Kontaktiere uns

Benötigen Sie weitere Informationen? In Kontakt kommen Heute. Wir helfen Ihnen dabei, den richtigen Maschinentyp und Nivellierfuß für Ihre Anforderungen zu finden.

Side guide brackets stainless steel Sanitary conveyor components

Stainless Steel Side Guide Brackets

In sanitary production environments, product guidance must be accurate—and every component must support fast, reliable cleaning. Seitenführungshalterungen aus Edelstahl are a core part of a sanitary conveyor system, keeping products aligned while minimizing contamination risks in washdown zones.

Sanitary Conveyor Components for Clean, Efficient Production

Whether you run a food packaging line, a dairy process conveyor, or a pharmaceutical transport system, the right sanitary conveyor components help reduce downtime, simplify sanitation, and protect product quality. That’s exactly where sanitary stainless steel side guide brackets deliver value: clean design, strong performance, and quick adjustment when your line needs flexibility.

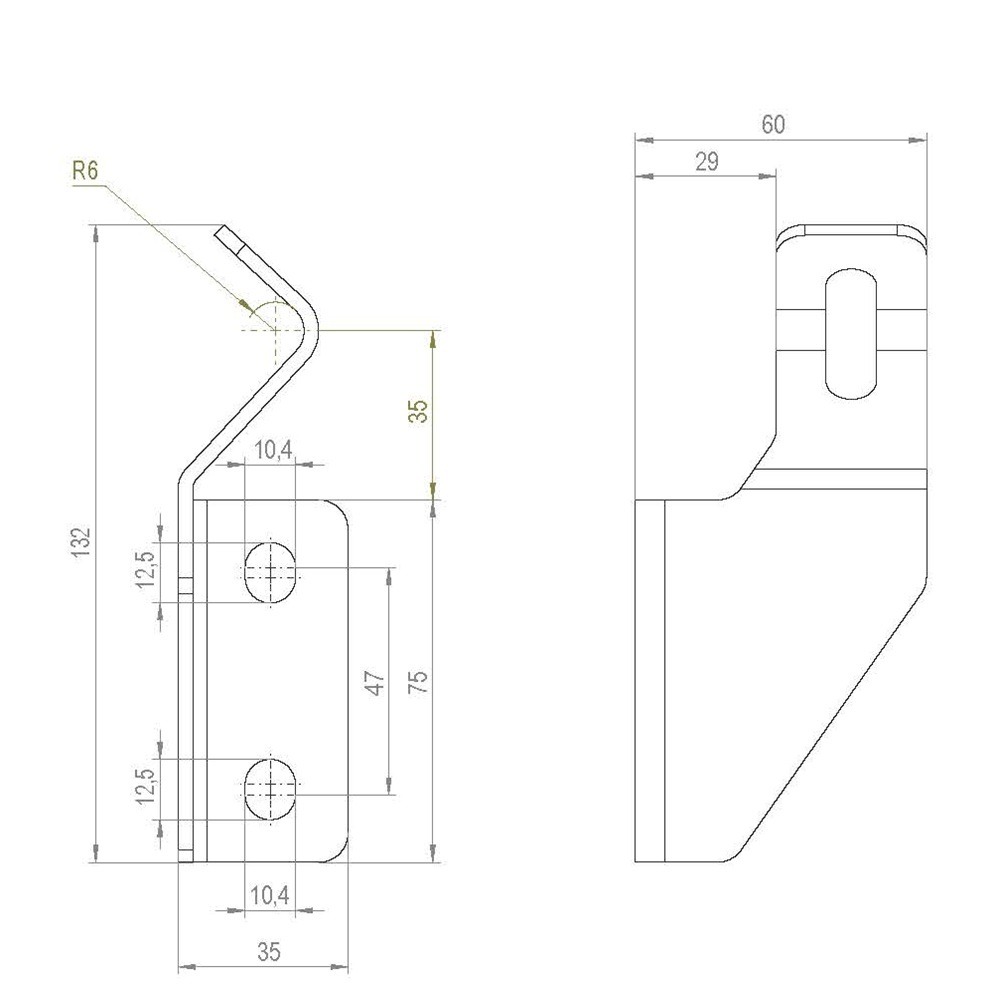

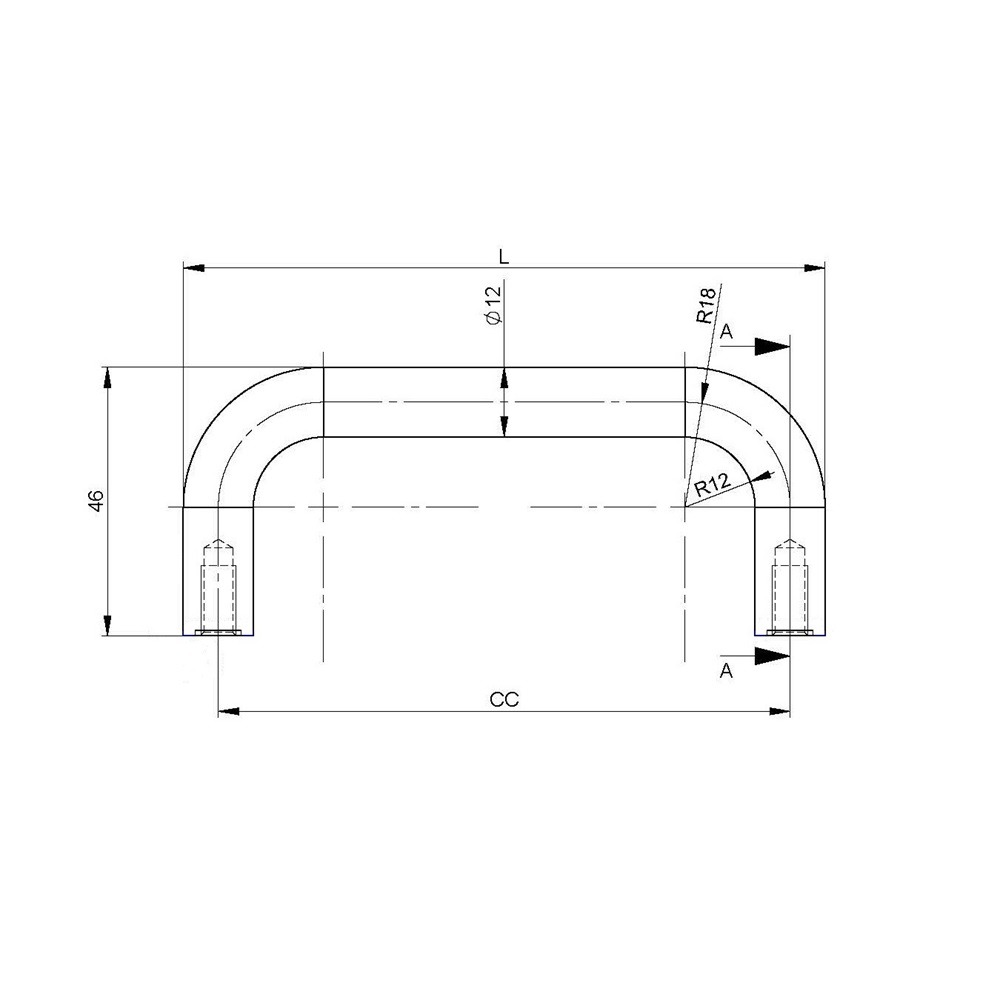

SG 132 29 Sanitary side guide brackets stainless steel

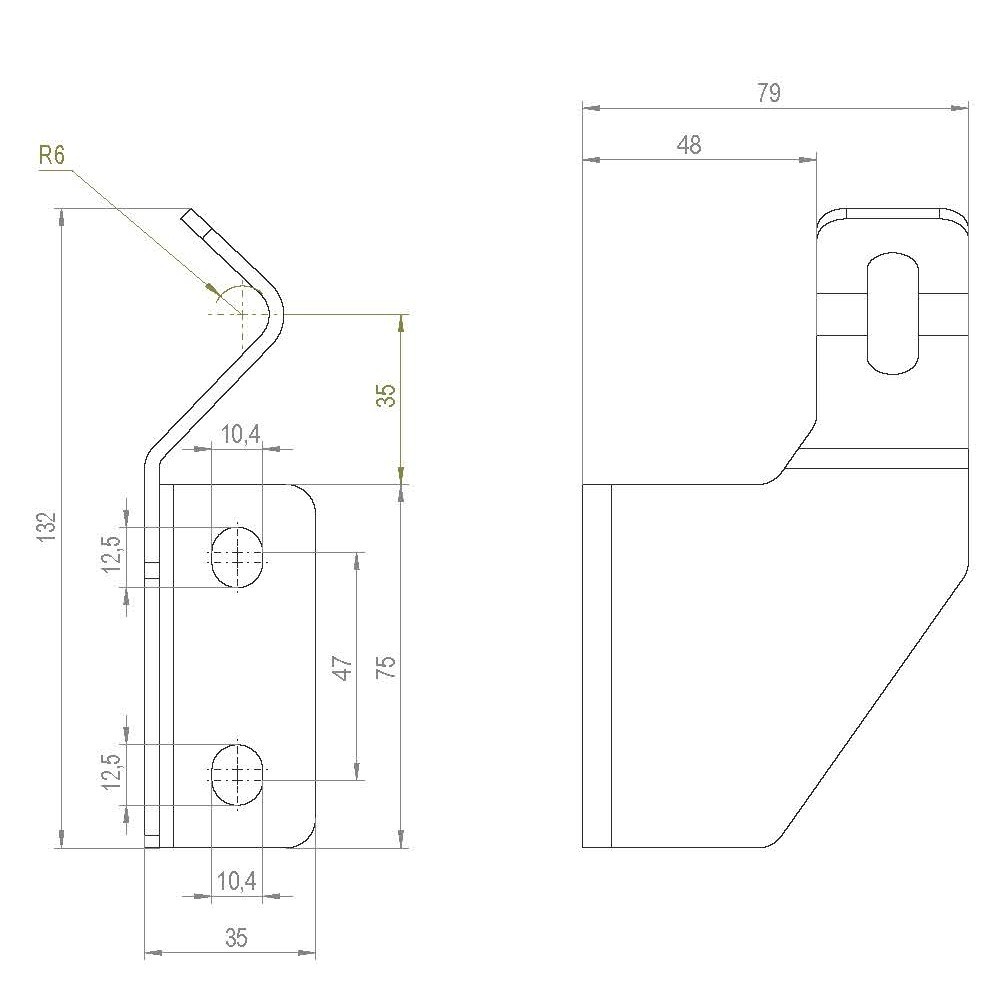

SG 132 48 Sanitary side guide brackets stainless steel

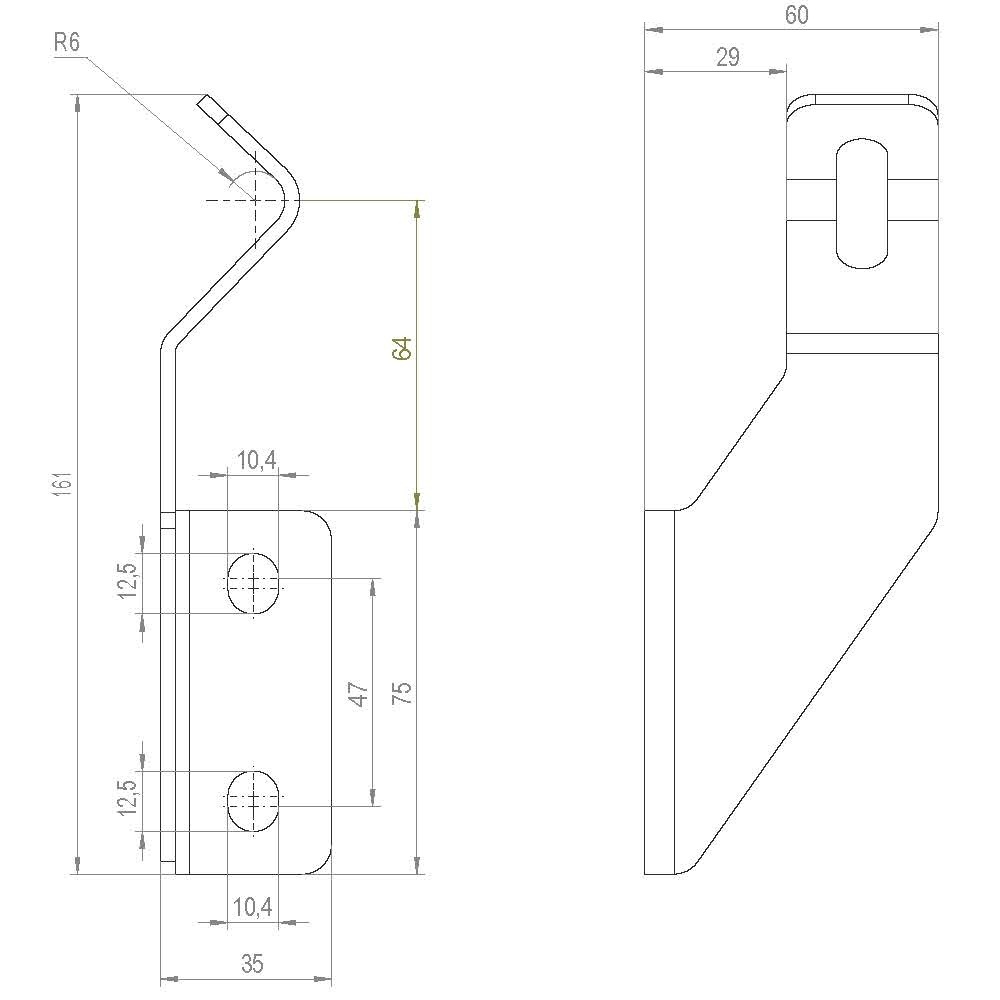

SG 161 29 Sanitary side guide brackets stainless steel

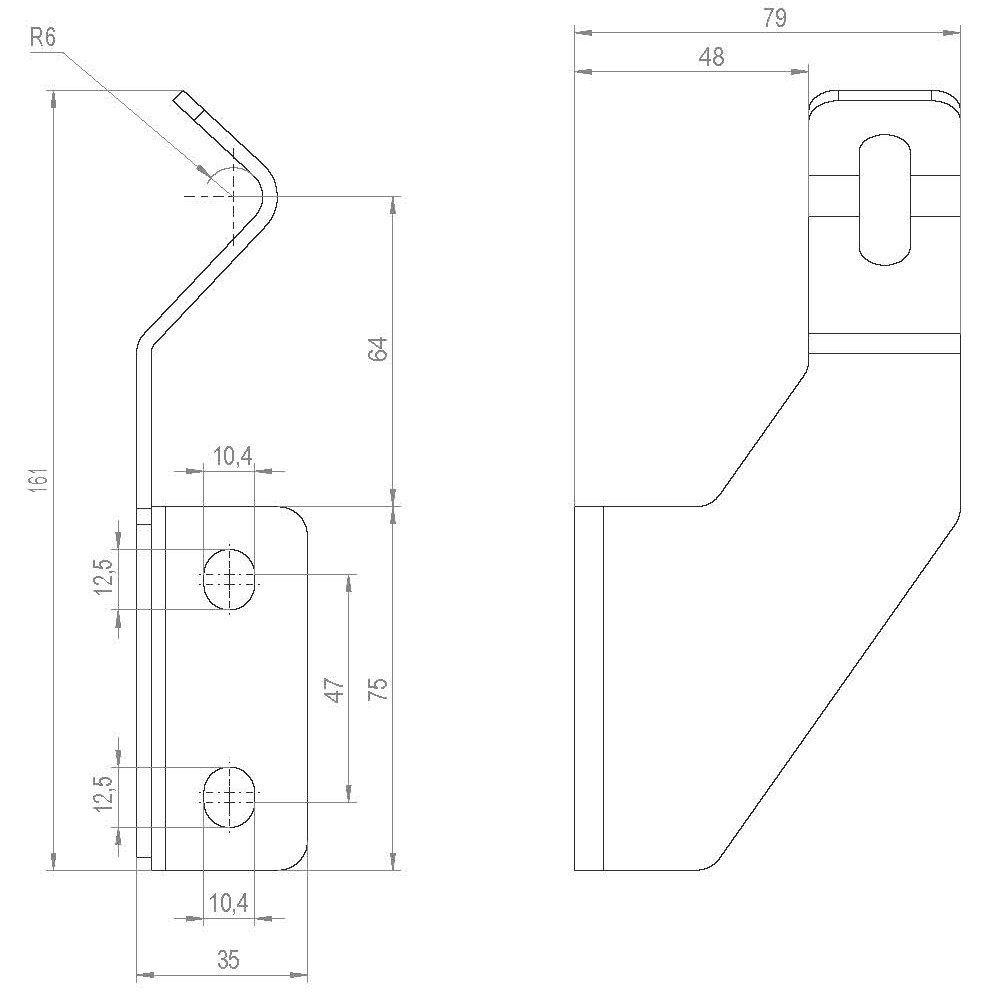

SG 161 48 Sanitary side guide brackets stainless steel

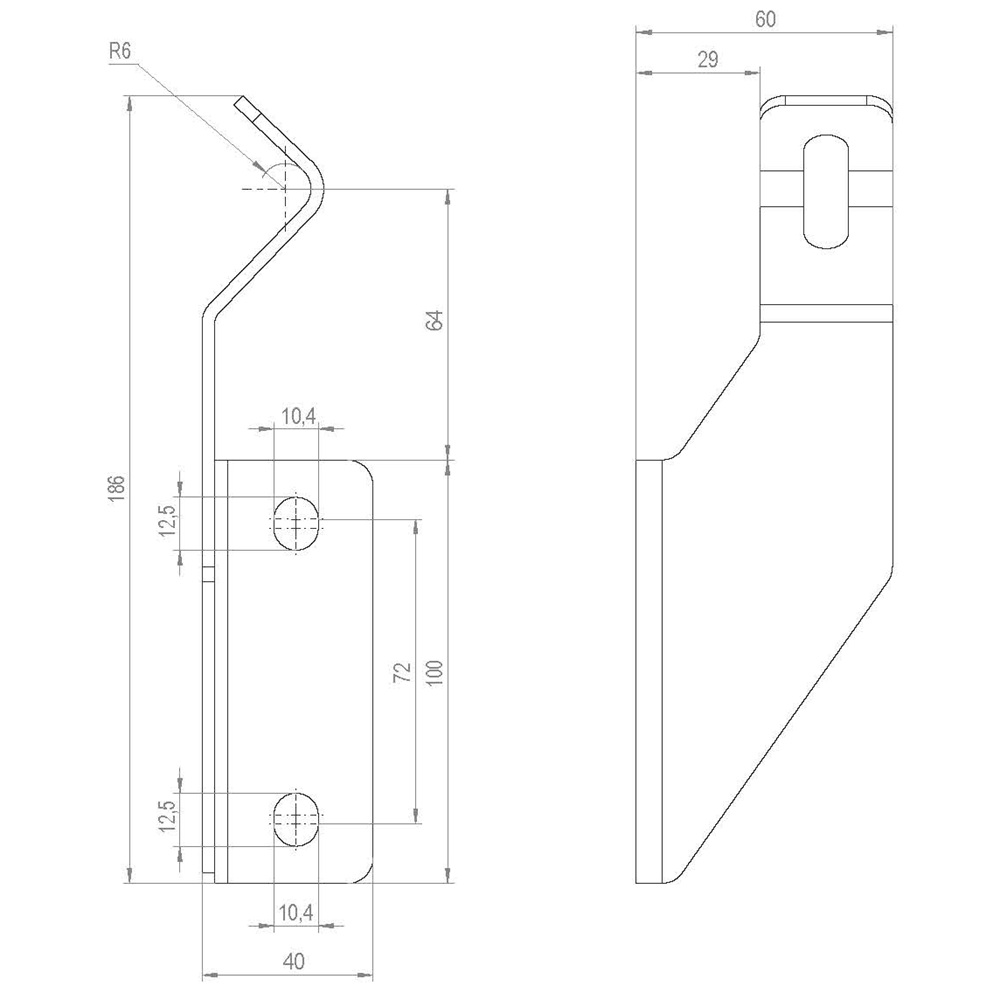

