

Yes—when designed for hygienic use. Look for smooth surfaces, minimal crevices, and stainless grades appropriate for your cleaning chemistry (often 304 or 316).

Should I choose AISI 304 or AISI 316?

304 is common for general hygienic use. 316 is recommended for harsher washdown, salt/brine exposure, and aggressive detergents where corrosion risk is higher.

Call to action

Upgrade your guide system with stainless steel swivel side guide brackets engineered for hygienic conveyors—for cleaner changeovers, better product flow, and washdown-ready durability. Choose a smooth, easy-to-clean design and the right stainless grade to match your hygiene zone.

Get your catalogue here

Swivel Side Guide Brackets in Stainless Steel

When conveyors run in hygienic environments, product guiding must be stable, adjustable, and easy to clean—every single day. Soportes de guía laterales giratorios de acero inoxidable. are an essential hygienic conveyor component that keeps guide rails aligned while supporting quick format changes and reliable washdown performance.

Hygienic Conveyor Components for Washdown, Food & Pharma Lines

Unlike fixed brackets, swivel side guide brackets allow controlled angular adjustment. This makes them ideal for curves, transfers, infeed/outfeed zones, and applications where product shapes vary slightly. Combined with hygienic design principles and stainless steel durability, swivel brackets help reduce contamination risks, improve line efficiency, and support compliance-driven production.

HSG 110 29/29 Hygienic swivel side guide brackets stainless steel

HSG 110 29/54 Hygienic swivel side guide brackets stainless steel

HSG 110 48/29 Hygienic swivel side guide brackets stainless steel

HSG 110 48/54 Hygienic swivel side guide brackets stainless steel

HSG 135 29/29 Hygienic swivel side guide brackets stainless steel

HSG 135 29/54 Hygienic swivel side guide brackets stainless steel

HSG 135 48/29 Hygienic swivel side guide brackets stainless steel

HSG 135 48/54 Hygienic swivel side guide brackets stainless steel

Why swivel side guide brackets matter on hygienic conveyors

Side guides do more than “hold a rail.” They protect throughput and product quality by:

preventing product tipping and jams

reducing scuffing, deformation, and packaging damage

keeping products centered for inspection, labeling, and packing steps

stabilizing flow through curves, merges, and transfer points

In washdown and high-care areas, the bracket itself must also support sanitation. Poorly designed brackets can create dirt traps, slow cleaning, and become a hidden hygiene risk.

Hygienic design features that support easier cleaning

A hygienic swivel bracket is defined as much by geometry as by material. The best designs focus on cleanability and contamination control:

Smooth surfaces: fewer places for residue, moisture, or biofilm to cling

Crevice-minimized construction: reduced gaps, pockets, and recesses

Open, accessible shape: easier rinsing, foaming, and visual inspection

Washdown-friendly hardware: fewer “dirt trap” fasteners and hard-to-reach interfaces

In practice, this means shorter cleaning cycles, better sanitation results, and less re-cleaning—especially important in regulated food and pharmaceutical environments.

Stainless steel options: AISI 304 vs AISI 316

Most hygienic conveyor components are offered in stainless steel grades suited to different environments:

AISI 304 (1.4301)

A strong all-round choice for many food, packaging, and general washdown applications. Good corrosion resistance and widely used across hygienic machinery components.

AISI 316 (1.4401 / 1.4404)

Preferred where the environment is more aggressive—salt exposure, brine, acidic products, or harsh detergents. If your cleaning chemistry is tough or your products contain chlorides (common in meat/seafood), 316 typically provides longer service life and better corrosion resistance.

Quick rule:

Elegir 304 for standard hygienic zones

Elegir 316 for harsher washdown, salt, or aggressive chemicals

Key benefits of stainless steel swivel side guide brackets

1) Faster, more reliable changeovers

Swivel adjustment supports quick repositioning of guide rails when switching product widths, formats, or packaging types—reducing downtime and setup variability.

2) Better guiding on curves and transitions

Swivel brackets are ideal where guides must follow conveyor geometry. They help maintain smooth product contact and reduce snagging at critical points.

3) Improved hygiene performance

Easy-to-clean design reduces residue build-up and supports consistent sanitation outcomes—especially in high-care food areas.

4) Washdown durability

Stainless steel construction withstands repeated cleaning cycles, moisture, and temperature swings—helping minimize maintenance and replacement frequency.

5) Increased line stability and product quality

A well-aligned guide system reduces jams, rework, and product damage—protecting throughput and OEE.

Typical industries and applications

Stainless steel swivel side guide brackets for hygienic conveyors are commonly used in:

Food processing & packaging: meat & poultry, dairy, seafood, bakery, ready meals, produce

Beverage and bottling lines: guiding through inspection, labeling, case packing

Pharmaceutical & biotech: hygienic transfer, secondary packaging, clean production zones

Medical/healthcare products: sanitary conveying and packing processes

They’re especially valuable where frequent washdown and tight hygiene standards are part of daily operations.

How to choose the right swivel side guide bracket

To select the best hygienic swivel bracket, match the component to your conveyor design and sanitation requirements:

Environment checklist

Is the bracket used in dry, wet, o full washdown zones?

Are you exposed to chlorides/salts or aggressive detergents?

Do you need 304 o 316 stainless steel?

Functional checklist

Do you need swivel adjustment for curves, angles, o variable product shapes?

Is tool-free adjustment required for operators (e.g., quick changeover routines)?

What level of rigidity is needed (high speed, vibration, heavy products)?

Interface checklist

Guide rail size and mounting type (tube, profile, frame)

Fastener type and locking method

Space constraints around the conveyor (cleaning access, guarding)

Tip: In hygienic lines, “easy to clean” often matters as much as load rating. A bracket that saves minutes per cleaning cycle can pay back quickly.

Installation and maintenance tips for hygienic performance

Set alignment under real production conditions (belt speed + product flow) before final tightening

Standardize tightening practice so guides don’t drift over time

Inspect swivel joints and contact points during planned maintenance (look for wear or looseness)

Include brackets in sanitation verification (visual inspection and swab points where relevant)

Replace worn adjustment hardware early to maintain secure locking and consistent guide positioning

Clean, repeatable adjustment is a major advantage of swivel brackets—keep them maintained so they stay reliable.

FAQ: Swivel side guide brackets

What’s the advantage of a swivel side guide bracket vs a fixed bracket?

Swivel brackets allow controlled angular alignment, which improves guiding through curves and transitions and supports quicker setup for changing product formats.

Are stainless steel swivel brackets suitable for washdown conveyors?

Yes—when designed for hygienic use. Look for smooth surfaces, minimal crevices, and stainless grades appropriate for your cleaning chemistry (often 304 or 316).

Should I choose AISI 304 or AISI 316?

304 is common for general hygienic use. 316 is recommended for harsher washdown, salt/brine exposure, and aggressive detergents where corrosion risk is higher.

Call to action

Upgrade your guide system with stainless steel swivel side guide brackets engineered for hygienic conveyors—for cleaner changeovers, better product flow, and washdown-ready durability. Choose a smooth, easy-to-clean design and the right stainless grade to match your hygiene zone.

Get your catalogue here

Contáctenos

necesitas más información? Ponerse en contacto hoy. Le ayudaremos a encontrar el tipo de máquina y pie nivelador adecuados para sus necesidades.