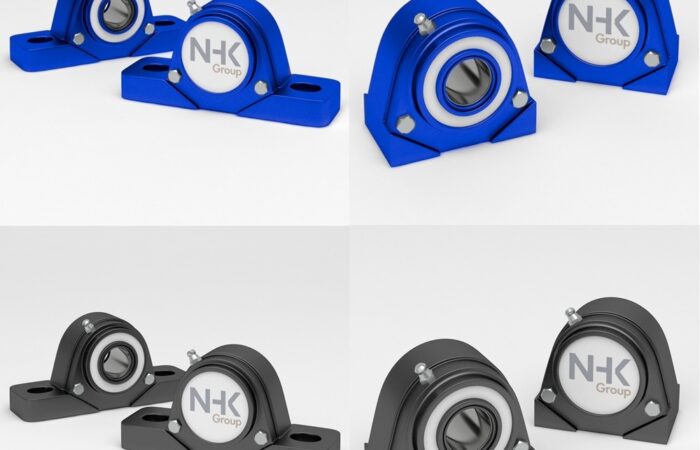

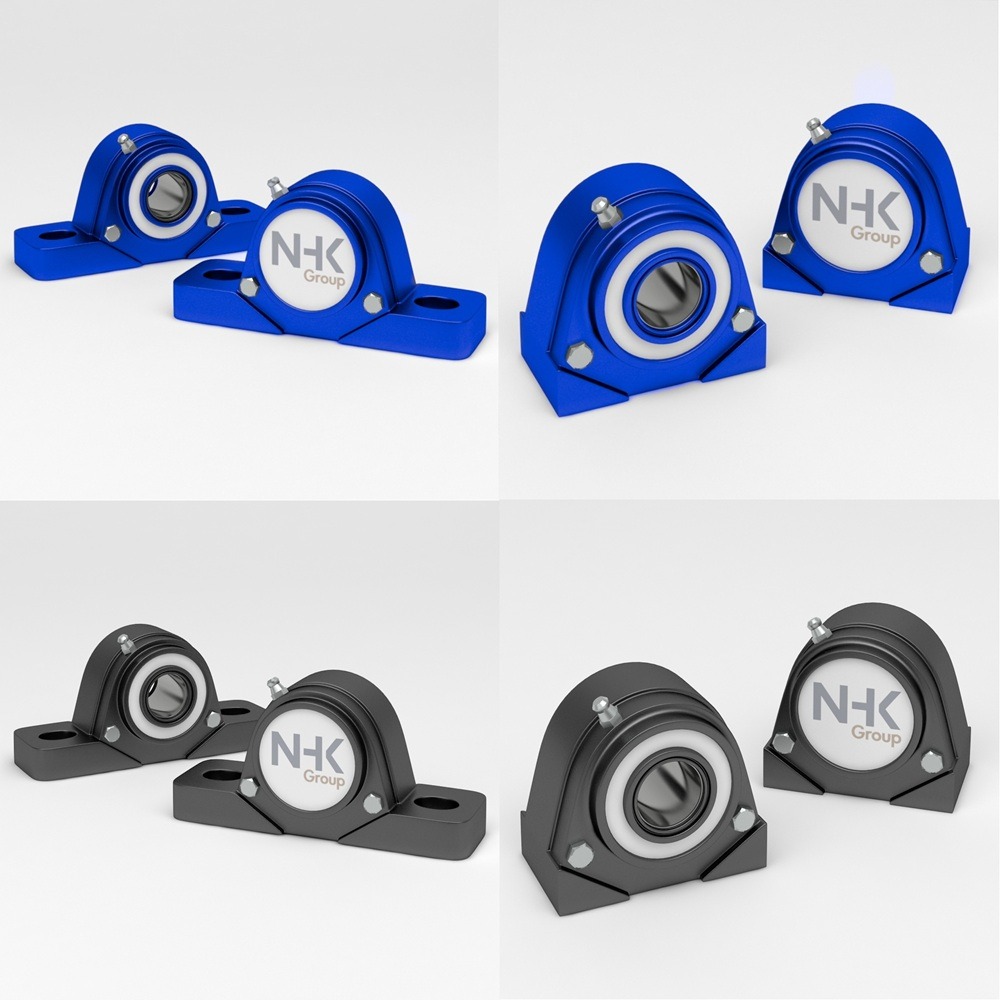

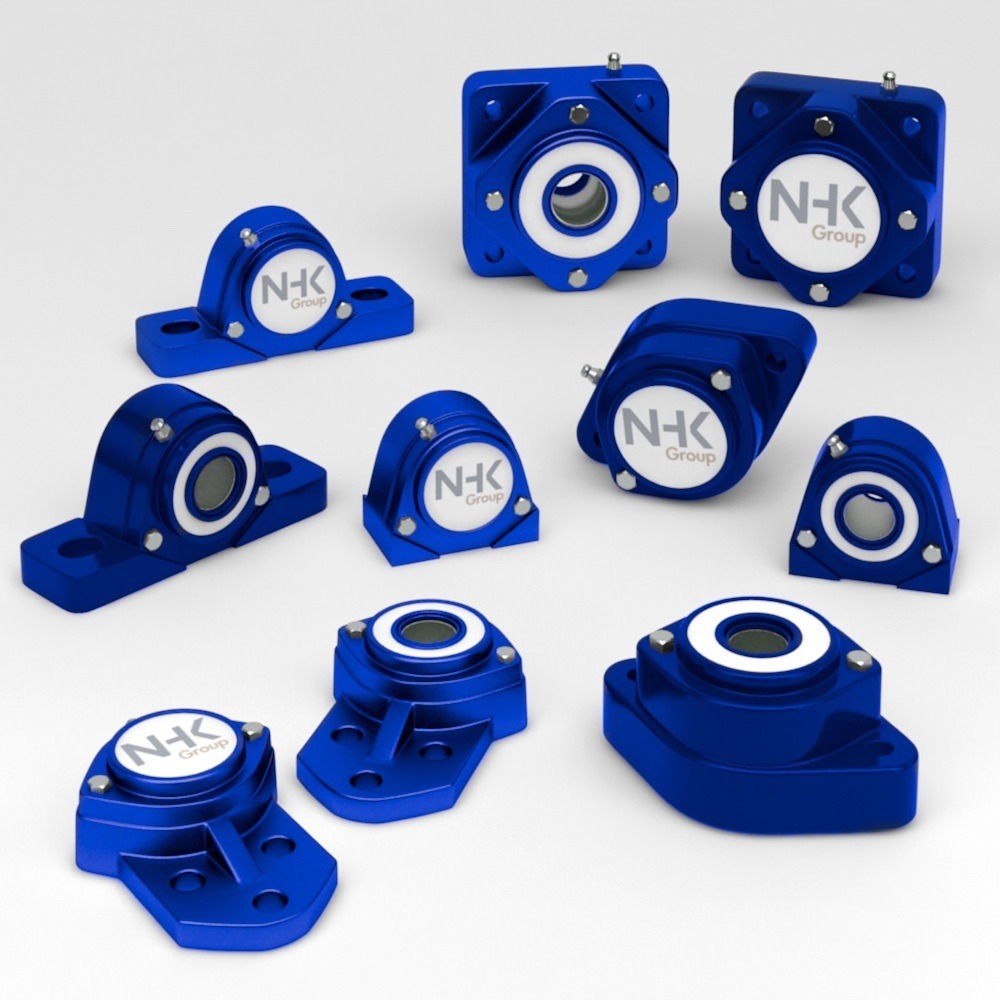

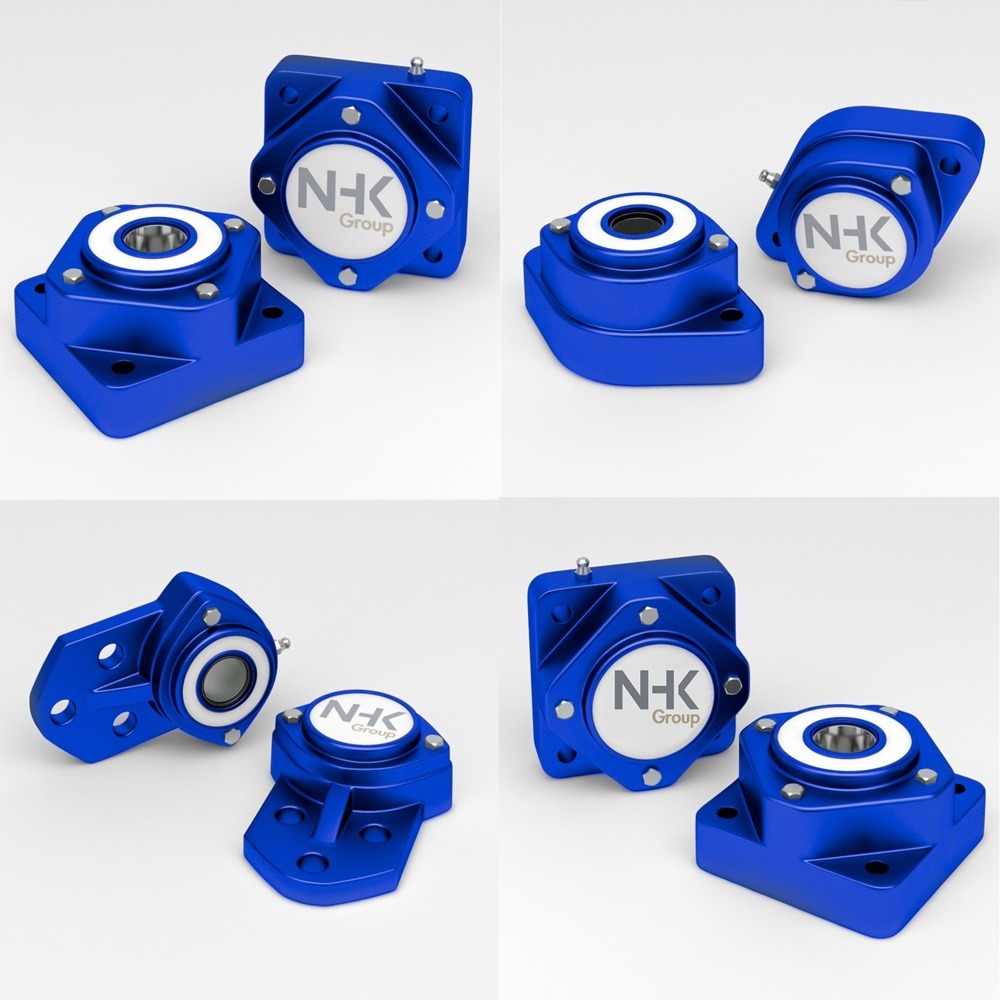

Certified IP67 Waterproof Pillow Block Bearing Units

In industries where machinery is exposed to extreme conditions—such as food processing, pharmaceuticals, marine applications, and heavy-duty manufacturing—precision, durability, and hygiene are critical. Certified IP67 waterproof pillow block bearing units are an essential component in ensuring equipment longevity, efficiency, and compliance with stringent industry regulations. These bearing units are designed to withstand high-pressure washdowns, chemical exposure, and fluctuating temperatures, making them indispensable for operations in harsh environments. This article explores the usage, material selection, and engineering excellence behind these specialized bearing units. We will also highlight the importance of experience, expertise, authoritativeness, and trustworthiness (E-E-A-T) in selecting the right solutions for demanding industrial applications. Certified IP67 waterproof pillow block bearing units are extensively used in industries where reliability in extreme environments is non-negotiable. These industries include: