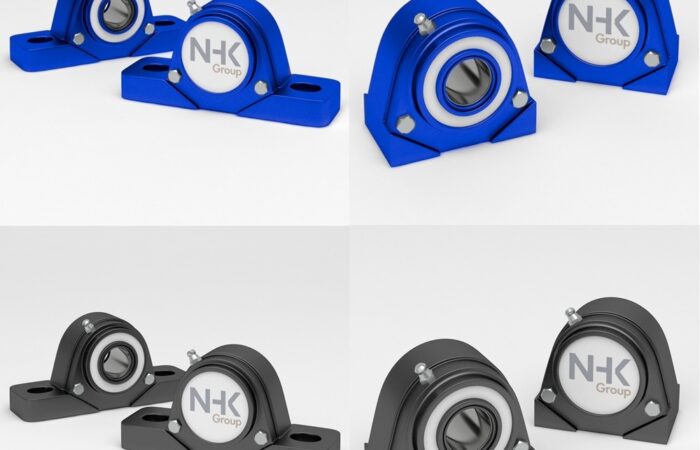

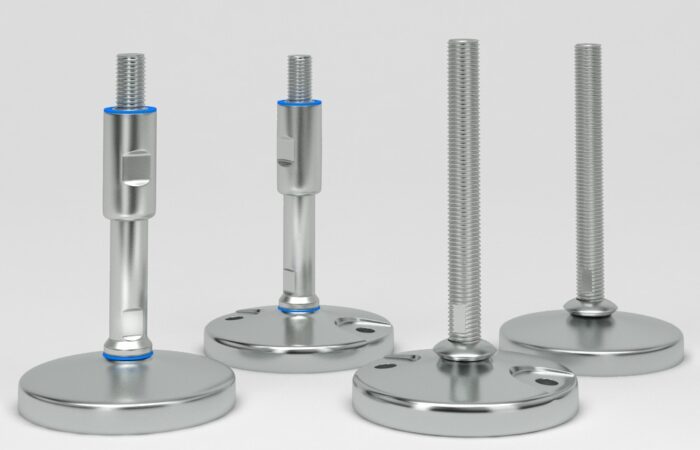

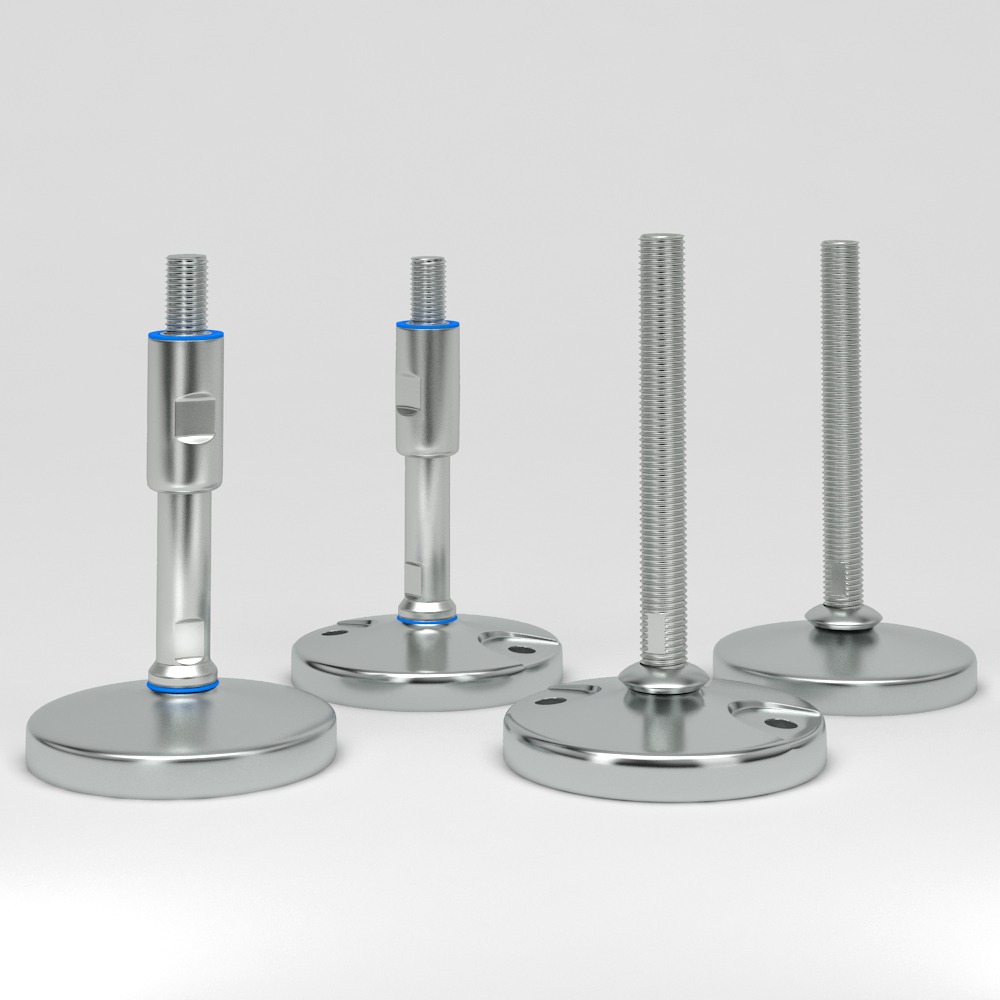

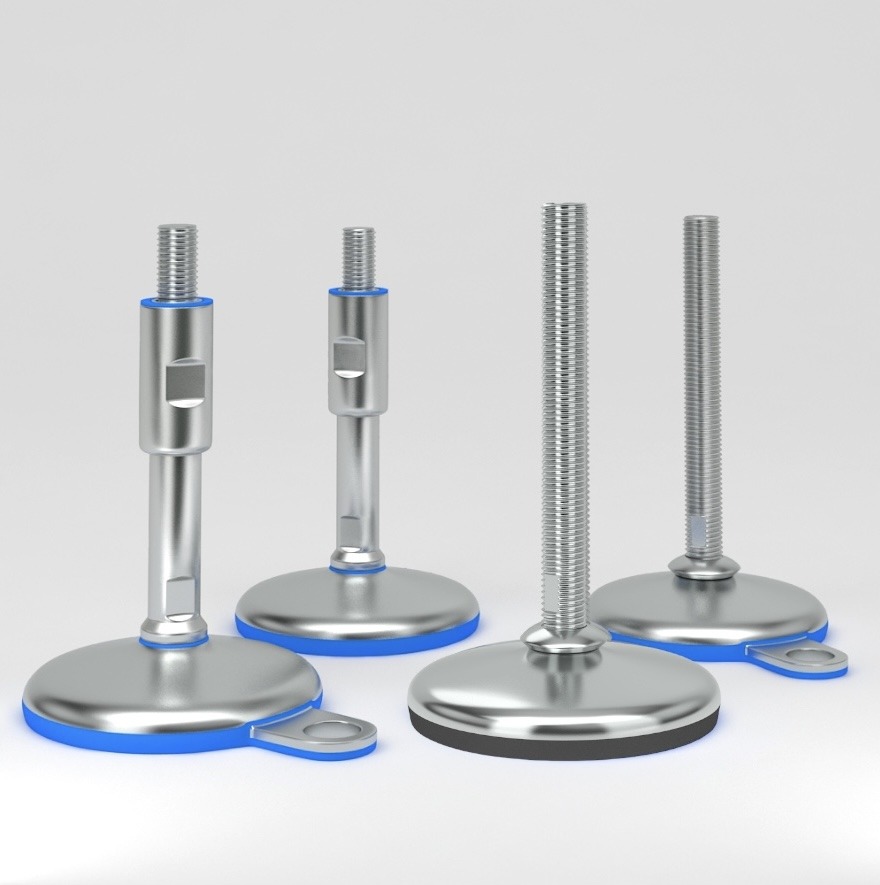

Heavy duty stainless steel machine feet

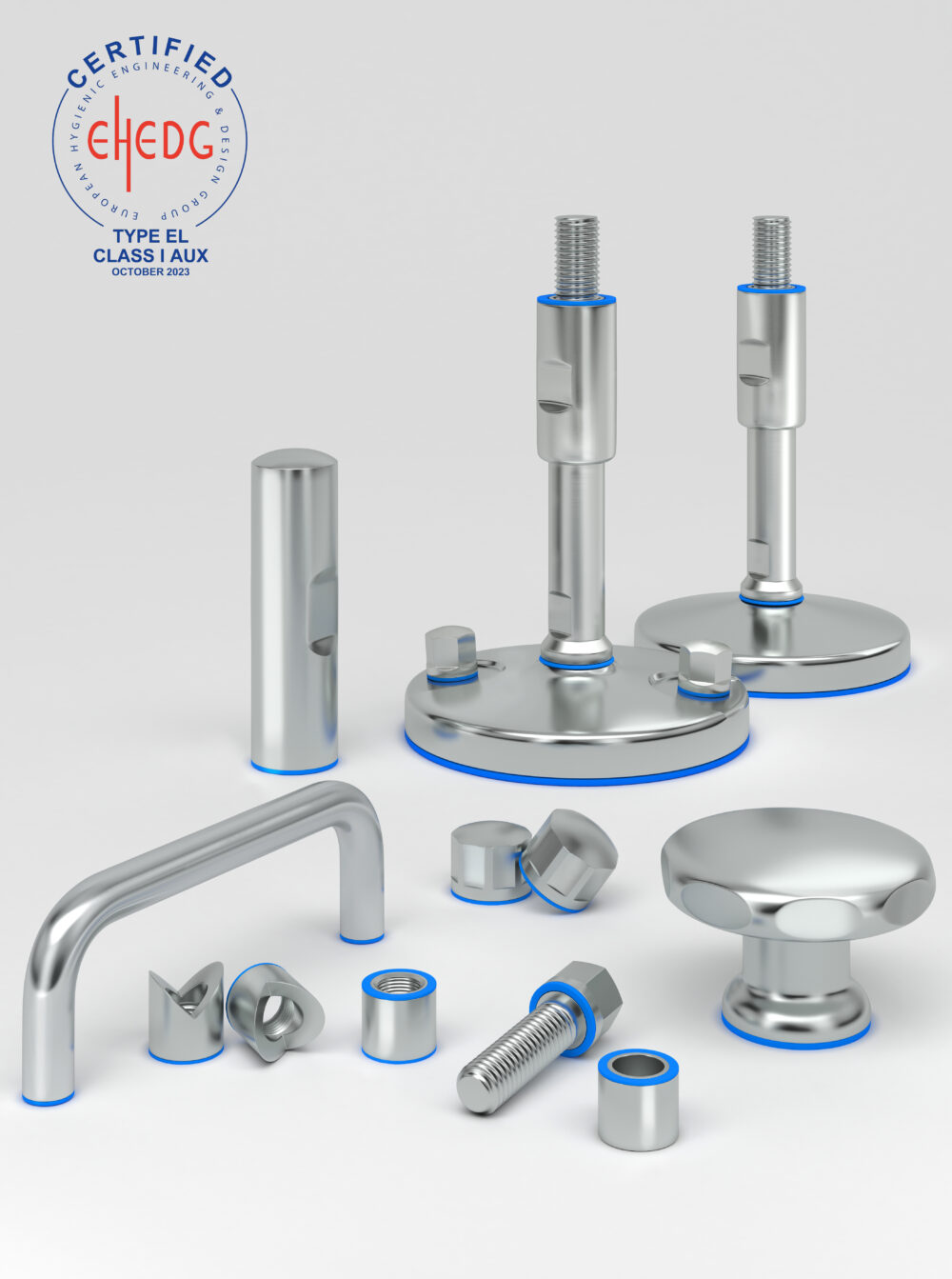

In industries like packaging, food processing, pharmaceuticals, and biotechnology, stringent hygiene, stability, and operational efficiency standards are not merely goals—they are imperatives. As these industries strive to maintain flawless quality control and streamlined operations, every component counts, no matter how seemingly insignificant. Heavy-duty stainless steel machine feet, often an underestimated component, play a pivotal role in ensuring both stability and hygiene, directly impacting productivity and safety standards. In this article, we will explore the strategic importance of these essential components and why they are indispensable for optimal performance and development across these industries. Heavy-duty stainless steel machine feet are robust leveling elements designed to support heavy machinery, maintain equipment stability, and resist corrosion in harsh environments. These components are typically manufactured from high-grade stainless steel, such as 304 or 316, known for its durability and resistance to rust. Heavy-duty machine feet are often adjustable, enabling equipment to maintain a level position on uneven surfaces, and they come with a variety of features, such as vibration isolation, anti-slip pads, and hygienic design certifications. The significance