SG 186 29 Sanitary side guide brackets stainless steel

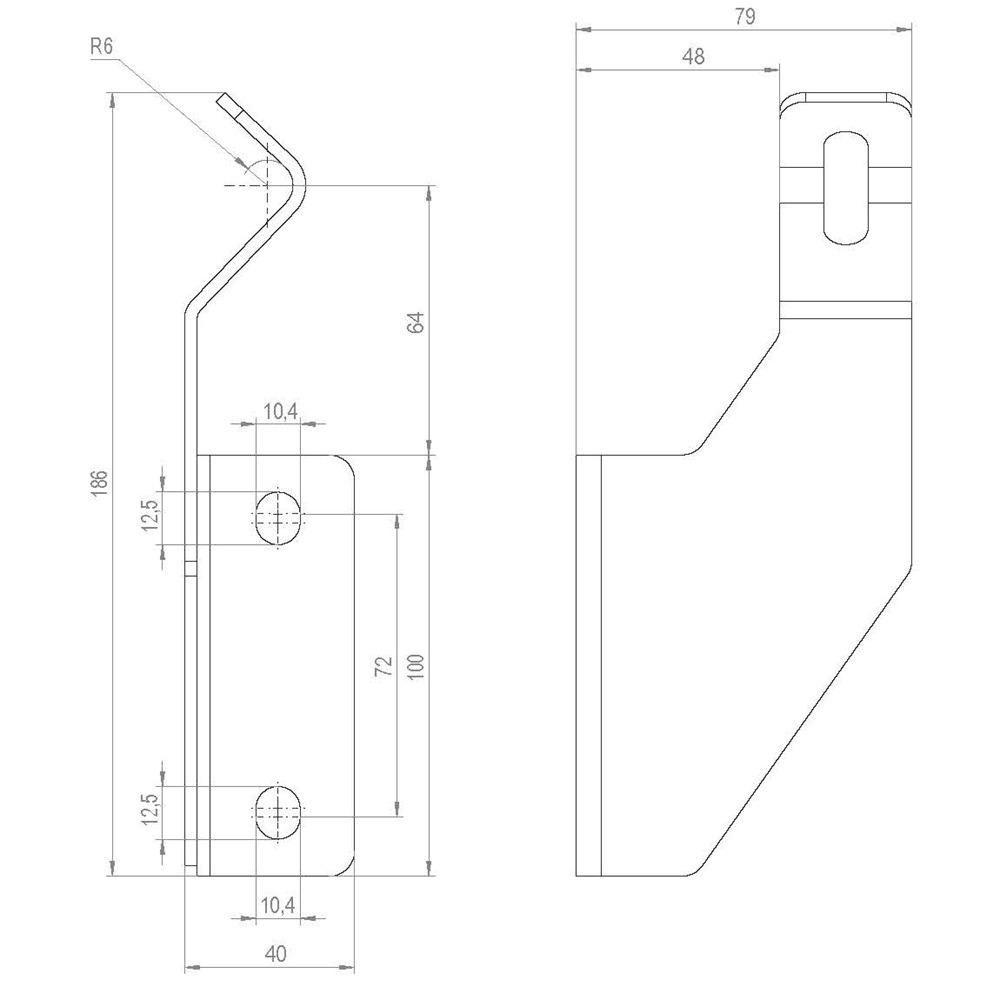

SG 186 48 Sanitary side guide brackets stainless steel

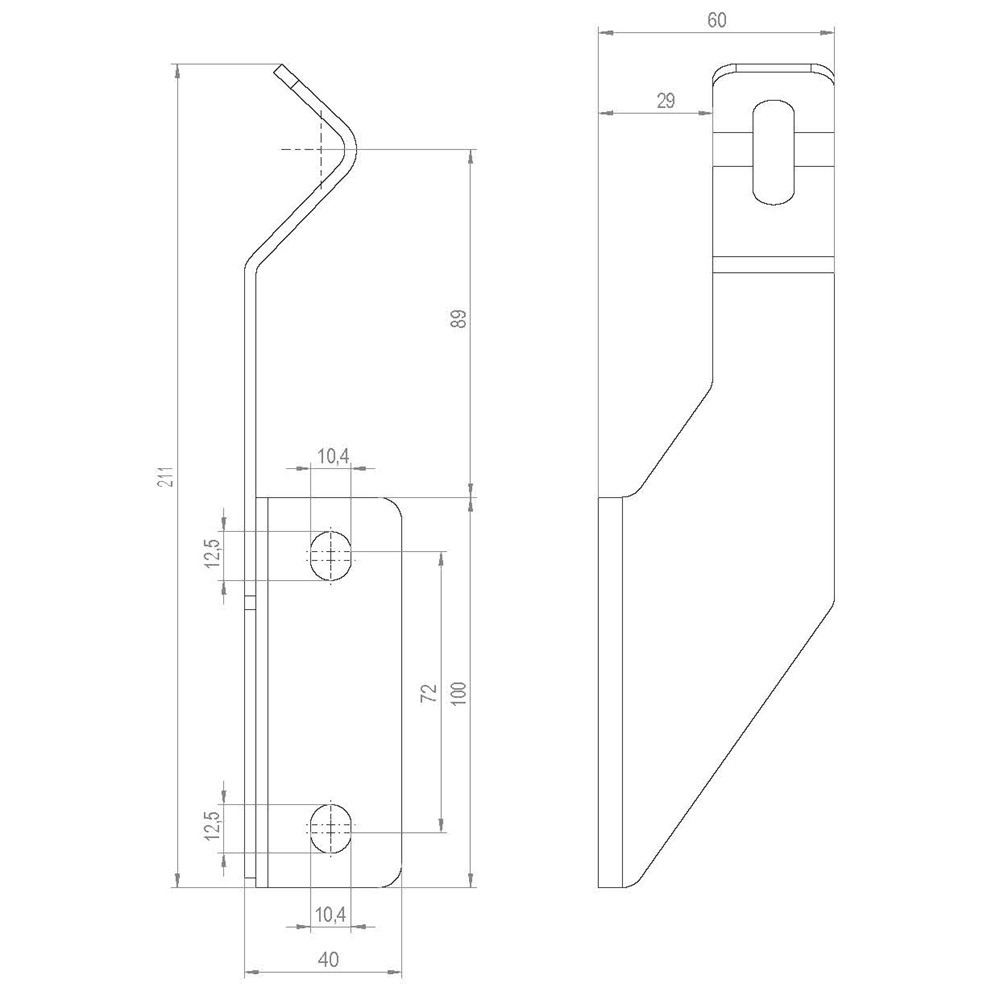

SG 211 29 Sanitary side guide brackets stainless steel

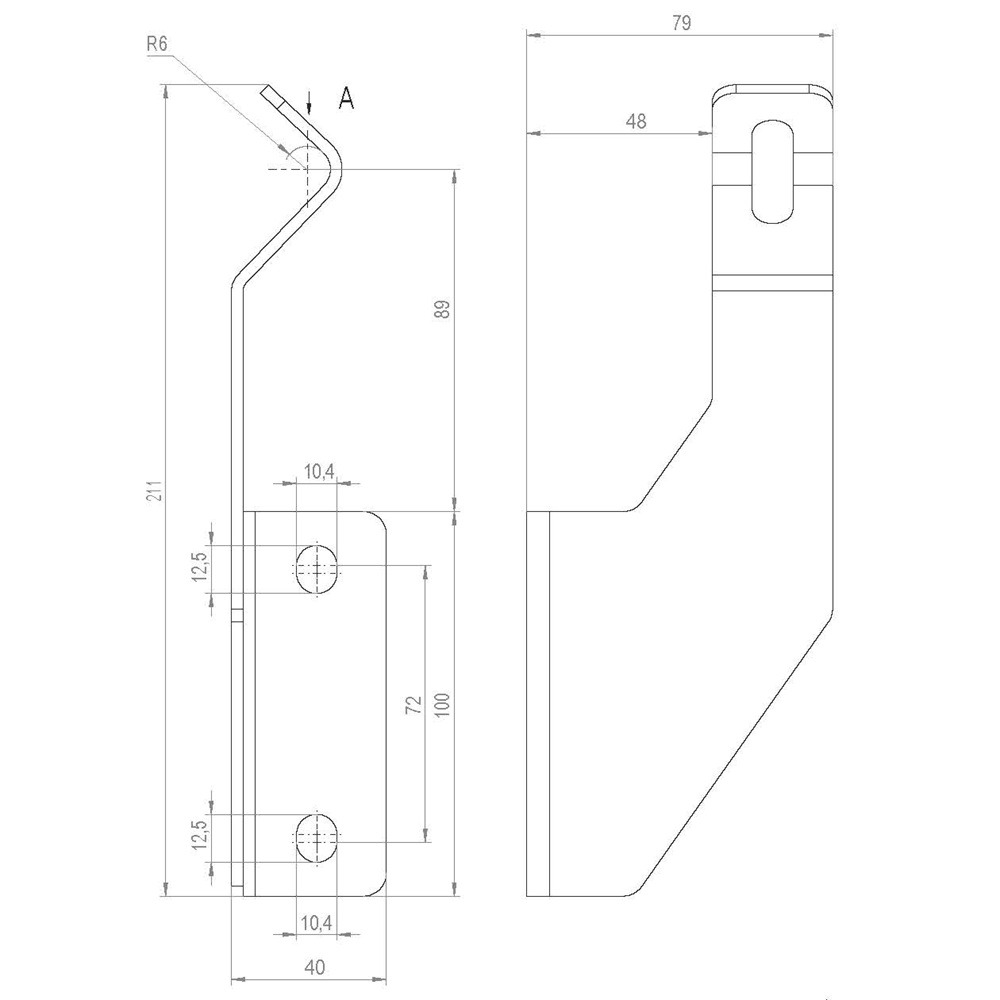

SG 211 48 Sanitary side guide brackets stainless steel

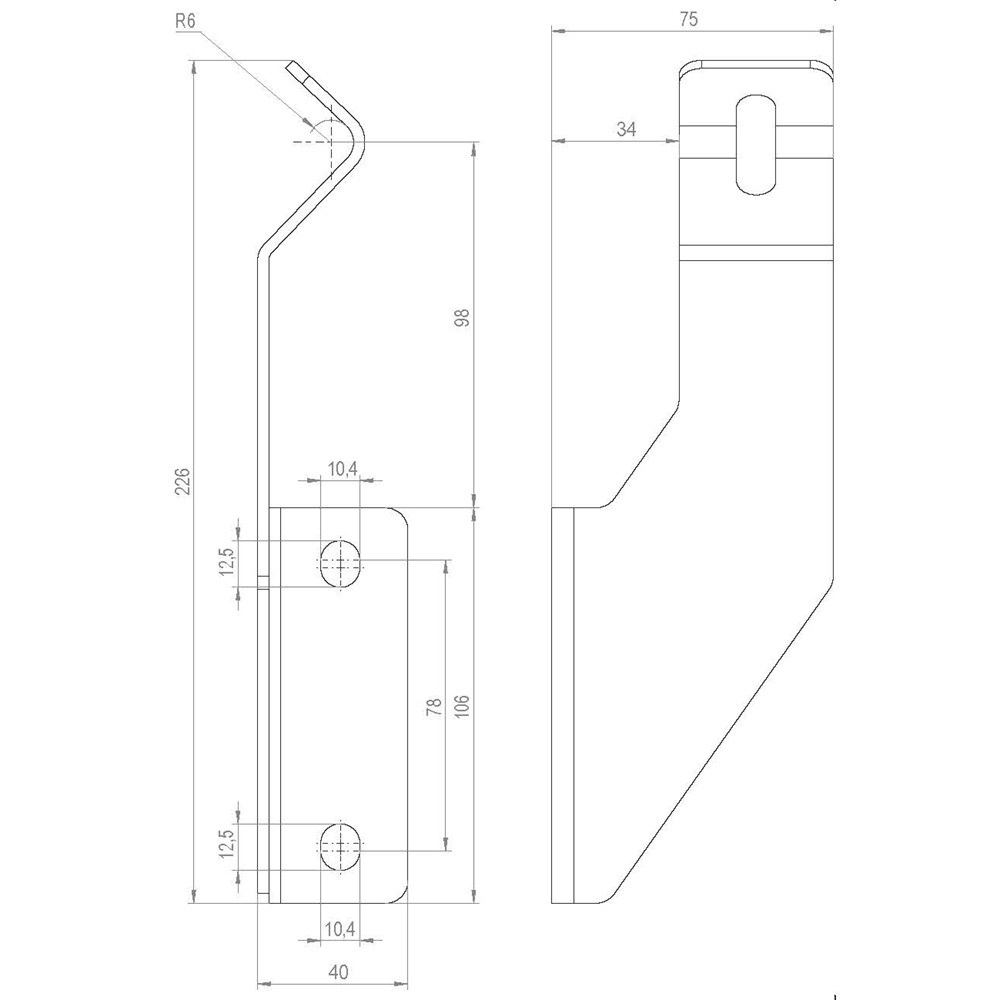

SG 226 34 Sanitary side guide brackets stainless steel

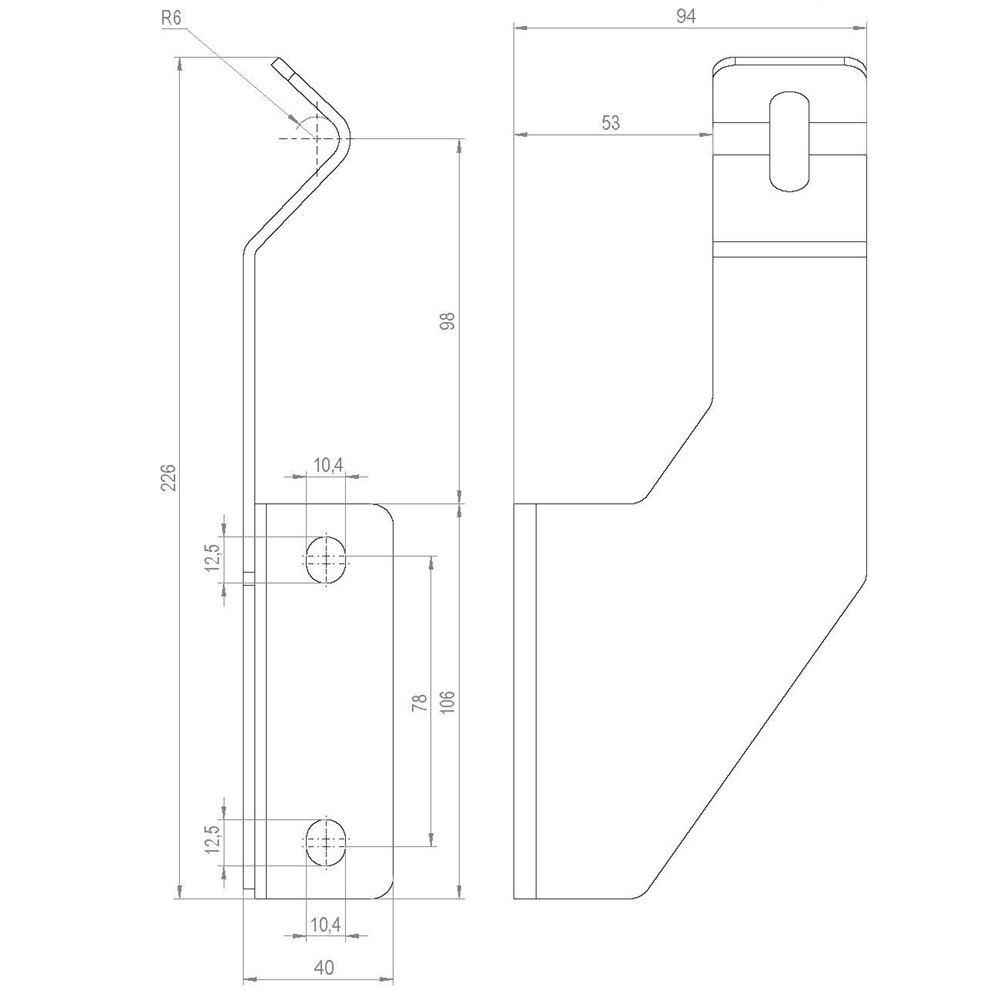

SG 226 53 Sanitary side guide brackets stainless steel

What are side guide brackets used for?

Side guide brackets hold and position guide rails along a conveyor to:

keep products centered and stable

prevent tipping, scuffing, and jams

support smooth flow through curves, transfers, and infeed/outfeed zones

