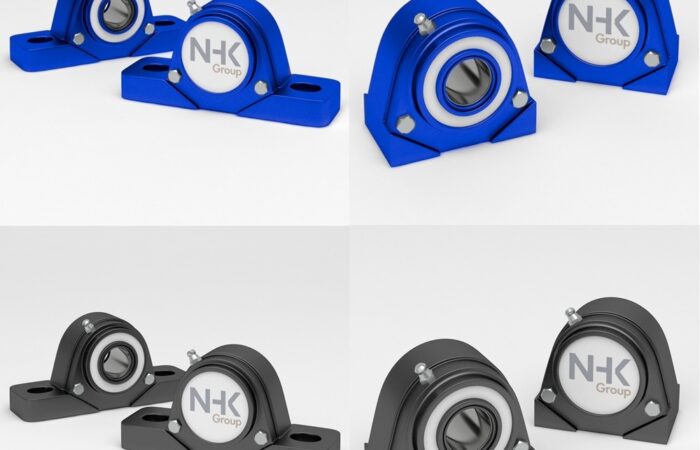

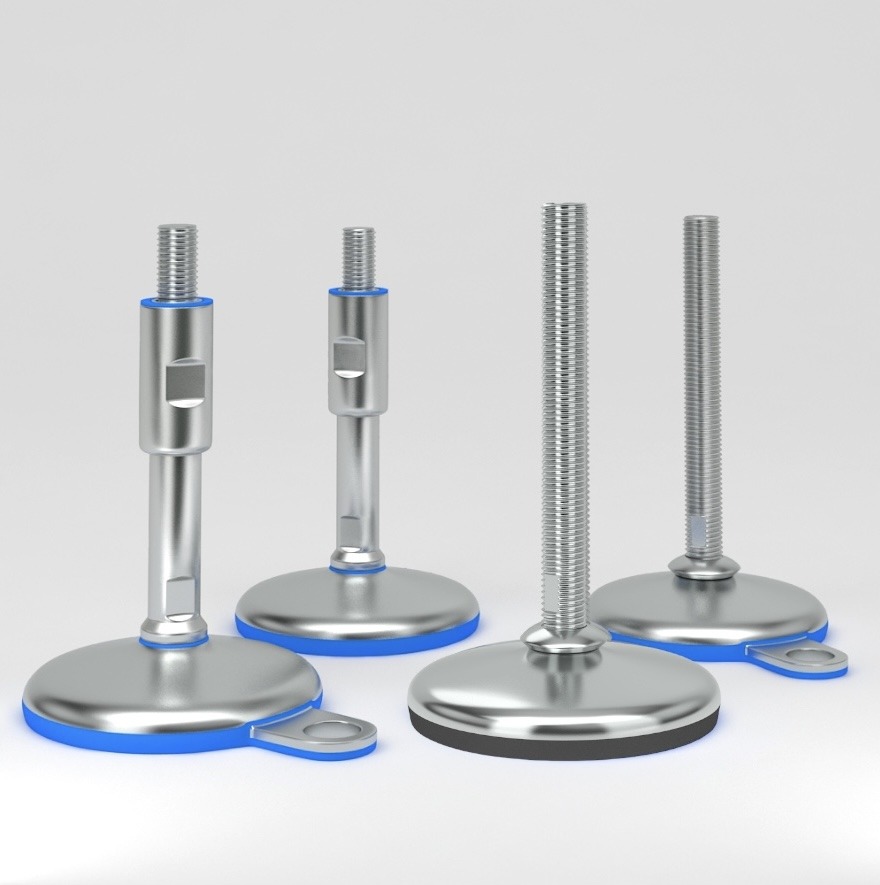

Certified stainless steel leveling feet

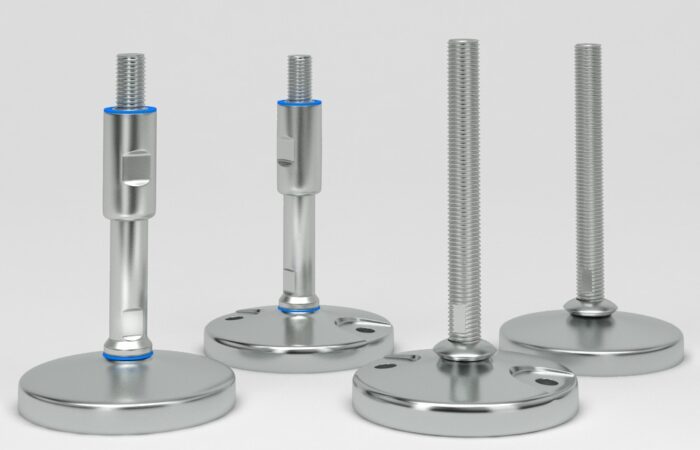

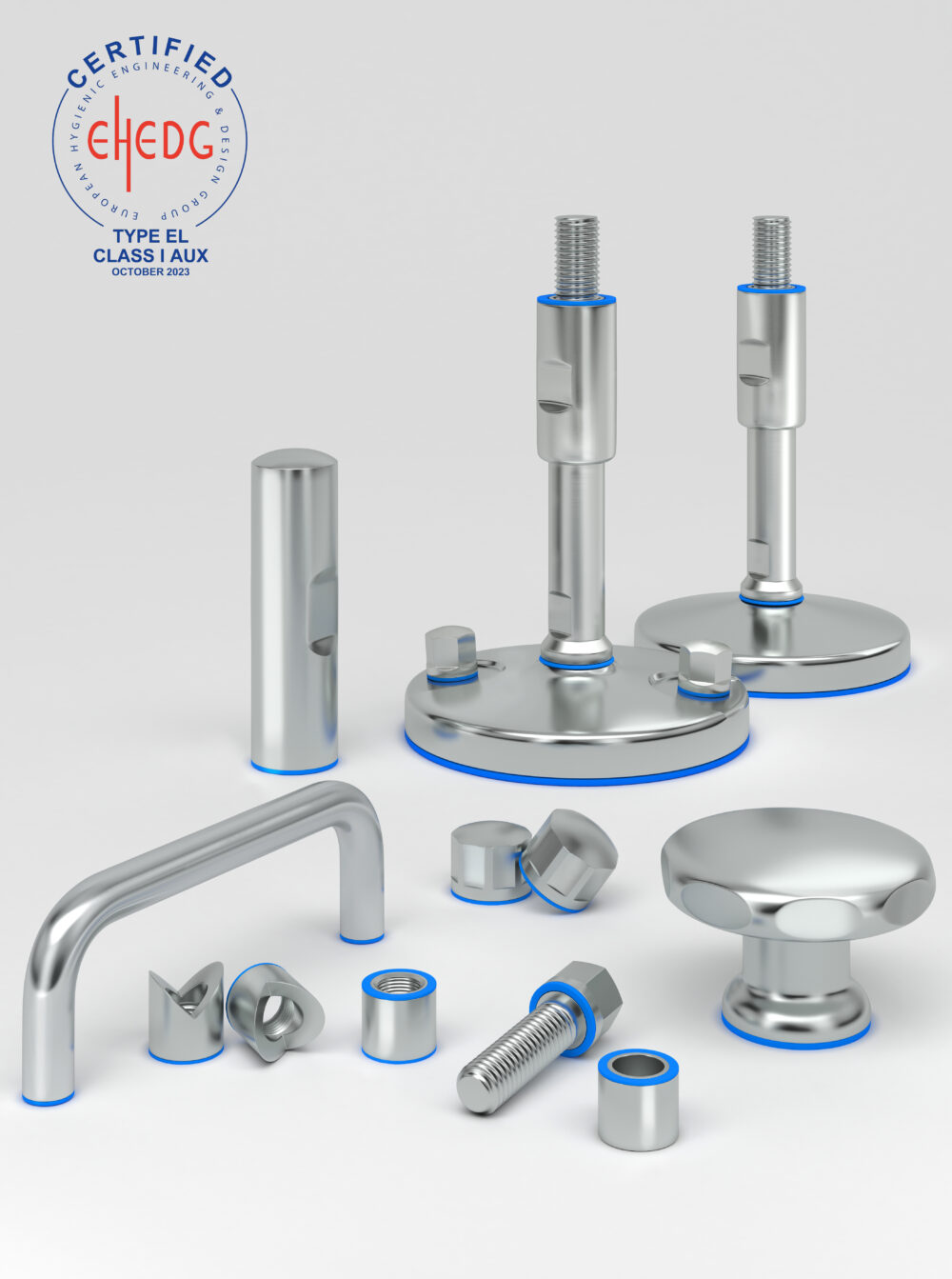

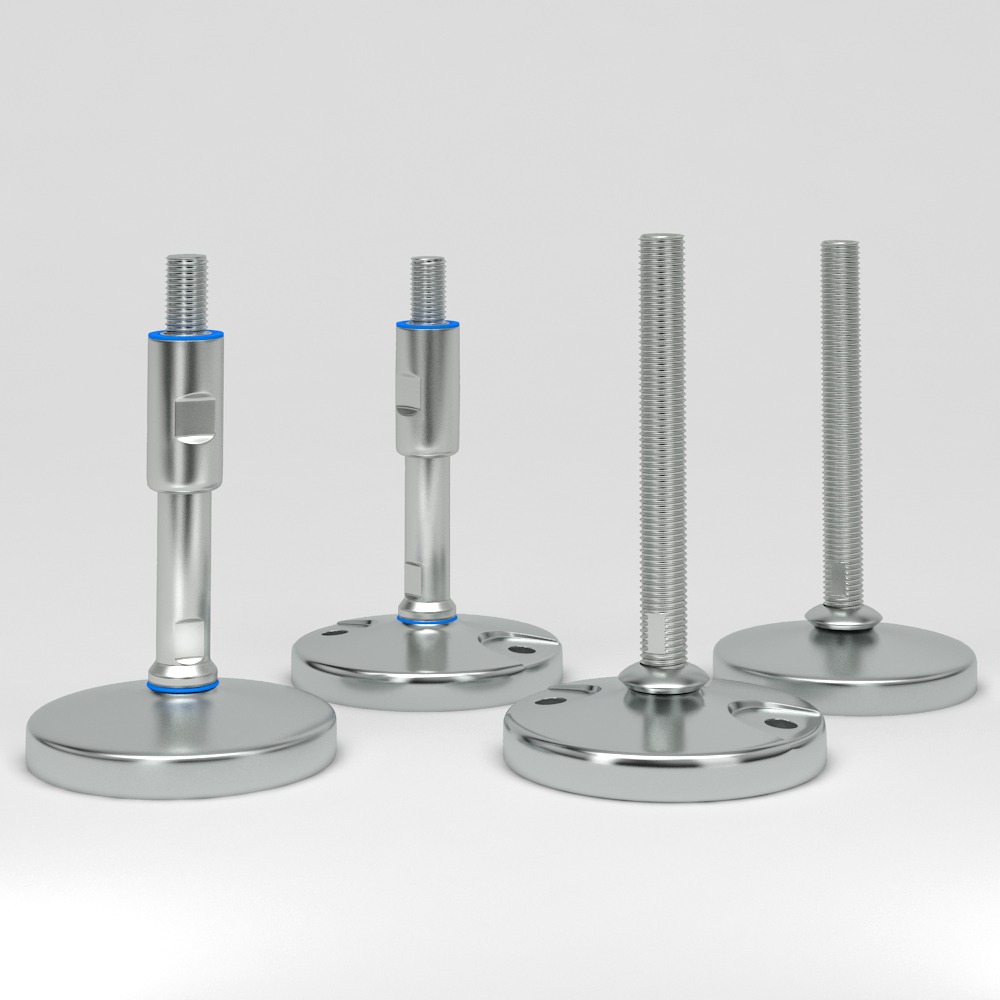

In today’s competitive industrial landscape, achieving operational efficiency, safety, and hygiene has become paramount. This is especially true in sectors such as food processing, packaging, pharmaceuticals, and biotechnology, where stringent cleanliness standards are not just desirable but mandatory. The implementation of certified stainless steel leveling feet can contribute significantly to strategic optimization and development within these industries. This article explores the critical role of these components in enhancing safety, maintaining hygiene, and optimizing machinery functionality. Stainless steel leveling feet are mechanical components designed to provide stability and leveling to machinery and equipment. Unlike standard leveling feet, certified stainless steel variants meet specific industry standards, such as NSF (National Sanitation Foundation) or FDA (Food and Drug Administration) certifications. These certifications ensure the material used is corrosion-resistant, easy to clean, and capable of withstanding harsh cleaning processes. Leveling feet are essential in maintaining machinery balance on uneven floors, minimizing vibrations, and reducing wear and tear. This stability is vital for industries where precision and hygiene are crucial. Certified stainless steel leveling feet offer the additional benefit of meeting regulatory requirements, making them a preferred choice in sensitive industries. In industries like food processing, packaging, pharmaceuticals, and biotechnology, hygiene and safety are non-negotiable. Contaminants in these environments can lead to severe health risks and significant financial and reputational damages. Regulations from entities such as the FDA, USDA (United States Department of Agriculture), and EU standards