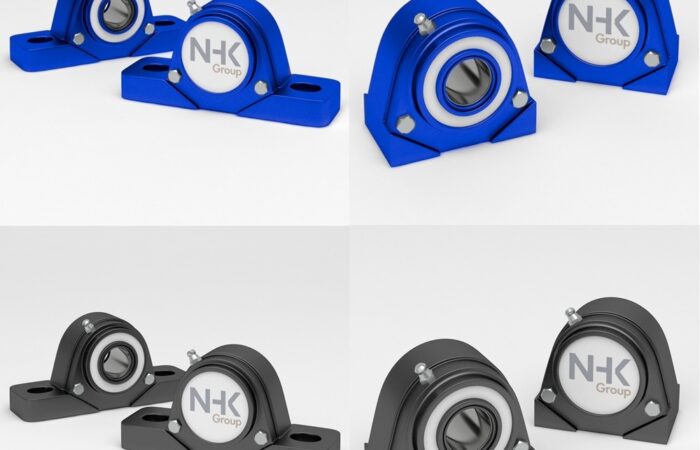

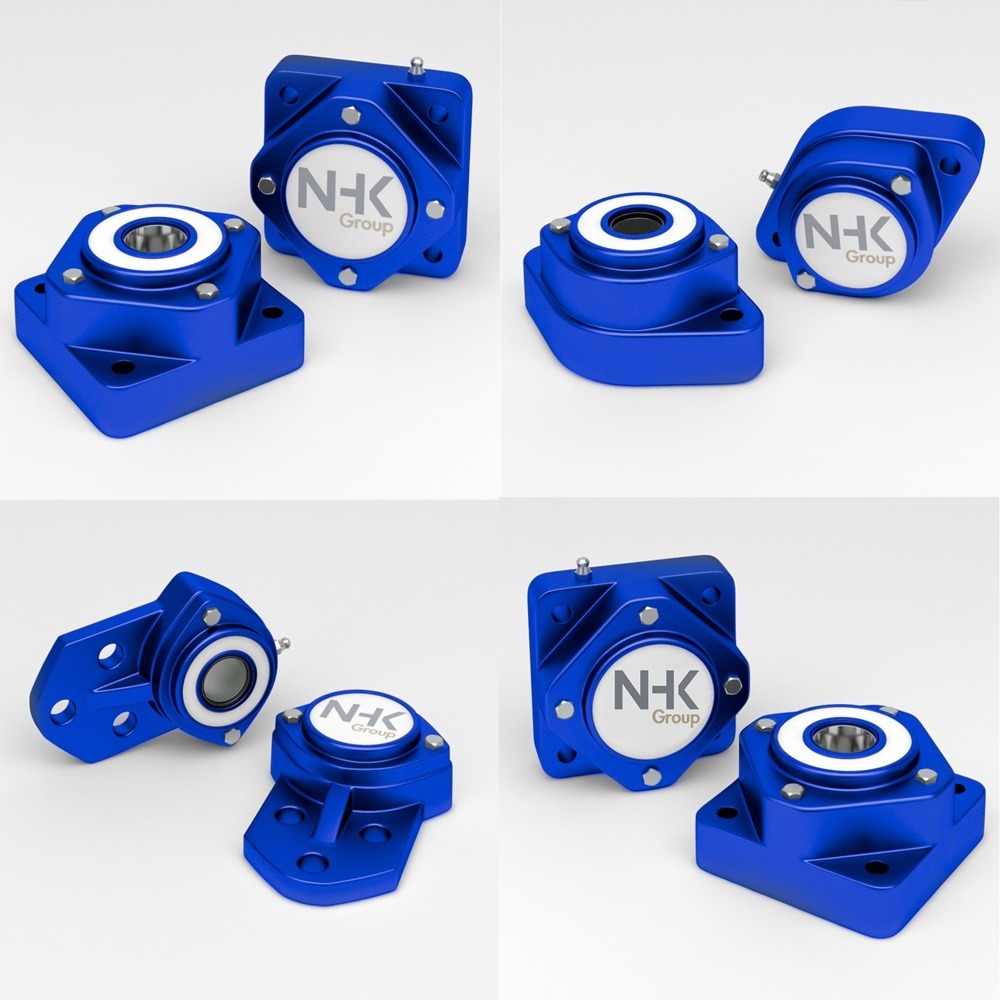

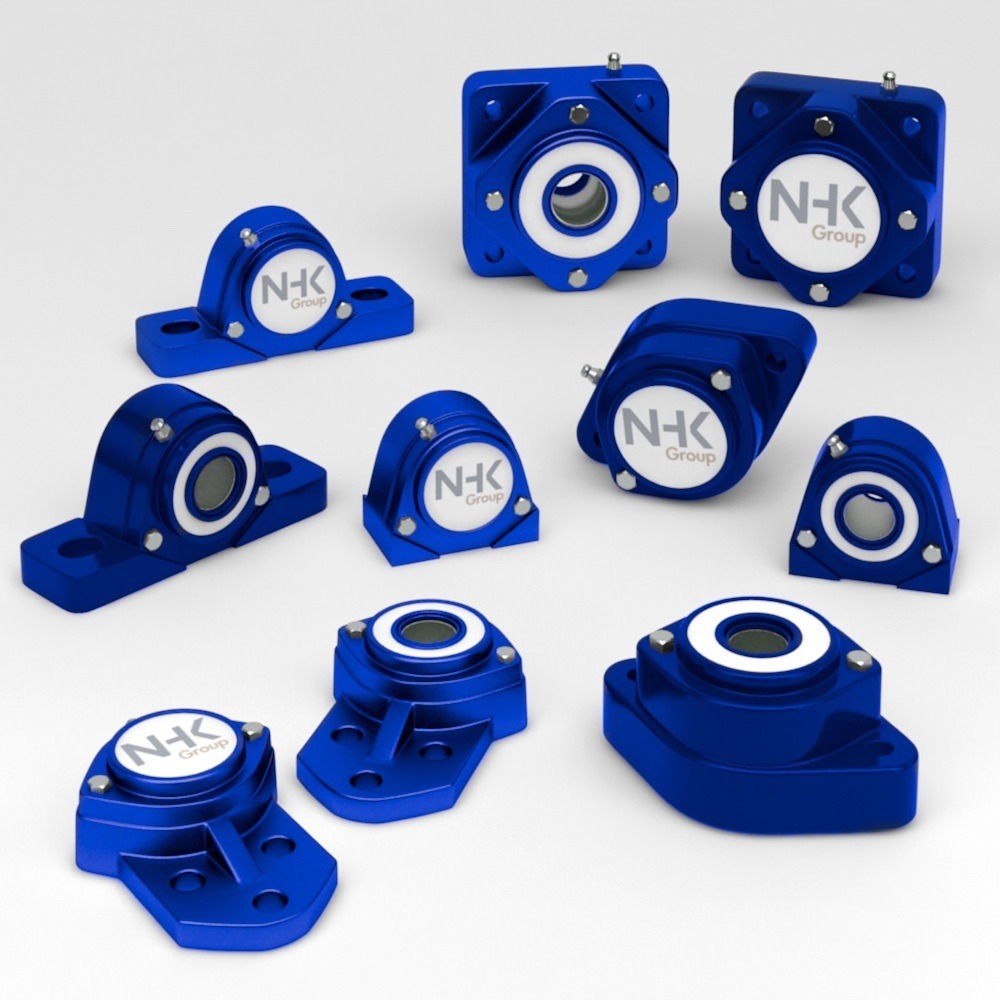

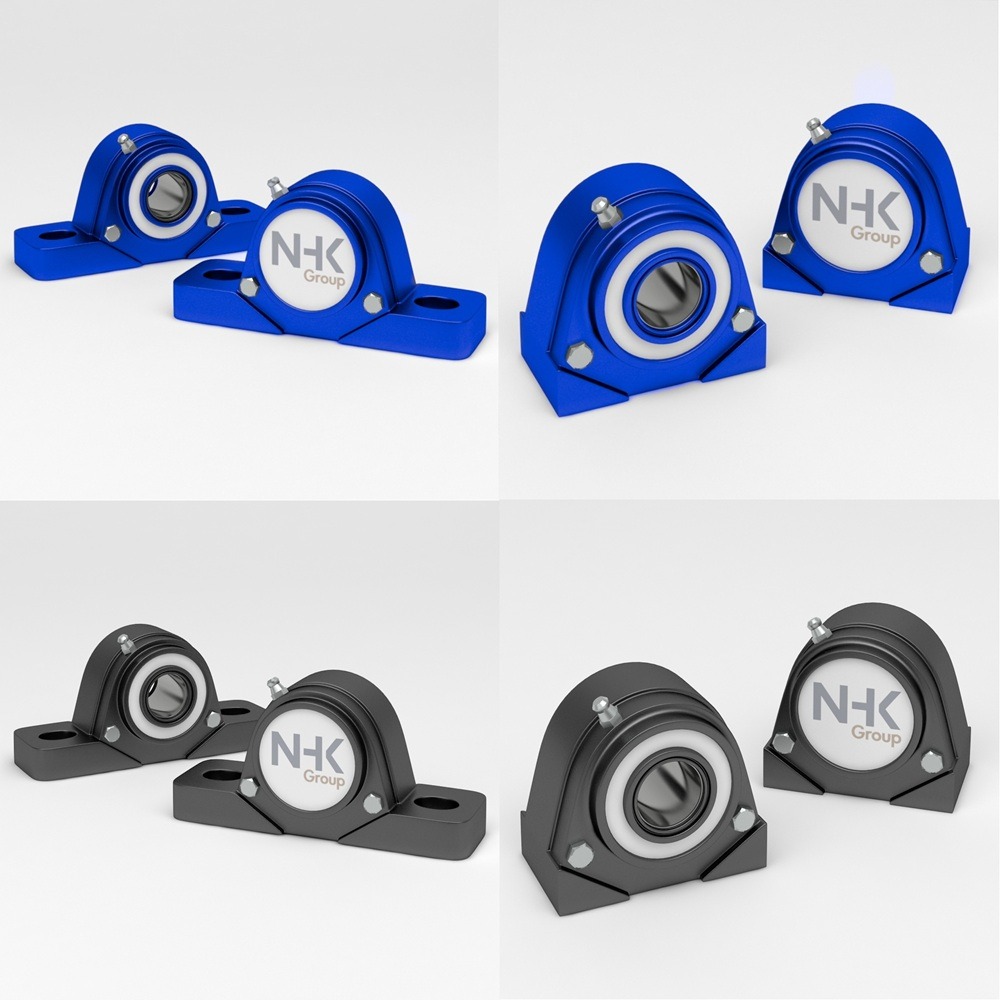

Certified IP67 Waterproof Flange Bearing Units

In industries where equipment is exposed to extreme conditions—such as food processing, pharmaceuticals, marine applications, and chemical production—component reliability is non-negotiable. Among the most critical elements of machinery, flange bearing units play a crucial role in maintaining operational efficiency, reducing downtime, and ensuring compliance with strict hygiene and safety standards. For industries that operate in harsh environments, where exposure to water, dust, chemicals, or extreme temperatures is common, certified IP67 waterproof flange bearing units provide unmatched durability, hygiene, and performance. This article explores their usage, material choice, industry expertise, and why certified solutions inspire trust and reliability. Flange bearing units are essential in various industries where precision, hygiene, and resilience are paramount. IP67 certification ensures that these bearings can withstand full submersion in water (up to 1 meter for 30 minutes) and resist dust infiltration, making them indispensable in applications requiring extreme cleanliness and moisture resistance. By incorporating IP67 waterproof flange bearing units, businesses can improve equipment longevity, reduce downtime, and enhance hygiene standards. To withstand extreme environments, material selection is crucial. Certified IP67 