enable fast format changeovers for different products and pack sizes

Because they sit close to product flow (and often in splash zones), side guide brackets must be easy to clean and resistant to corrosion.

Why stainless steel is the sanitary standard

Sanitary conveyors operate under frequent cleaning, chemicals, and moisture—conditions that quickly damage standard materials.

Seitenführungshalterungen aus Edelstahl offer:

Korrosionsbeständigkeit in wet and washdown environments

Durability under cleaning chemicals and repeated thermal cycles

Mechanische Festigkeit for stable guiding at higher conveyor speeds

Long service life, reducing replacement costs and maintenance stops

AISI 304 vs AISI 316 (quick guide)

AISI 304 (1.4301): excellent for general food and packaging areas

AISI 316 (1.4401 / 1.4404): better for salt, brine, aggressive detergents, and harsh washdown zones

If you handle salty products (meat, seafood, snacks) or use strong chemicals, 316 can be the smarter long-term choice.

Sanitary design: what makes a bracket “easy-to-clean”

Not all stainless brackets are sanitary. True sanitary conveyor components focus on geometry that prevents buildup and supports faster cleaning.

Look for brackets with:

glatte Oberflächen that rinse clean quickly

minimal crevices and recesses where residue can accumulate

open, accessible shapes for visual inspection and sanitation checks

reduced dirt traps around joints, fasteners, and contact points

This helps reduce water usage, shorten sanitation windows, and lower contamination risk—especially in high-risk food zones.

Key benefits of sanitary side guide brackets on conveyors

Cleaner line, less downtime

Easy-to-clean bracket design supports quicker washdowns and less re-cleaning—so you start production faster.

Improved product flow and less waste

Stable guides reduce product tipping, edge damage, and misalignment at critical points like transfers and infeed zones.

Faster changeovers

Adjustable brackets (often with ergonomic hand knobs) let operators reposition guides quickly for new SKUs.

Stronger performance in washdown areas

Sanitary stainless brackets maintain strength and alignment even under vibration, temperature shifts, and repeated cleaning cycles.