mandate equipment that resists corrosion, can withstand frequent cleaning, and does not harbor bacteria. Certified stainless steel leveling feet meet these criteria, providing a foundation that supports safe and hygienic operations. Moreover, ensuring a clean and safe environment can prevent product contamination, reduce downtime for cleaning, and extend the lifespan of machinery. Leveling feet play a surprisingly important role in supporting these outcomes by ensuring the stability and cleanliness of industrial equipment. Stainless steel leveling feet are designed to withstand harsh environments. In food processing and pharmaceutical settings, machinery is often exposed to water, chemicals, and corrosive substances during regular cleaning and sanitization processes. Certified stainless steel is highly resistant to corrosion, ensuring that the leveling feet retain their functionality and appearance over time, even in demanding environments. Certified stainless steel leveling feet are designed with hygiene in mind. Many of these components feature smooth surfaces and rounded edges to prevent dirt, dust, and bacteria accumulation. In industries where cleanliness is a priority, such as food processing and biotechnology, equipment that’s easy to clean can reduce contamination risks significantly. Regular cleaning can be performed quickly and efficiently without the risk of bacteria hiding in crevices. Certification ensures that stainless steel leveling feet meet specific hygiene and safety standards required by the food, pharmaceutical, and biotechnology industries. Compliance with these standards not only enhances safety but also aids in regulatory inspections. Companies can demonstrate that they’ve invested in components that meet industry standards, which can be advantageous in audits and compliance assessments. Uneven floors can lead to unstable machinery, causing excessive vibrations and misalignment. Certified stainless steel leveling feet offer durability and strength, providing the necessary support to maintain