waterproof flange bearing units are engineered from premium materials that ensure superior resistance to water, chemicals, and mechanical stress. Choosing certified stainless steel and non-corrosive materials ensures that these flange bearing units can perform in the harshest environments without compromising safety or efficiency. Developing IP67-rated waterproof flange bearing units requires years of engineering experience and expertise in designing components for extreme industrial conditions. Leading manufacturers employ cutting-edge manufacturing processes and rigorous quality control testing to deliver precision-engineered solutions. Manufacturers with decades of experience in hygienic and industrial bearings provide solutions that not only meet industry regulations but exceed performance expectations. Authoritativeness in the industry is established through certifications, testing, and compliance with international standards. Certified IP67 waterproof flange bearing units are developed and tested to ensure their suitability for use in harsh and extreme industrial conditions. Manufacturers that adhere to these standards reinforce their authoritativeness in producing reliable, high-performance components. When selecting components for mission-critical applications, trust in the manufacturer and product quality is key. Certified IP67 waterproof flange bearing units deliver on trustworthiness by ensuring long-term durability, operational efficiency, and reduced total cost of ownership. By choosing certified waterproof flange bearing units, companies benefit from higher operational efficiency, increased safety, and regulatory compliance, ensuring a secure and long-term investment. Industries operating in harsh environments demand high-performance, waterproof, and corrosion-resistant solutions. Certified IP67 waterproof flange bearing units are specifically designed to withstand extreme conditions, providing superior durability, hygiene, and efficiency. From food processing and pharmaceuticals to marine, agriculture, and chemical industries, these bearings deliver unmatched reliability. Their advanced material selection, engineering expertise, authoritative certifications, and trusted performance make them an indispensable choice for industries requiring waterproof, dustproof, and long-lasting bearing solutions. Invest in certified IP67 waterproof flange bearing units today and experience enhanced equipment performance, reduced downtime, and long-term cost savings.

Engineered for Extreme Conditions in Harsh Environments

Usage of Certified IP67 Waterproof Flange Bearing Units

Common Applications:

Material Choice: The Foundation of Durability and Hygiene

High-Quality Material Composition:

Experience & Expertise in Manufacturing IP67 Waterproof Bearings

Key Aspects of Expertise:

Authoritativeness: Certified Solutions for Maximum Reliability

Certifications & Compliance:

Trustworthiness: Why Certified IP67 Flange Bearing Units are a Secure Investment

Reasons to Trust Certified Solutions:

Elevate Performance with Certified IP67 Waterproof Flange Bearing Units

Contact

Articles