Common industries and applications

Stainless steel side guide brackets for sanitary conveyors werden häufig verwendet in:

Food processing & packaging: dairy, meat & poultry, seafood, ready meals, bakery, produce

Beverage & bottling lines: alignment through inspection, labeling, and packing areas

Pharmaceutical & biotech: sanitary handling and secondary packaging

Medical and healthcare products: clean manufacturing and packaging zones

Choosing the right side guide bracket for your conveyor

When selecting a sanitary side guide bracket, match the component to your operating environment and conveyor layout:

Sanitation level: dry area vs washdown zone vs aggressive chemical cleaning

Material grade: AISI 304 or AISI 316

Bracket type: fixed, adjustable, or swivel for curves/angles

Mounting system: tube/frame/profile compatibility

Load and stability: product weight, belt speed, vibration points

Operator handling: tool-free adjustment vs set-and-forget configuration

A good bracket should stay rigid during production, but adjust quickly when you change format.

Maintenance and sanitation tips

Inspect contact points and fasteners during planned cleaning

Standardize tightening procedure to prevent guide drift over time

Replace worn knobs, bushings, or seals early to keep locking reliable

Include brackets in your hygiene verification plan (visual checks + swabs when needed)

FAQ: Stainless steel side guide brackets

Are stainless side guide brackets compliant with sanitary requirements?

They support sanitary operations when made from appropriate stainless grades and designed for easy cleaning with minimal crevices. Compliance depends on your plant standards and validation process.

Do I need swivel side guide brackets?

Swivel versions are ideal for curves, angled guiding, or applications where products vary slightly in shape and need adaptable guiding.

How do I decide between 304 and 316?

Choose 316 for harsh washdown, salt exposure, and aggressive chemicals. Choose 304 for general sanitary areas with less corrosive exposure.

Call to action

Upgrade your conveyor guiding system with stainless steel side guide brackets designed for sanitary production. You’ll get cleaner changeovers, smoother product flow, and components built to withstand washdown—helping protect product quality while reducing downtime.

Get your catalogue here

Kontaktiere uns

Benötigen Sie weitere Informationen? In Kontakt kommen Heute. Wir helfen Ihnen dabei, den richtigen Maschinentyp und Nivellierfuß für Ihre Anforderungen zu finden.

Stainless Steel Side Guide Brackets

In sanitary production environments, product guidance must be accurate—and every component must support fast, reliable cleaning. Seitenführungshalterungen aus Edelstahl are a core part of a sanitary conveyor system, keeping products aligned while minimizing contamination risks in washdown zones.

Sanitary Conveyor Components for Clean, Efficient Production

Whether you run a food packaging line, a dairy process conveyor, or a pharmaceutical transport system, the right sanitary conveyor components help reduce downtime, simplify sanitation, and protect product quality. That’s exactly where sanitary stainless steel side guide brackets deliver value: clean design, strong performance, and quick adjustment when your line needs flexibility.

SG 132 29 Sanitary side guide brackets stainless steel

SG 132 48 Sanitary side guide brackets stainless steel

SG 161 29 Sanitary side guide brackets stainless steel

SG 161 48 Sanitary side guide brackets stainless steel

SG 186 29 Sanitary side guide brackets stainless steel

SG 186 48 Sanitary side guide brackets stainless steel

SG 211 29 Sanitary side guide brackets stainless steel

SG 211 48 Sanitary side guide brackets stainless steel

SG 226 34 Sanitary side guide brackets stainless steel

SG 226 53 Sanitary side guide brackets stainless steel

What are side guide brackets used for?

Side guide brackets hold and position guide rails along a conveyor to:

keep products centered and stable

prevent tipping, scuffing, and jams

support smooth flow through curves, transfers, and infeed/outfeed zones

enable fast format changeovers for different products and pack sizes

Because they sit close to product flow (and often in splash zones), side guide brackets must be easy to clean and resistant to corrosion.

Why stainless steel is the sanitary standard

Sanitary conveyors operate under frequent cleaning, chemicals, and moisture—conditions that quickly damage standard materials.

Seitenführungshalterungen aus Edelstahl offer:

Korrosionsbeständigkeit in wet and washdown environments

Durability under cleaning chemicals and repeated thermal cycles

Mechanische Festigkeit for stable guiding at higher conveyor speeds

Long service life, reducing replacement costs and maintenance stops

AISI 304 vs AISI 316 (quick guide)

AISI 304 (1.4301): excellent for general food and packaging areas

AISI 316 (1.4401 / 1.4404): better for salt, brine, aggressive detergents, and harsh washdown zones

If you handle salty products (meat, seafood, snacks) or use strong chemicals, 316 can be the smarter long-term choice.

Sanitary design: what makes a bracket “easy-to-clean”

Not all stainless brackets are sanitary. True sanitary conveyor components focus on geometry that prevents buildup and supports faster cleaning.

Look for brackets with:

glatte Oberflächen that rinse clean quickly

minimal crevices and recesses where residue can accumulate

open, accessible shapes for visual inspection and sanitation checks

reduced dirt traps around joints, fasteners, and contact points

This helps reduce water usage, shorten sanitation windows, and lower contamination risk—especially in high-risk food zones.

Key benefits of sanitary side guide brackets on conveyors

Cleaner line, less downtime

Easy-to-clean bracket design supports quicker washdowns and less re-cleaning—so you start production faster.

Improved product flow and less waste

Stable guides reduce product tipping, edge damage, and misalignment at critical points like transfers and infeed zones.

Faster changeovers

Adjustable brackets (often with ergonomic hand knobs) let operators reposition guides quickly for new SKUs.

Stronger performance in washdown areas

Sanitary stainless brackets maintain strength and alignment even under vibration, temperature shifts, and repeated cleaning cycles.

Common industries and applications

Stainless steel side guide brackets for sanitary conveyors werden häufig verwendet in:

Food processing & packaging: dairy, meat & poultry, seafood, ready meals, bakery, produce

Beverage & bottling lines: alignment through inspection, labeling, and packing areas

Pharmaceutical & biotech: sanitary handling and secondary packaging

Medical and healthcare products: clean manufacturing and packaging zones

Choosing the right side guide bracket for your conveyor

When selecting a sanitary side guide bracket, match the component to your operating environment and conveyor layout:

Sanitation level: dry area vs washdown zone vs aggressive chemical cleaning

Material grade: AISI 304 or AISI 316

Bracket type: fixed, adjustable, or swivel for curves/angles

Mounting system: tube/frame/profile compatibility

Load and stability: product weight, belt speed, vibration points

Operator handling: tool-free adjustment vs set-and-forget configuration

A good bracket should stay rigid during production, but adjust quickly when you change format.

Maintenance and sanitation tips

Inspect contact points and fasteners during planned cleaning

Standardize tightening procedure to prevent guide drift over time

Replace worn knobs, bushings, or seals early to keep locking reliable

Include brackets in your hygiene verification plan (visual checks + swabs when needed)

FAQ: Stainless steel side guide brackets

Are stainless side guide brackets compliant with sanitary requirements?