machinery stability. By reducing vibrations, these leveling feet help to extend the life of machinery, optimize production accuracy, and prevent equipment damage. Certified leveling feet contribute to strategic optimization by enhancing the operational efficiency of machinery. By stabilizing equipment, they ensure that machines can run at their optimal speed and efficiency without unnecessary interruptions due to misalignment or uneven floors. In sectors like food processing, where production lines run continuously, this stability is invaluable. In the food processing industry, maintaining hygiene is crucial to avoid contamination. Stainless steel leveling feet are ideal for equipment such as mixers, conveyors, and packaging machines, which require stability and are subject to frequent cleaning. Their corrosion resistance and hygienic design ensure that they meet stringent industry standards, making them indispensable in food processing and packaging. The pharmaceutical industry requires an exceptionally high level of cleanliness. Stainless steel leveling feet are used in tablet presses, filling machines, and packaging equipment. Their compliance with FDA and GMP (Good Manufacturing Practices) guidelines ensures that pharmaceutical companies meet the hygiene and safety standards necessary to protect the integrity of their products. In biotechnology, where processes involve sensitive biological substances, any contamination can have severe consequences. Stainless steel leveling feet are essential in equipment used in research labs, production facilities, and clean rooms. These leveling feet support stability while meeting cleanliness requirements, preventing contamination in biotechnological applications. Investing in certified stainless steel leveling feet aligns with broader strategic goals in the food processing, packaging, pharmaceutical, and biotechnology industries. Here’s how: As industries continue to advance, there’s a growing focus on automation and the use of smart technologies to further enhance