of heavy-duty stainless steel machine feet extends far beyond their basic functionality. They are an essential element of machine stability and sanitation, vital for industries where precision and cleanliness are paramount. In packaging, food processing, pharmaceutical, and biotechnology industries, production lines often involve complex, high-speed machinery. Maintaining machine stability is critical, as even minor vibrations can lead to inaccuracies in production, misalignment, or accelerated wear and tear. Heavy-duty stainless steel machine feet provide stability to machines by absorbing and isolating vibrations. This stability: The industries mentioned are heavily regulated, with stringent requirements for cleanliness, particularly in food processing, pharmaceuticals, and biotechnology. Heavy-duty stainless steel machine feet play a significant role in helping companies meet sanitation standards and industry certifications, such as ISO 14159, EHEDG, and 3-A Sanitary Standards. These certifications ensure that the components are easy to clean and resistant to bacterial buildup, essential in maintaining a safe and sterile production environment. Heavy-duty machine feet can be tailored to specific needs, allowing companies to choose the best options based on industry-specific demands. Key customizable features include: The long-term advantages of using heavy-duty stainless steel machine feet can be profound, impacting both the bottom line and operational efficiency. By investing in durable, hygienic, and stable components, companies can realize strategic development goals: Heavy-duty stainless steel machine feet may seem like a minor component, but they play an essential role in optimizing production lines in packaging, food processing, pharmaceutical, and biotechnology industries. Their impact on stability, hygiene, and operational efficiency underscores their importance in strategic optimization and development. By choosing high-quality, customizable machine feet, companies can improve productivity, reduce maintenance costs, and ensure compliance with industry standards. In a competitive environment where even the smallest details matter, these components are an investment in both quality and long-term success.

Strategic Optimization and Development Using Heavy-Duty Stainless Steel Machine Feet: An Underestimated Essential Component in the Packaging, Food Processing, Pharmaceutical, and Biotechnology Industries

What Are Heavy-Duty Stainless Steel Machine Feet?

Strategic Optimization Through Enhanced Stability

Sanitation and Compliance: Meeting Industry Standards

Customization and Flexibility: Tailored to Industry Needs

Strategic Development: Reducing Costs and Increasing Efficiency

Applications Across Industries

Heavy duty stainless steel machine feet

Adjustable industrial stainless steel leveling feet: an essential element for stability and efficiency

Heavy duty stainless steel machine feet: an underestimated essential component

Certified stainless steel leveling feet: ensuring hygiene and safety in food processing

Contact

Articles