They support sanitary operations when made from appropriate stainless grades and designed for easy cleaning with minimal crevices. Compliance depends on your plant standards and validation process.

Do I need swivel side guide brackets?

Swivel versions are ideal for curves, angled guiding, or applications where products vary slightly in shape and need adaptable guiding.

How do I decide between 304 and 316?

Choose 316 for harsh washdown, salt exposure, and aggressive chemicals. Choose 304 for general sanitary areas with less corrosive exposure.

Call to action

Upgrade your conveyor guiding system with stainless steel side guide brackets designed for sanitary production. You’ll get cleaner changeovers, smoother product flow, and components built to withstand washdown—helping protect product quality while reducing downtime.

Get your catalogue here

Stainless Steel Side Guide Brackets

In sanitary production environments, product guidance must be accurate—and every component must support fast, reliable cleaning. Seitenführungshalterungen aus Edelstahl are a core part of a sanitary conveyor system, keeping products aligned while minimizing contamination risks in washdown zones.

Sanitary Conveyor Components for Clean, Efficient Production

Whether you run a food packaging line, a dairy process conveyor, or a pharmaceutical transport system, the right sanitary conveyor components help reduce downtime, simplify sanitation, and protect product quality. That’s exactly where sanitary stainless steel side guide brackets deliver value: clean design, strong performance, and quick adjustment when your line needs flexibility.

SG 132 29 Sanitary side guide brackets stainless steel

SG 132 48 Sanitary side guide brackets stainless steel

SG 161 29 Sanitary side guide brackets stainless steel

SG 161 48 Sanitary side guide brackets stainless steel

SG 186 29 Sanitary side guide brackets stainless steel

SG 186 48 Sanitary side guide brackets stainless steel

SG 211 29 Sanitary side guide brackets stainless steel

SG 211 48 Sanitary side guide brackets stainless steel

SG 226 34 Sanitary side guide brackets stainless steel

SG 226 53 Sanitary side guide brackets stainless steel

What are side guide brackets used for?

Side guide brackets hold and position guide rails along a conveyor to:

keep products centered and stable

prevent tipping, scuffing, and jams

support smooth flow through curves, transfers, and infeed/outfeed zones

enable fast format changeovers for different products and pack sizes

Because they sit close to product flow (and often in splash zones), side guide brackets must be easy to clean and resistant to corrosion.

Why stainless steel is the sanitary standard

Sanitary conveyors operate under frequent cleaning, chemicals, and moisture—conditions that quickly damage standard materials.

Seitenführungshalterungen aus Edelstahl offer:

Korrosionsbeständigkeit in wet and washdown environments

Durability under cleaning chemicals and repeated thermal cycles

Mechanische Festigkeit for stable guiding at higher conveyor speeds

Long service life, reducing replacement costs and maintenance stops

AISI 304 vs AISI 316 (quick guide)

AISI 304 (1.4301): excellent for general food and packaging areas

AISI 316 (1.4401 / 1.4404): better for salt, brine, aggressive detergents, and harsh washdown zones

If you handle salty products (meat, seafood, snacks) or use strong chemicals, 316 can be the smarter long-term choice.

Sanitary design: what makes a bracket “easy-to-clean”

Not all stainless brackets are sanitary. True sanitary conveyor components focus on geometry that prevents buildup and supports faster cleaning.

Look for brackets with:

glatte Oberflächen that rinse clean quickly

minimal crevices and recesses where residue can accumulate

open, accessible shapes for visual inspection and sanitation checks

reduced dirt traps around joints, fasteners, and contact points

This helps reduce water usage, shorten sanitation windows, and lower contamination risk—especially in high-risk food zones.

Key benefits of sanitary side guide brackets on conveyors

Cleaner line, less downtime

Easy-to-clean bracket design supports quicker washdowns and less re-cleaning—so you start production faster.

Improved product flow and less waste

Stable guides reduce product tipping, edge damage, and misalignment at critical points like transfers and infeed zones.

Faster changeovers

Adjustable brackets (often with ergonomic hand knobs) let operators reposition guides quickly for new SKUs.

Stronger performance in washdown areas

Sanitary stainless brackets maintain strength and alignment even under vibration, temperature shifts, and repeated cleaning cycles.

Common industries and applications

Stainless steel side guide brackets for sanitary conveyors werden häufig verwendet in:

Food processing & packaging: dairy, meat & poultry, seafood, ready meals, bakery, produce

Beverage & bottling lines: alignment through inspection, labeling, and packing areas

Pharmaceutical & biotech: sanitary handling and secondary packaging

Medical and healthcare products: clean manufacturing and packaging zones

Choosing the right side guide bracket for your conveyor

When selecting a sanitary side guide bracket, match the component to your operating environment and conveyor layout:

Sanitation level: dry area vs washdown zone vs aggressive chemical cleaning

Material grade: AISI 304 or AISI 316

Bracket type: fixed, adjustable, or swivel for curves/angles

Mounting system: tube/frame/profile compatibility

Load and stability: product weight, belt speed, vibration points

Operator handling: tool-free adjustment vs set-and-forget configuration

A good bracket should stay rigid during production, but adjust quickly when you change format.

Maintenance and sanitation tips

Inspect contact points and fasteners during planned cleaning

Standardize tightening procedure to prevent guide drift over time

Replace worn knobs, bushings, or seals early to keep locking reliable

Include brackets in your hygiene verification plan (visual checks + swabs when needed)

FAQ: Stainless steel side guide brackets

Are stainless side guide brackets compliant with sanitary requirements?

They support sanitary operations when made from appropriate stainless grades and designed for easy cleaning with minimal crevices. Compliance depends on your plant standards and validation process.

Do I need swivel side guide brackets?

Swivel versions are ideal for curves, angled guiding, or applications where products vary slightly in shape and need adaptable guiding.

How do I decide between 304 and 316?

Choose 316 for harsh washdown, salt exposure, and aggressive chemicals. Choose 304 for general sanitary areas with less corrosive exposure.

Call to action

Upgrade your conveyor guiding system with stainless steel side guide brackets designed for sanitary production. You’ll get cleaner changeovers, smoother product flow, and components built to withstand washdown—helping protect product quality while reducing downtime.

Get your catalogue here

Kontaktiere uns

Benötigen Sie weitere Informationen? In Kontakt kommen Heute. Wir helfen Ihnen dabei, den richtigen Maschinentyp und Nivellierfuß für Ihre Anforderungen zu finden.