The choice of materials in IP67 waterproof pillow block bearings is crucial for their performance in extreme environments. The most commonly used materials include: Companies specializing in IP67 waterproof pillow block bearings leverage decades of engineering expertise to optimize bearing design for extreme applications. This includes: Choosing certified IP67 waterproof pillow block bearings ensures compliance with industry regulations and enhances operational reliability. Some factors reinforcing the trustworthiness of these bearings include: Certified IP67 waterproof pillow block bearing units are essential components for industries that demand reliability, durability, and compliance with stringent standards. Their advanced material selection, superior engineering, and compliance with global hygiene regulations make them the preferred choice for applications in food processing, pharmaceuticals, marine, and chemical industries. By selecting trustworthy manufacturers with proven expertise, companies can enhance operational efficiency, improve safety, and reduce maintenance costs. Investing in certified, high-performance bearing solutions ensures that industrial equipment continues to operate flawlessly in the most demanding environments.

Engineered for Extreme Conditions in Harsh Environments

Usage of Certified IP67 Waterproof Pillow Block Bearing Units

Industries Benefiting from IP67 Pillow Block Bearings

Key Functional Advantages

Certified IP67 waterproof ratings ensure that these bearings can withstand submersion in water up to 1 meter for 30 minutes, making them ideal for applications requiring frequent washdowns and high humidity resistance.

By using corrosion-resistant materials and food-safe lubricants, these bearings reduce maintenance frequency and operational downtime.

Heavy-duty environments require bearings that can absorb mechanical shocks and sustain long-term performance under heavy loads.

Designed with smooth surfaces and sealed stainless steel construction, these bearing units prevent bacterial contamination and meet strict sanitary requirements.

Material Choice: Engineering for Longevity & Performance

1. Stainless Steel (AISI 304 & AISI 316)

2. Thermoplastic Housing (FDA-Compliant PBT or Polypropylene)

3. High-Performance Sealing (NBR, FKM, or PTFE Seals)

4. Food-Grade Lubricants

Experience and Expertise in Bearing Engineering

Authoritativeness & Trustworthiness: Why Certified IP67 Bearings Matter

The Best Choice for Extreme Conditions

Contact

Articles