safety, efficiency, and sustainability. Innovations in leveling feet include self-adjusting models and materials that resist extreme environmental conditions. Certified stainless steel will likely continue to be integral to these advancements, ensuring that components meet increasingly stringent hygiene and safety standards. Certified stainless steel leveling feet offer numerous benefits to industries where hygiene and safety are paramount. Their durability, ease of cleaning, and compliance with industry standards make them essential for strategic optimization and development in food processing, packaging, pharmaceuticals, and biotechnology. By investing in certified stainless steel leveling feet, companies can enhance operational efficiency, reduce costs, and ensure the safety and quality of their products. As these industries evolve, the role of certified components like stainless steel leveling feet will continue to be critical in achieving regulatory compliance, operational excellence, and sustainable growth.

Certified Stainless Steel Leveling Feet: Ensuring Hygiene and Safety in Food Processing, Packaging, Pharmaceutical, and Biotechnological Industries

Understanding Stainless Steel Leveling Feet

The Importance of Hygiene and Safety Standards

Benefits of Certified Stainless Steel Leveling Feet

1. Corrosion Resistance

2. Easy to Clean

3. Compliance with Industry Standards

4. Enhanced Machinery Stability

5. Operational Efficiency

Applications of Certified Stainless Steel Leveling Feet

1. Food Processing and Packaging

2. Pharmaceutical Industry

3. Biotechnology Sector

Strategic Optimization with Certified Stainless Steel Leveling Feet

Future Outlook and Innovations

Certified stainless steel leveling feet

Adjustable industrial stainless steel leveling feet: an essential element for stability and efficiency

Heavy duty stainless steel machine feet: an underestimated essential component

Certified stainless steel leveling feet: ensuring hygiene and safety in food processing

Contact

Articles